Patents

Literature

30results about How to "Increase the amount of mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

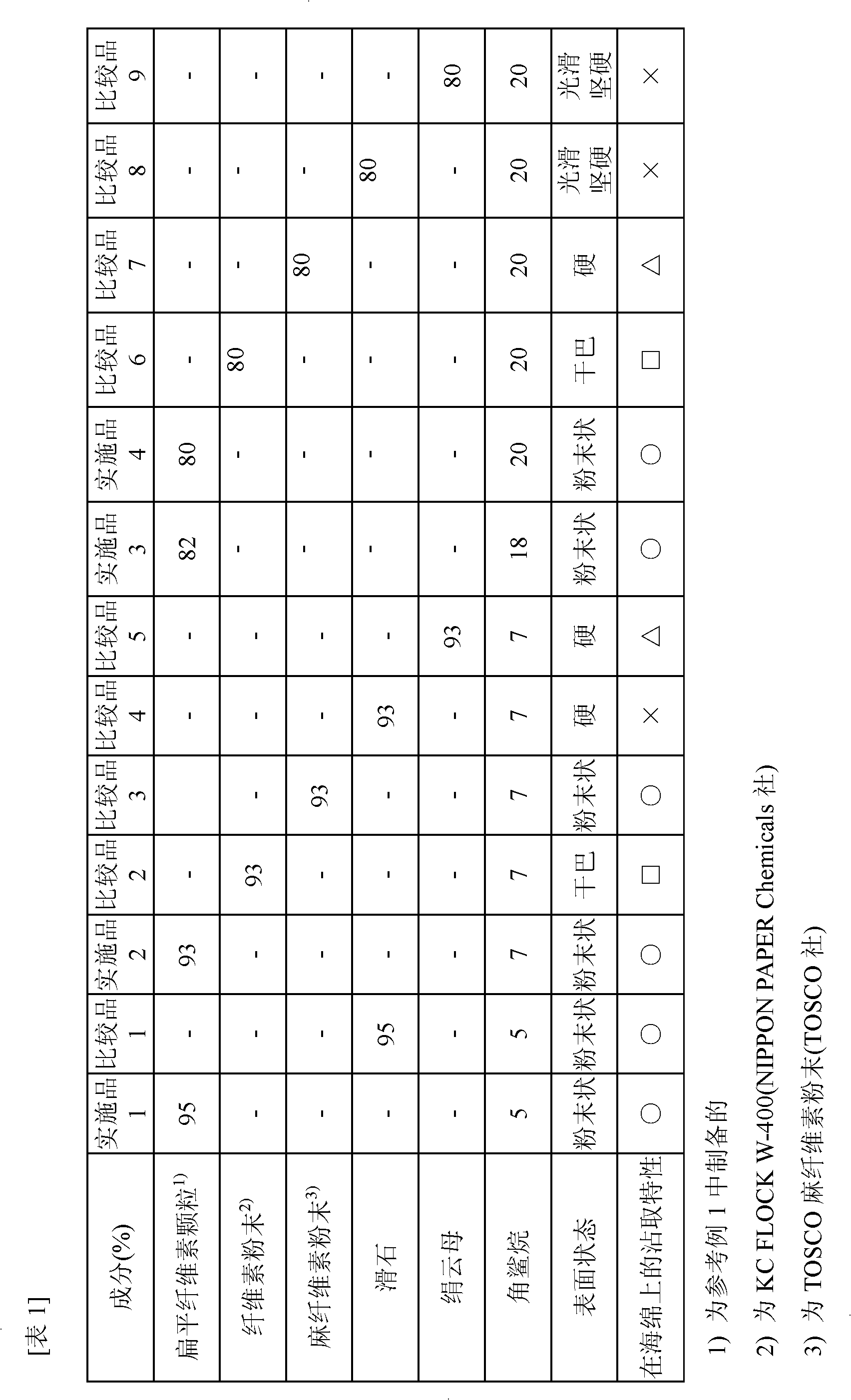

Powder cosmetic material

The invention aims to provide a powder cosmetic in which the powder component causes no aggregation and the surface powder component causes no caking in press processing even if a large amount of oily component is contained therein. Said powder cosmetic is characterized by comprising oblate cellulose particles and an oily component.

Owner:OHKEN +2

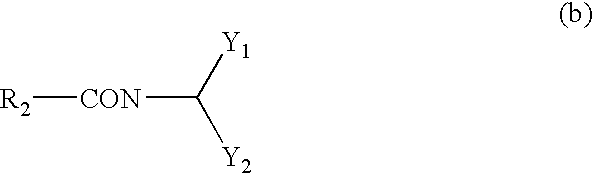

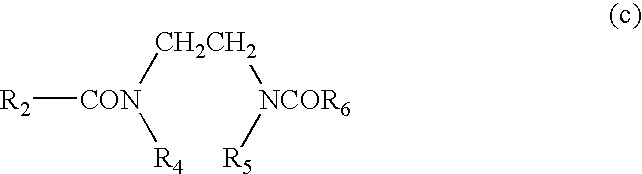

Paper quality improver composition for papermaking

InactiveUS6565708B2Bulky brightnessBulky opacityNatural cellulose pulp/paperSpecial paperCLARITYPapermaking

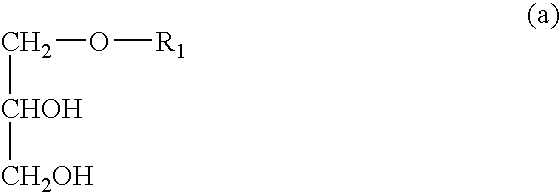

The present invention provides a paper quality improver composition for papermaking, which is excellent in improved efficiencies of bulky value, brightness, opacity and the like of pulp sheet, demanded at lightening paper and increasing a blending amount of deinked pulp, even by adding a small amount thereof as well as which is further excellent in an improved efficiency of paper-strength. That is, the present invention provides a paper quality improver composition for papermaking; which comprises (A) a compound having lyotropic degree measured by a specific method of not less than 4% and satisfying at least two of (i) standard improved bulky value of not less than 0.02 g / cm3, (ii) standard improved brightness of not less than 0.5 point, and (iii) standard improved opacity of not less than 0.5 point and (B) a water-soluble polymer satisfying an average molecular weight and / or a viscosity thereof of specific value.

Owner:KAO CORP

Aqueous ink composition

InactiveUS20180237646A1Excellent color development and image qualityReduce viscosityDuplicating/marking methodsInksBoiling pointTitanium

An aqueous ink composition containing, at least, water, a pigment (but excluding titanium oxides in which the pigment surface has been treated with an organic compound), a pigment dispersing resin, and two or more types of alkyl polyols having boiling points of at least 180° C. but not more than 250° C. at 1 atmosphere, wherein the pigment dispersing resin has an alkyl group of 10 to 36 carbon atoms, and the total amount of the alkyl polyols, relative to the total weight of the aqueous ink composition, is at least 10% by weight but not more than 30% by weight.

Owner:TOYOCOLOR CO LTD +1

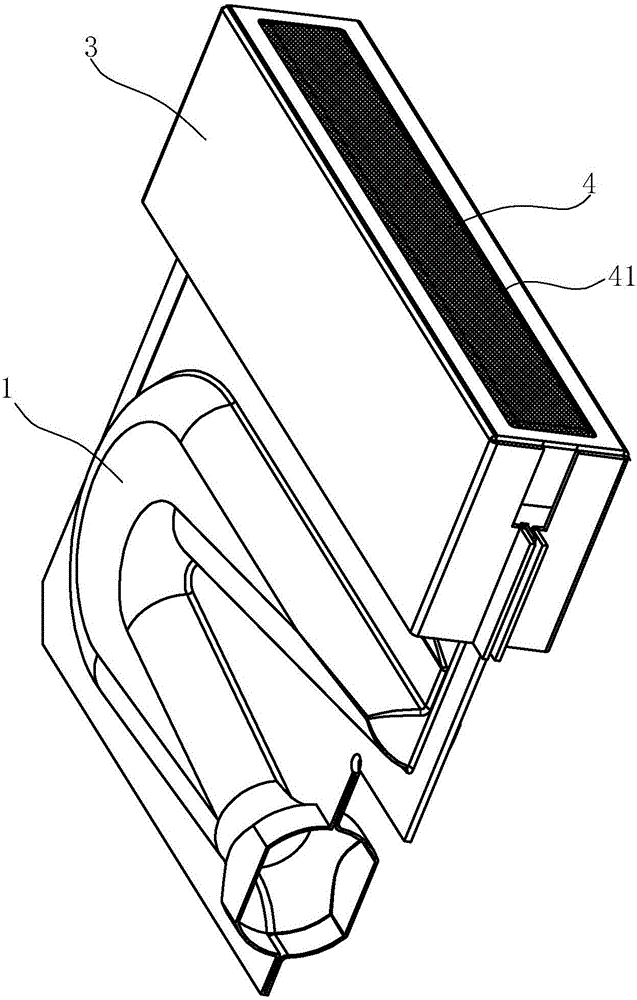

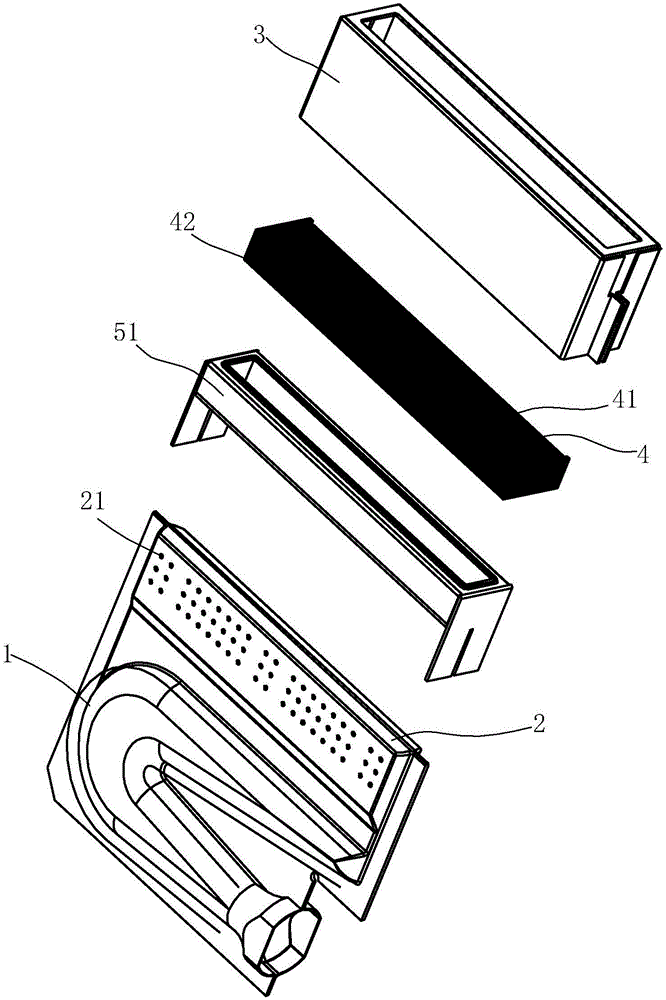

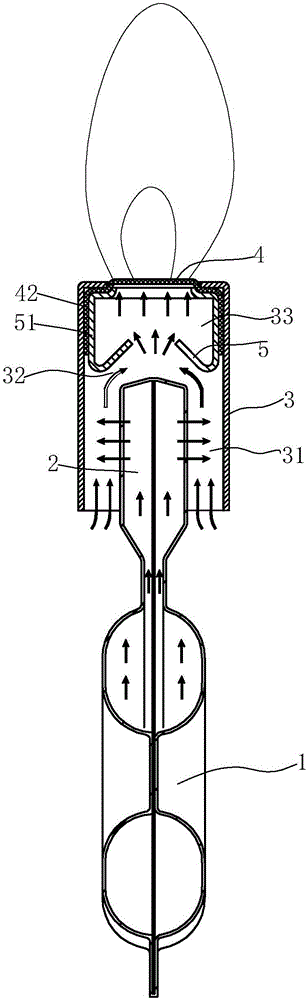

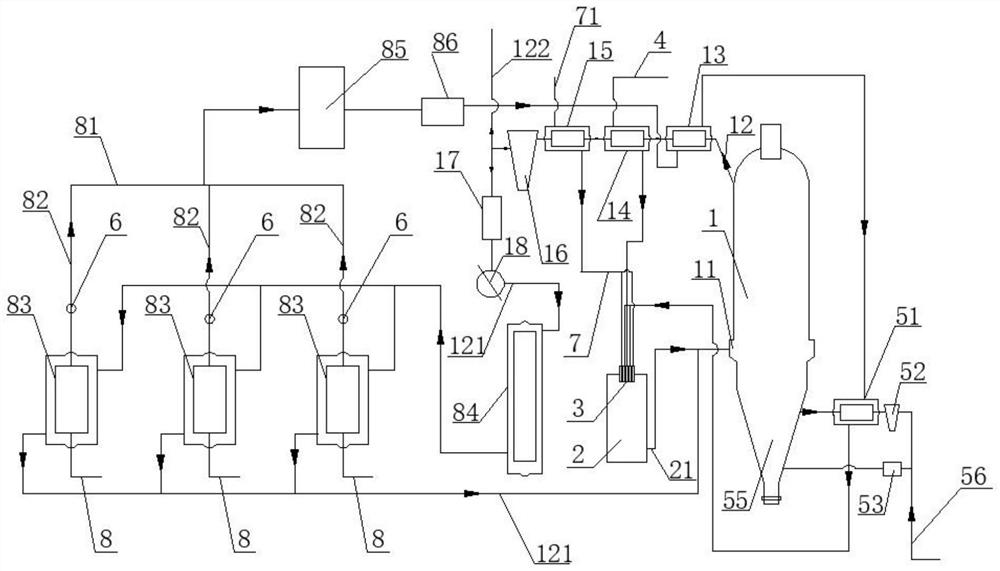

Combustor used for gas water heater

The invention relates to a combustor used for a gas water heater. The combustor comprises flame tunnels communicating with an ejector. The combustor is characterized in that each flame tunnel comprises a blending chamber communicating with the ejector, and multiple gas outlet holes are formed in the side wall of the blending chamber at intervals; the blending chamber is sleeved with a sleeve; a once-again gas mixing cavity is formed by the space between the sleeve and the blending chamber; a flame plate is arranged on an outlet of the sleeve, and multiple flame holes are formed in the flame plate at intervals; a diversion plate is further arranged on the portion, between the blending chamber and the flame plate, in the sleeve; and the space between the blending chamber and the flame plate is divided into a diversion cavity and a blending cavity by the diversion plate, the diversion cavity and the blending cavity communicate with each other, and the blending cavity communicates with all the flame holes. By means of the combustor, secondary air can be supplemented multiple times, meanwhile, mixed gas is subjected to blending multiple times, it is ensured that gas is sufficiently combusted, the combustion efficiency of the gas is improved, NOx is effectively reduced, and the combustor is environment-friendly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

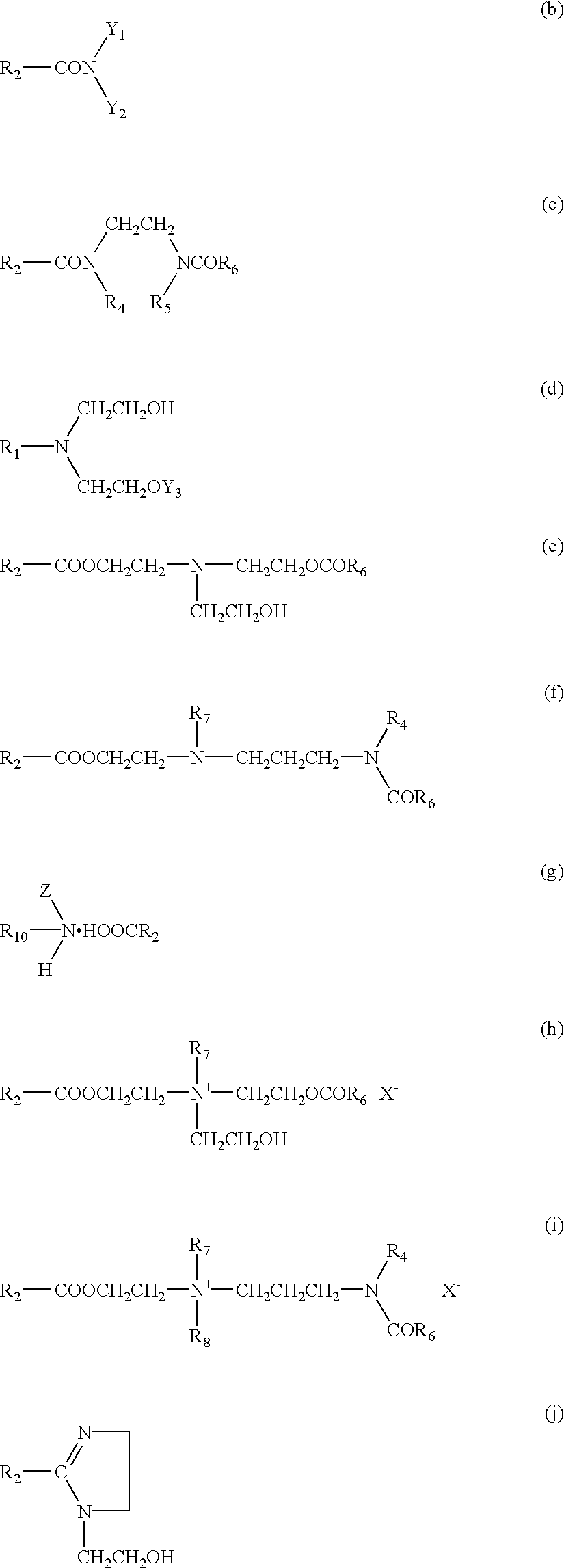

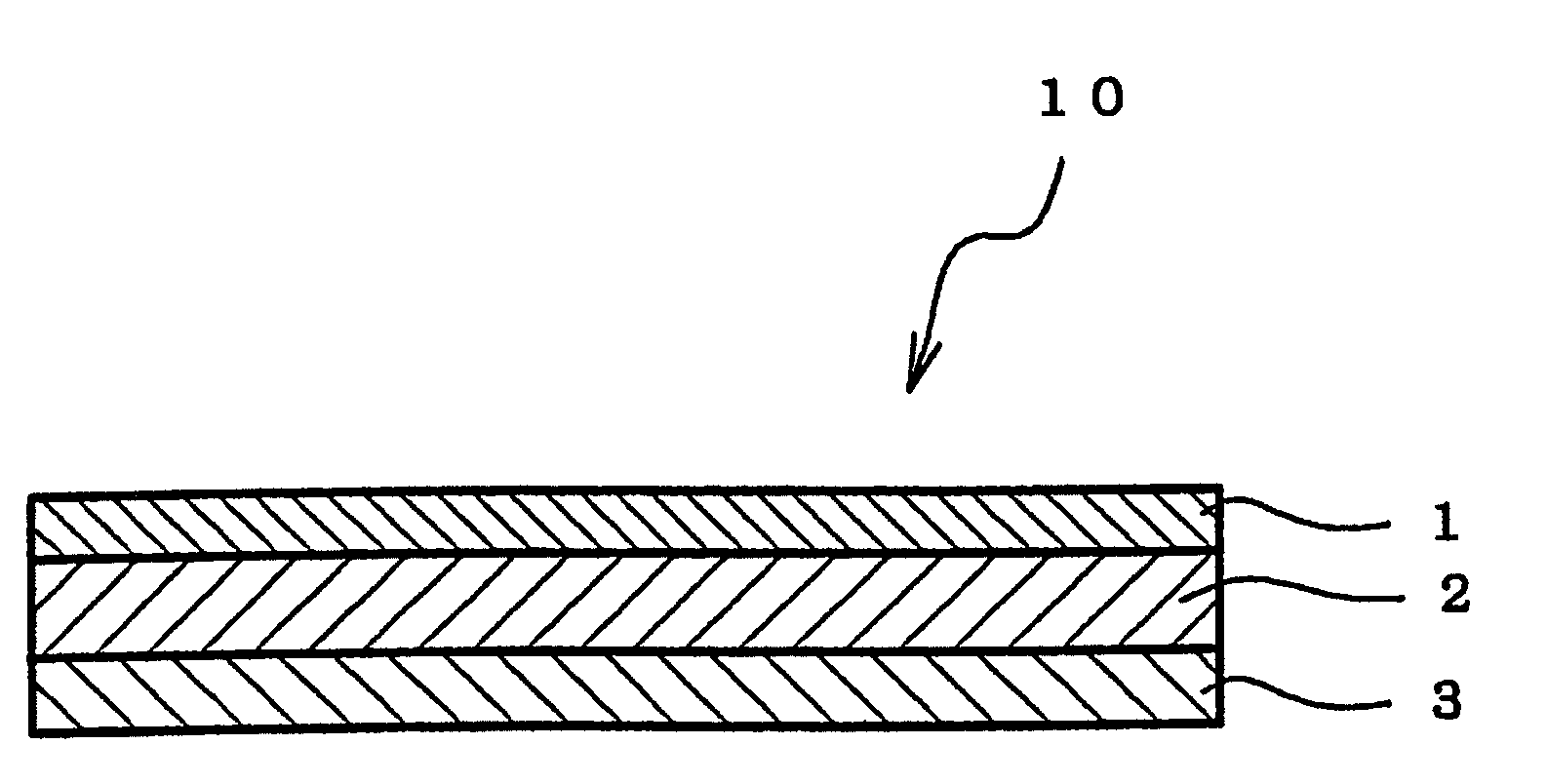

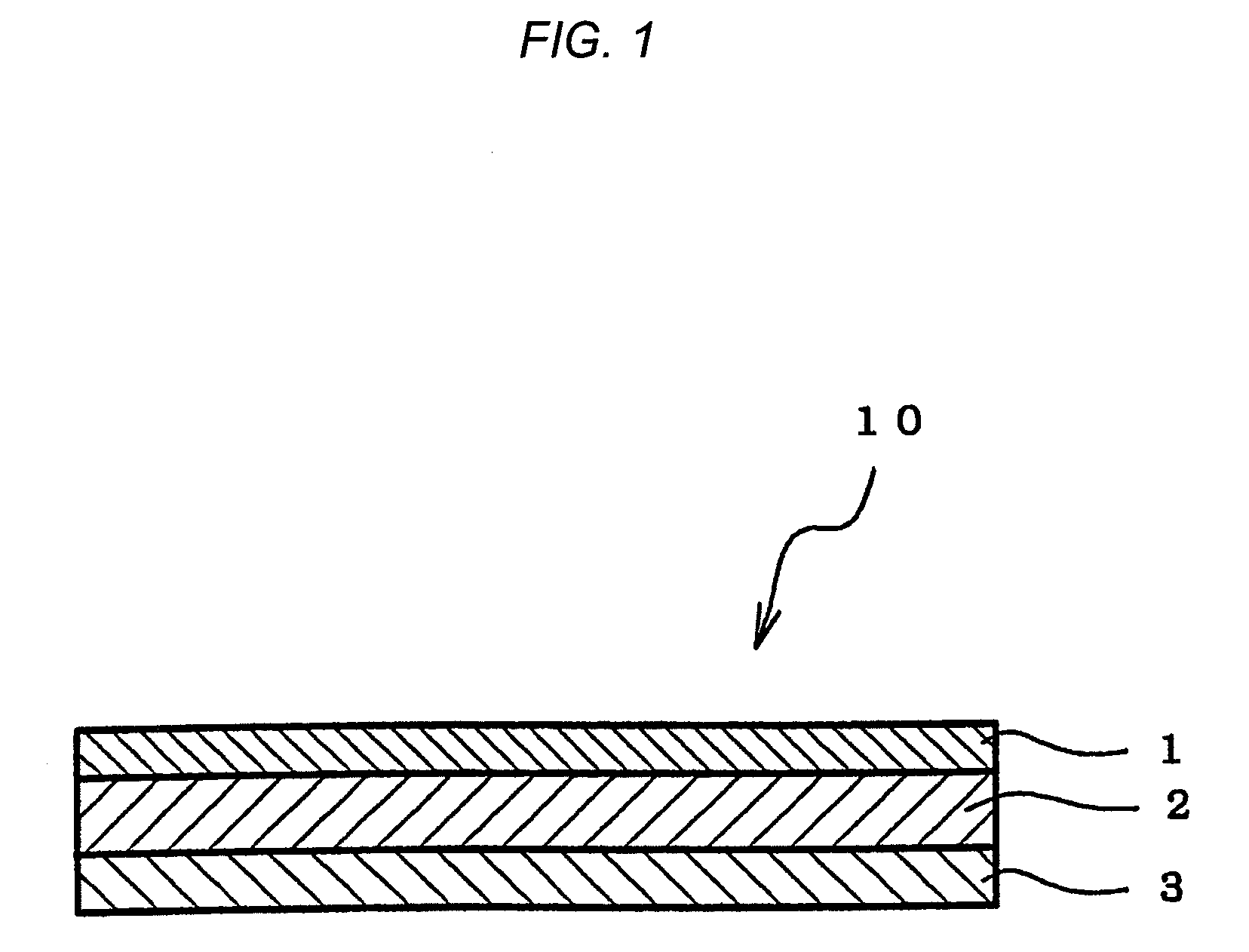

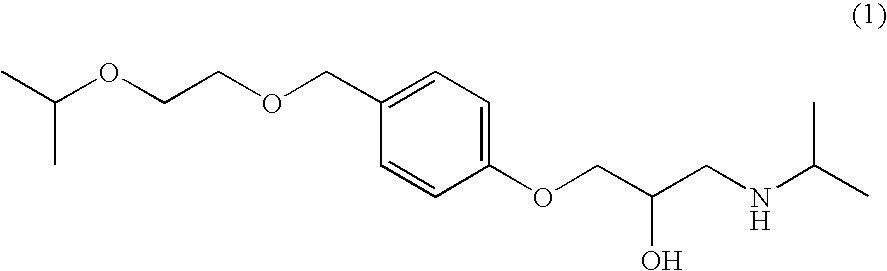

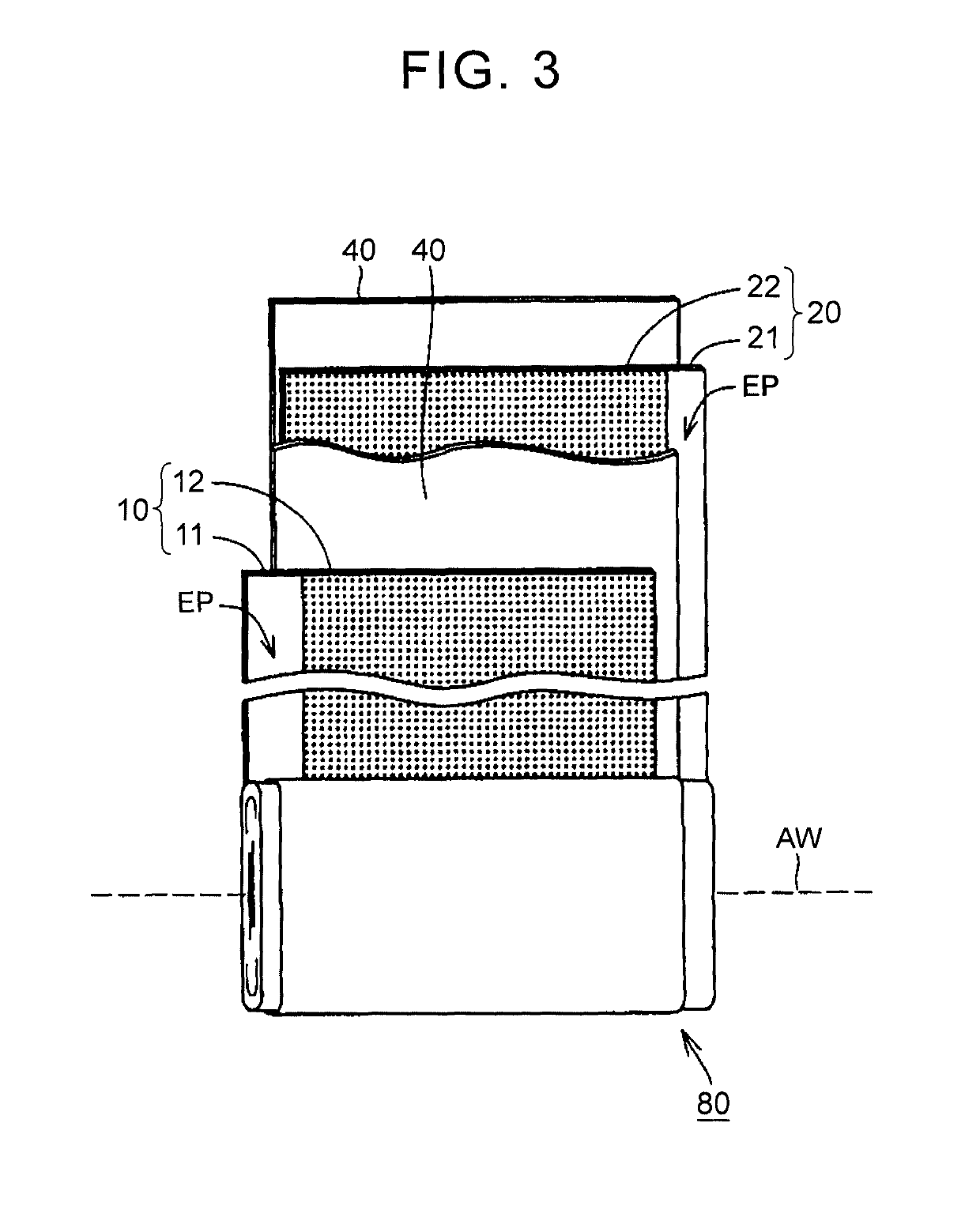

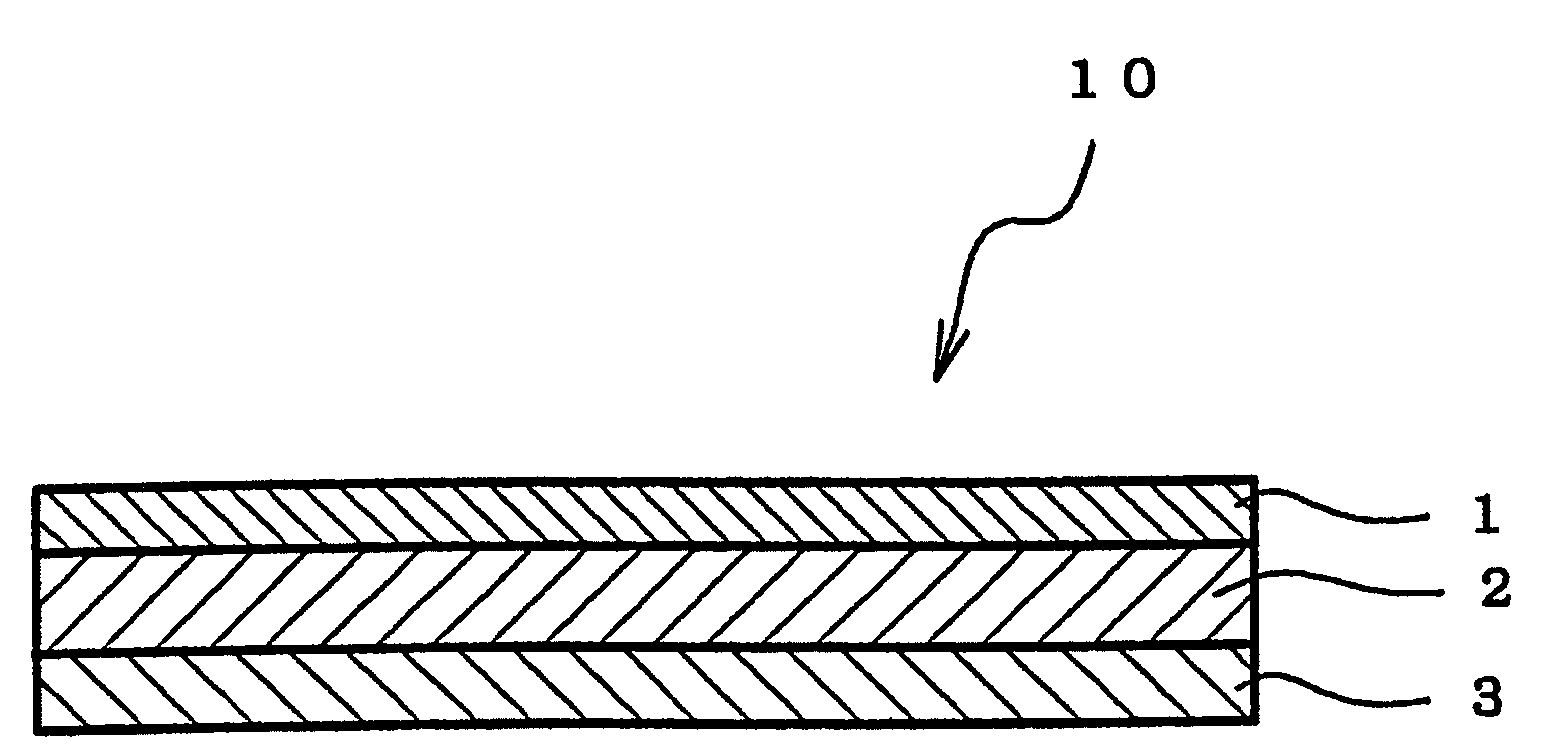

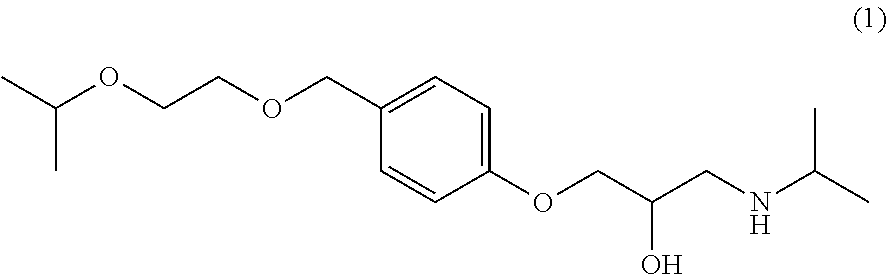

Adhesive Pharmaceutical Preparation Containing Bisoprolol

InactiveUS20090169604A1Improve compatibilitySufficient characteristicBiocideNervous disorderPressure sensitiveChemistry

In the adhesive pharmaceutical preparation of the invention containing bisoprolol, a pressure-sensitive adhesive layer is laminated on one side of the backing. The pressure-sensitive adhesive layer contains a branched monoalcohol having from 12 to 28 carbon atoms, a free base of bisoprolol and a polyisobutylene pressure-sensitive adhesive. Accordingly, compatibility of the polyisobutylene pressure-sensitive adhesive with the free base of bisoprolol can be specifically increased. As a result, not only it becomes possible to increase blending amount of the free base of bisoprolol but also bleed of the free base of bisoprolol from the pressure-sensitive adhesive layer can be suppressed and, what is more, the pressure-sensitive adhesion characteristics sufficient from the practical point of view can be obtained.

Owner:NITTO DENKO CORP +1

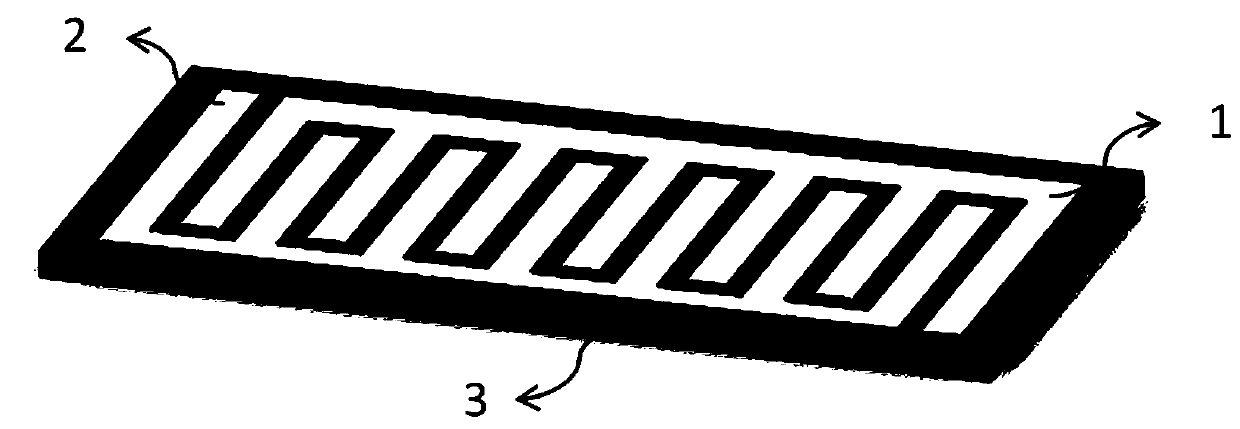

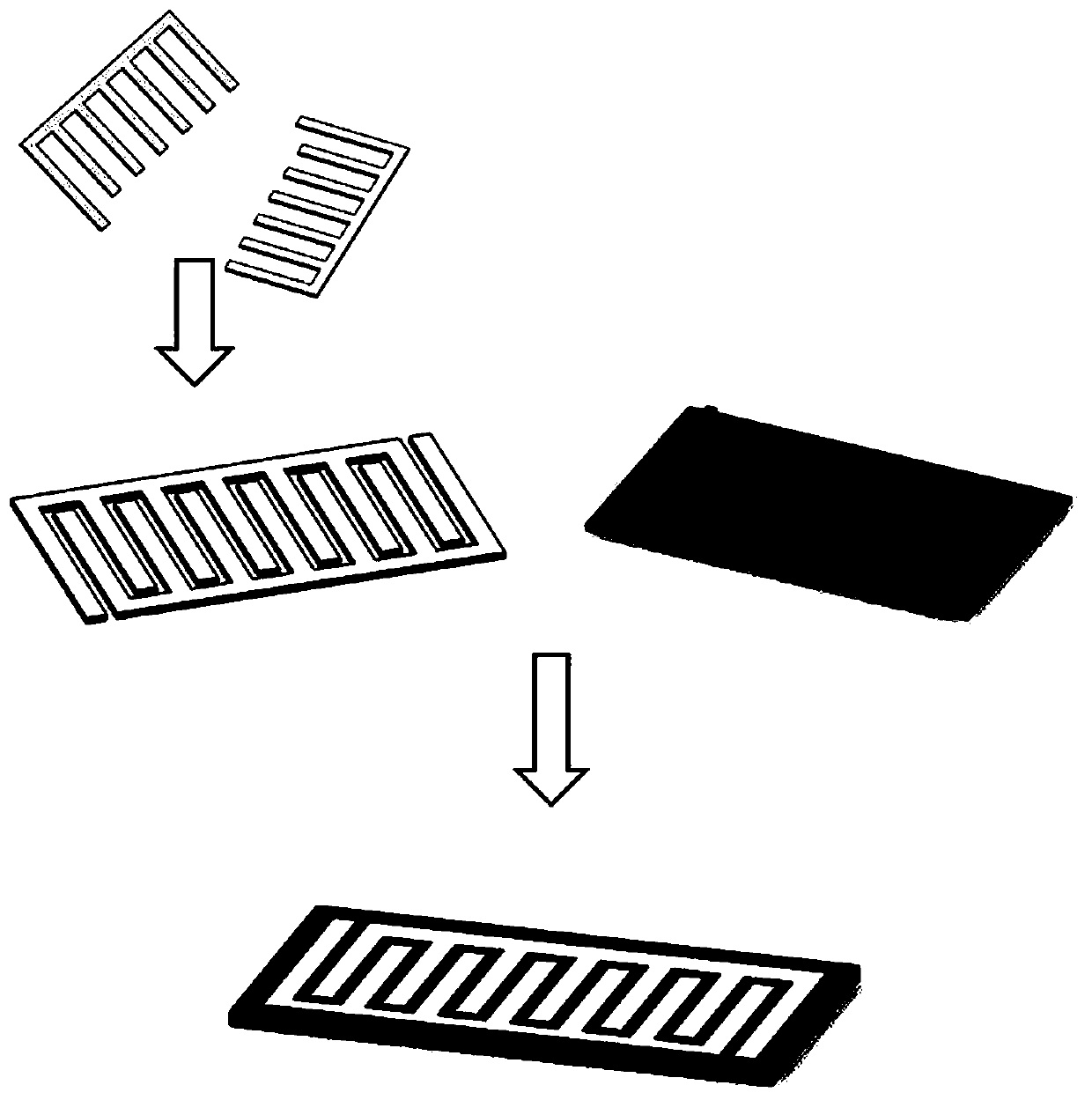

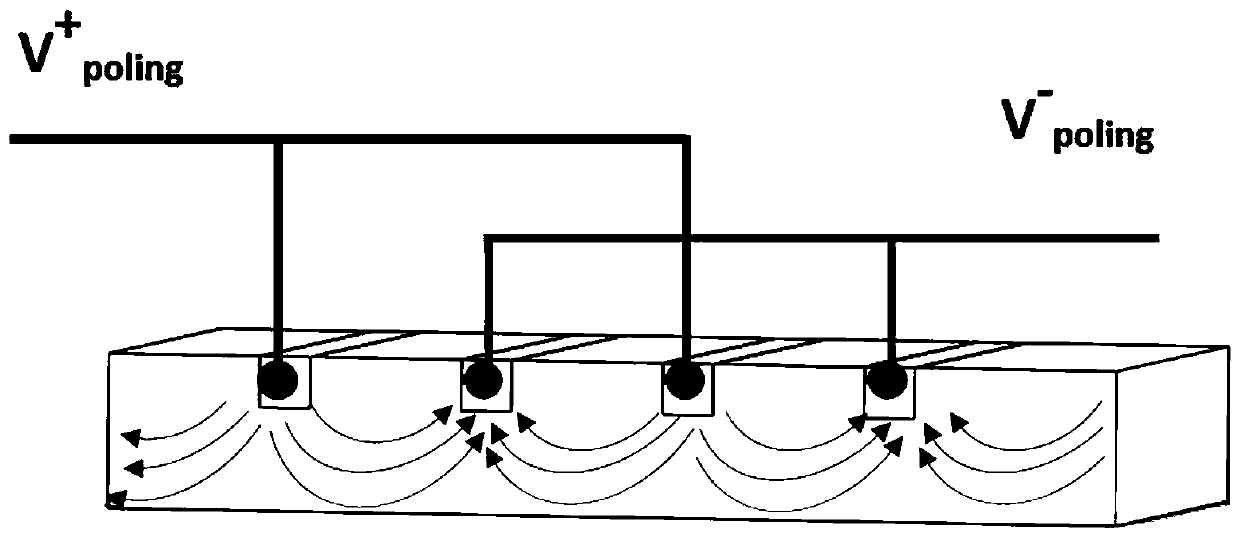

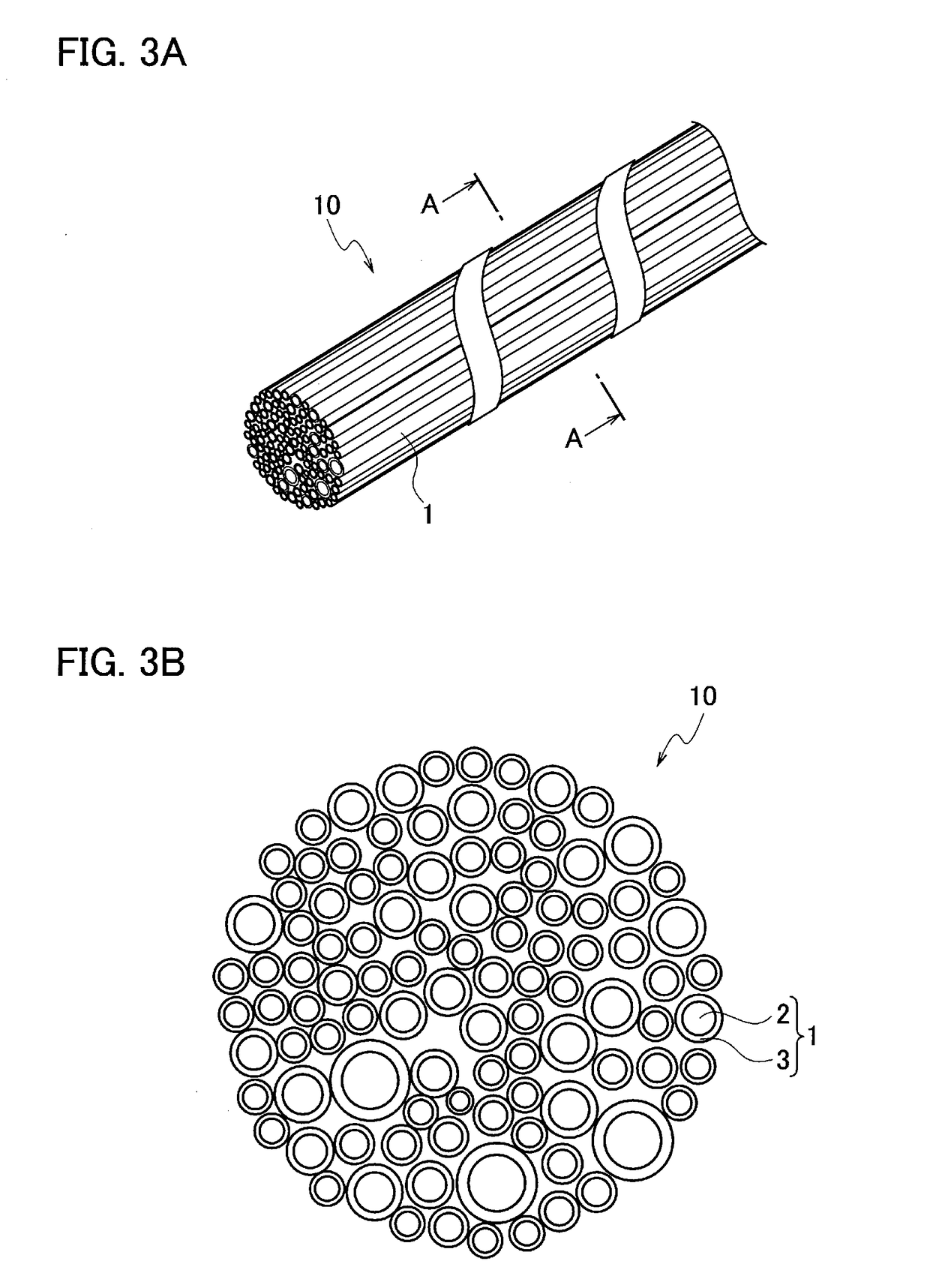

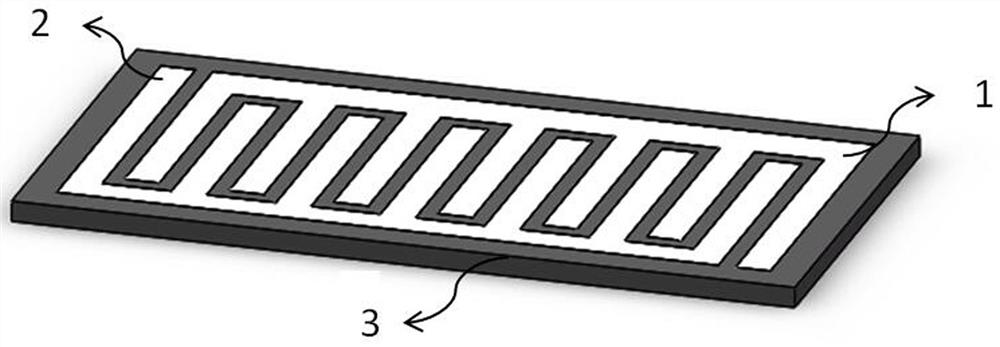

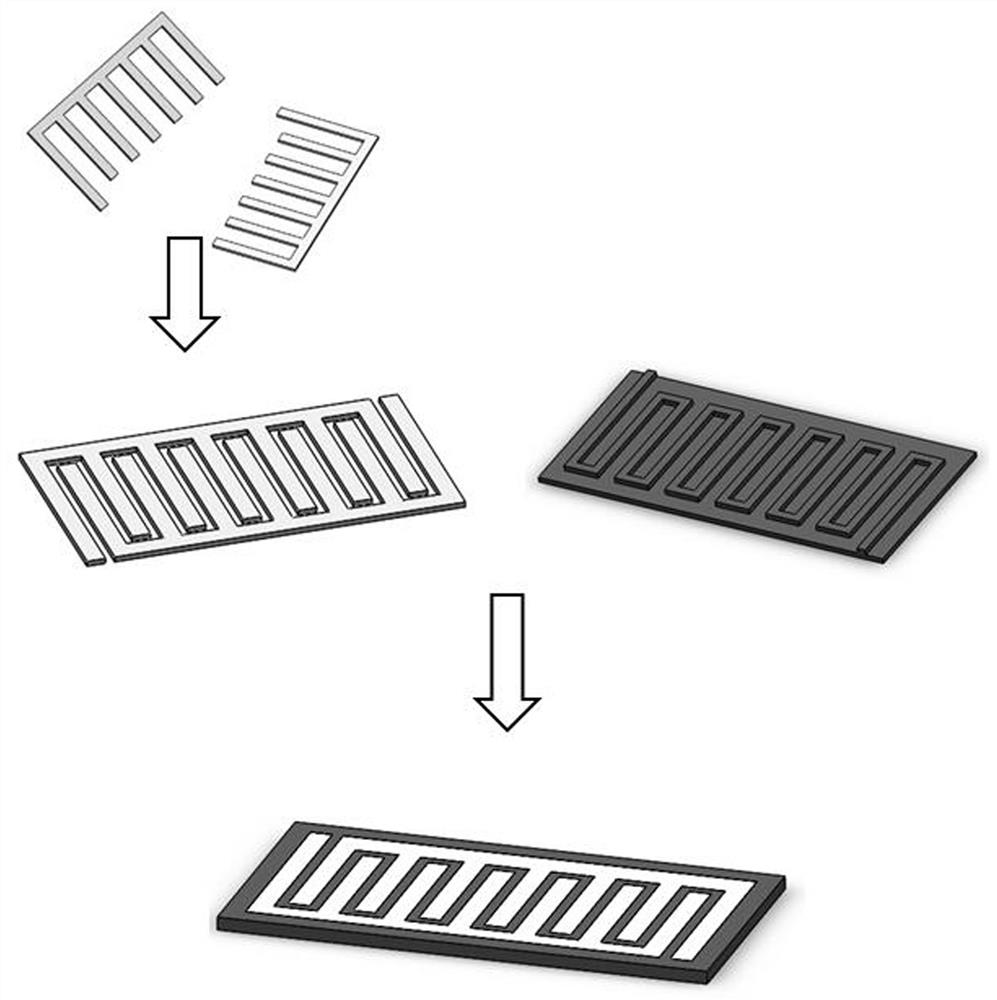

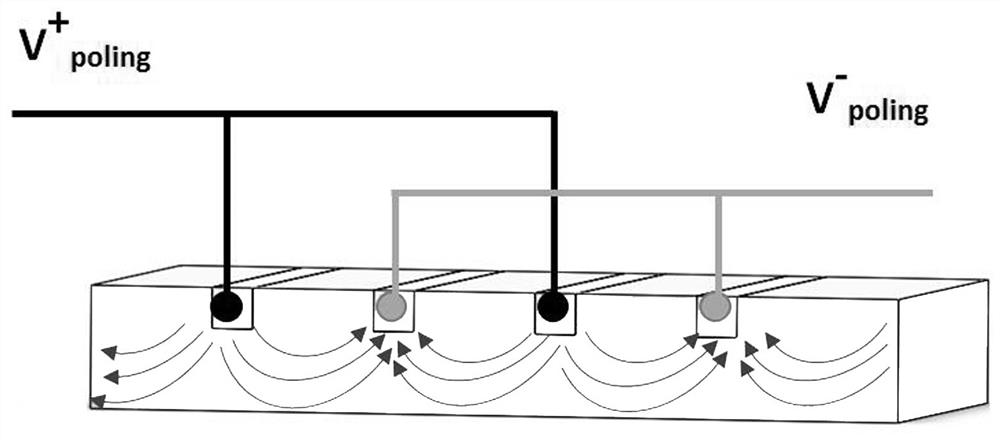

Flexible stretchable piezoelectric nano generator based on interdigital electrode structure and preparation method thereof

ActiveCN107623068AIncrease the amount of mixingEvenly distributedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesNanogeneratorCoupling

The invention discloses a film-type piezoelectric nano generator based on an interdigital electrode structure. The film-type piezoelectric nano generator includes a piezoelectric film layer and an interdigital electrode film layer. The interdigital electrode film layer is composed of a unilateral electrode A and a unilateral electrode B. The interdigital electrode film layer is half-embedded intothe piezoelectric film layer. The piezoelectric film layer is prepared by filling a flexible polymer material with a piezoelectric material. The unilateral electrode A and the unilateral electrode B in the interdigital electrode film layer are prepared by filling the flexible polymer material with conductive particles. The nano generator adopts a d33 coupling mode. Thus, the problem that the ordinary piezoelectric nano generator has low output voltage in a d31 coupling mode is solved on the basis of ensuring good flexibility and stretchability.

Owner:ZHONGBEI UNIV

Powder cosmetic material

The invention aims to provide a powder cosmetic in which the powder component causes no aggregation and the surface powder component causes no caking in press processing even if a large amount of oily component is contained therein. Said powder cosmetic is characterized by comprising oblate cellulose particles and an oily component.

Owner:OHKEN +2

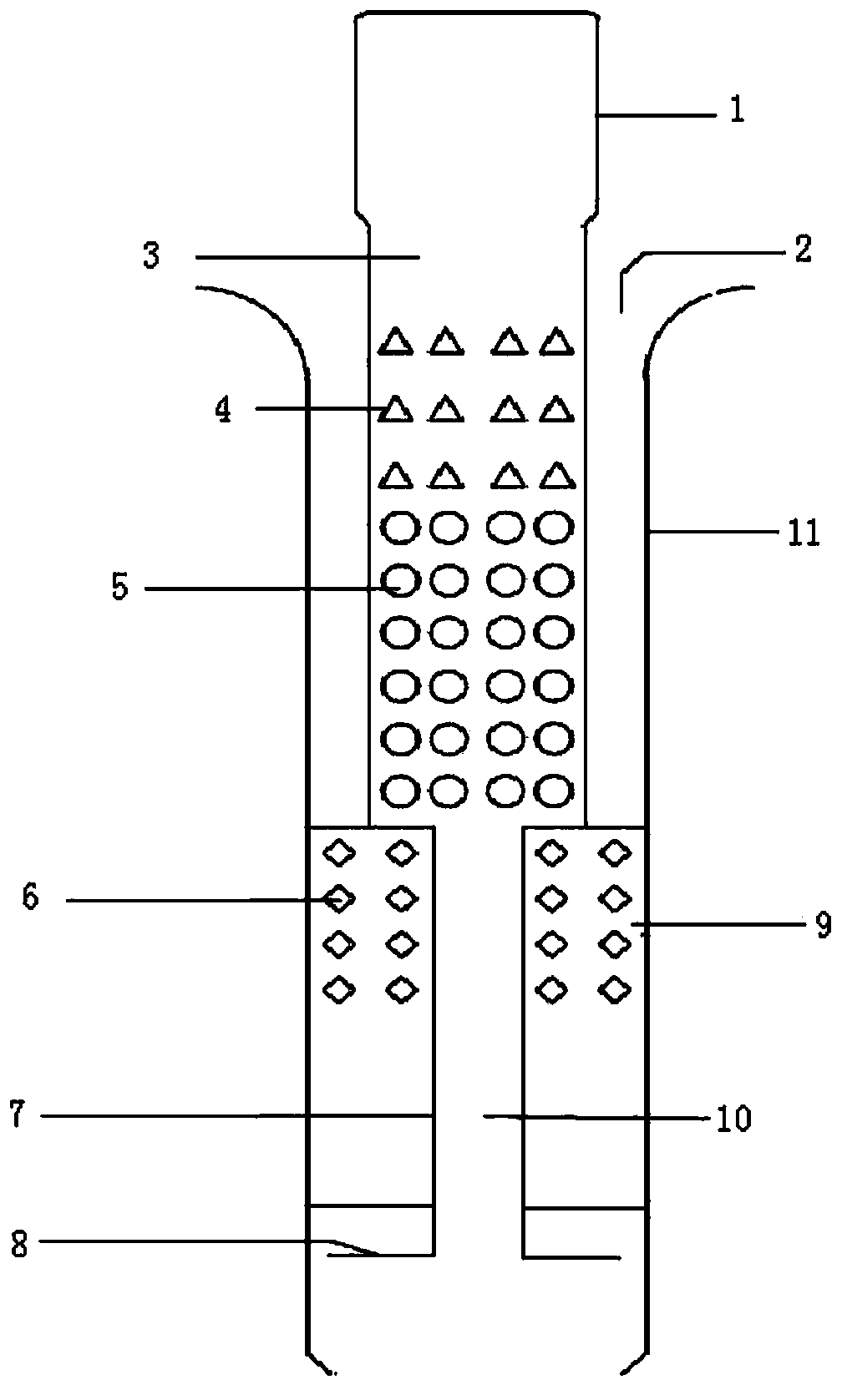

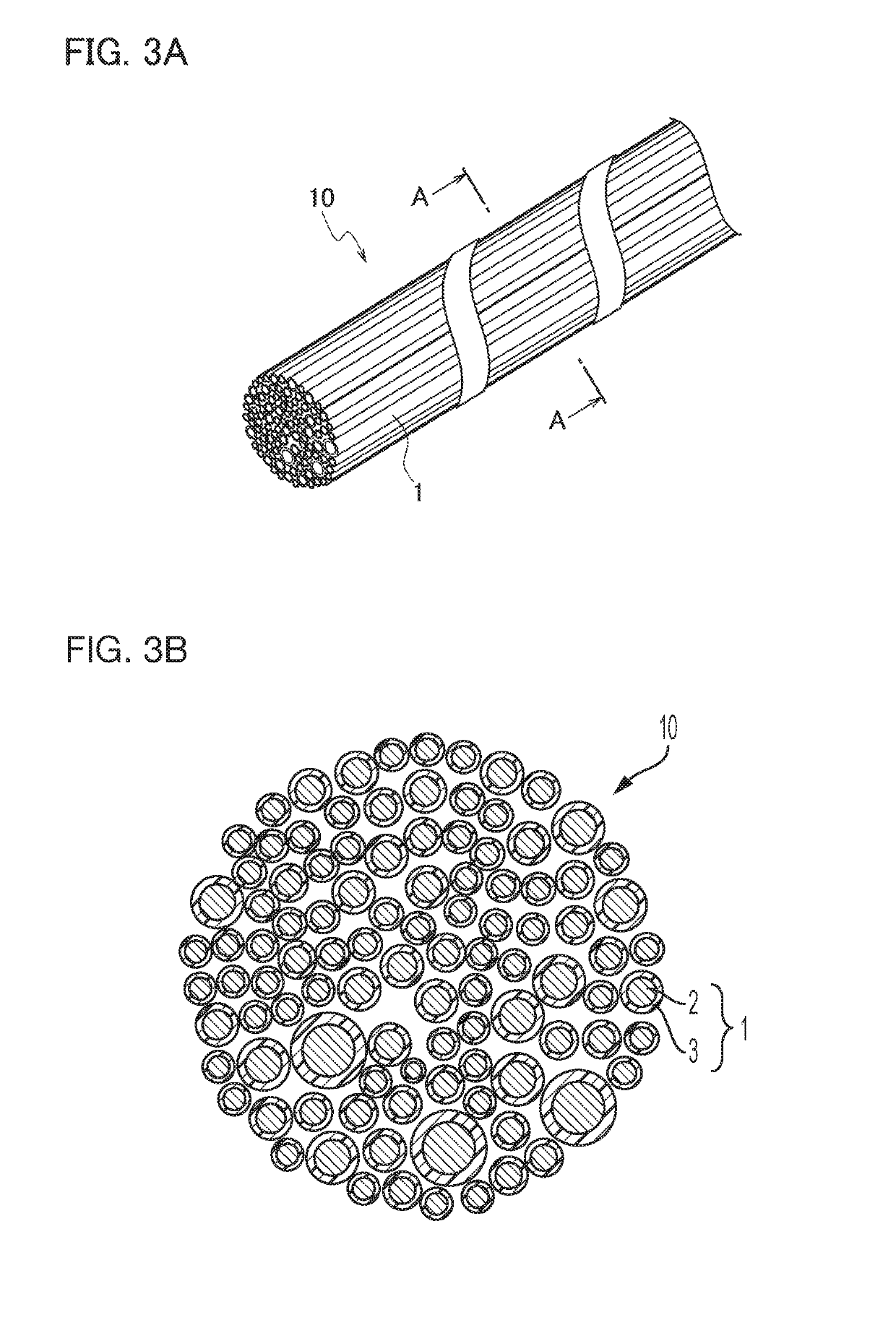

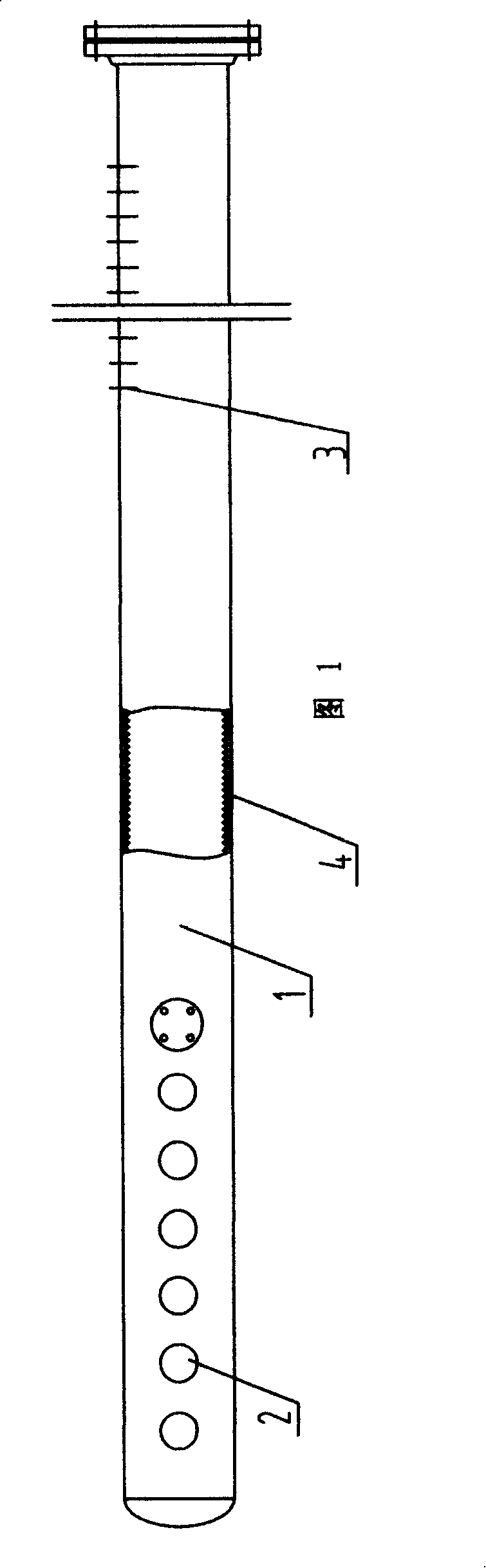

Automobile tail gas exhaust device and method for exhausting automobile tail gas

InactiveCN103670643AReduce sound intensityPlay a sound-absorbing effectExhaust apparatusSilencing apparatusGasolineEngineering

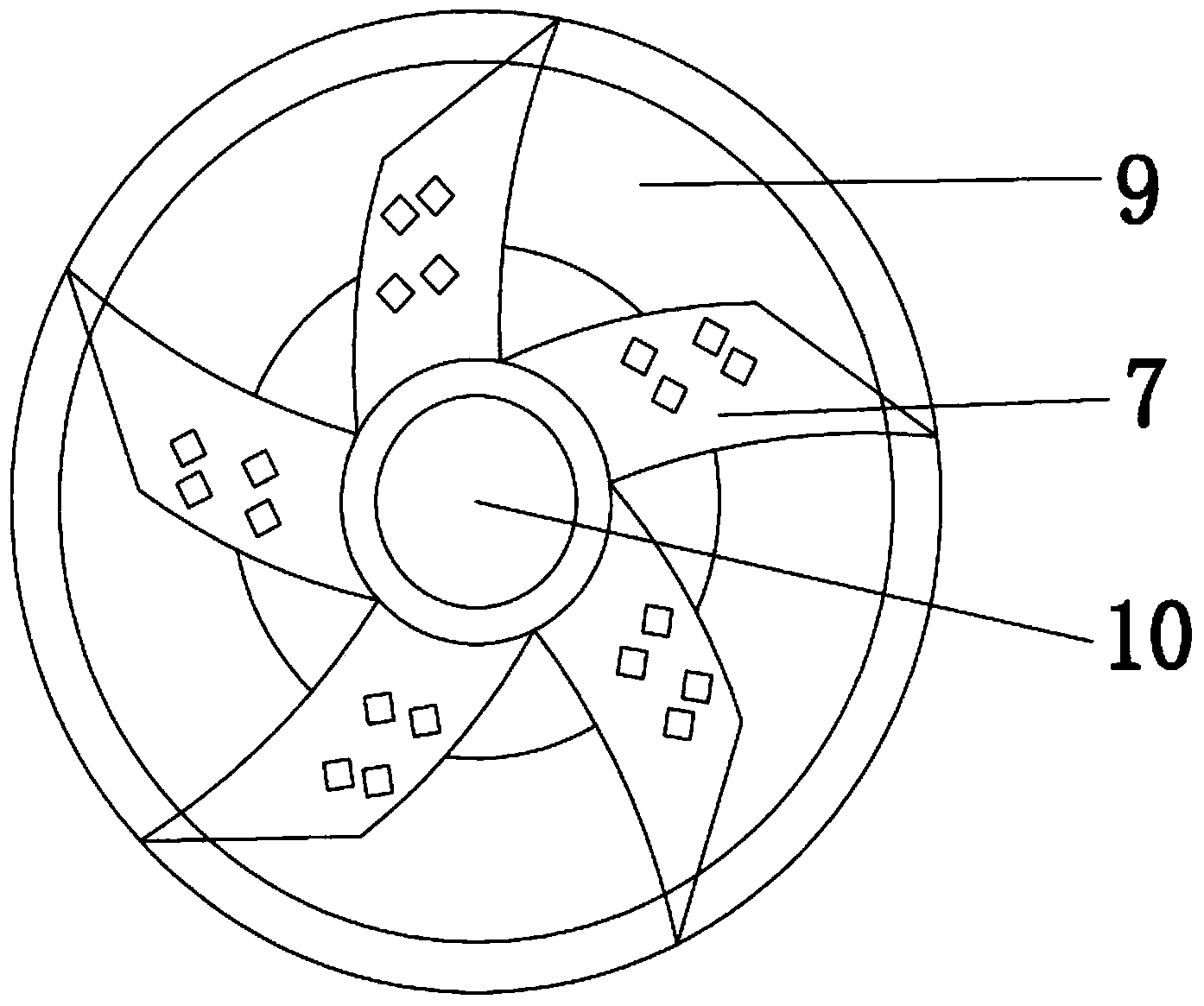

The invention provides an automobile tail gas exhaust device and a method for exhausting automobile tail gas. The device comprises a connecting body (1), a multi-hole-shaped cellular shunt silencer (3), a rotational flow supercharger (9) and a shell (11), wherein the connecting body (1) is used for being connected with an automobile tail gas exhaust pipe, the multi-hole-shaped cellular shunt silencer (3) is connected with the connecting body (1) is a sealed mode, a certain space is reserved between the multi-hole-shaped cellular shunt silencer (3) and the shell (11) to form an air inlet (2), the rotational flow supercharger (9) is connected with the multi-hole-shaped cellular shunt silencer (3), a guide pipe (10) is arranged in the rotational flow supercharger (9), and the guide pipe (10) is communicated with the multi-hole-shaped cellular shunt silencer (3). According to probationary certificate, the device and method are applicable to various gasoline and diesel engine automobiles, the device is reasonable in structure and convenient to install, original performance of the automobiles is not affected, and the energy conservation and noise reduction effect is achieved.

Owner:张玉龙 +1

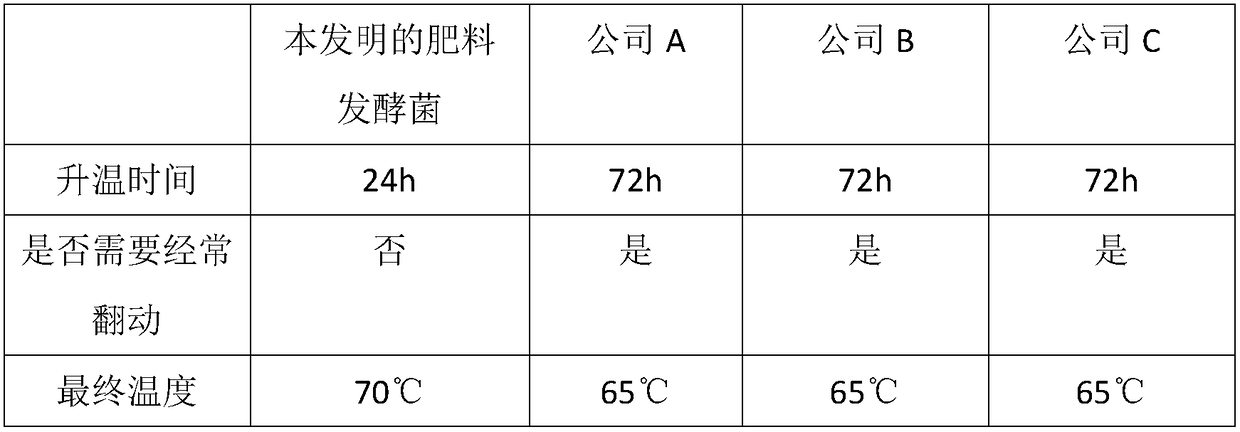

Bacterium agent for fermentation treatment of waste organic matters and preparation method

InactiveCN108192840AReduced manual turning and increased mixing volumeIncrease the amount of mixingFungiBacteriaMetaboliteOxygen

The invention belongs to the technical field of treatment of waste organic matters. Aiming at solving the technical problems in the prior art that fermentation is low, manual overturning is needed andthe waste organic matters are easy to corrupt in a fermentation process, the invention provides a bacterium agent for fermentation treatment of the waste organic matters and a preparation method. Thebacterium agent comprises a liquid bacterium agent; the liquid bacterium agent is prepared from the following components in parts by weight: 0.005 to 0.015 part of beef extract, 0.02 to 0.04 part ofpeptone, 0.04 to 0.06 part of glucose, 0.002 to 0.006 part of sodium chloride, 101.2 to 101.8 parts of distilled water, 2 to 4 parts of egg white, 0.05 to 0.2 part of sheep serum, 2 to 4 parts of brown sugar, 0.02 to 0.06 part of metabolite of photosynthetic bacteria, 0.02 to 0.06 part of metabolite of saccharomycetes and 0.2 to 0.6 part of an EM bacterium; the bacterium agent further comprises acarrier; the weight ratio of the carrier to the liquid bacterium agent is (20 to 30) to 1; the carrier is composed of organic matter particles with the mesh quantity of 10 to 20 meshes. The bacteriumagent provided by the invention has the characteristics of manpower saving and capabilities of prolonging the fermentation time and improving the fermentation efficiency, and is suitable for the wasteorganic matters with high aerobic fermentation difficulty.

Owner:熊万国

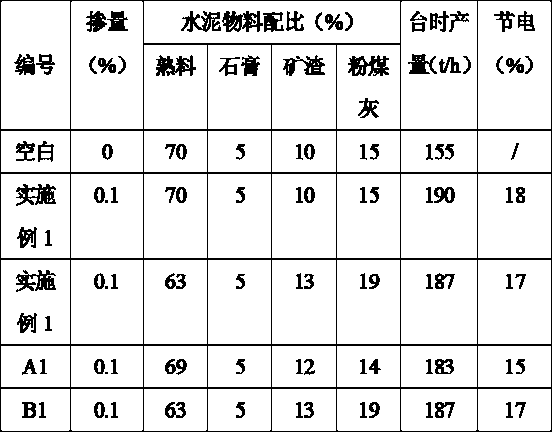

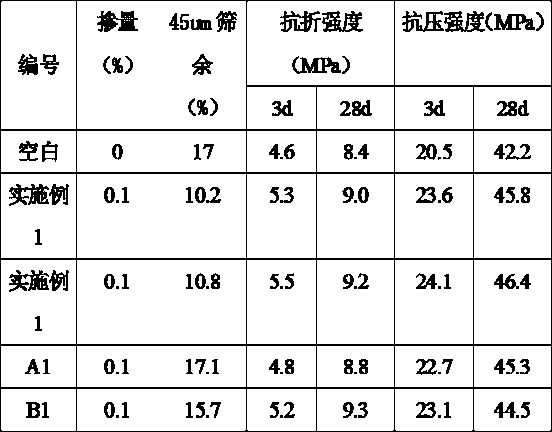

High-mill-temperature cement grinding aid and preparation method thereof

The invention relates to the field of cement grinding aids and in particular relates to a high-mill-temperature cement grinding aid and a preparation method thereof. The high-mill-temperature cement grinding aid is characterized by being prepared from the following components in parts by mass: 30 to 60 parts of a mixed solution of aliphatic sodium sulfonate and aluminum sulfate, 1 to 10 parts of triethanolamine, 5 to 10 parts of alcamines, 1 to 10 parts of sodium tripolyphosphate, 1 to 10 parts of sodium gluconate, 0.1 to 5 parts of a dispersant and 10 to 30 parts of water. By adopting the high-mill-temperature cement grinding aid provided by the invention, the surface energy of a material can be reduced and an aggregation effect generated by molecular attraction is weakened; accelerated expansion of particle cracks are facilitated when an external force acts, so that the grinding efficiency is improved and the aims of high quality, energy saving and high yield of a ball mill are realized; the fineness of cement can be reduced and the output per machine hour of the ball mill can be improved.

Owner:NINGXIA PAGODA CHEM CENT LAB CO LTD

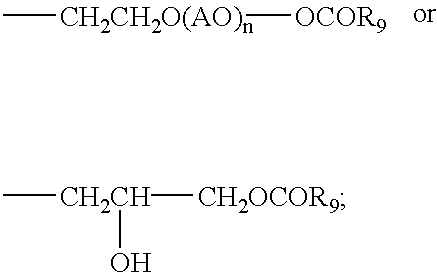

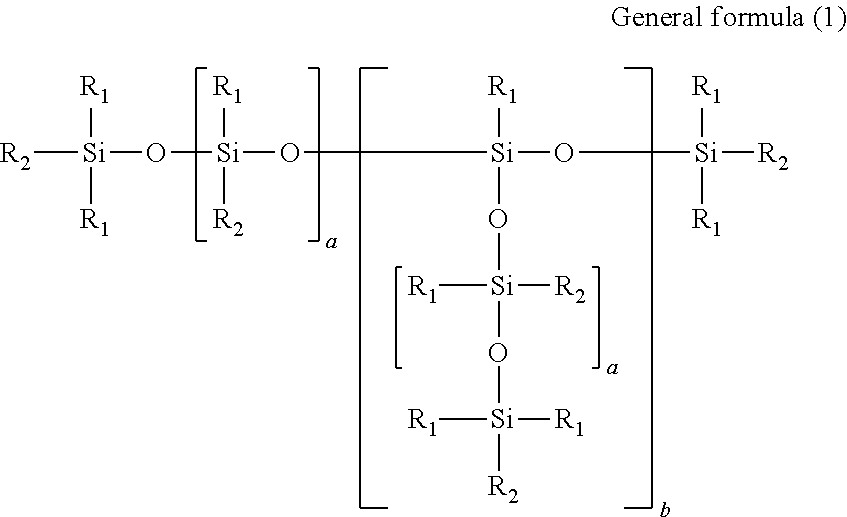

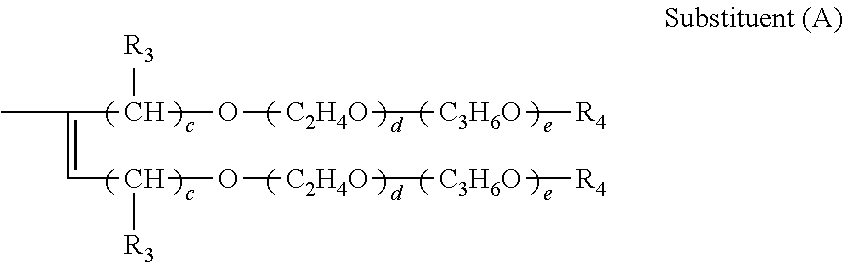

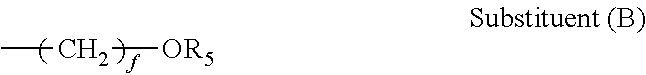

Paper quality improver for papermaking and method for producing pulp sheet

InactiveUS7122098B1Significant valueBulky brightnessNatural cellulose pulp/paperSpecial paperPapermakingSlurry

The present invention provides a paper quality improver for papermaking, for improving bulk value, brightness, and opacity of the pulp sheet. Further, the present invention provides a dry efficiency improver. A compound is used as the paper quality improver for papermaking, wherein the compound has less than 4% of lyotropic degree measured by a specific method and the compound satisfies at least two selected from (i) standard improved bulky value of not less than 0.02 g / cm3, (ii) standard improved brightness of not less than 0.5 point and (iii) standard improved opacity of not less than 0.5 point. The compound is added internally into pulp slurry before or in papermaking step.

Owner:KAO CORP

Cigarette wrapper paper with suppressed scattering of ash

InactiveUS20020189626A1Suppress scatterReduce the amount of solutionNon-fibrous pulp additionNatural cellulose pulp/paperFiberCombustion

A cigarette wrapper paper formed of a pulp containing at least 60% by weight of fibrous components, particularly, a flax pulp. The cigarette wrapper paper permits markedly suppressing the scattering of the cigarette ash without increasing the addition amount of a loading material promoting combustion or the addition amount of a combustion assistant.

Owner:JAPAN TOBACCO INC

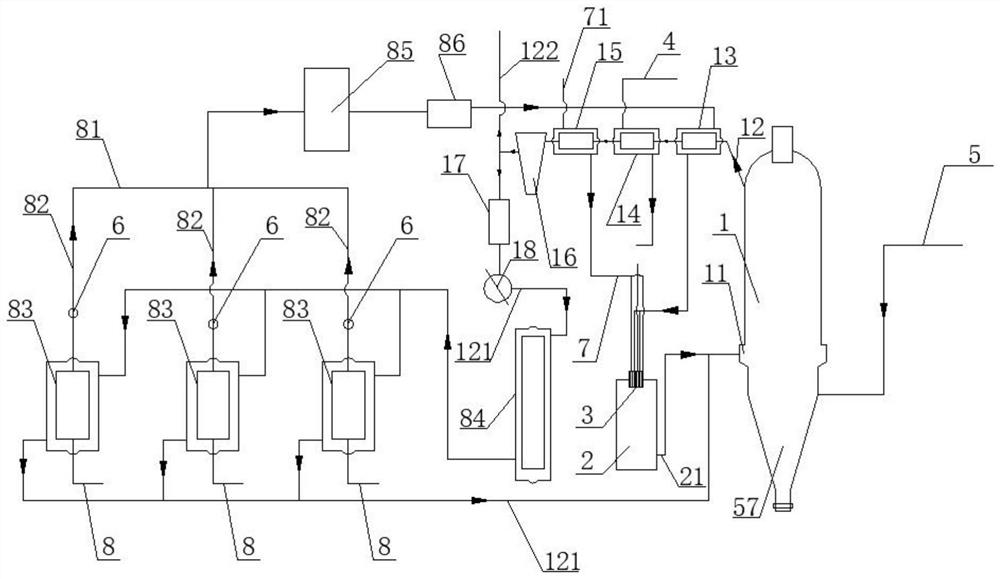

Method for smelting schreyerite in coke oven gas-based shaft furnace-electric furnace melt separation deep reduction

The invention belongs to the field of comprehensive utilization of schreyerite, and particularly relates to a method for smelting schreyerite in a coke oven gas-based shaft furnace and smelting deep reduction in an electric furnace, in particular to a method for smelting schreyerite in a coke oven gas-based shaft furnace and smelting deep reduction in an electric furnace. The vanadium-titanium pellets are reduced in the gas-based shaft furnace, and vanadium-titanium direct reduction iron is obtained; the vanadium-titanium direct reduction iron is subjected to melting reduction in an electric furnace to obtain vanadium-containing molten iron and titanium slag, the gas-based shaft furnace at least uses one coke oven gas as a gas source, and purified gas at the top of the gas-based shaft furnace exchanges heat with hot gas in a gas ascending pipe of the coke oven and then is mixed into high-temperature reducing gas generated by the coke oven gas to form furnace-entering reducing gas of the gas-based shaft furnace; and reducing gas is blown into the molten layer in the electric furnace, the reducing gas reacts with the vanadium and iron oxides to generate vanadium and iron metal liquid and titanium slag, and the vanadium and iron metal liquid enters the molten iron. Electric furnace smelting power consumption can be reduced, the influence of newly added materials of the electric furnace on the titanium slag grade is reduced, and efficient and reasonable utilization of different types of heat energy is achieved.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

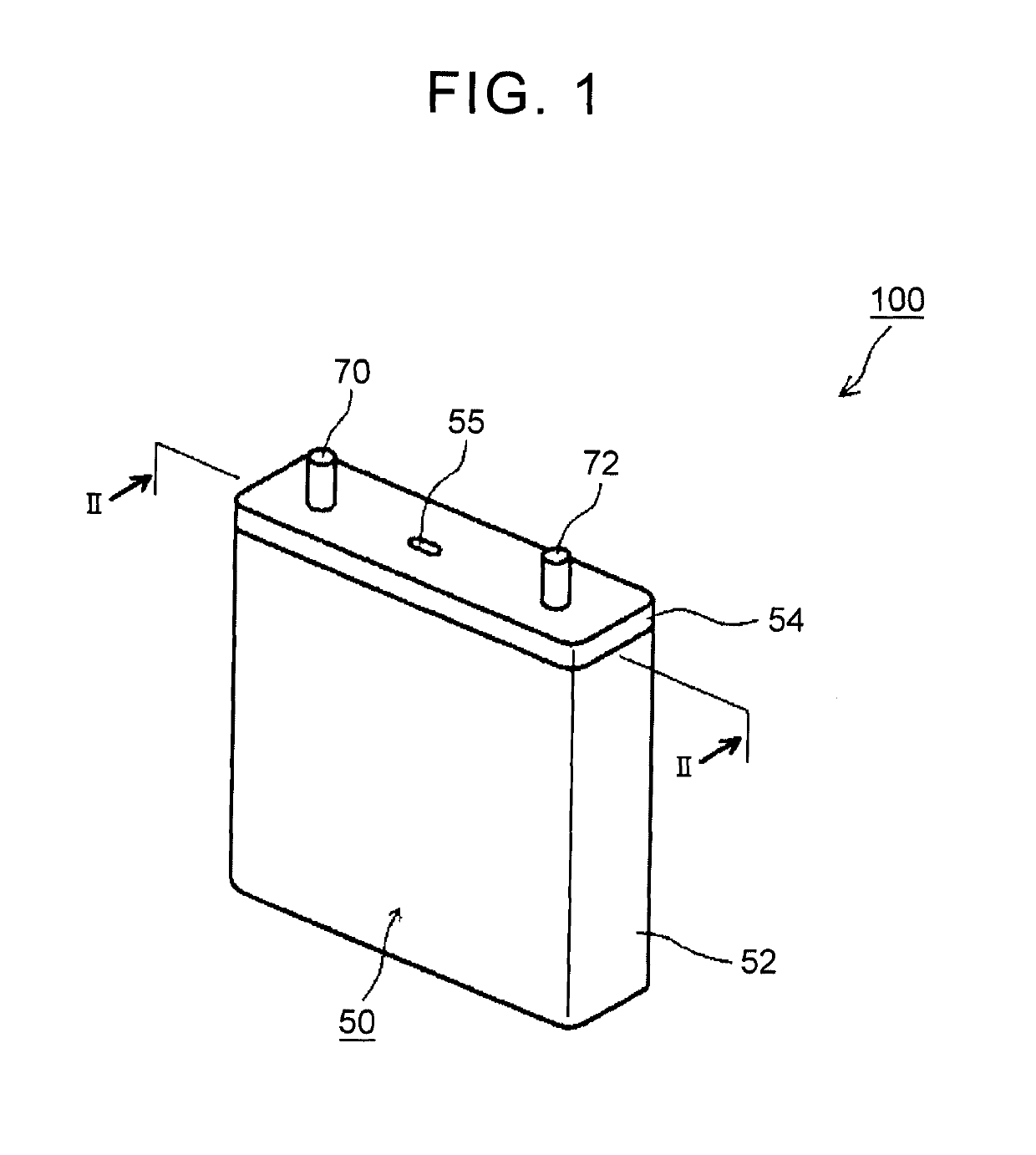

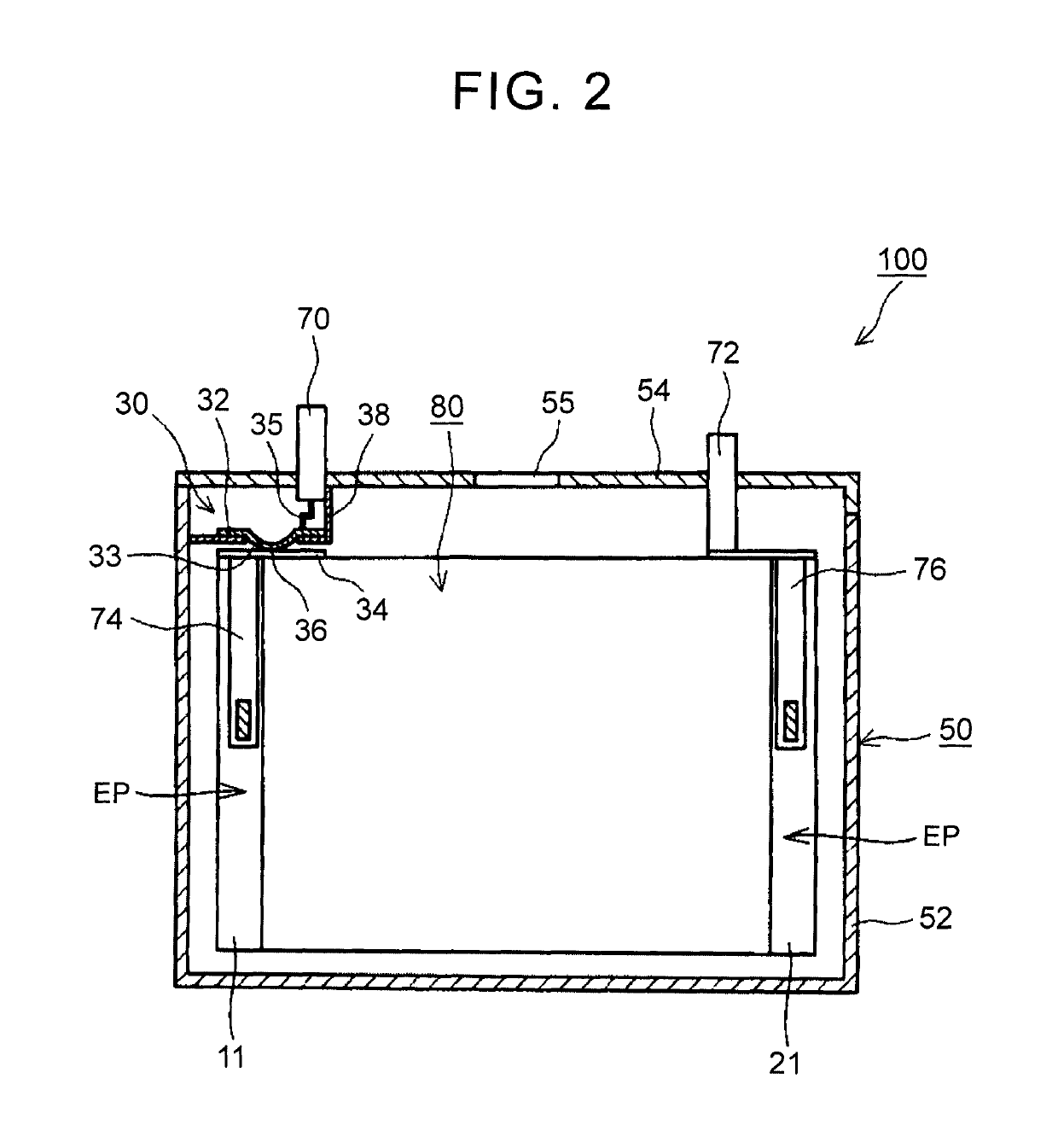

Nonaqueous electrolyte secondary battery

ActiveUS10243196B2High porosityReduce gas volumePositive electrodesLi-accumulatorsLithium iron phosphateCobalt

Owner:TOYOTA JIDOSHA KK

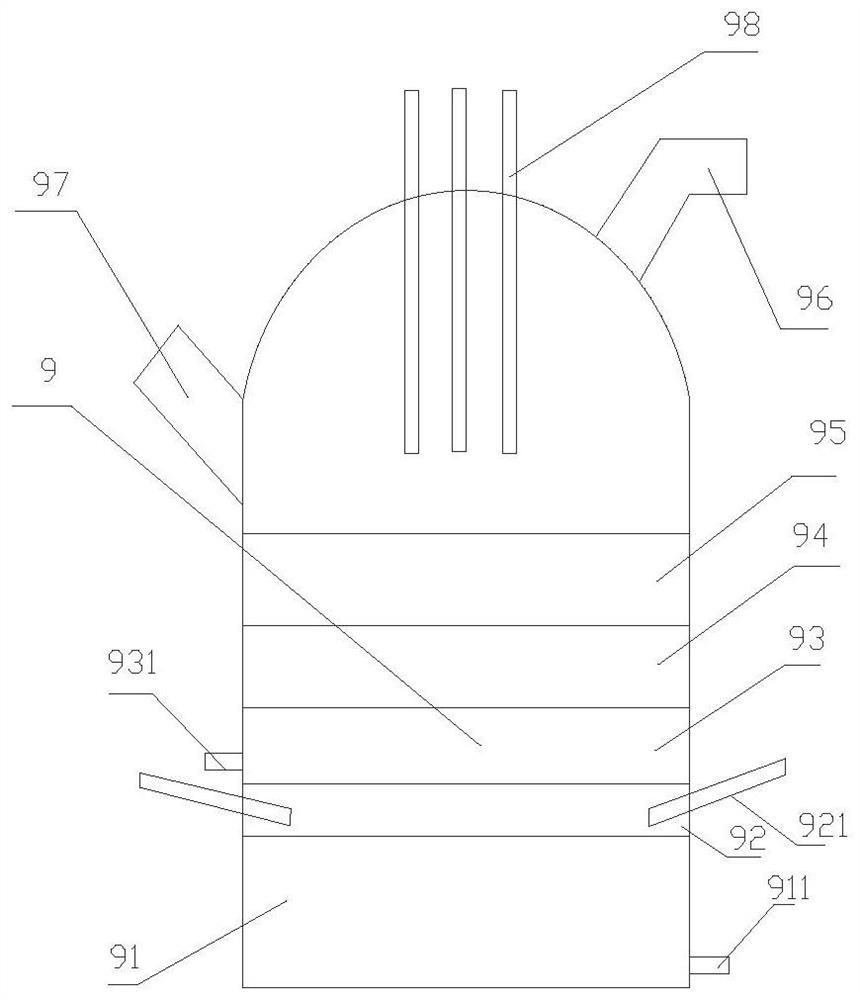

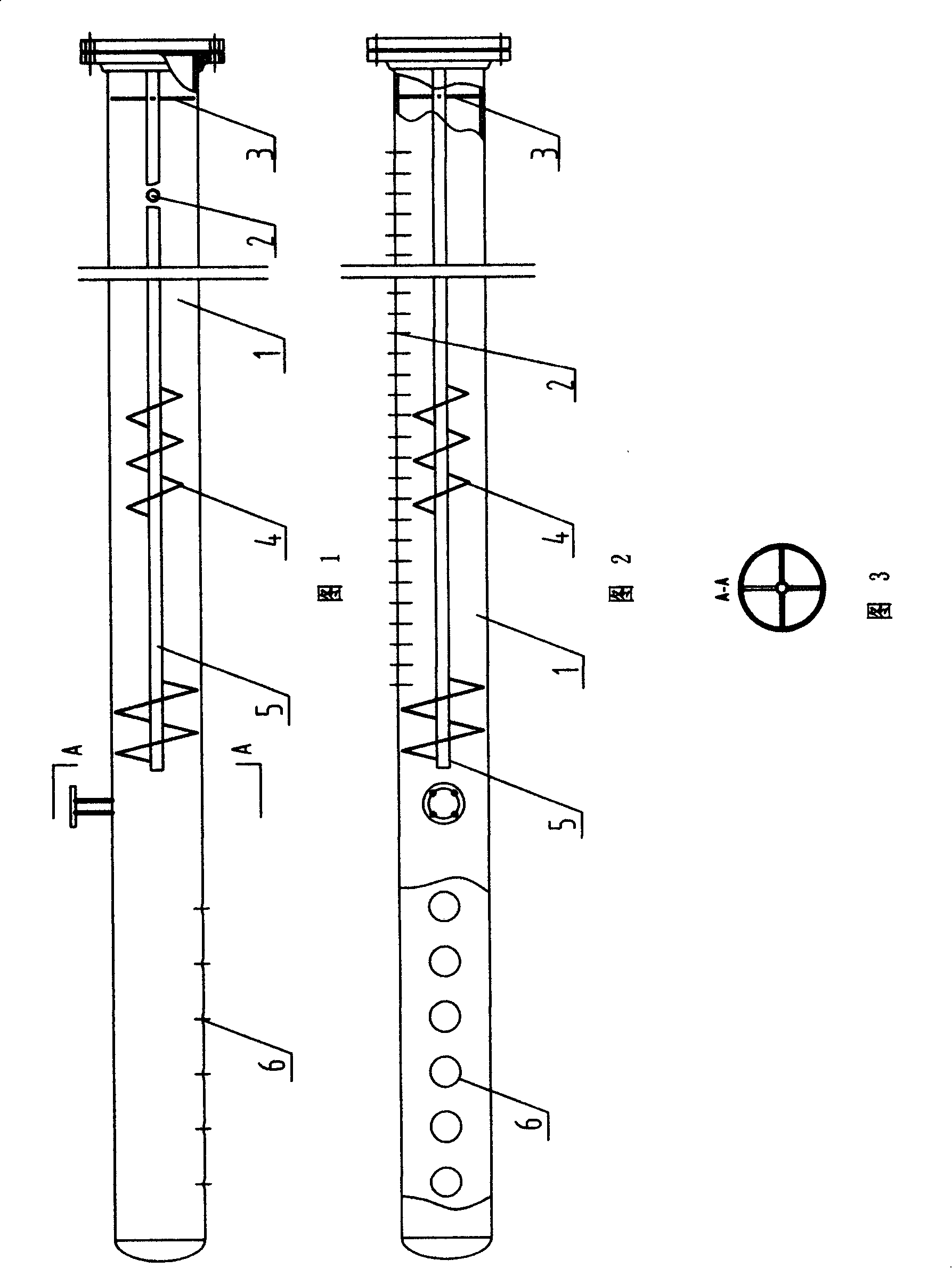

Medial mixer used for heat conducting oil boiler

The invention relates to an intermediate mixer used in a heat-conduction oil boiler. The intermediate mixer can completely mix media that flow therein from multi-path convection bank bundles, and can keep good consistency in temperature. The intermediate mixer comprises a gallery and is characterized in that a spiral conductive sheet is arranged inside the gallery and is sleeved on a supporting rod, crisscross supporting frames are arranged at two ends of the supporting rod, and the outer margins of the crisscross supporting frames are connected with the wall of the gallery.

Owner:顾利平

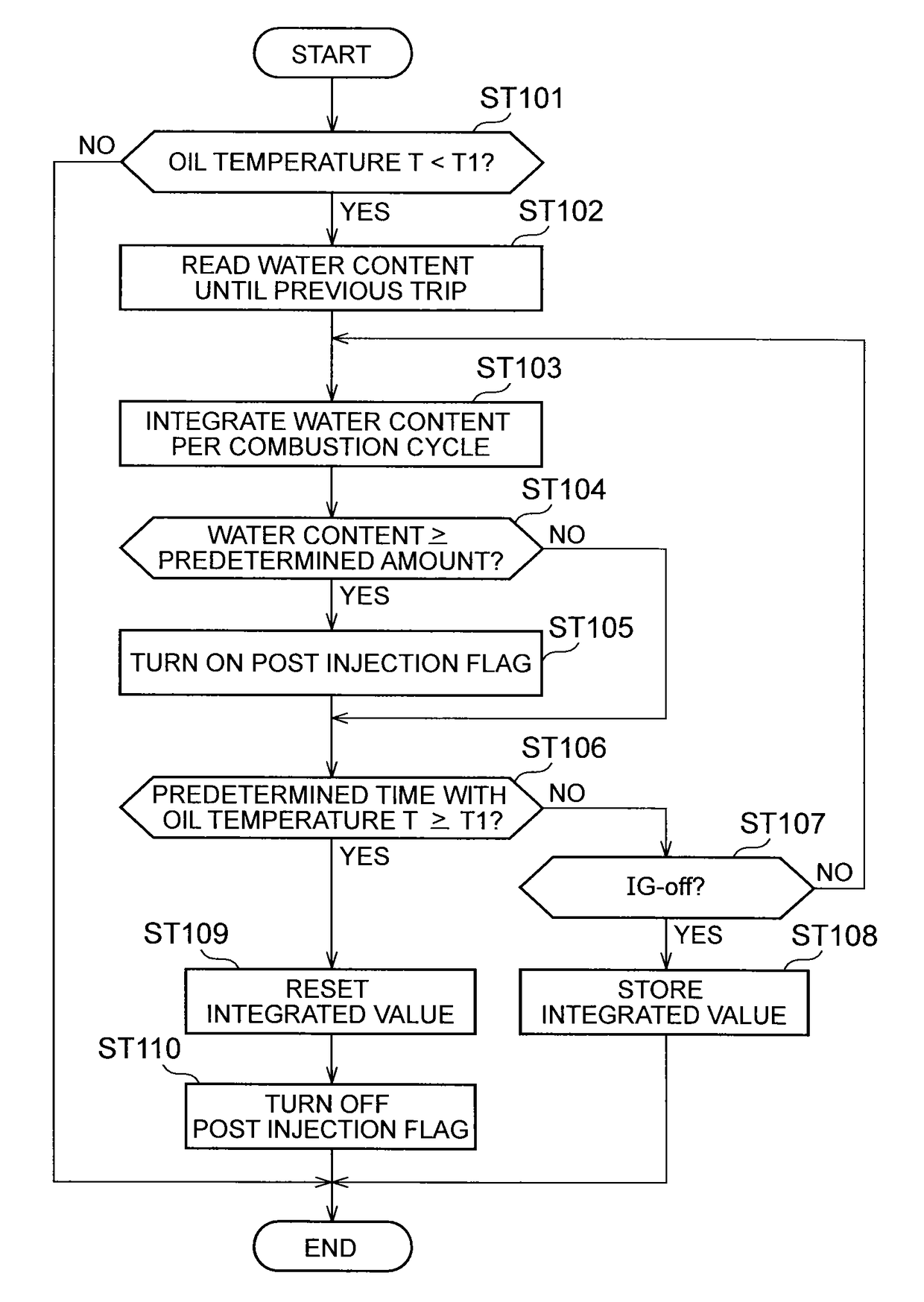

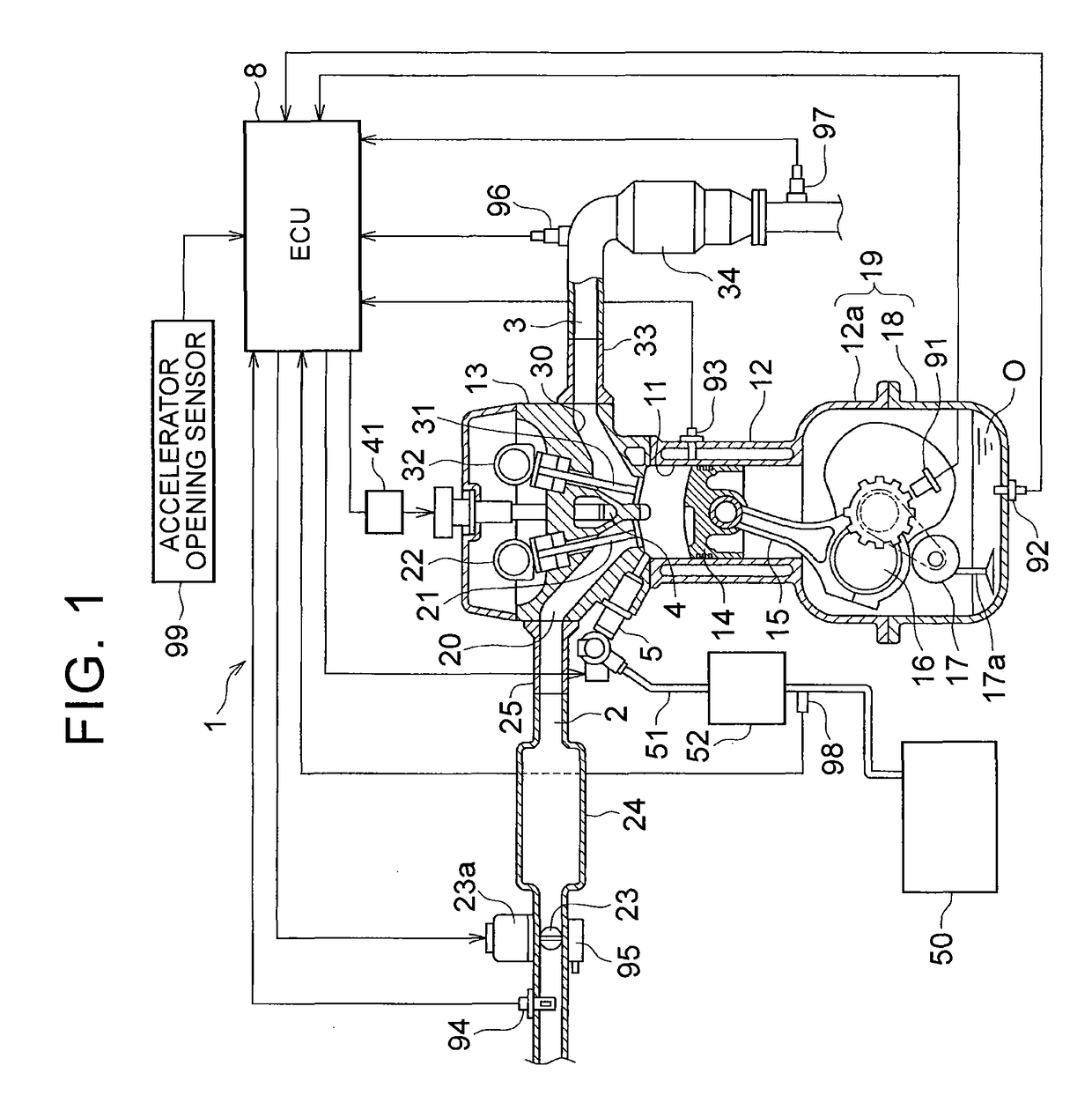

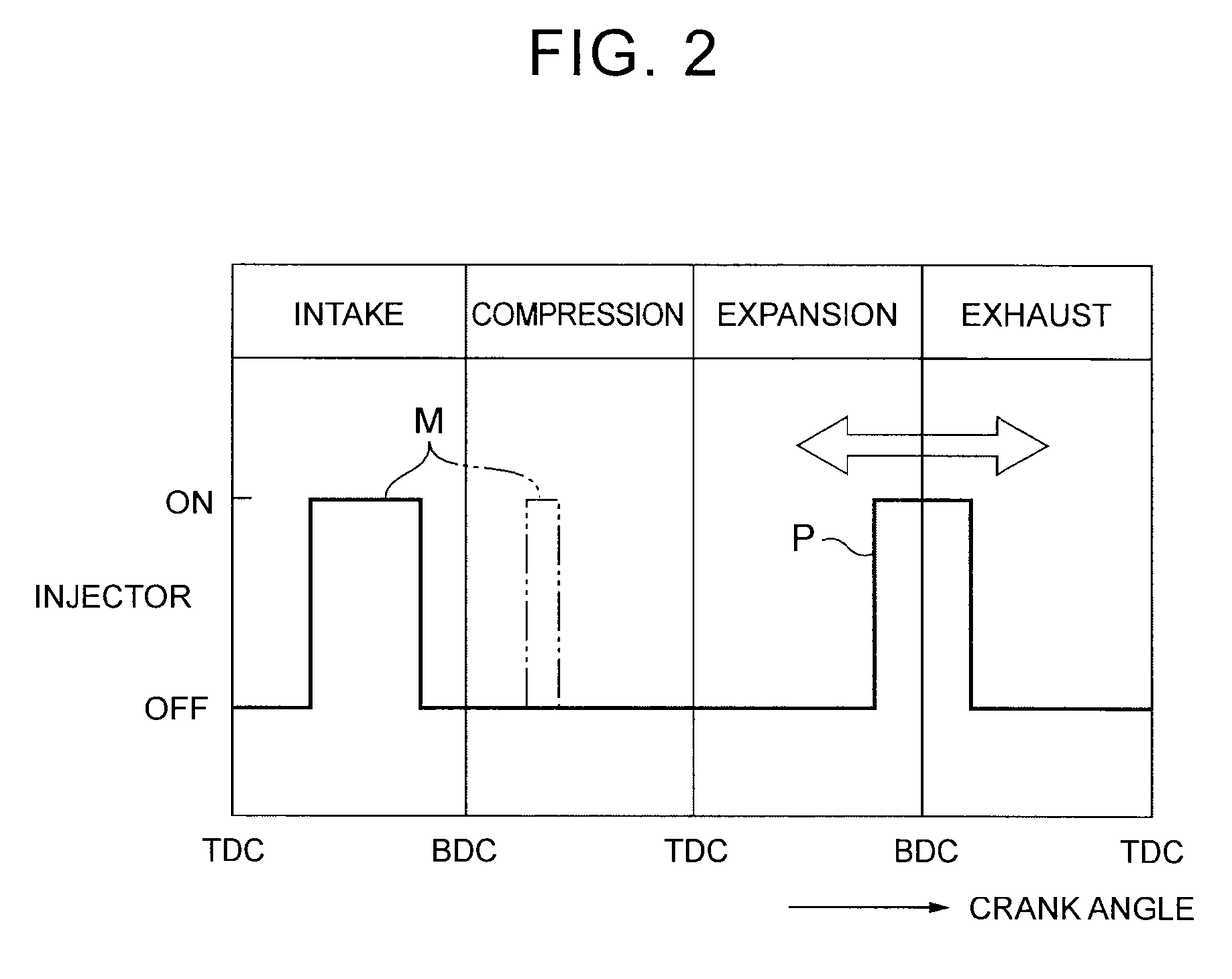

Oil dilution estimation and mitigation control in a fuel injected engine

InactiveUS10107212B2Increase the amount of waterAvoid it happening againElectrical controlInternal combustion piston enginesOil temperatureWater content

A control device for an engine includes an electronic control unit configured to estimate a water content mixed in engine oil based on a history of a fuel injection amount during an operation of the engine and restrain freezing of water such that, when the water content thus estimated is a predetermined amount or more, the electronic control unit increases a mixing amount of the fuel into the engine oil as compared with a case where the water content thus estimated is less than the predetermined amount. The control device estimates the water content mixed in the engine oil as a function of an integrated value of water content while an oil temperature of the engine is less than a predetermined temperature.

Owner:TOYOTA JIDOSHA KK

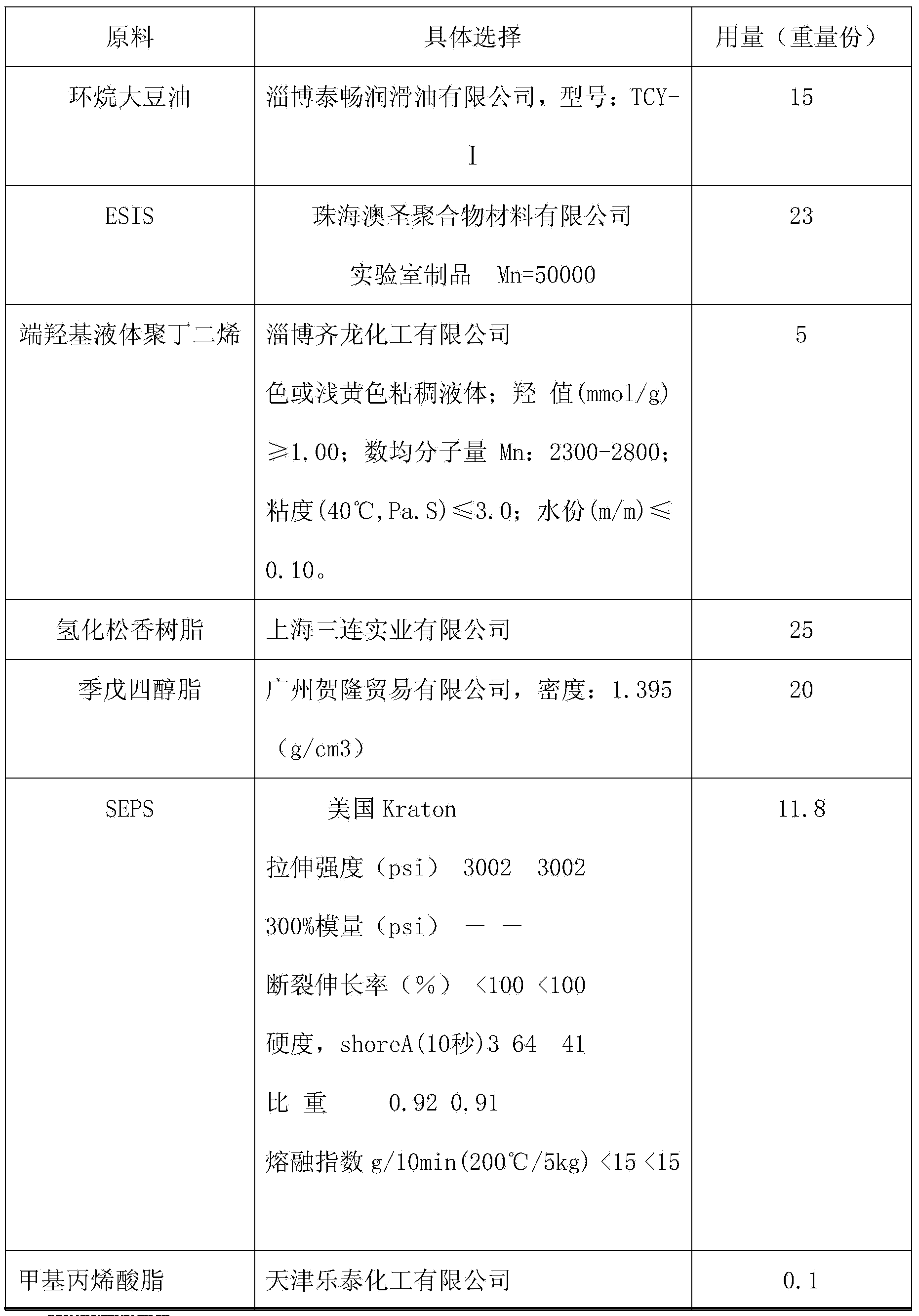

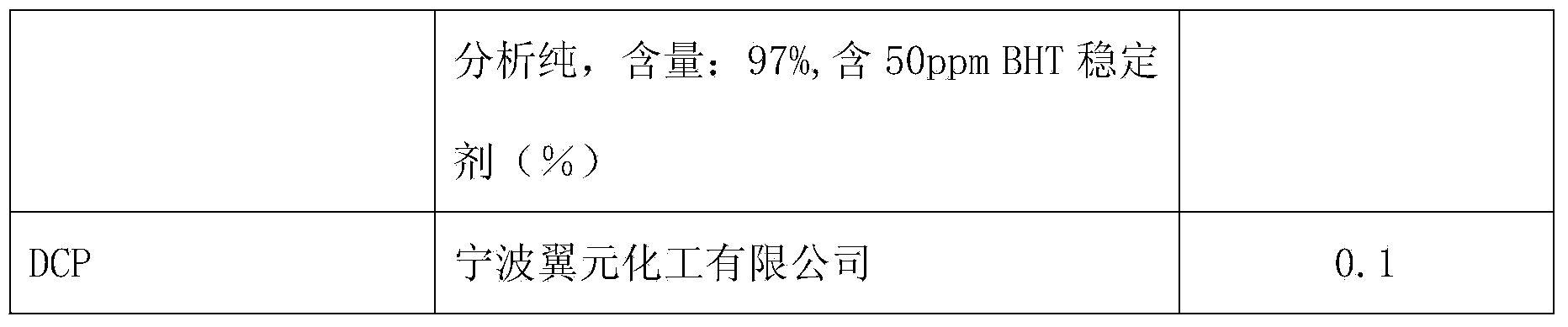

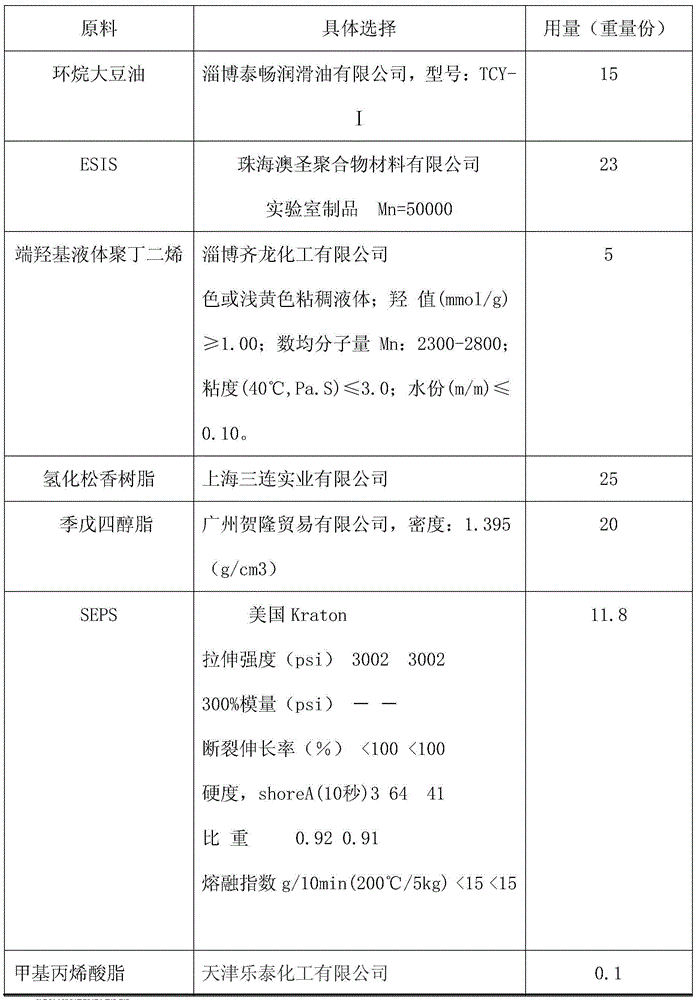

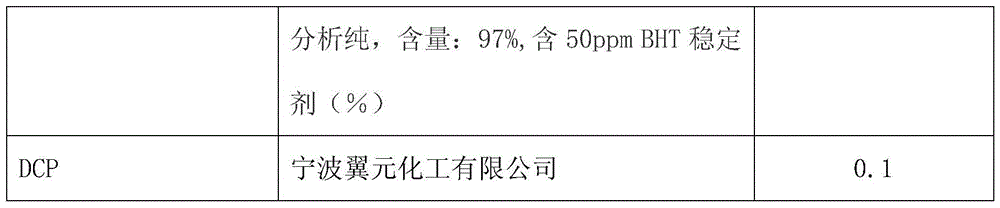

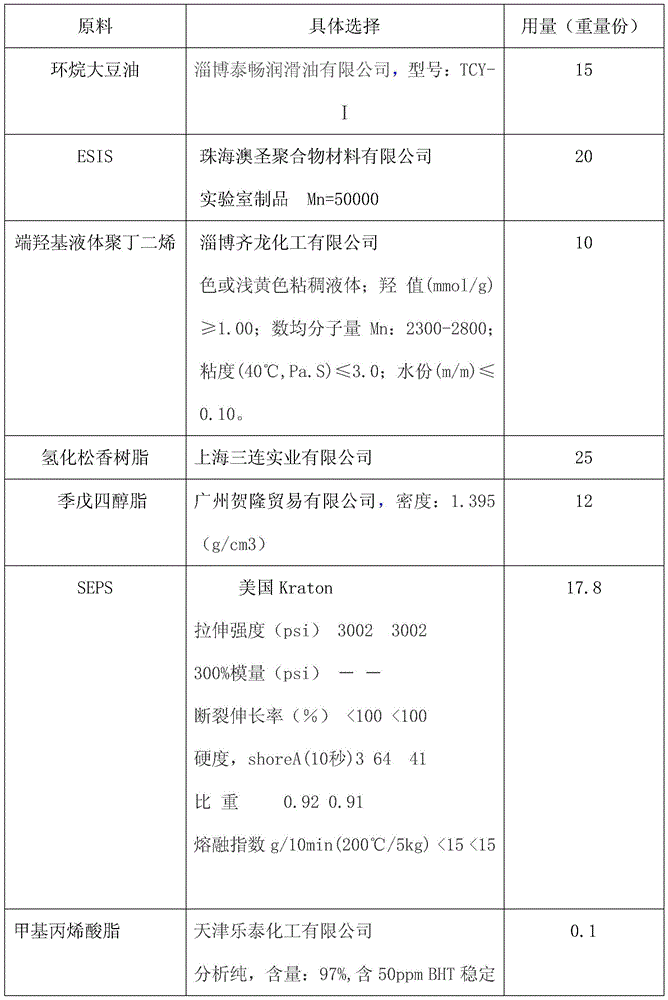

Epoxystyrene-isoprene-styrene segmented copolymer medicine paster and preparation method thereof

ActiveCN104013604AGood for postingIncrease the amount of mixingOrganic non-active ingredientsSheet deliveryPentaerythritolAntioxidant

The invention discloses an epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster and a preparation method thereof, and aims to provide the epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster with good adhesion ability, good air permeability and high stability and the preparation method thereof; the epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster includes 20-35 parts of epoxystyrene-isoprene-styrene segmented copolymer (ESIS), 10-18 parts of hydrogenatedstyrene-isoprene-styrene segmented copolymer(SEPS), 15-25 parts of epoxy soybean oil, 8-15 parts of hydroxy terminated liquid polybutadiene, 15-25 parts of hydrogenated rosin resin, 10-20 parts of rosin pentaerythritol ester and 0.2 part of an antioxidant, and the epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster has the advantages of strong adhesion, good air permeability, good flexibility, more stable performance, and the like.

Owner:浙江固特新材料科技股份有限公司

Adhesive pharmaceutical preparation containing bisoprolol

InactiveUS8298572B2Suppress bleedSufficient pressure-sensitive adhesion characteristicBiocideNervous disorderBisoprololPharmaceutical formulation

In the adhesive pharmaceutical preparation of the invention containing bisoprolol, a pressure-sensitive adhesive layer is laminated on one side of the backing. The pressure-sensitive adhesive layer contains a branched monoalcohol having from 12 to 28 carbon atoms, a free base of bisoprolol and a polyisobutylene pressure-sensitive adhesive. Accordingly, compatibility of the polyisobutylene pressure-sensitive adhesive with the free base of bisoprolol can be specifically increased. As a result, not only it becomes possible to increase blending amount of the free base of bisoprolol but also bleed of the free base of bisoprolol from the pressure-sensitive adhesive layer can be suppressed and, what is more, the pressure-sensitive adhesion characteristics sufficient from the practical point of view can be obtained.

Owner:NITTO DENKO CORP +1

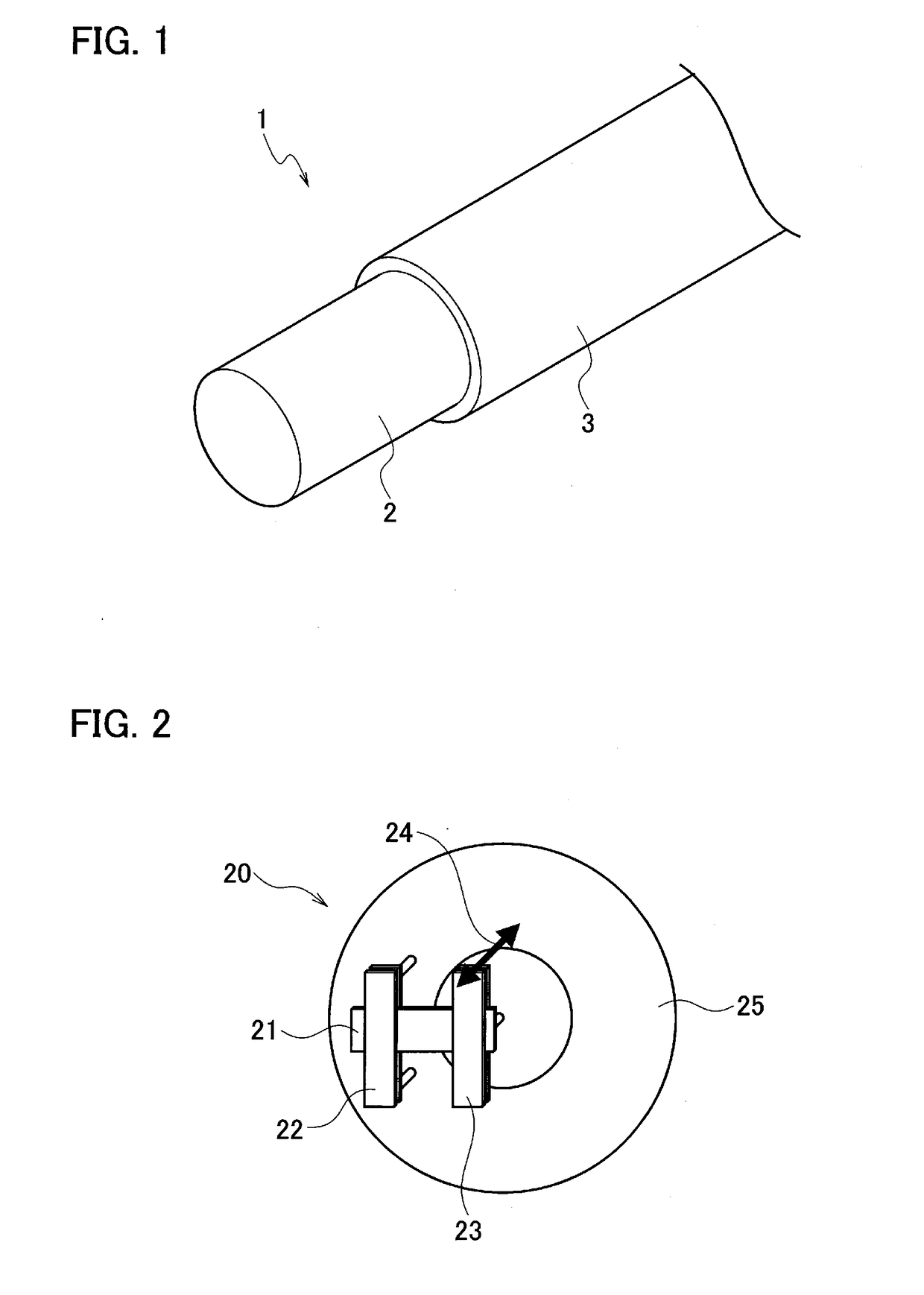

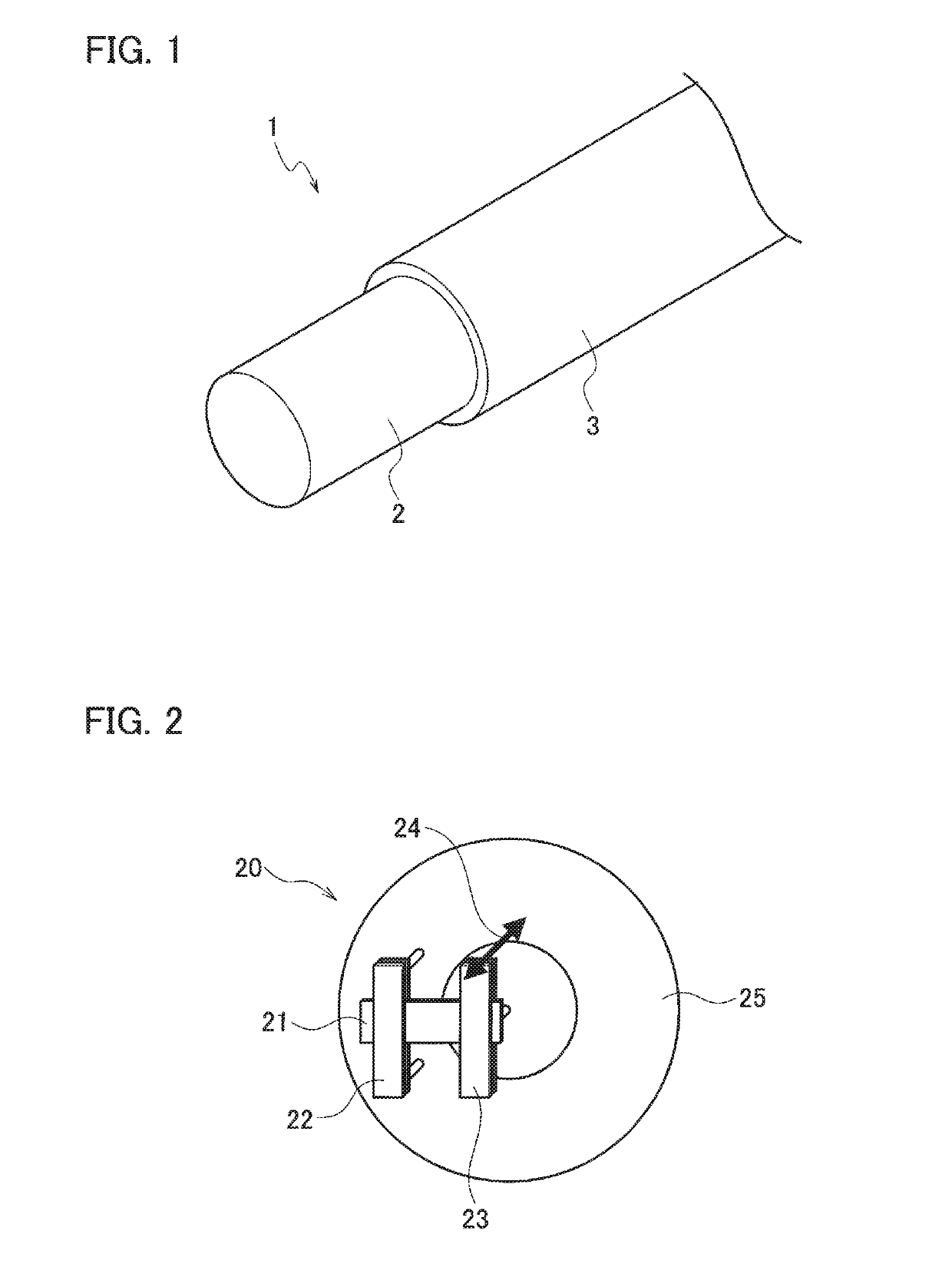

Vehicle electric wire and wire harness using the same

ActiveUS20190057793A1Increase the amount of mixingInhibitory responseVehicle connectorsPlastic/resin/waxes insulatorsMeasurement devicePlasticizer

A vehicle electric wire includes: an electrical insulation coating layer which contains a vinyl chloride resin, a plasticizer and a compound containing a lanthanoid; and an electrical conductor which is coated with the electrical insulation coating layer. In the electrical insulation coating layer, a content of the plasticizer with respect to 100 parts by mass of the vinyl chloride resin is 25 parts by mass or more and less than 50 parts by mass. Furthermore, when dynamic viscoelasticity measurement using a dynamic viscoelasticity measurement device is performed on the electrical insulation coating layer at 0.5 Hz in frequency and under a temperature rise condition of 2° C. / minute in temperature rise speed in a single cantilever measurement mode, a storage modulus at 140° C. is 0.1 MPa or more. A wire harness includes the above vehicle electric wire.

Owner:YAZAKI CORP

Vehicle electric wire and wire harness using the same

InactiveUS10366806B2Increase the amount of mixingInhibitory responseVehicle connectorsPlastic/resin/waxes insulatorsElectrical conductorPlasticizer

Owner:YAZAKI CORP

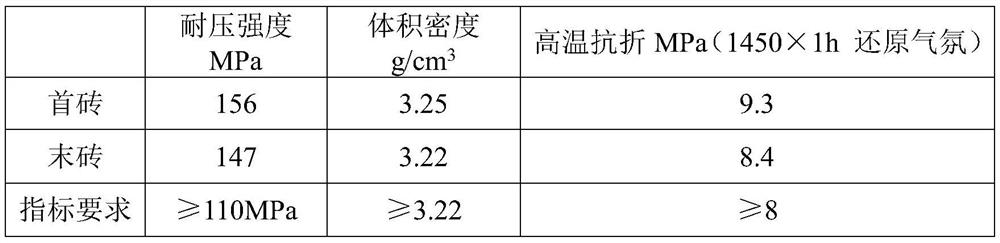

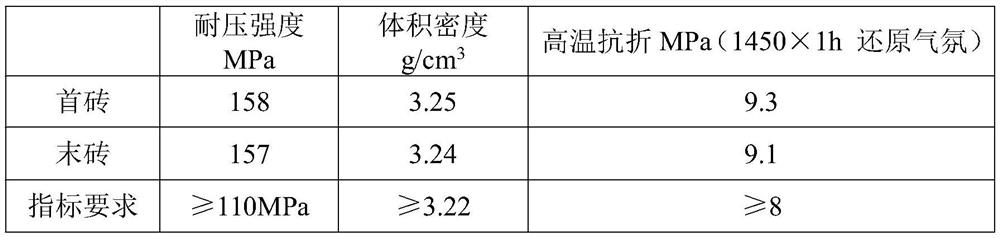

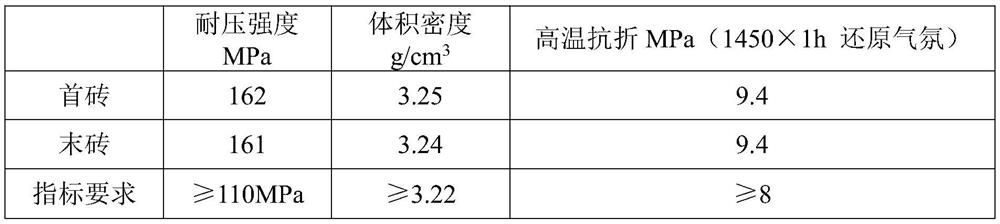

A kind of rh brick with excellent mud retention and preparation method thereof

ActiveCN110510999BGood moisturizing performanceEffective molding time is longMoisture retentionMagnesium

The invention relates to the technical field of refractory materials for RH furnaces, relates to a kind of RH brick with good moisture retention of mud material and its preparation method, in particular to a kind of brick which uses fused magnesia, magnesia spinel, etc. as main raw materials, and has moisture retention function by adding additive, and the prepared mud has excellent moisture-retaining properties of periclase-spinel brick for RH furnaces. The moisturizer is carboxylic acid organic matter and a polysaccharide substance, and the ratio of the two is 0.8:1-1.2 : 1, the carboxylic acid organic matter is selected from sodium citrate or citric acid, and the polysaccharide material can be glucose or sodium gluconate; after adding a humectant, the moisture retention performance of the RH brick mud material is good, and the effective molding time of the mud material increases, Specifically, the RH brick produced by the present invention can obviously slow down the volatilization rate of moisture in the mud material when the outdoor temperature is above 35, the effective molding time is increased to 60min, the mixing amount of the mud material is increased to 600kg-800 / mill, and the brick molding is improved. quality and production efficiency.

Owner:瑞泰马钢新材料科技有限公司

Flexible and stretchable piezoelectric nanogenerator based on interdigitated electrode structure and its preparation method

ActiveCN107623068BIncrease the amount of mixingEvenly distributedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesNanogeneratorThin membrane

The invention discloses a thin-film piezoelectric nanogenerator based on an interdigital electrode structure, which includes a piezoelectric film layer and an interdigital electrode film layer; the interdigital electrode film layer is composed of a single-sided electrode A and a single-sided electrode B. ; The interdigital electrode film layer is semi-embedded in the piezoelectric film layer. Wherein, the piezoelectric film layer is made by filling piezoelectric material into a flexible polymer material; the single-sided electrode A and the single-sided electrode B in the interdigital electrode film layer are made by filling conductive particles into a flexible polymer material. Made from polymer materials. This nanogenerator uses d 33 Coupling mode, on the basis of ensuring good flexibility and stretchability, solves the problem of ordinary piezoelectric nanogenerators in d 31 There is a problem of small output voltage in coupling mode.

Owner:ZHONGBEI UNIV

Medial mixer for heat conducting oil boiler capable of increasing mixing effect

The invention relates to an intermediate mixer used in a heat-conduction oil boiler to improve the mixing effect. The intermediate mixer can completely mix media that flow therein from multi-path convection bank bundles, and can keep good consistency in temperature. The intermediate mixer comprises a gallery and is characterized in that the gallery has a spiral wall.

Owner:顾利平

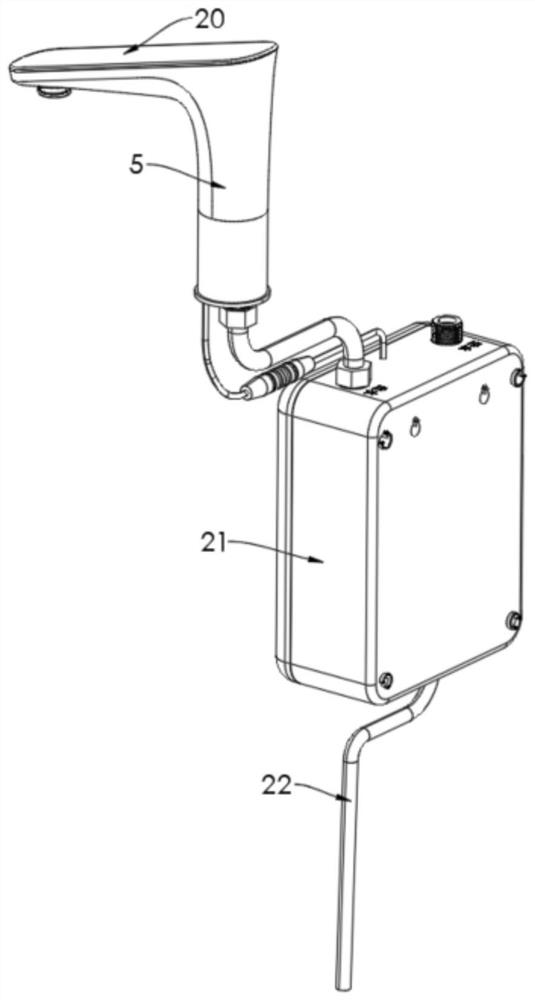

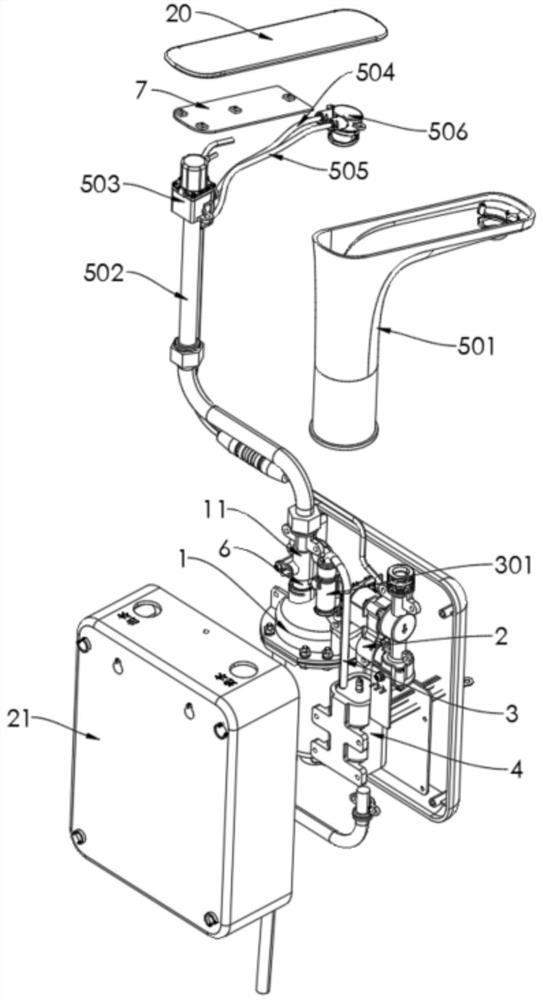

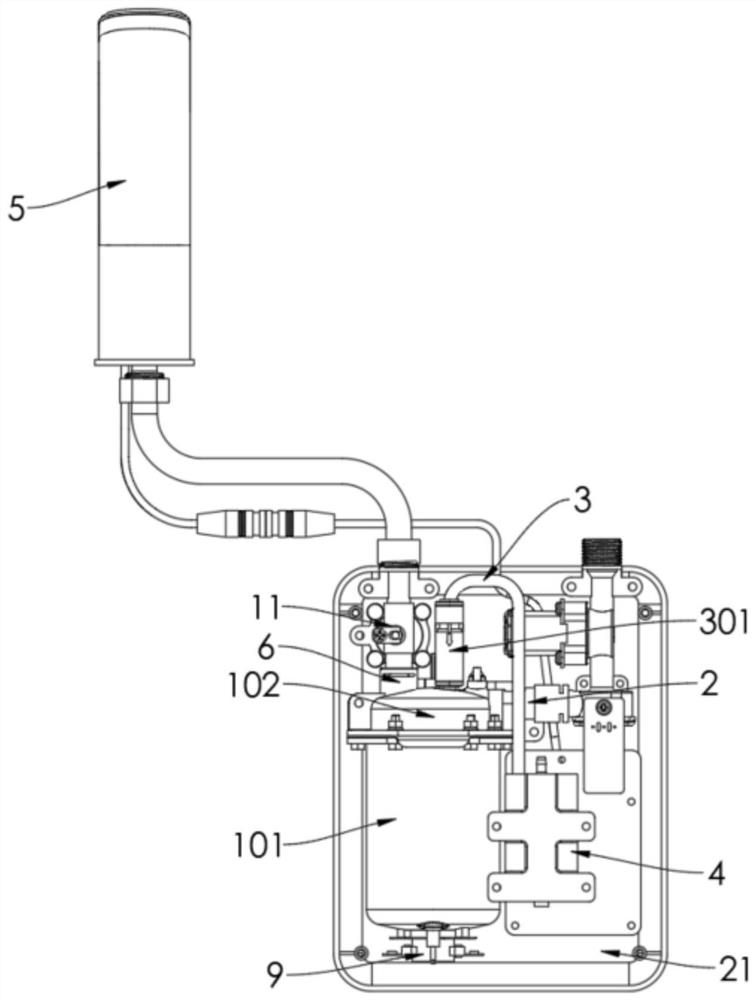

Efficient intelligent beauty faucet

PendingCN114439079ADoes not affect mixinsIncrease the use of functionsDomestic plumbingWater heatersAir pumpEnvironmental engineering

The efficient intelligent beauty faucet comprises a water container, a water inlet pipe is arranged on the water container in a communicating mode, the water outlet end of the water inlet pipe extends to the lower side of the water container, the water inlet pipe is outwards communicated and connected with a corresponding air inlet pipe, and the air inlet pipe is connected to a corresponding air pump; the water container is communicated with a water outlet pipe, and the water inlet end of the water outlet faucet is connected to the water outlet pipe; and the electric controller is used for controlling the working process of the air pump. Under the condition that normal water outlet is not affected, the water inlet pipe is effectively connected with the corresponding air inlet pipe in an outward communicating mode, the air inlet pipe is connected to the corresponding air pump, the working process of the air pump is controlled through the electric controller, a large amount of air can be effectively and selectively mixed in the water outlet process of the faucet according to needs, and the water outlet efficiency is improved. The nanometer effluent is effectively formed.

Owner:XIAMEN AMASU ELECTRONICS SANITARY WARE

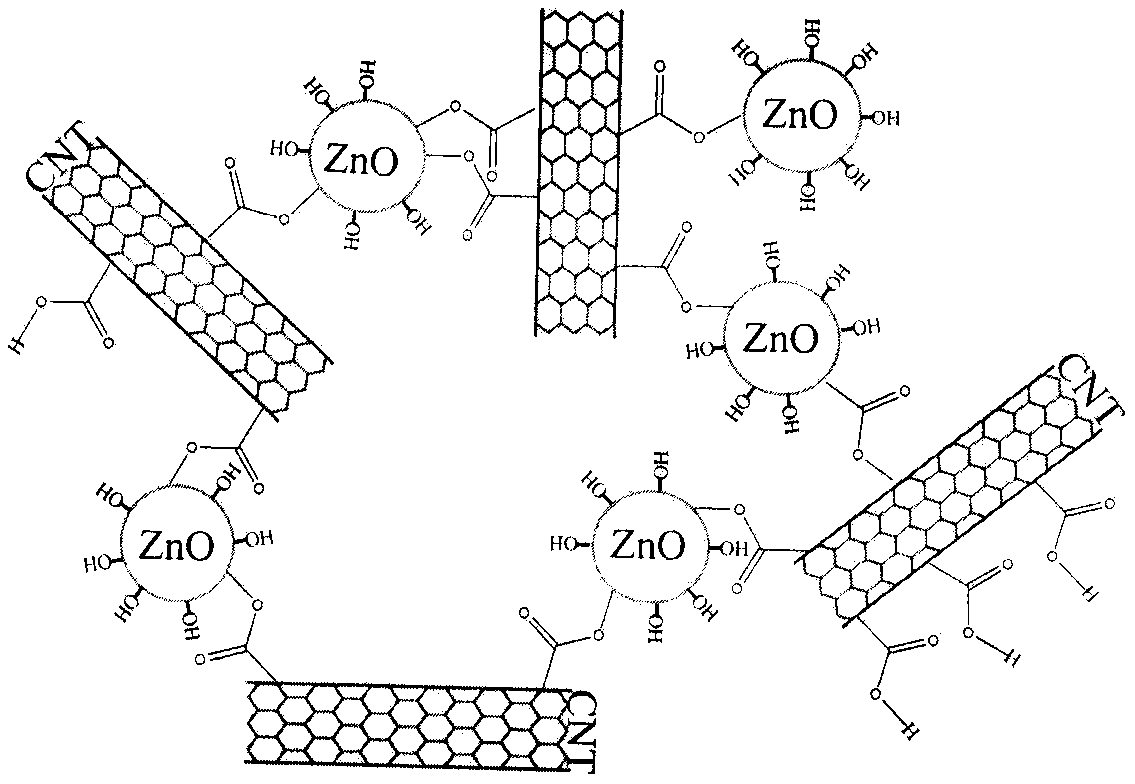

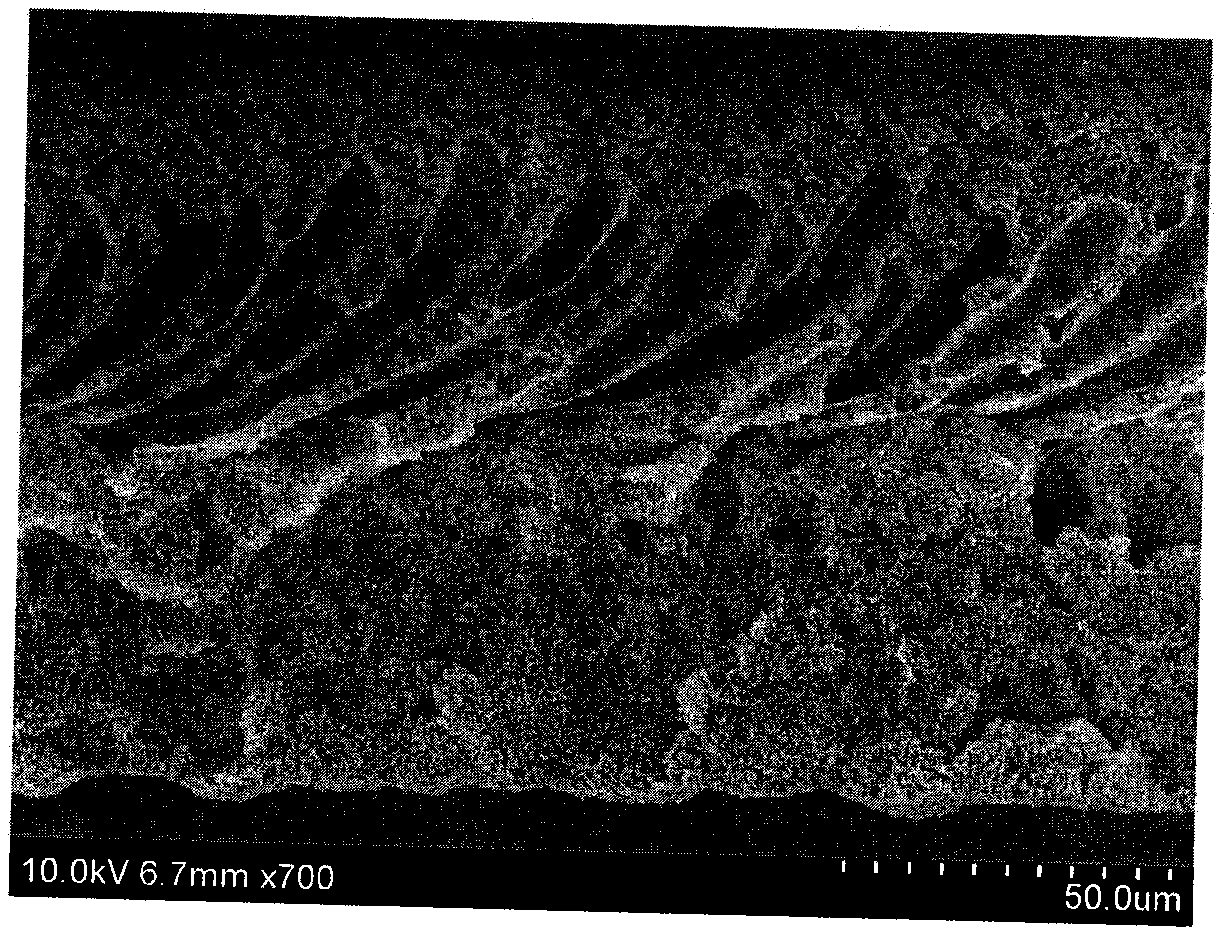

Anti-pollution photocatalytic degradation blended membrane

InactiveCN110787643AImprove self-cleaning abilityIncrease the amount of mixingSemi-permeable membranesMembranesCarboxyl radicalCarbon nanotube

The invention discloses an anti-pollution photocatalytic degradation blended membrane. The preparation steps include: dissolving polyvinylidene fluoride (PVDF) in a diluent at a high temperature to form a PVDF transparent solution; respectively adding zinc oxide (ZnO) and carboxylated carbon nanotubes (MWCNTS) into a diluent, and carrying out ultrasonic treatment to obtain an MWCNTS mixed solution(A) and a ZnO mixed solution (B); sequentially adding A and B into the PVDF membrane casting solution, stirring the substances uniformly, and carrying out in-situ reaction on the MWCNTS and ZnO to generate an MWCNTS-ZnO compound; and preparing an MWCNTS-ZnO / PVDF blended membrane by thermally induced phase inversion method. The MWCNTS-ZnO / PVDF blended membrane is stable in structure and high in strength, has the advantages of photodegradation, self-cleaning and pollution resistance, and is suitable for large-scale treatment of dye wastewater.

Owner:TIANJIN POLYTECHNIC UNIV

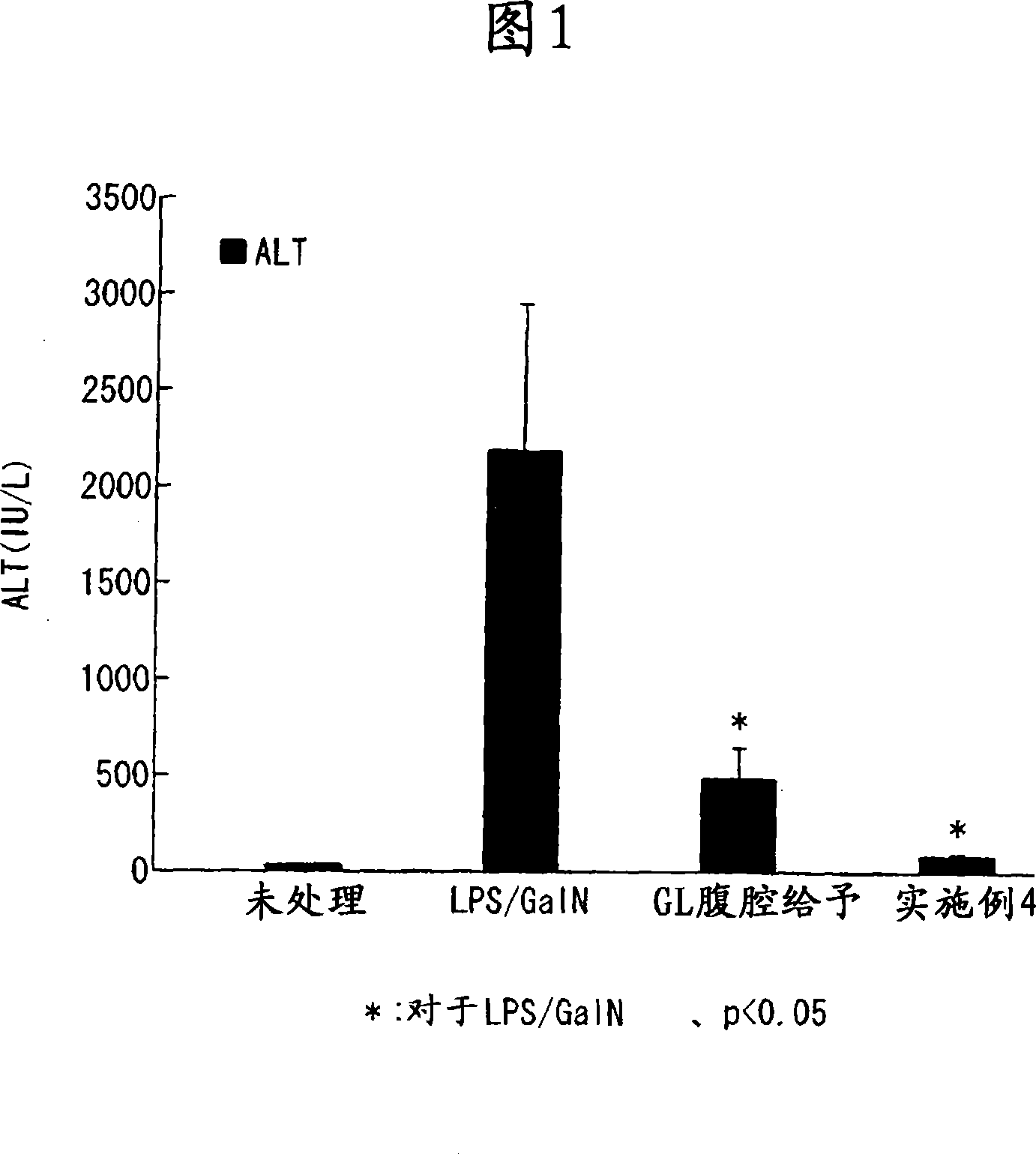

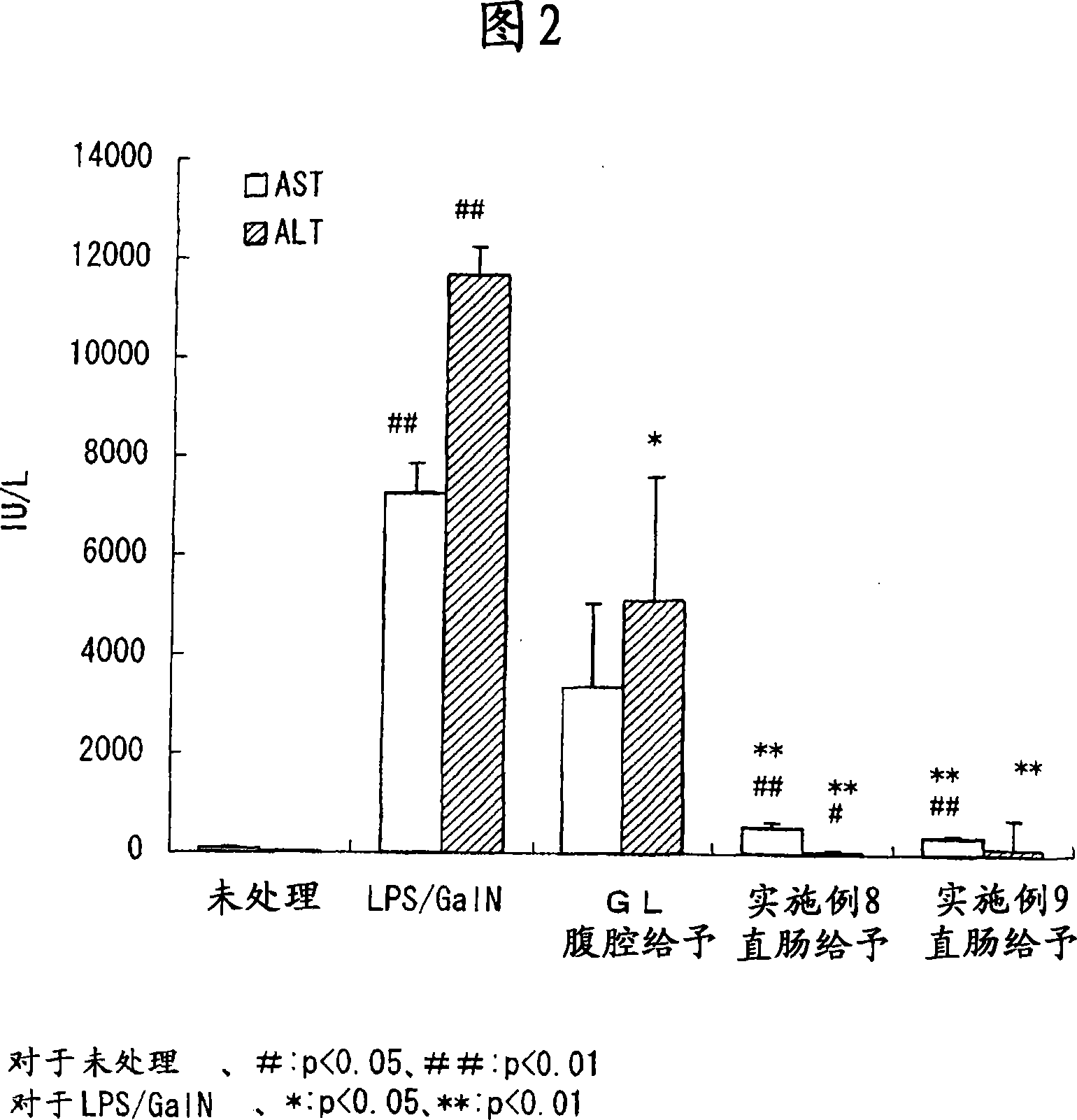

Glycyrrhizin-containing suppository compositions for rectal infusion

InactiveCN1980679AExcellent GL absorbencyReduce GL mix volumeOrganic active ingredientsDigestive systemGynecologySuppository

A glycyrrhizin-containing suppository composition for rectal infusion which comprises at least one member selected from among glycyrrhizin and pharmaceutically acceptable salts thereof, a nonionic surfactant, an oily base, and water and which exhibits a solid-liquid phase transition point of 10 to 4500Pa at 37 DEG C; and a glycyrrhizin-containing suppository composition for rectal infusion which comprises at least one member selected from among glycyrrhizin and pharmaceutically acceptable salts thereof, an oily base, water, and an alkali.

Owner:MINOPHAGEN PHARMA

Odorizing device for city gas

The invention provides an odorizing device for city gas. The odorizing device comprises a support. An alarm and a controller are fixed to a cross rod in the middle of the support, and the controller is located on the right side of the alarm. An odorizing agent barrel is a cylindrical bucket, an end cover sealed through threads is arranged at the top of the odorizing barrel, and an odorizing agentcan be added into the odorizing agent barrel after the end cover is opened. A through hole is formed in the right side of the end cover, and the hole is a threaded hole. A one-way valve is in sealed connection with the through hole of the end cover at the top of the odorizing agent barrel through a thread. An odorizing agent pipe is made from a transparent material, and connected to the right sideof the odorizing agent barrel through an upper pipe and a lower pipe, and the odorizing agent pipe communicates with the odorizing agent barrel. Pressure in the odorizing agent pipe is kept consistent with pressure in the odorizing agent barrel, and an odorizing agent at the same liquid level can be obtained. By arranging the one-way valve, when negative pressure in the odorizing agent barrel reaches the pressure value of the one-way valve, external air can enter the odorizing agent barrel to maintain the internal pressure, so that the pressure value in the odorizing agent barrel is larger than the air pressure value in an air conveying pipe all the time, and it is guaranteed that the pressure difference exists, and so that the oxidizing agent enters the air conveying pipe.

Owner:魏灿

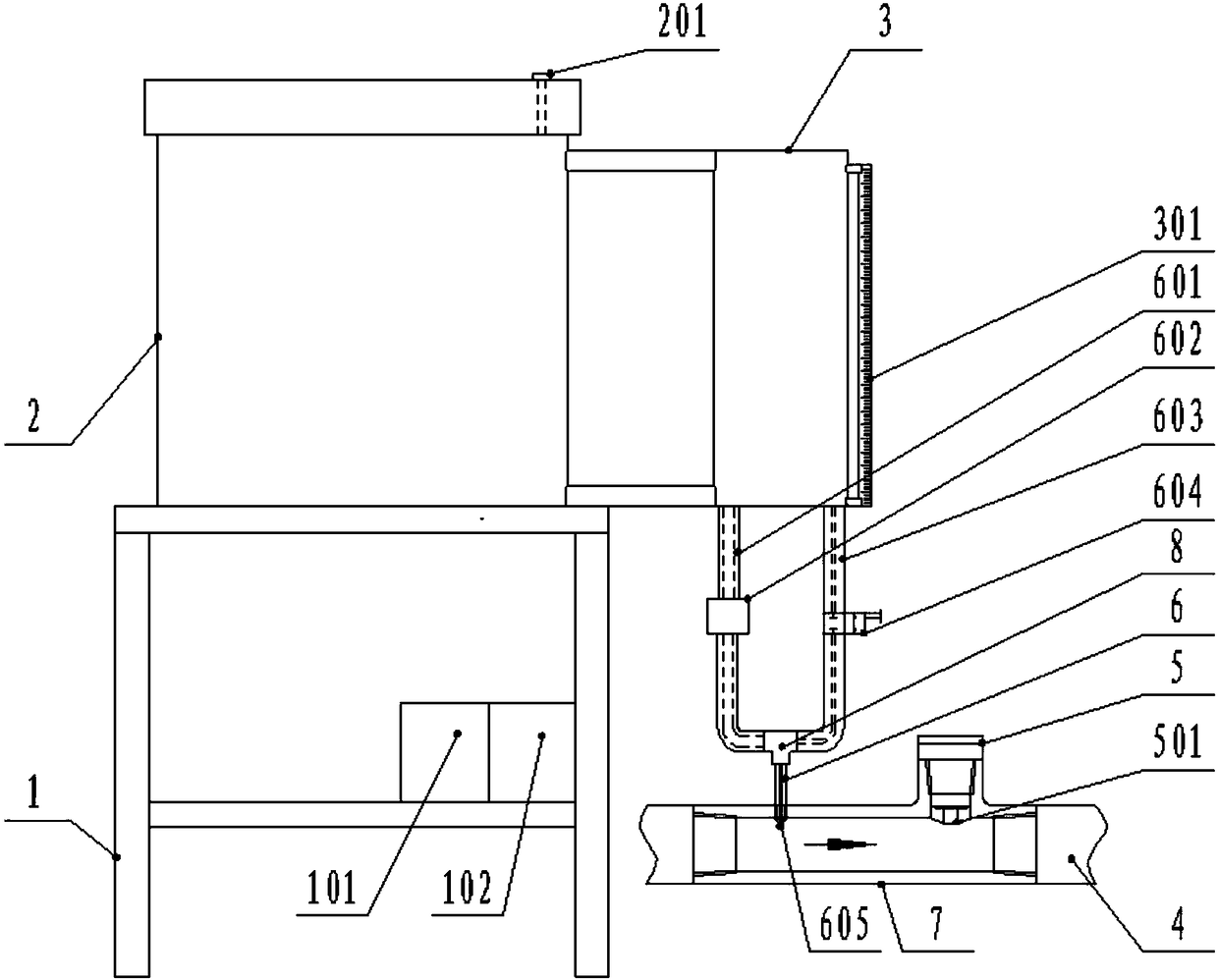

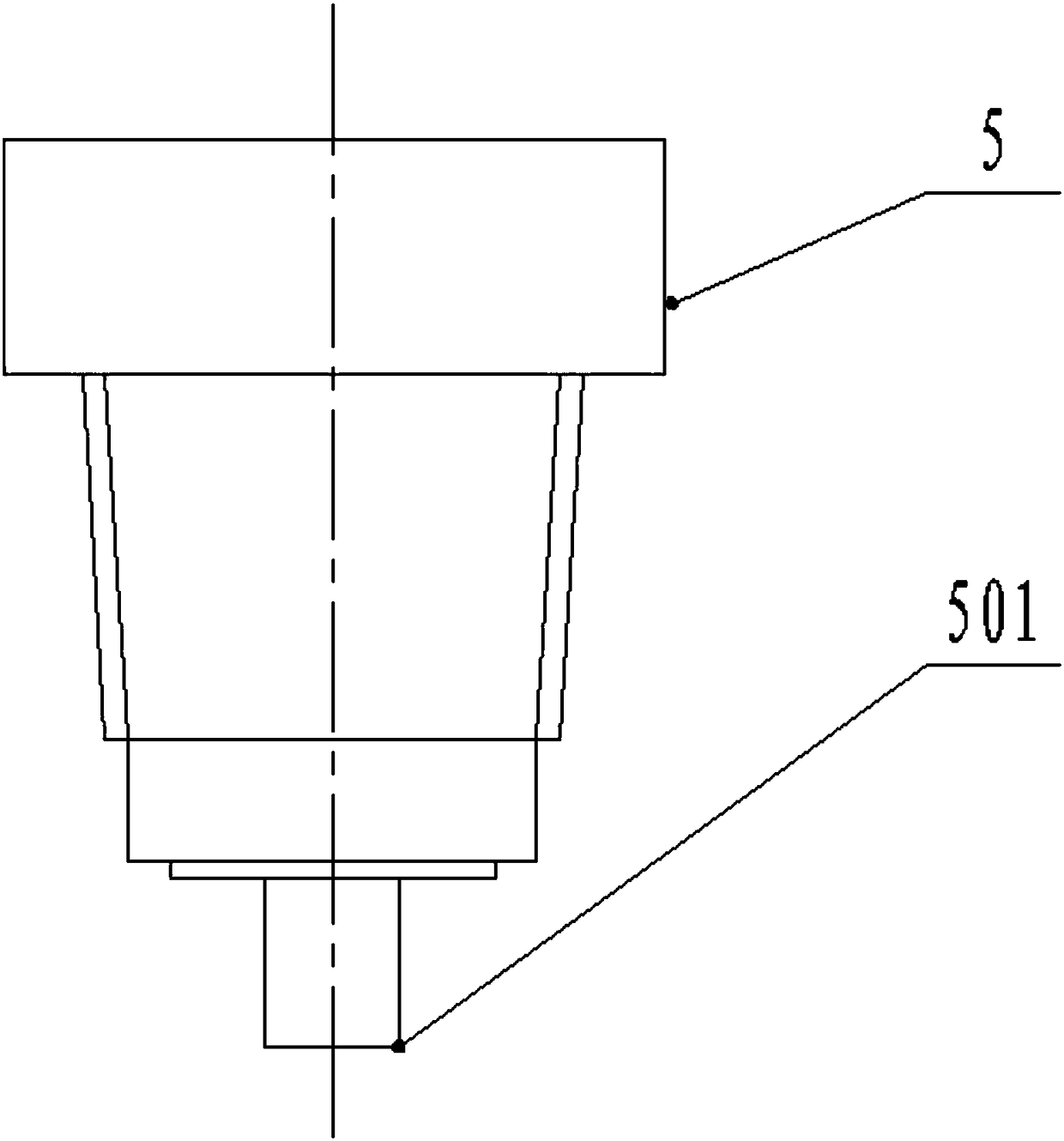

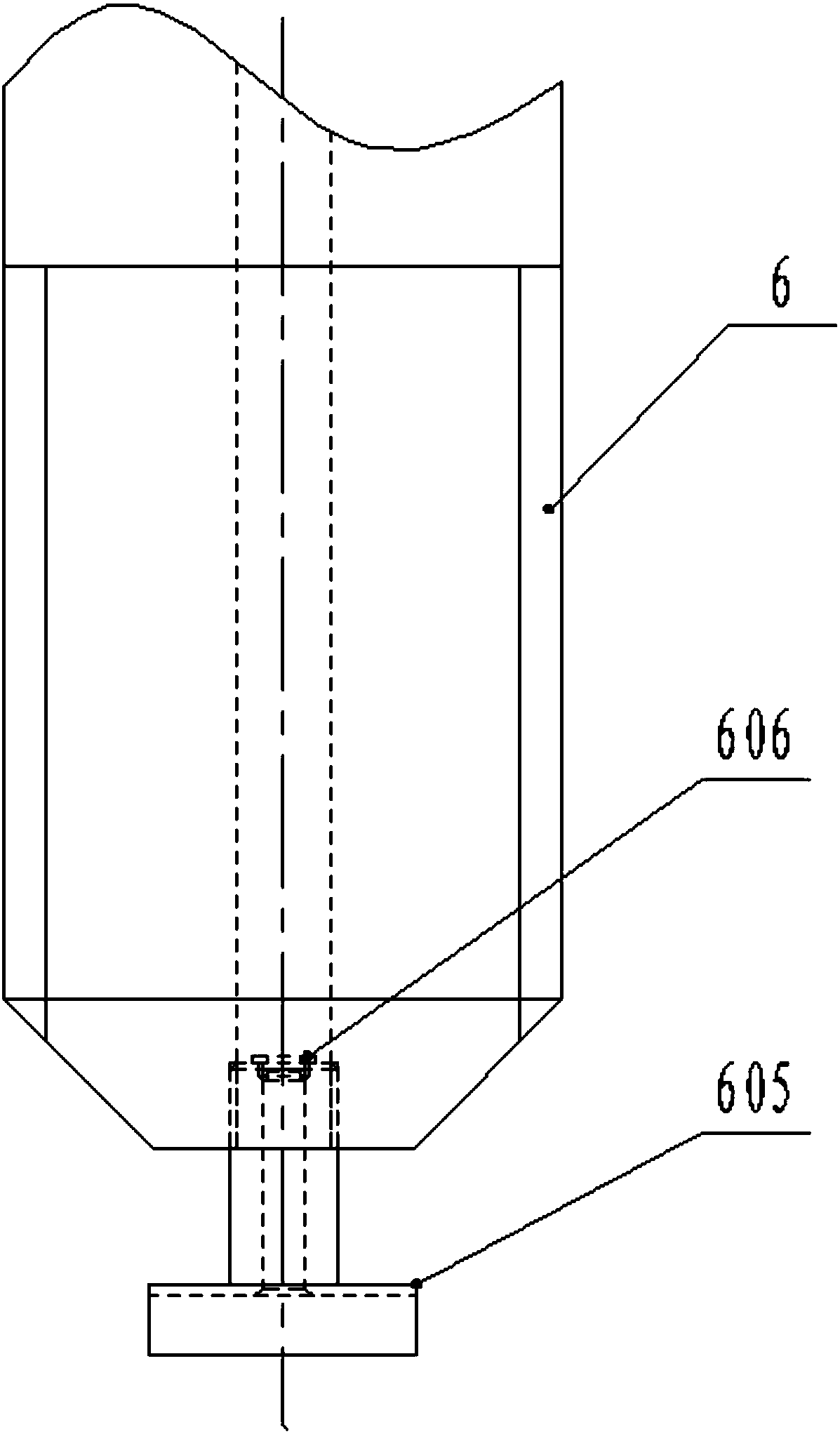

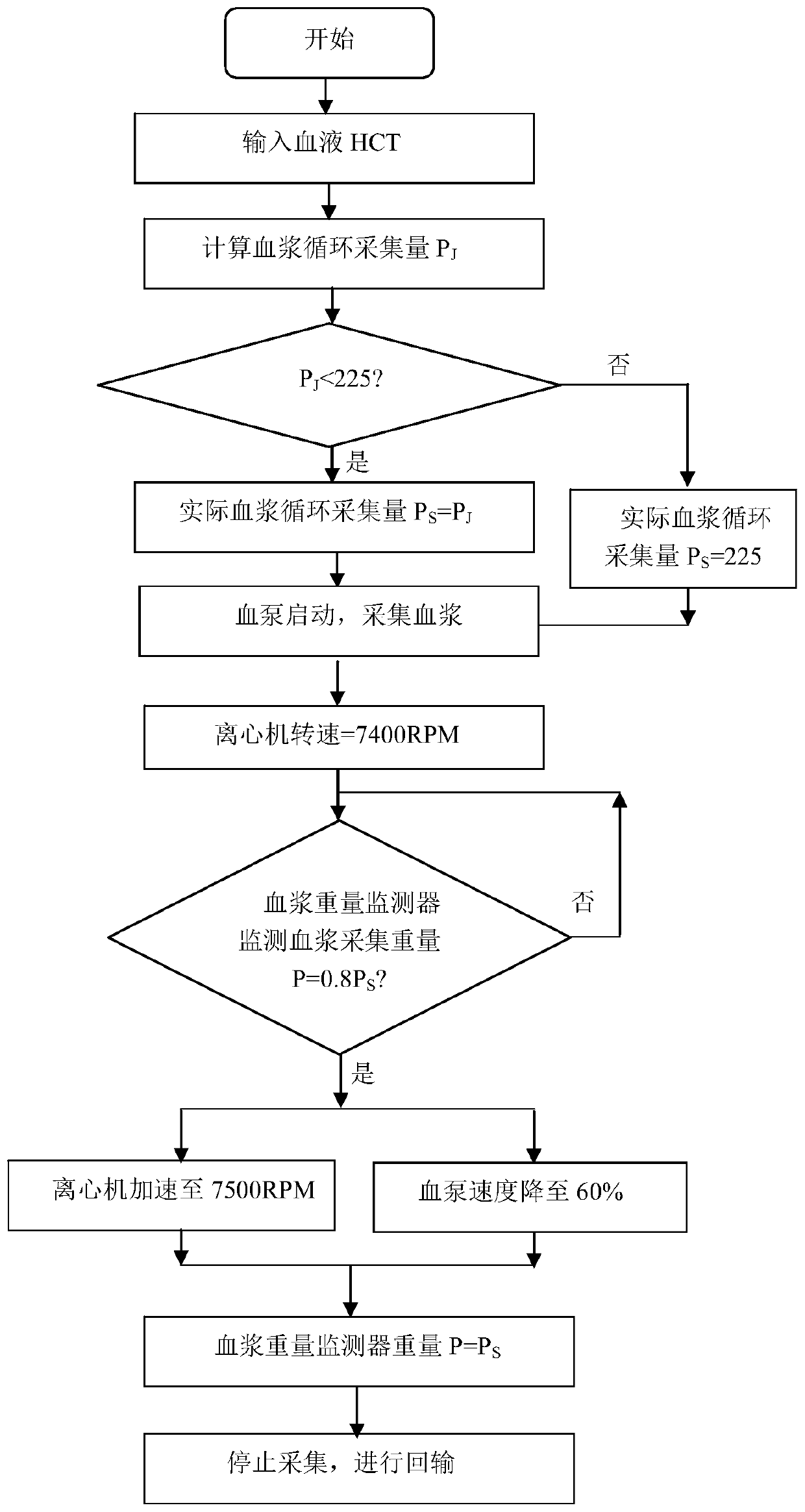

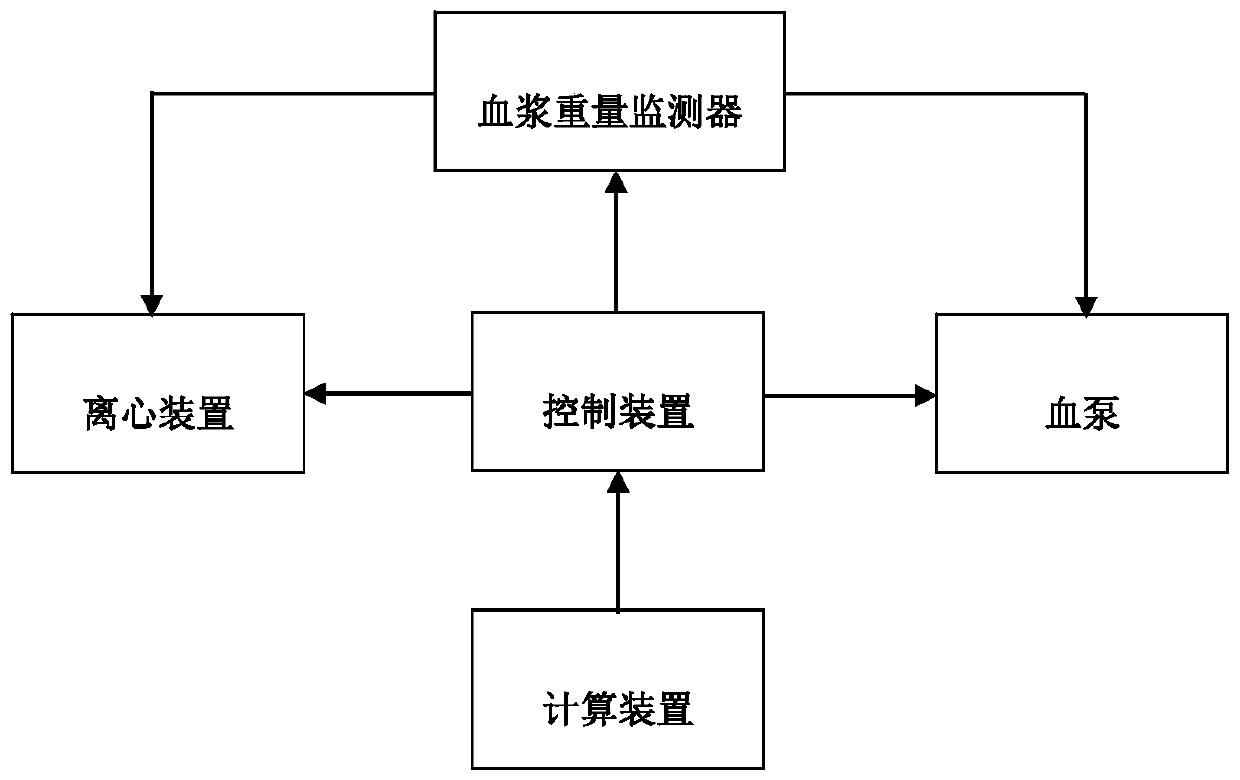

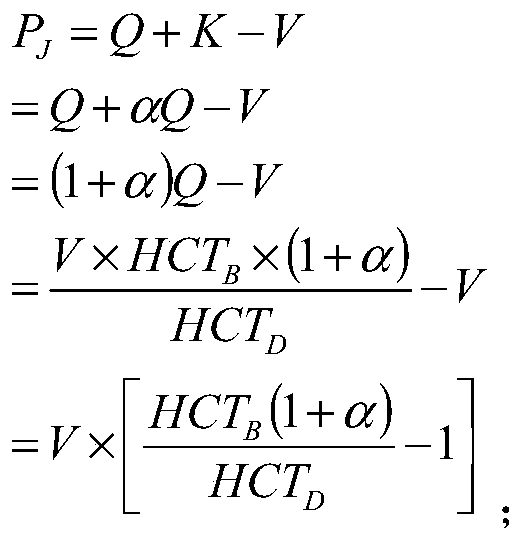

Method and plasma collection system capable of reducing mixing amount of leukocytes in collected plasma

ActiveCN111529791AReduce the amount of mixingDesign scienceOther blood circulation devicesCentrifugesWhite blood cellRed blood cell

The invention discloses a method and plasma collection system capable of reducing the mixing amount of leukocytes in collected plasma. The problem of excessive mixing of leukocytes in the plasma in the prior art is solved. The method includes the steps that first a hematocrit HCT value of a donor is obtained and an optimal plasma collection volume per cycle Ps of the donor is calculated accordingto the HCT value, then the whole blood of the donor is introduced into a centrifugal device for separation to obtain plasma, a plasma volume P collected in a plasma collection bag is monitored in realtime during the process, when the P is 0.7-0.9 Ps, the rotation speed of the centrifugal device is increased and the blood introduction speed of the whole blood is reduced until the plasma collectionis completed when P=PS. The method and plasma collection system are scientific in design, simple in method and simple to operation, the mixing amount of leukocytes in plasma can be effectively reduced, and the requirements of clinical plasma are met.

Owner:四川天府亨特生命科技有限公司

Epoxidized styrene-isoprene-styrene block copolymer medical patch and preparation method thereof

ActiveCN104013604BGood for postingIncrease the amount of mixingOrganic non-active ingredientsSheet deliveryPentaerythritolAntioxidant

The invention discloses an epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster and a preparation method thereof, and aims to provide the epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster with good adhesion ability, good air permeability and high stability and the preparation method thereof; the epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster includes 20-35 parts of epoxystyrene-isoprene-styrene segmented copolymer (ESIS), 10-18 parts of hydrogenatedstyrene-isoprene-styrene segmented copolymer(SEPS), 15-25 parts of epoxy soybean oil, 8-15 parts of hydroxy terminated liquid polybutadiene, 15-25 parts of hydrogenated rosin resin, 10-20 parts of rosin pentaerythritol ester and 0.2 part of an antioxidant, and the epoxystyrene-isoprene-styrene segmented copolymer (SIS) medicine paster has the advantages of strong adhesion, good air permeability, good flexibility, more stable performance, and the like.

Owner:浙江固特新材料科技股份有限公司

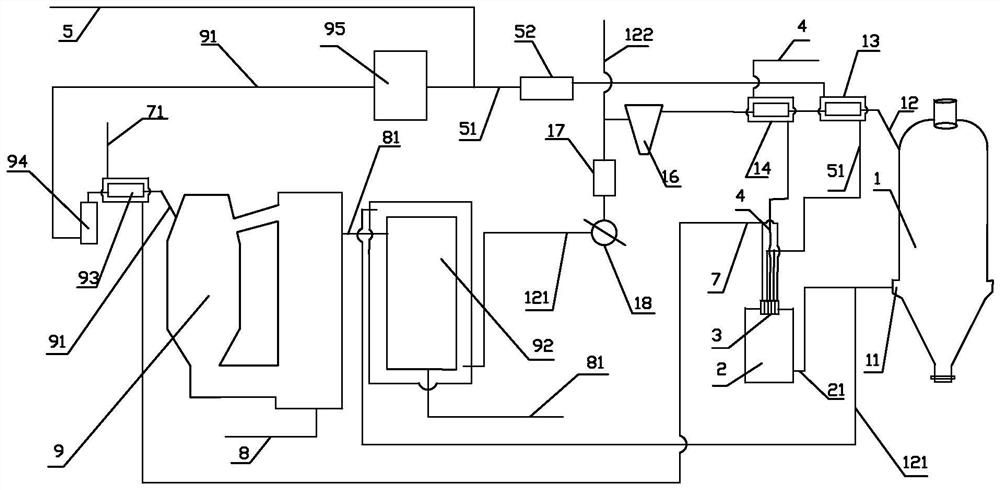

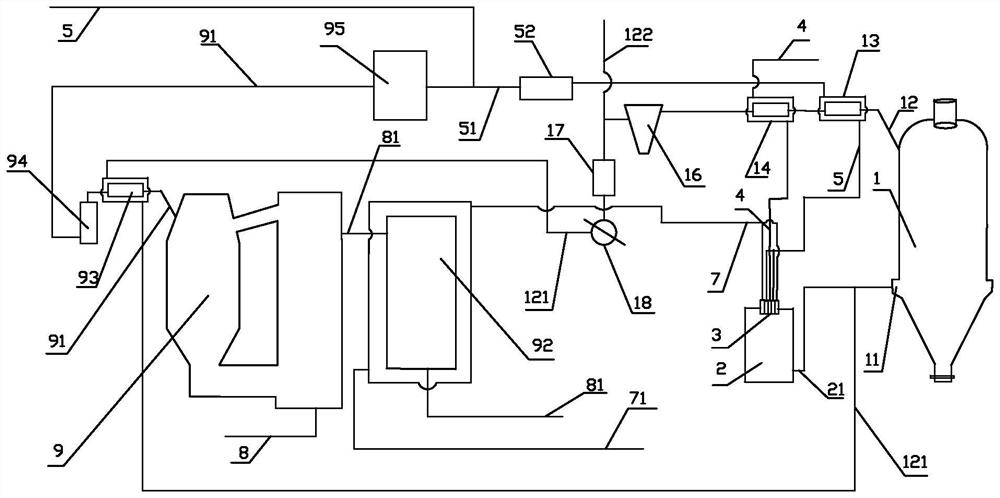

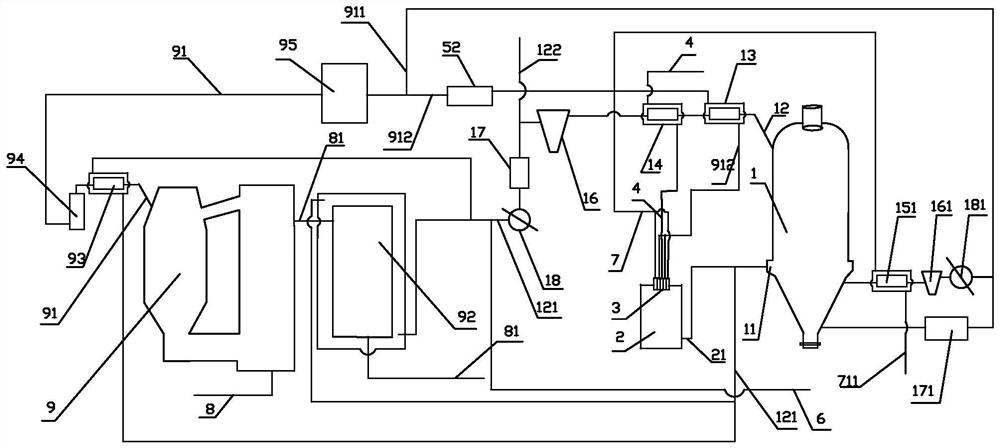

Device and method for preparing gas-based shaft furnace reducing gas by purifying biomass gas

ActiveCN114657304ASolve the problem of external combustion heating and exhaust gasAvoid wastingHydrogen separation using liquid contactHydrogen productionExhaust fumesProcess engineering

The invention discloses a device and a method for preparing gas-based shaft furnace reducing gas by purifying biomass gas, and relates to a device for preparing the gas-based shaft furnace reducing gas. The invention aims to solve the problems of heat waste and air pollution caused by high preparation cost and generation of discharged CO2 and other waste gases in the existing system for preparing the reducing gas by the tubular heating furnace. Raw material gas containing biomass gas is introduced into a gas heating furnace through a pipeline to be heated; gas in the gas heating furnace is reformed into first reducing gas, the first reducing gas enters the gas-based shaft furnace, iron oxide reacts with the reducing gas in the gas-based shaft furnace and is directly reduced into reduced iron, the directly reduced iron is discharged out of the furnace through the lower part of the gas-based shaft furnace, raw gas generated by the reaction is discharged from the top of the shaft furnace, and second reducing gas is added into the first reducing gas; and after the temperature is adjusted, the gas enters the gas-based shaft furnace. The problems of external combustion heating and smoke emission of the tubular heating furnace are solved, intermediate medium heat exchange is not needed, and the heat exchange efficiency is high. The method is used for preparing the reduced iron.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com