Medial mixer used for heat conducting oil boiler

A heat-conducting oil boiler and mixer technology, applied in the field of boilers, can solve the problems of inconsistent liquid medium temperature, limited length of collecting pipe, deviation of multi-channel small flow medium temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

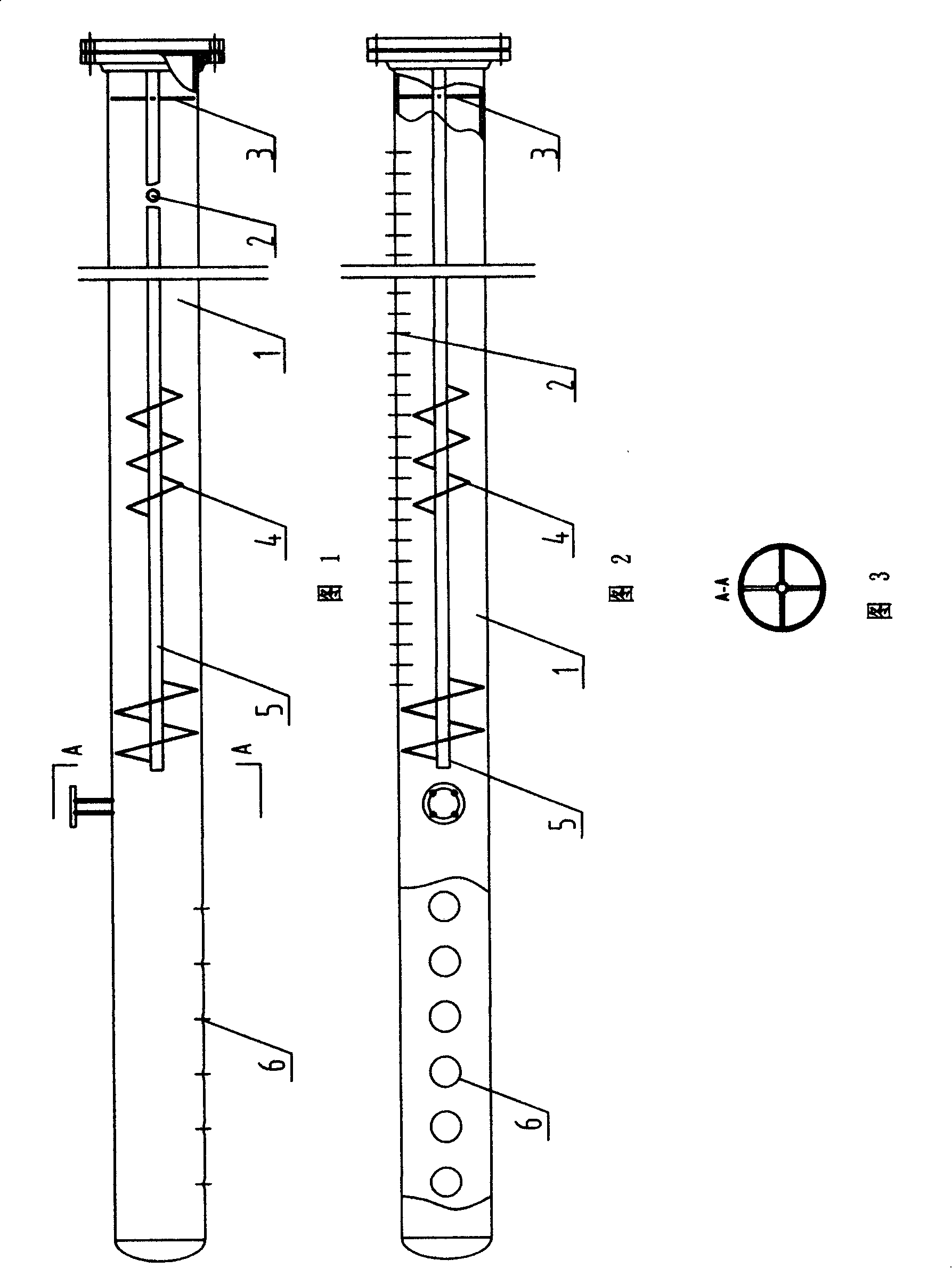

[0009] See Fig. 1, Fig. 2, the present invention comprises collection pipe 1, and the helical guide piece 4 is arranged in the collection pipe 1, and the helical guide piece 4 is sleeved on the support rod 5, and the two ends of the support rod 5 are installed on the cross support frame 3 (see figure 1, Fig. 3), the outer edge of support frame 3 is connected with the pipe wall of collecting pipe 1, and 2,6 are respectively the water inlet and the water outlet of collecting pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com