Patents

Literature

47results about How to "Drying property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink composition for ink jet

InactiveUS20120225968A1Improve curing effectDrying propertyDuplicating/marking methodsInksCross-linkOrganic solvent

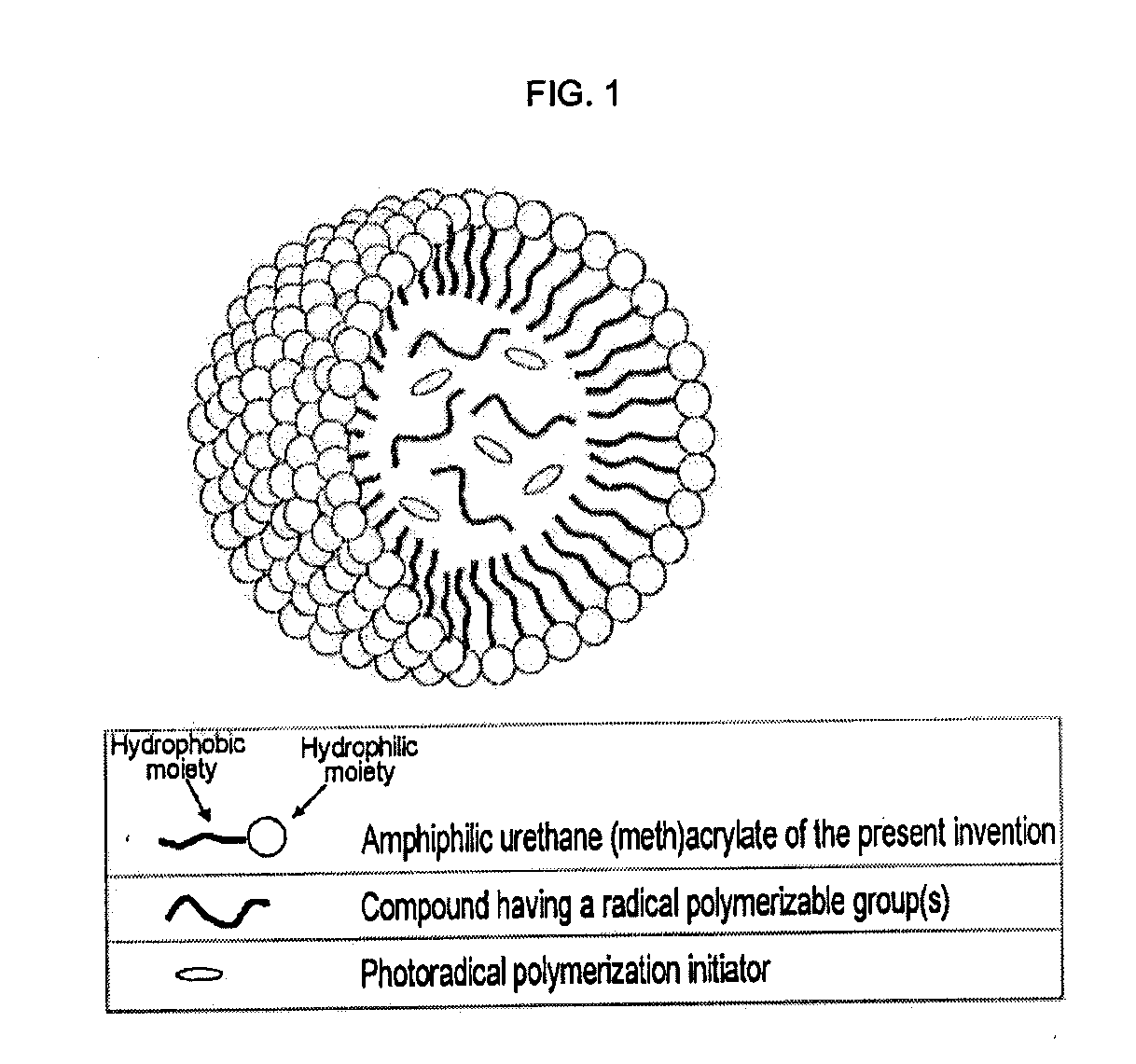

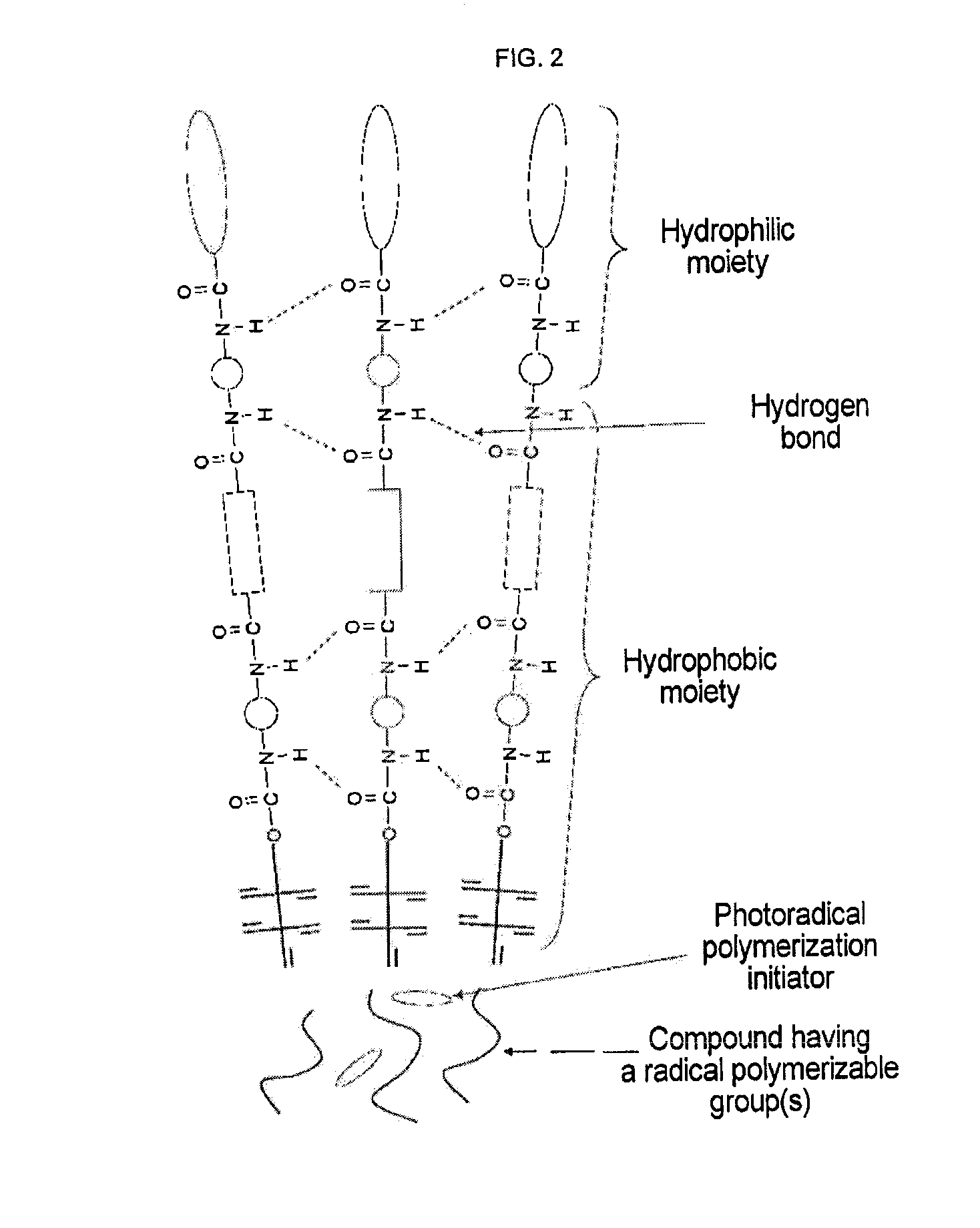

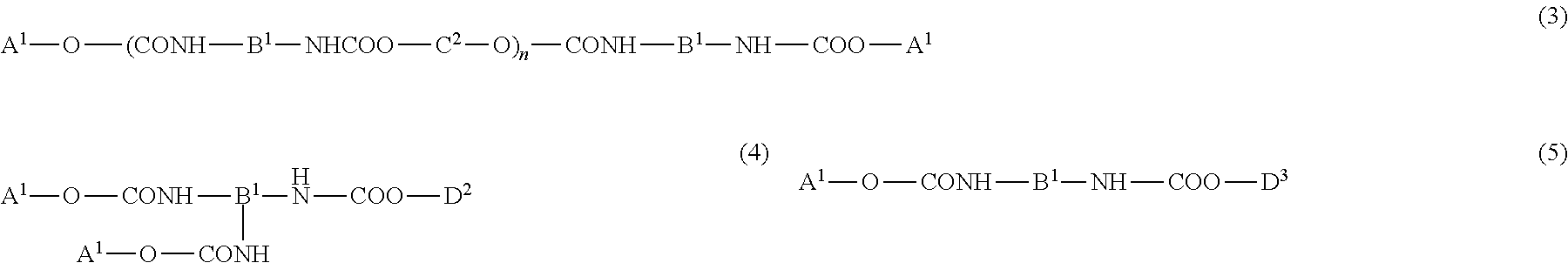

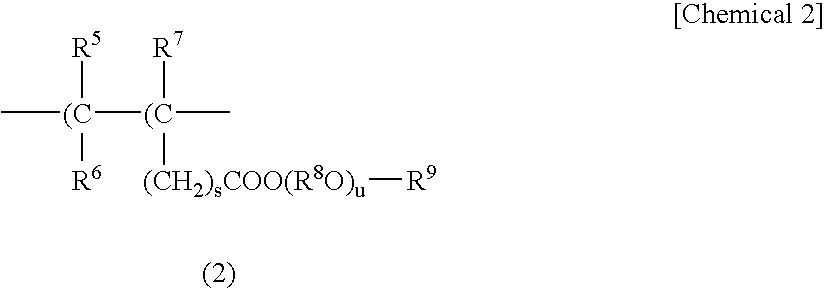

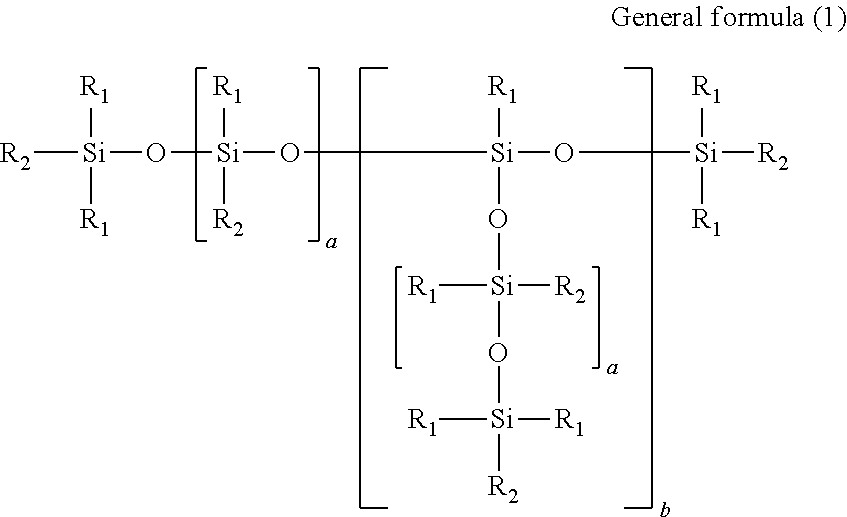

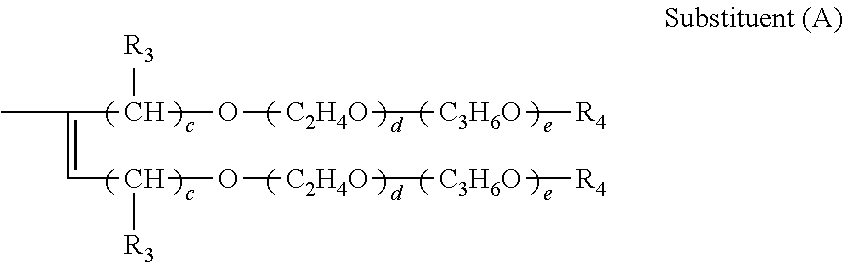

An ink composition for ink jet providing excellent in the curability based on ultraviolet irradiation in the presence of water or a solvent, the ejection stability with respect to the factors such as dot loss or flight deflection, and the storage stability of ink. Also provided herein is an ink composition for ink jet including: a pigment; a water-soluble organic solvent; a surfactant; at least either of a urethane (meth)acrylate being represented by the following general formula (1) and having a weight average molecular weight of 1,000 to 10,000 and a cross-linked urethane (meth)acrylate having a constitutional unit including the urethane (meth)acrylate; a compound having a radical polymerizable group(s); a photoradical polymerization initiator; and water:A1-O—(CONH—B1—NHCOO—C1—O)n—CONH—B1—NH—COO-D1 (1)where each of A1, B1, C1, D1, and n in formula (1) are described herein.

Owner:SEIKO EPSON CORP

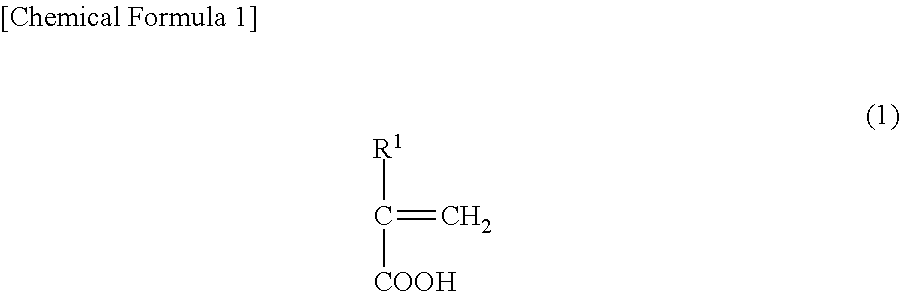

Drying shrinkage-reducing agent

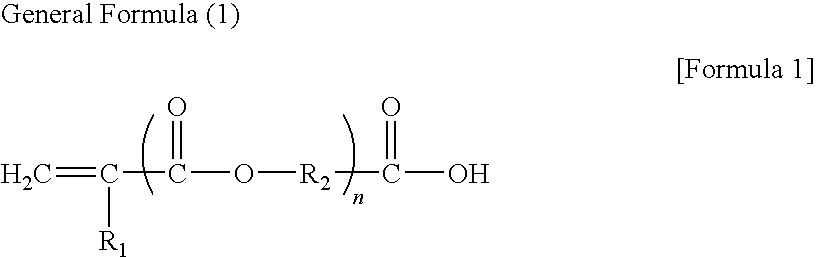

A drying shrinkage-reducing agent which comprises a polymer containing as an essential component at least one structural unit (I) represented by the following formula (1): wherein R1, R2, and R3 independently stand for a hydrogen atom, a methyl group, or a —(CH2)pCOOX group, wherein X stands for a hydrogen atom, a monovalent metal, a divalent metal, an ammonium group, an organic amine group, or a hydrocarbon group, and p is an integer of 0-2; and R4 stands for a hydrocarbon group of 4-30 carbon atoms, and exhibiting surface tension in the range of 25-50 mN / m in a solution containing 0.2 mass % of the polymer in a cement supernatant is provided. The drying shrinkage-reducing agent manifests no dispersibility in an amount capable of attaining necessary drying shrinking-reducing properties and, when used in combination with a dispersing agent, acquires ability to adjust the dispersibility and the drying shrinkage-reducing properties fit for the purpose.

Owner:NIPPON SHOKUBAI CO LTD

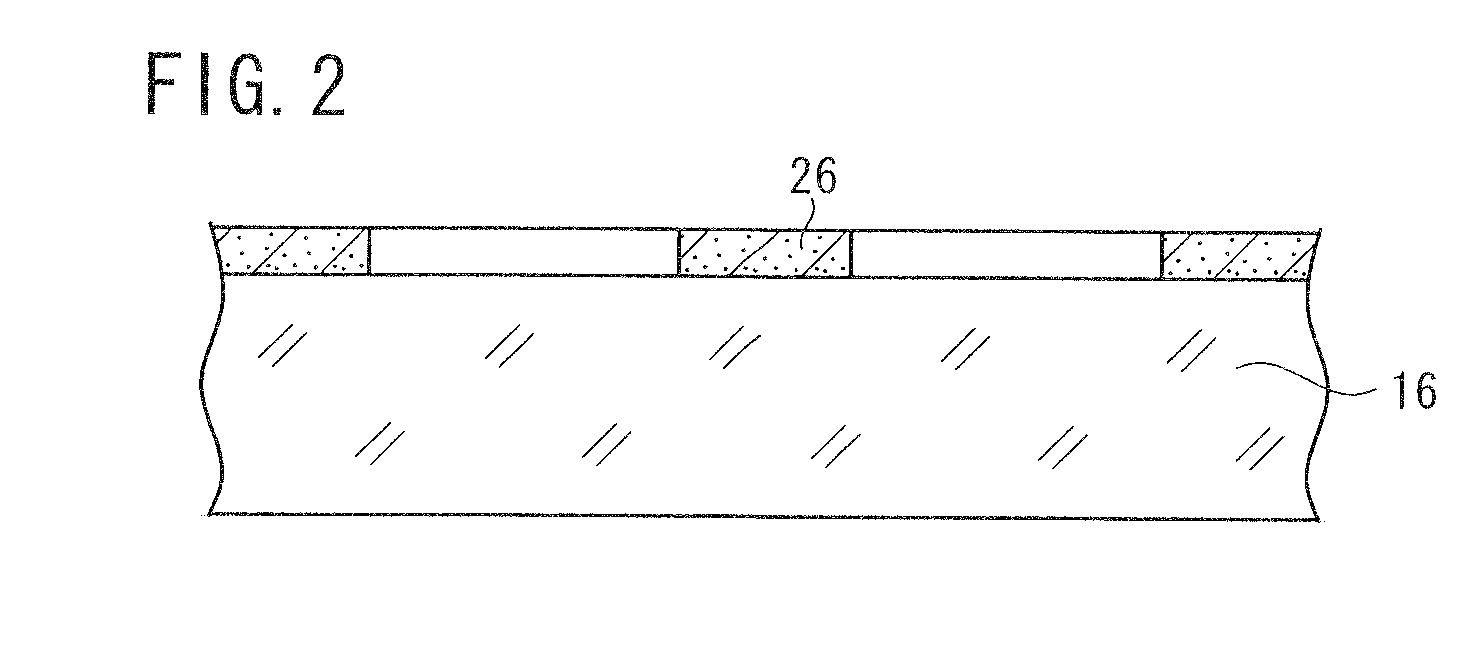

Water-based emulsion for vibration damper

ActiveUS20050101697A1Improve vibration damping effectSatisfactory compatibilitySpringsOther chemical processesWater basedVitrification

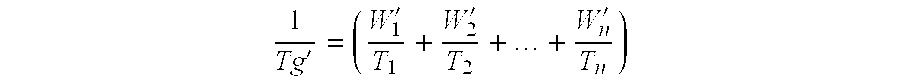

A water-based emulsion for vibration damper is provided for the formation of an excellent vibration damper. In an aspect, the emulsion for vibration damper contains a particle including a core part formed of an acrylic copolymer (A) and a shell part formed of an acrylic copolymer (B) which covers the core part, the glass transition point of the acrylic copolymer (B) being not lower than −9° C., and the difference between the glass transition point of the acrylic copolymer (B) and the glass transition point of the acrylic copolymer (A) being not less than 20° C.

Owner:NIPPON SHOKUBAI CO LTD

Oil-based pigmented ink composition

InactiveUS7682435B2Increase surface tensionImprove spraying effectNon-fibrous pulp additionInksOrganic solventNitrogen

The present invention relates to an oil-based pigmented ink composition containing at least a pigment, a polymer compound and an organic solvent, which contains, as the organic solvent, methoxybutyl acetate in an amount of 20 to 90% by weight based on the entire ink composition; and particularly to the above oil-based pigmented ink composition, which contains, as the other organic solvent, a nitrogen-containing and / or oxygen-containing heterocyclic compound in an amount of 1 to 50% by weight based on the entire ink composition and / or a (poly)alkylene glycol derivative in an amount of 1 to 50% by weight based on the entire ink composition; and to the above oil-based pigmented ink composition, which has a flash point of 61° C. or higher, a viscosity of 2.0 to 6.5 cp at 25° C., and a surface tension of 20 to 40 mN / m at 25° C.

Owner:MAXELL HLDG LTD

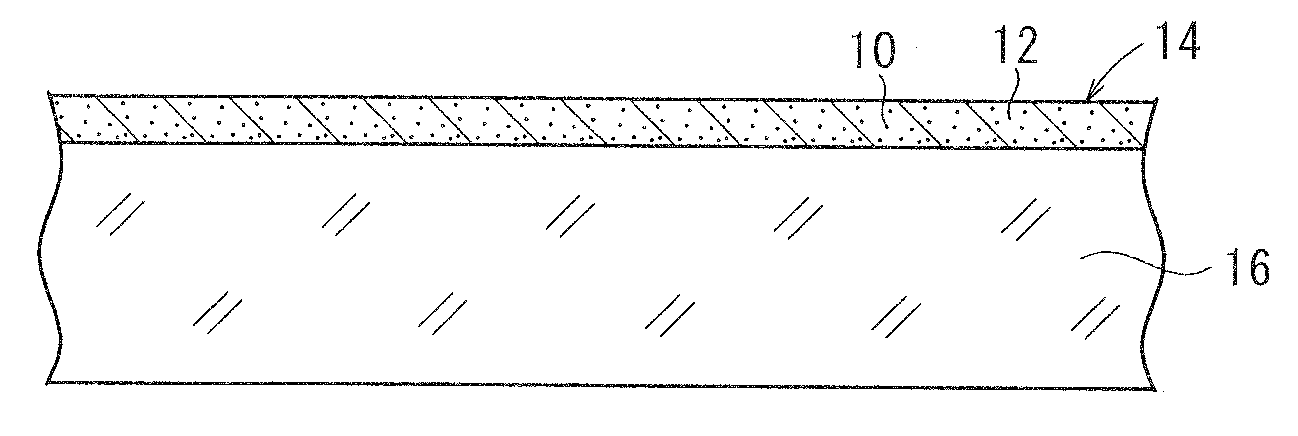

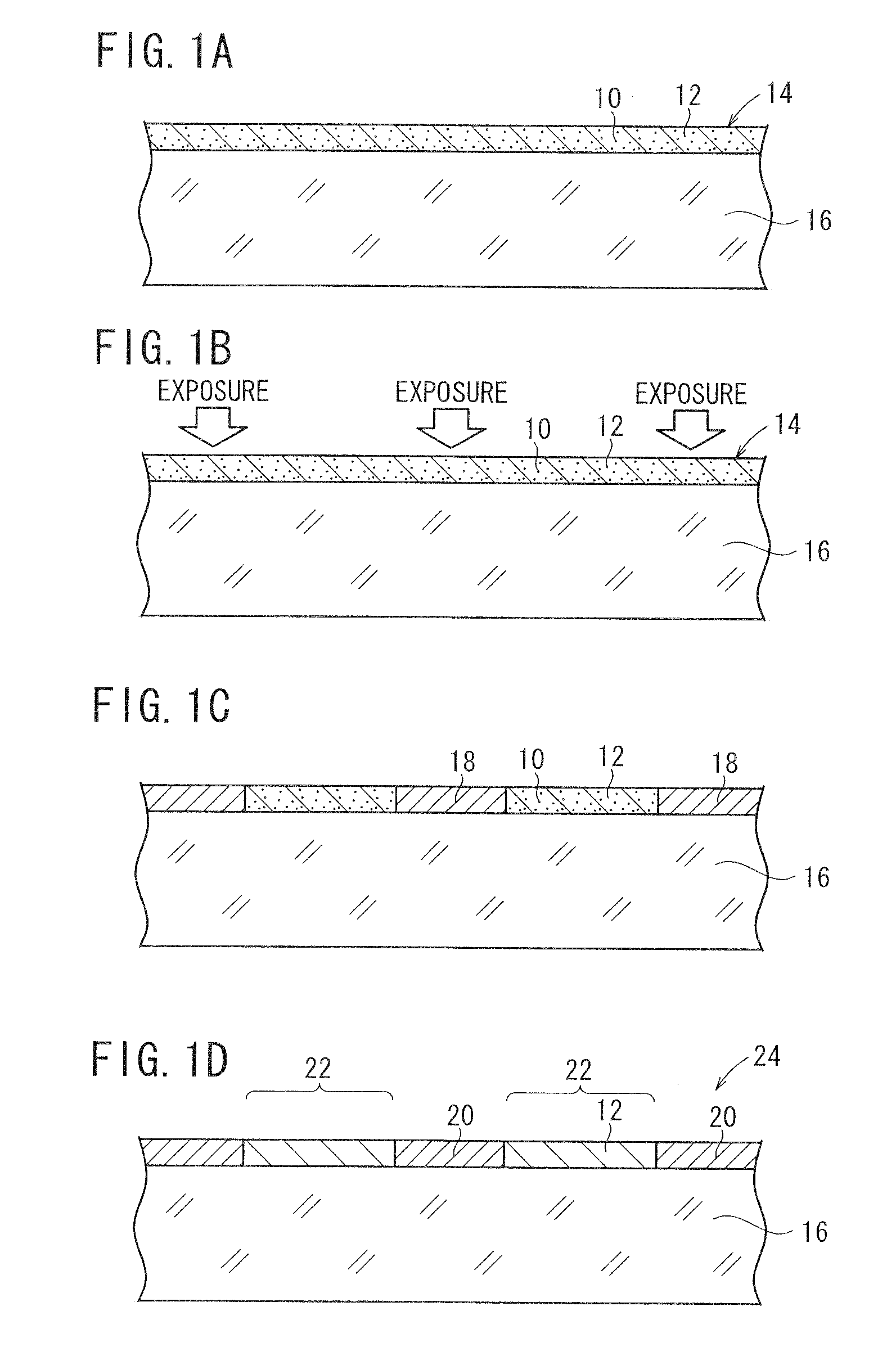

Method and apparatus for producing conductive material

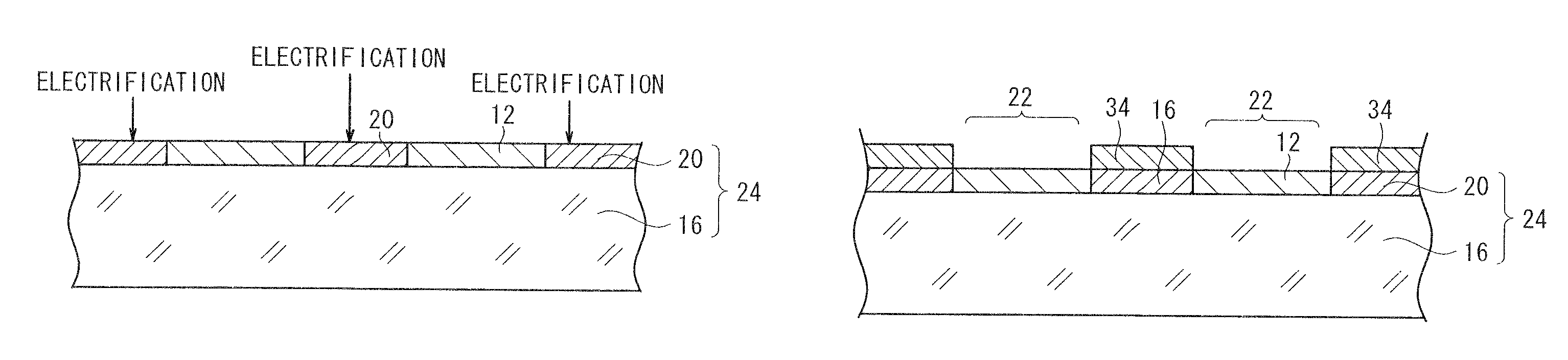

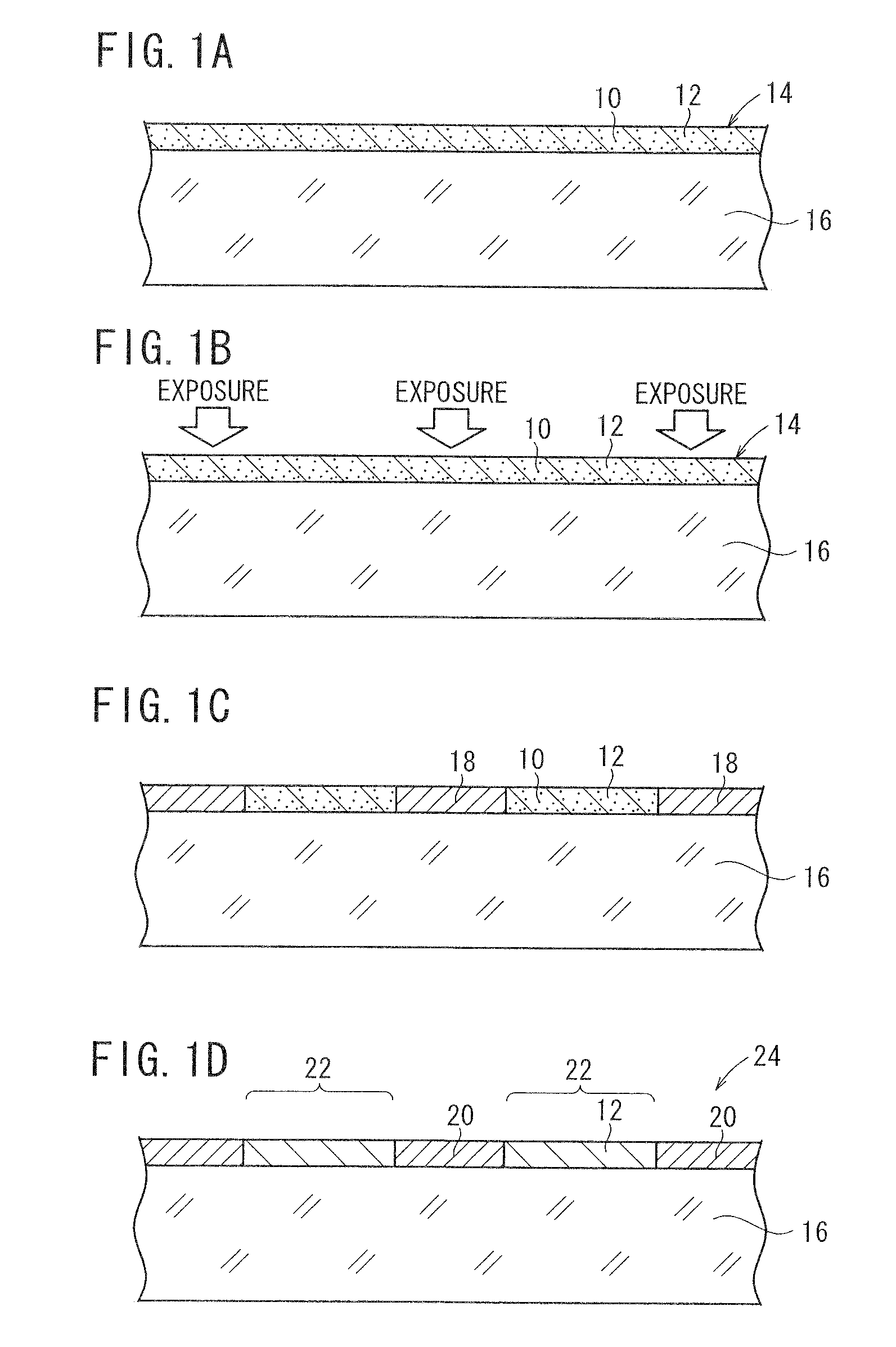

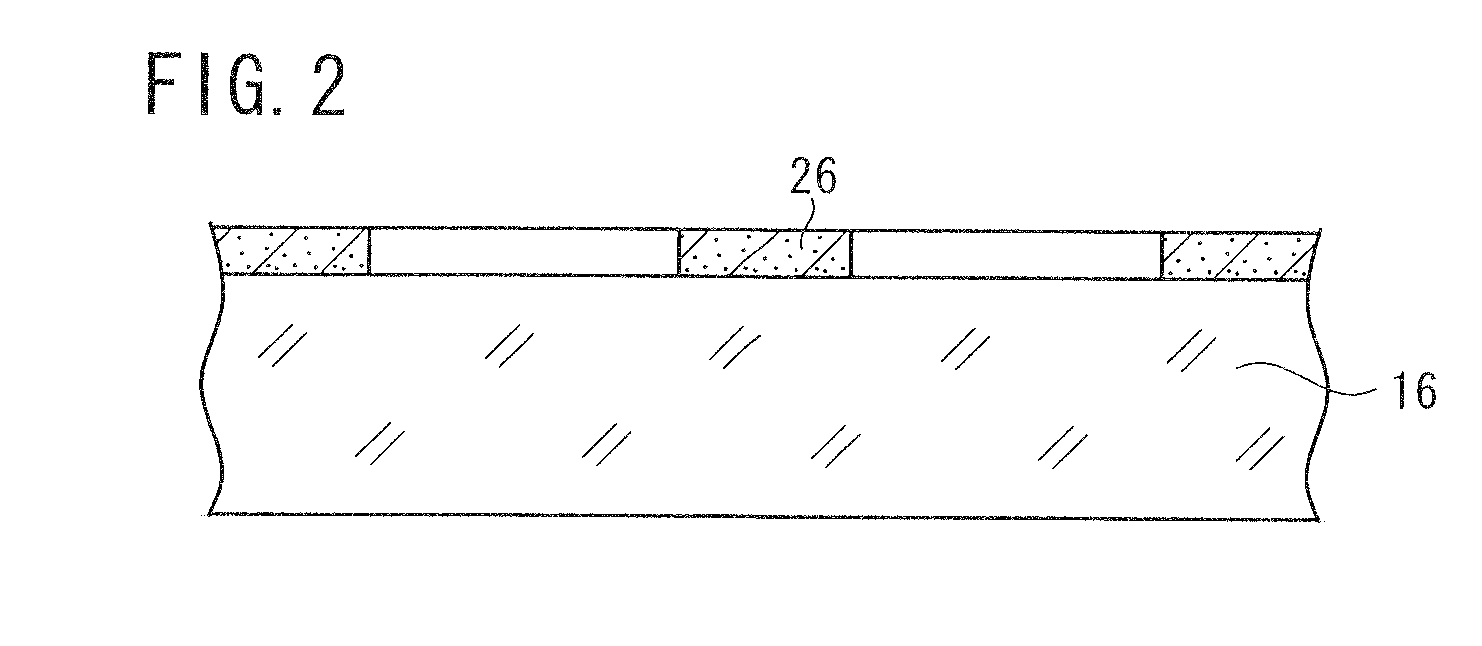

InactiveUS20090087800A1Increase awarenessReduce light reflectionPrinted circuit aspectsPretreated surfacesEmulsionConductive materials

A photosensitive film, which has a transparent support and a silver salt emulsion layer containing a silver salt formed thereon, is exposed and developed to form a metallic silver portion. The base material to be plated is electrified in a solution containing a metal ion, using the metallic silver portion as a cathode. Then, the electrified base material is subjected to an electroless plating treatment to form a plated layer only on the metallic silver portion. The metal ion in the solution is preferably an ion of copper, nickel, cobalt, or tin.

Owner:FUJIFILM CORP

Water-based emulsion for vibration damper

ActiveUS7176258B2Improve propertiesGood coating performanceSpringsOther chemical processesWater basedEmulsion

A water-based emulsion for vibration damper is provided for the formation of an excellent vibration damper. In an aspect, the emulsion for vibration damper contains a particle including a core part formed of an acrylic copolymer (A) and a shell part formed of an acrylic copolymer (B) which covers the core part, the glass transition point of the acrylic copolymer (B) being not lower than −9° C., and the difference between the glass transition point of the acrylic copolymer (B) and the glass transition point of the acrylic copolymer (A) being not less than 20° C.

Owner:NIPPON SHOKUBAI CO LTD

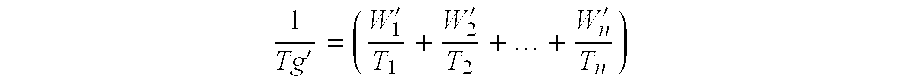

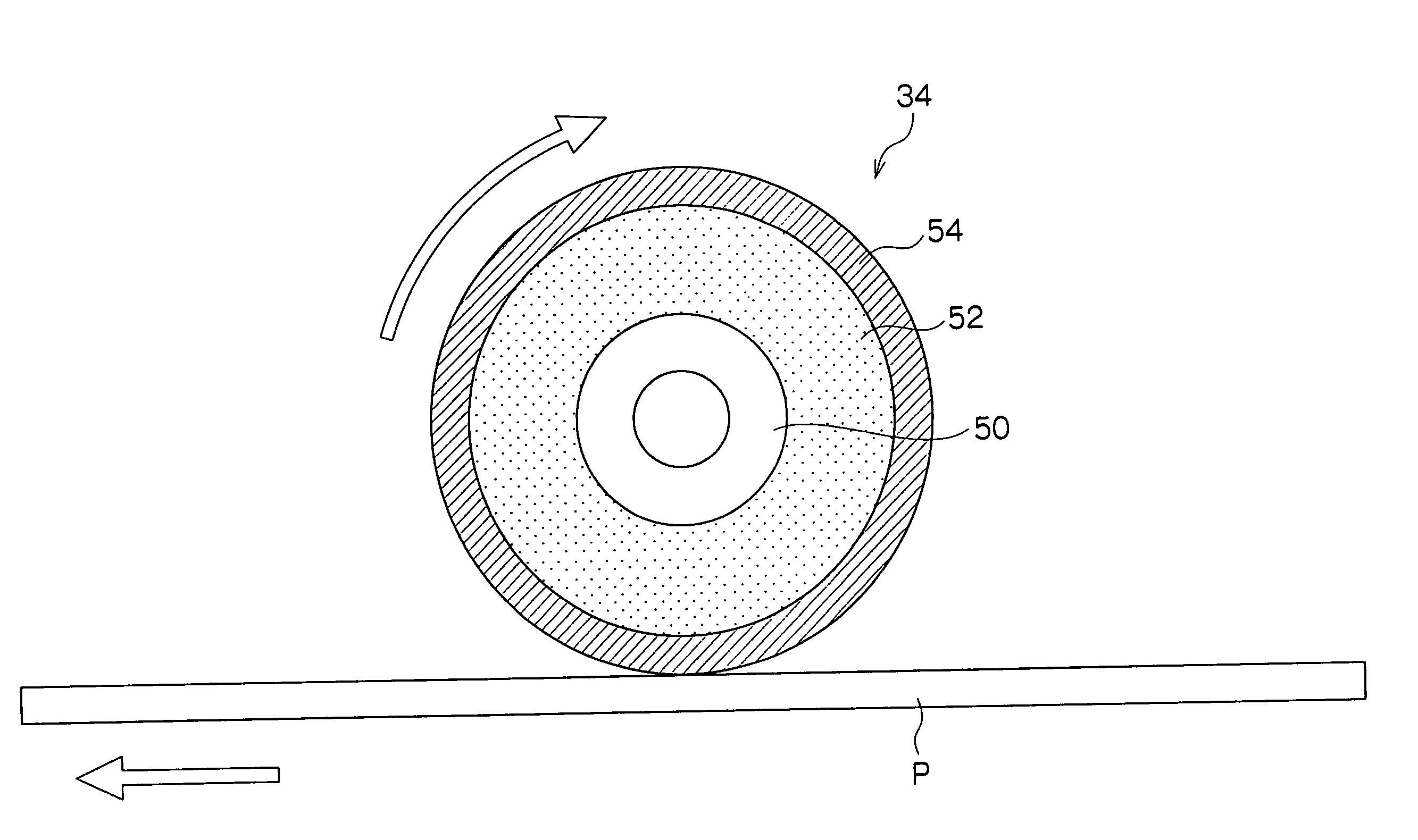

Aqueous polyurethane resin dispersion and preparation process for the same

The invention relates to an aqueous polyurethane resin dispersion having a good dispersibility in an aqueous medium and capable of forming a paint film excellent in strength when cured by ultraviolet light, and an aqueous polyurethane resin dispersion excellent in drying property, having a high hardness and being capable of providing a paint film having a scratch resistance, wherein the polyurethane resin is obtained by reacting at least a polycarbonate polyol (a); an acidic group-containing polyol (b); and an optional polyol (c) other than (a) and (b), with a polyisocyanate (d), and optionally further reacting with a chain extender (B), as well as a paint composition and a coating agent composition containing the same, and a preparation process of the same.

Owner:UBE IND LTD

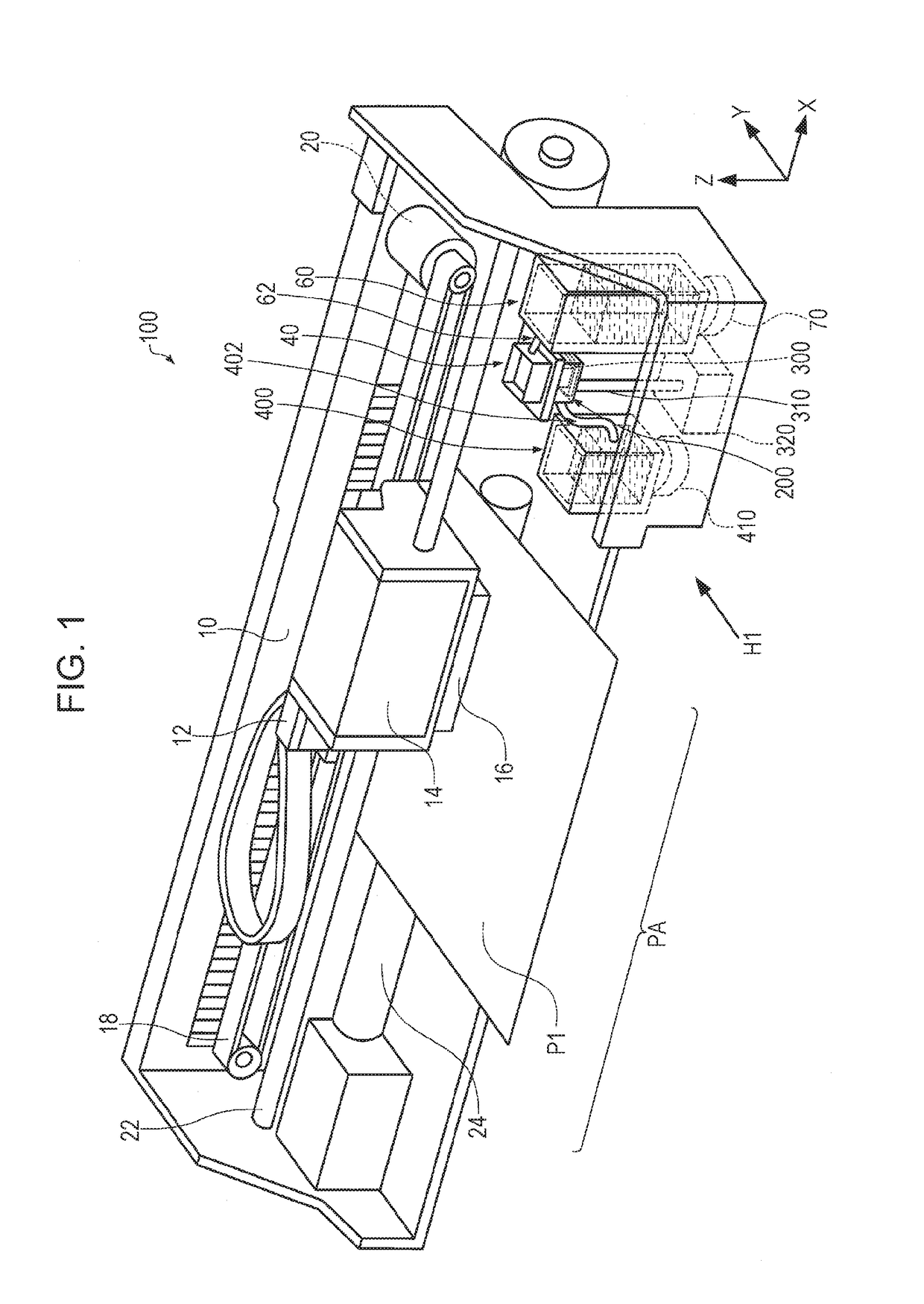

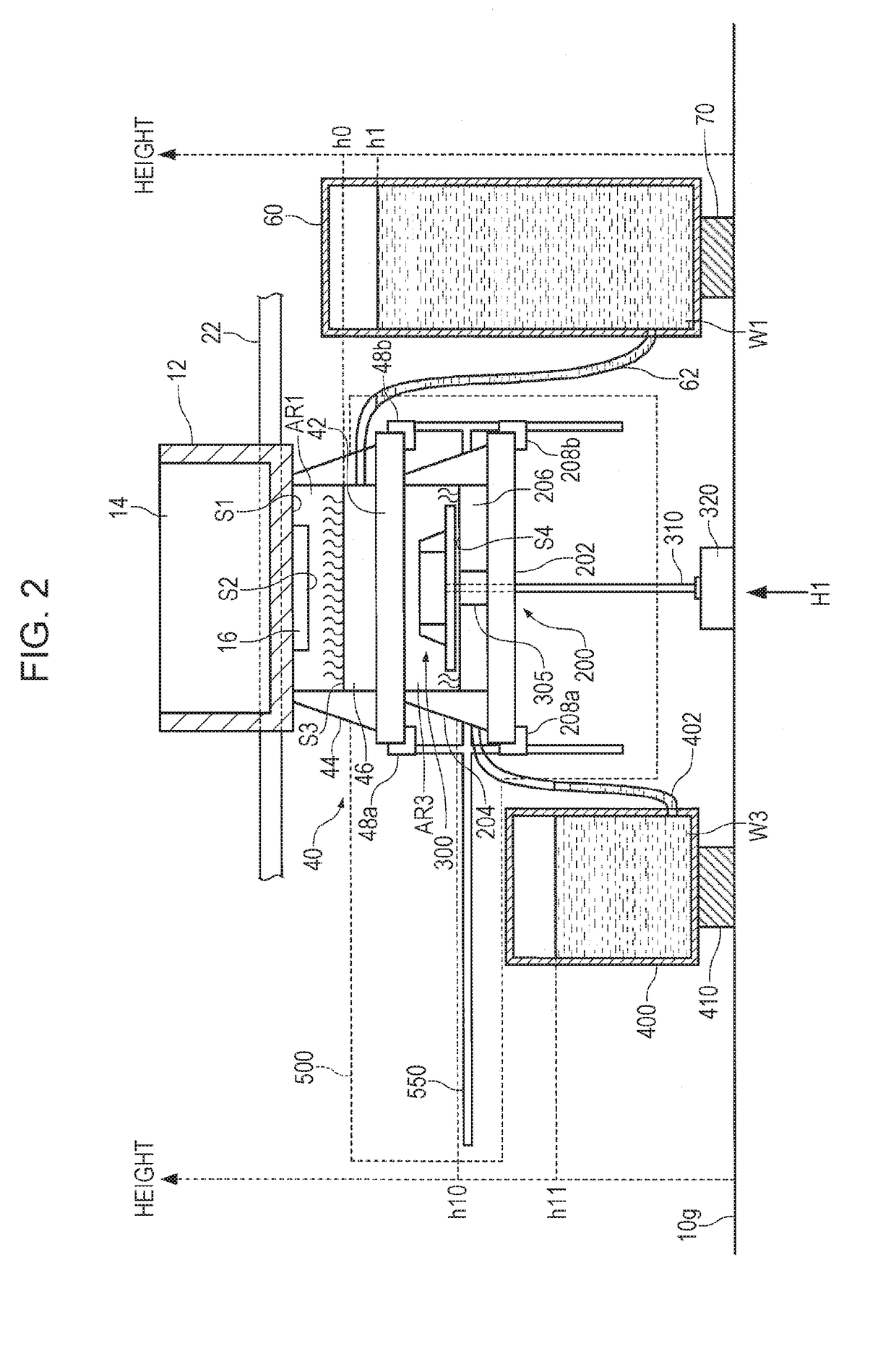

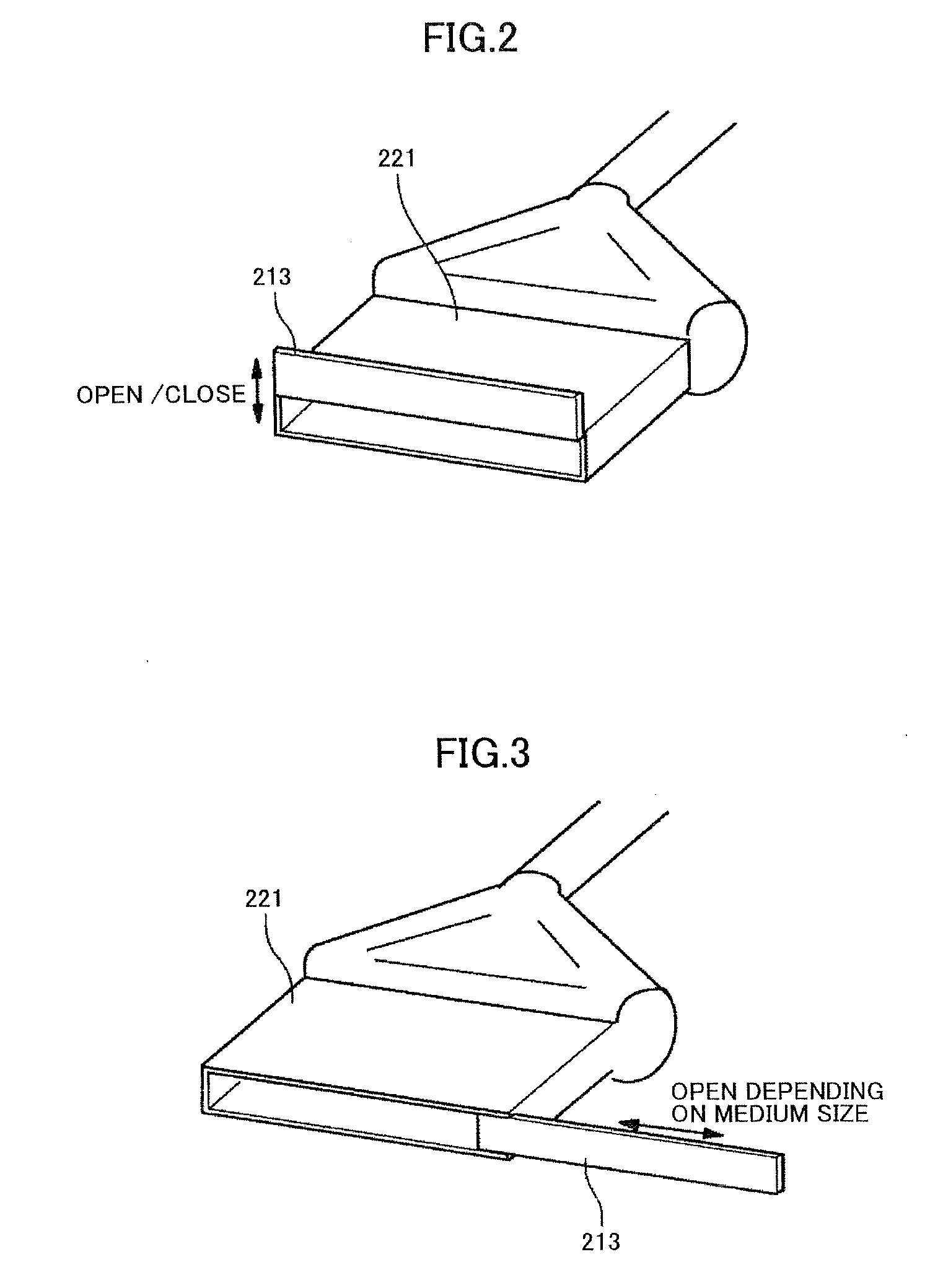

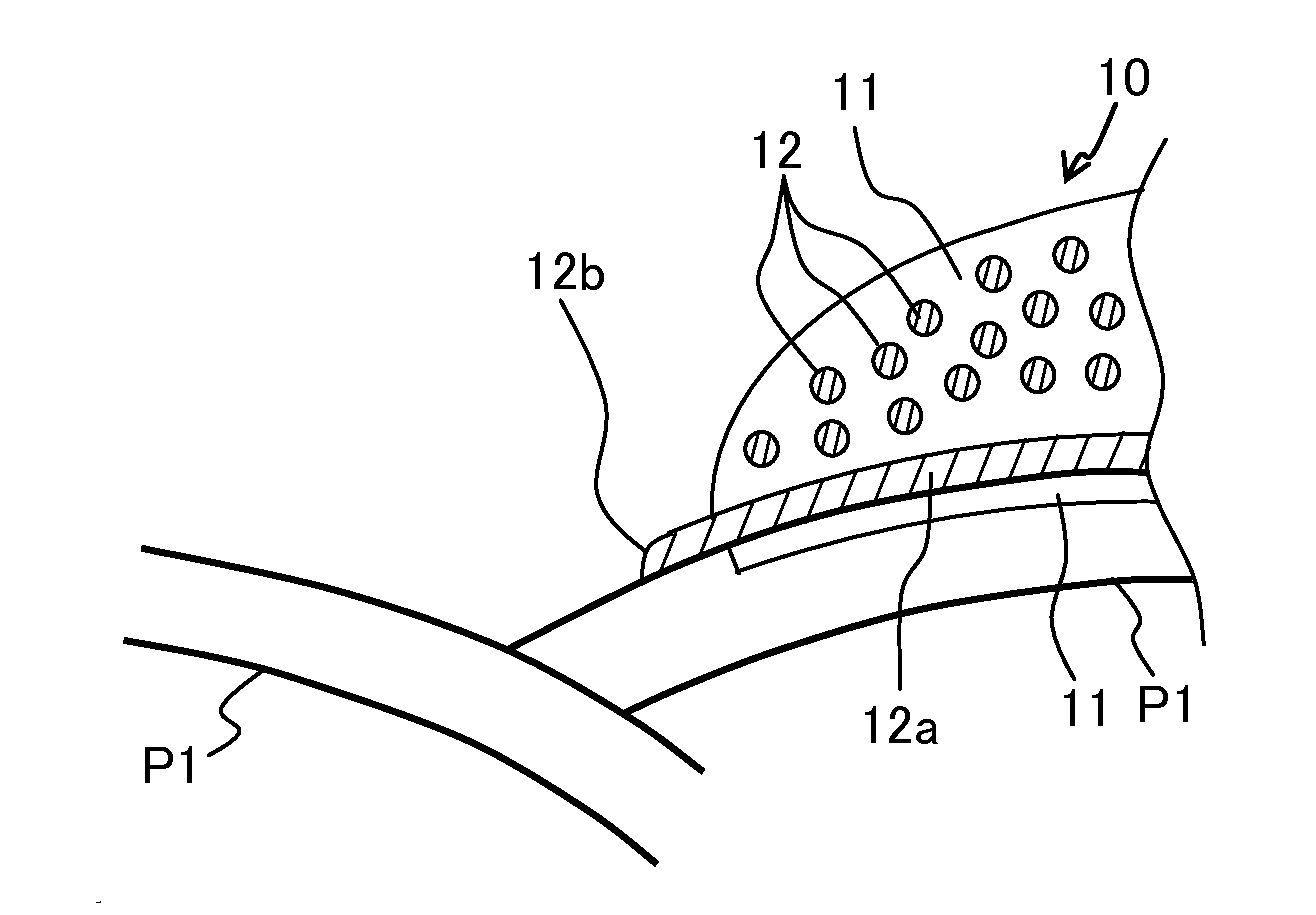

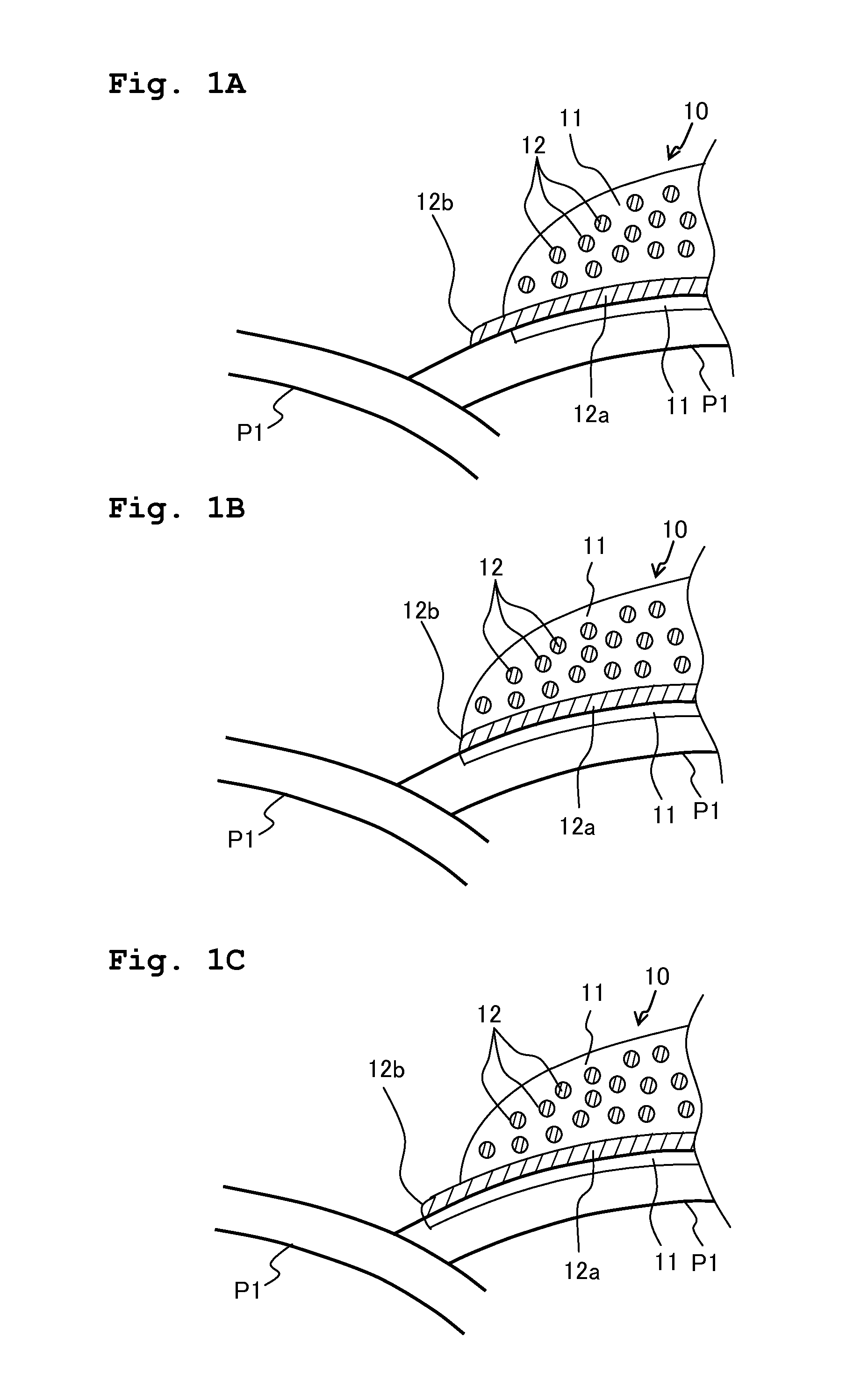

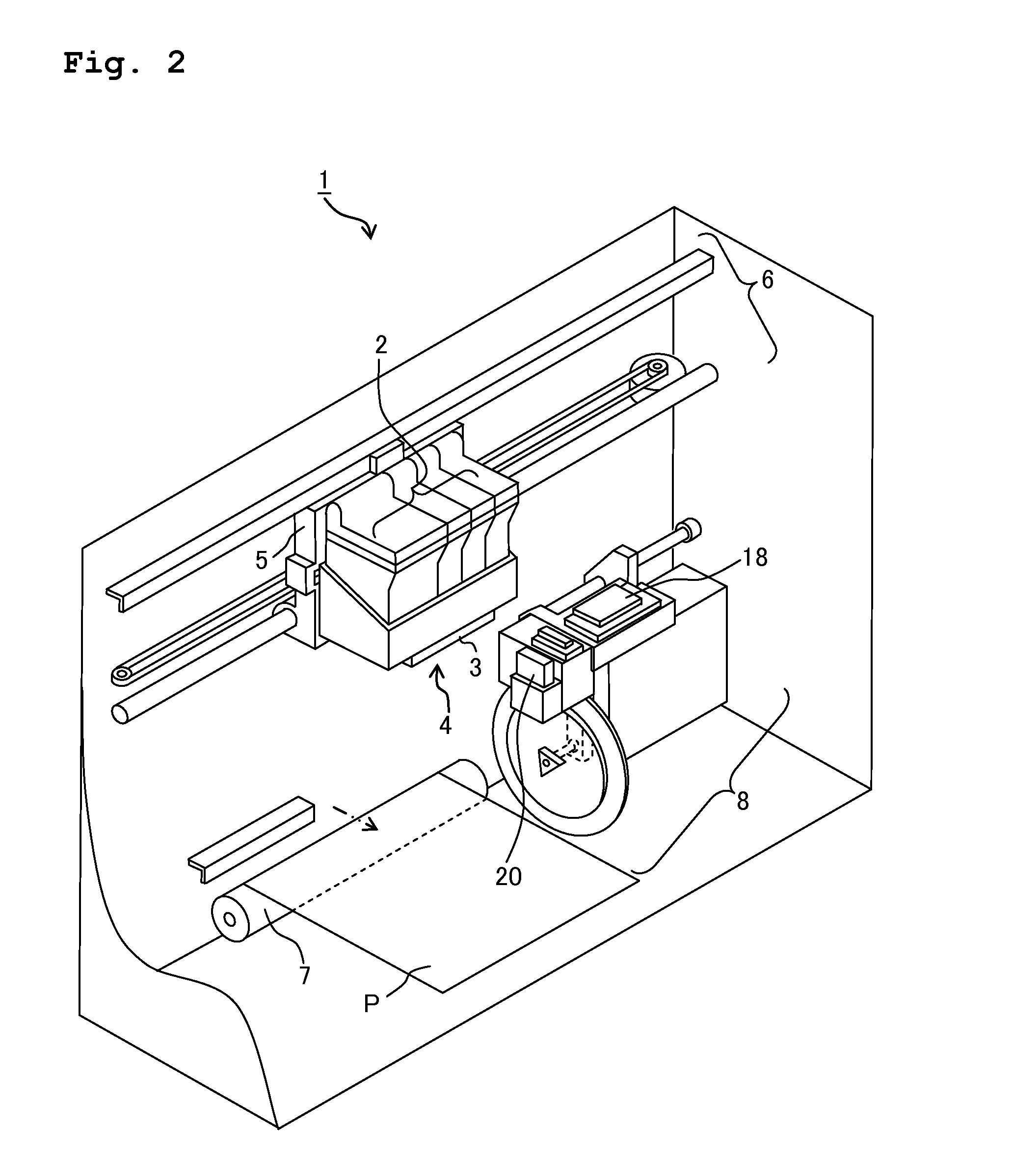

Ink jet recording device and method for ink jet recording using the same

InactiveUS7237887B2Curling and cockle can be preventedDrying property of inkDuplicating/marking methodsInksEngineeringRecording media

An ink jet recording device including a recording head for depositing ink on a recording medium and a liquid absorbing device for absorbing excess liquid of the ink remaining on the recording medium after the depositing of the ink on the recording medium using the recording head, wherein the liquid absorbing device includes an absorber including a hydrophilic surface which contacts the excess liquid, and the hydrophilic surface has a residual fine particle ratio of not less than about 90%, the residual fine particle ratio being a ratio of fine particles remaining on the hydrophilic surface when fine particles having an average particle size of 5 μm are filtered by the hydrophilic surface.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Process for Producing Resin-Coated Pigment, Resin-Coated Pigment, Aqueous Pigment Dispersion and Aqueous Colorant Composition Containing the Same

ActiveUS20080262122A1Good storage stabilityHigh densityDuplicating/marking methodsInksDispersion stabilityOrganic solvent

A process for producing a resin-coated pigment capable of providing an ink and a paint being superior in dispersion stability of a pigment and having rapid drying property, high gloss and density without containing those such as an organic solvent and a salt that cause the lowering of performance of pigment dispersion, characterized in that a pigment is dispersed in an aqueous solution in which an anionic group-containing resin is dissolved in the presence of a basic compound and then, the anionic group-containing resin is precipitated on the surface of the pigment by removing the basic compound in the aqueous solution, using an ion exchange means.

Owner:SAKATA INX

Inkjet Ink And Printing Method Using The Same

InactiveUS20080043080A1Keep dryImprove breathabilityMeasurement apparatus componentsDuplicating/marking methodsInk printerProtic solvent

Disclosed are an inkjet ink and a method for printing on hydrophobic media such as offset coated media using the inkjet ink. Specifically disclosed is an inkjet containing a pigment, water and a surfactant which is characterized by also containing 40 to 75 weight % of a polar non-protic solvent with a molecular weight of 40 to 130 which has permeability to a hydrophobic surface such as the coating of an offset coated medium. Such an inkjet ink enables better printing on hydrophobic media such as offset coated media than the conventional inks.

Owner:GENERAL CO LTD

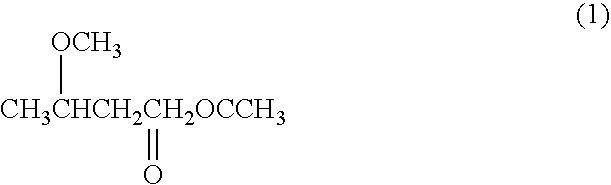

Solvent-based ink jet ink composition

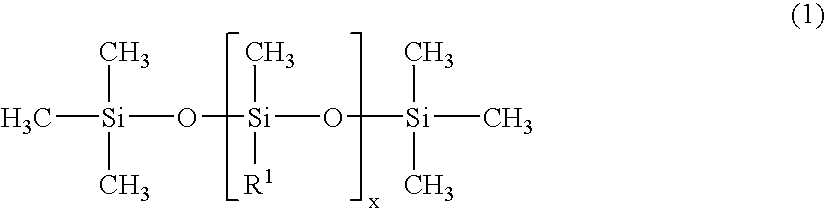

A solvent-based ink jet ink composition includes a coloring material; and a solvent; in which the composition includes, as the solvent, two or more types of solvent that are compounds represented by the following general formula (1), and R1, R2, and R3 have the same structure as one another and m are consecutive integers, in the solvent.R1O—(R2O)m—R3 (1)(in the formula, R1 is a hydrogen atom or an alkyl group with 1 to 6 carbon atoms, R2 is an alkylene group with 2 or 3 carbon atoms, and R3 is a hydrogen atom, an acetyl group, or an alkyl group with 1 to 4 carbon atoms. However, both of R1 and R3 are not hydrogen atoms. m is an integer of 1 to 7).

Owner:SEIKO EPSON CORP

Method and apparatus for producing conductive material

InactiveUS8268400B2Low electroless plating activityHigh electroless plating activityPrinted circuit aspectsPhotomechanical apparatusEmulsionConductive materials

A photosensitive film, which has a transparent support and a silver salt emulsion layer containing a silver salt formed thereon, is exposed and developed to form a metallic silver portion. The base material to be plated is electrified in a solution containing a metal ion, using the metallic silver portion as a cathode. Then, the electrified base material is subjected to an electroless plating treatment to form a plated layer only on the metallic silver portion. The metal ion in the solution is preferably an ion of copper, nickel, cobalt, or tin.

Owner:FUJIFILM CORP

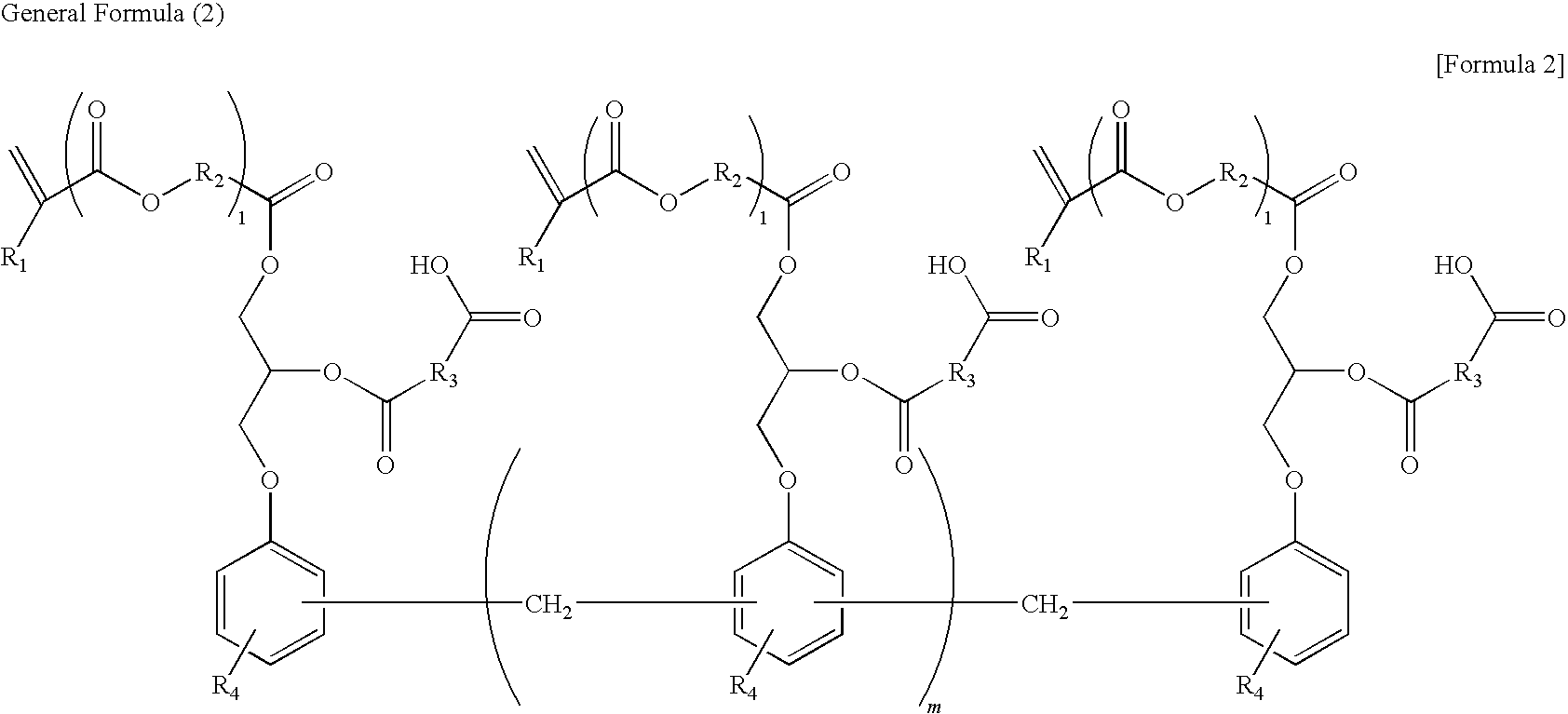

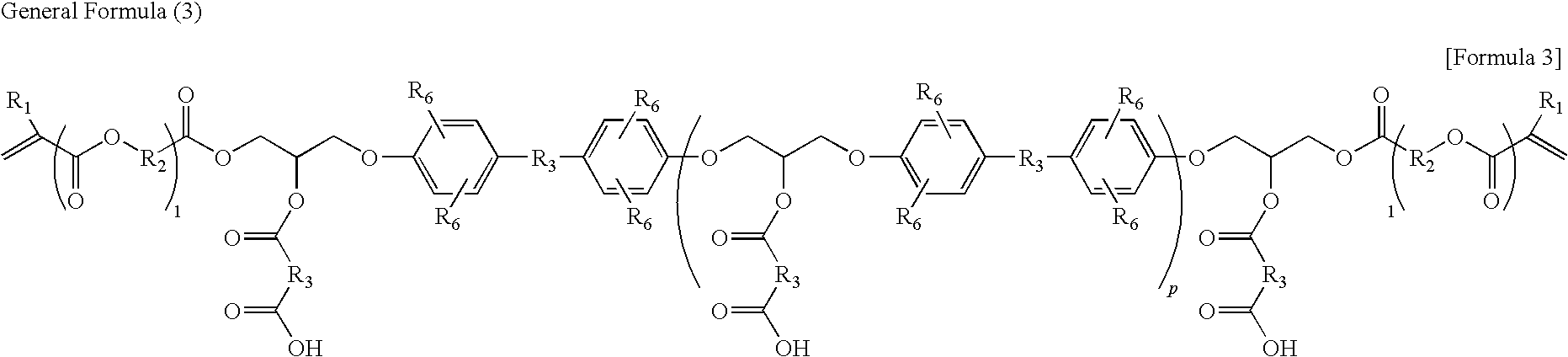

Photosensitive resin composition

ActiveUS20090233231A1Improve curing effectExcellent developabilityPhotosensitive materialsPhotosensitive materials for photomechanical apparatusPolymer scienceSimple aromatic ring

A photosensitive resin composition of the present invention includes an acid group-containing vinyl ester resin and a photopolymerization initiator as essential components, wherein the acid group-containing vinyl ester resin is an acid group-containing vinyl ester resin having a multiple-branched molecular structure obtained by the following steps where a polybasic anhydride (a3) is reacted with an epoxy vinyl ester resin (v1) that is a reaction product of an aromatic epoxy resin (a1) and a radically-polymerizable unsaturated-double bond-containing monocarboxylic acid (a2); a radically-polymerizable unsaturated-double bond-containing monoepoxy compound (a4) is subsequently reacted with an acid group formed by the reaction; and a polybasic anhydride (a3) is subsequently reacted with a secondary hydroxyl group formed by the reaction of the compound (a4) with the acid group, thereby obtaining the acid group-containing vinyl ester resin having a multiple-branched molecular structure; and contains 1.75 to 3.5 radically-polymerizable unsaturated double bonds per aromatic ring in the acid group-containing vinyl ester resin, and the acid groups within a range where the acid value of the acid group-containing vinyl ester resin reaches 30 to 150 mg KOH / g. According to the present invention, a resin composition for a resist ink that simultaneously has ultrahigh sensitivity, excellent developability, and broad heat control range can be provided.

Owner:DAINIPPON INK & CHEM INC

Method for maintaining ink jet head

ActiveUS20170291421A1Eliminate ejection failure of nozzle surfaceEliminate failure problemsPrintingOrganic solventBoiling point

A method for maintaining an ink jet head according to the invention includes at least one of a maintenance step of attaching a maintenance liquid to a nozzle surface of an ink jet head, which ejects a reaction solution including an aggregating agent for aggregating or thickening components of an ink composition, to clean the nozzle surface, and a maintenance step of covering and moisturizing the nozzle surface with a head moisturizing cap supplied with the maintenance liquid, in which the maintenance liquid includes a water-soluble organic solvent having a boiling point of 280° C. or less and water.

Owner:SEIKO EPSON CORP

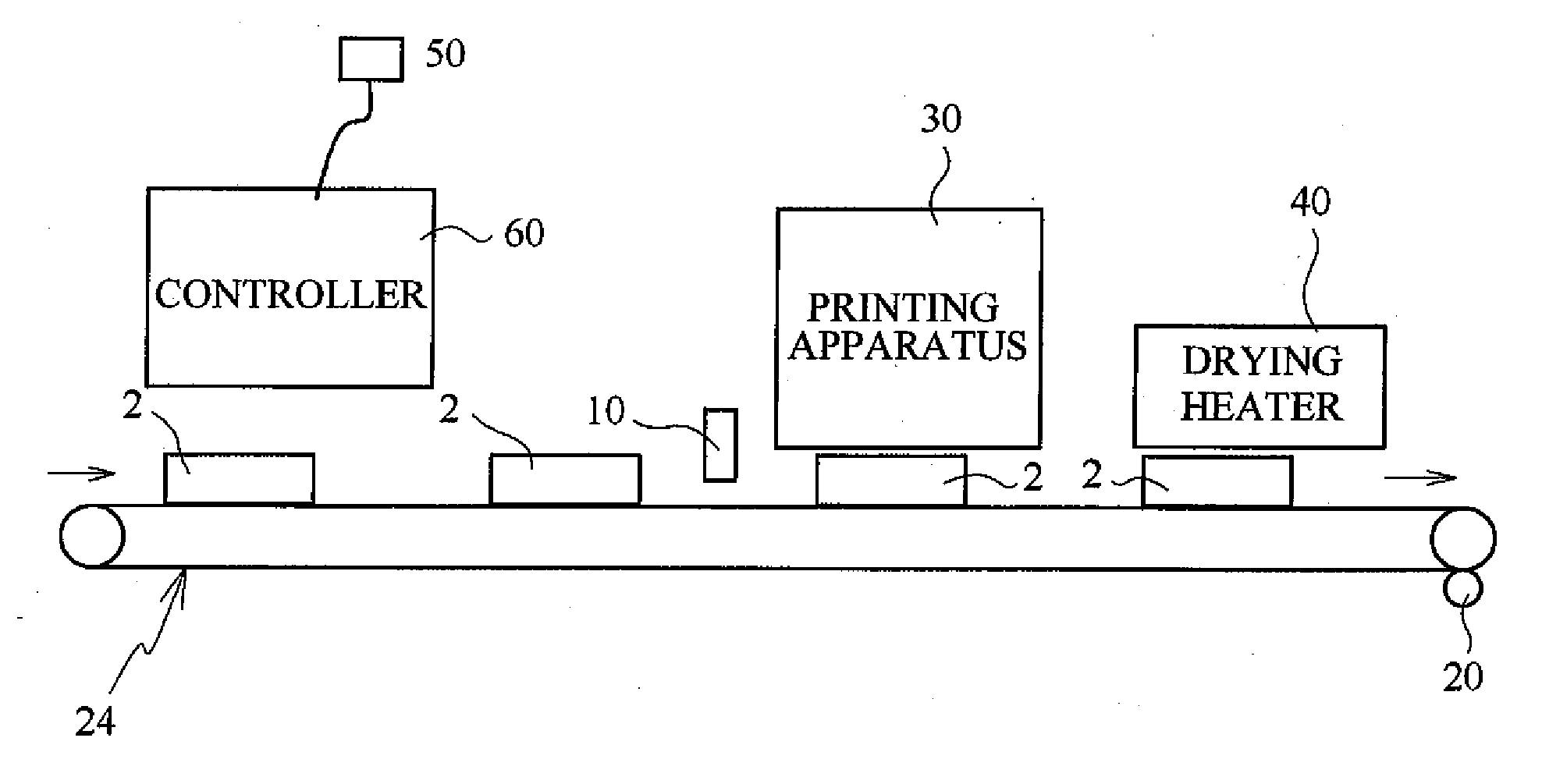

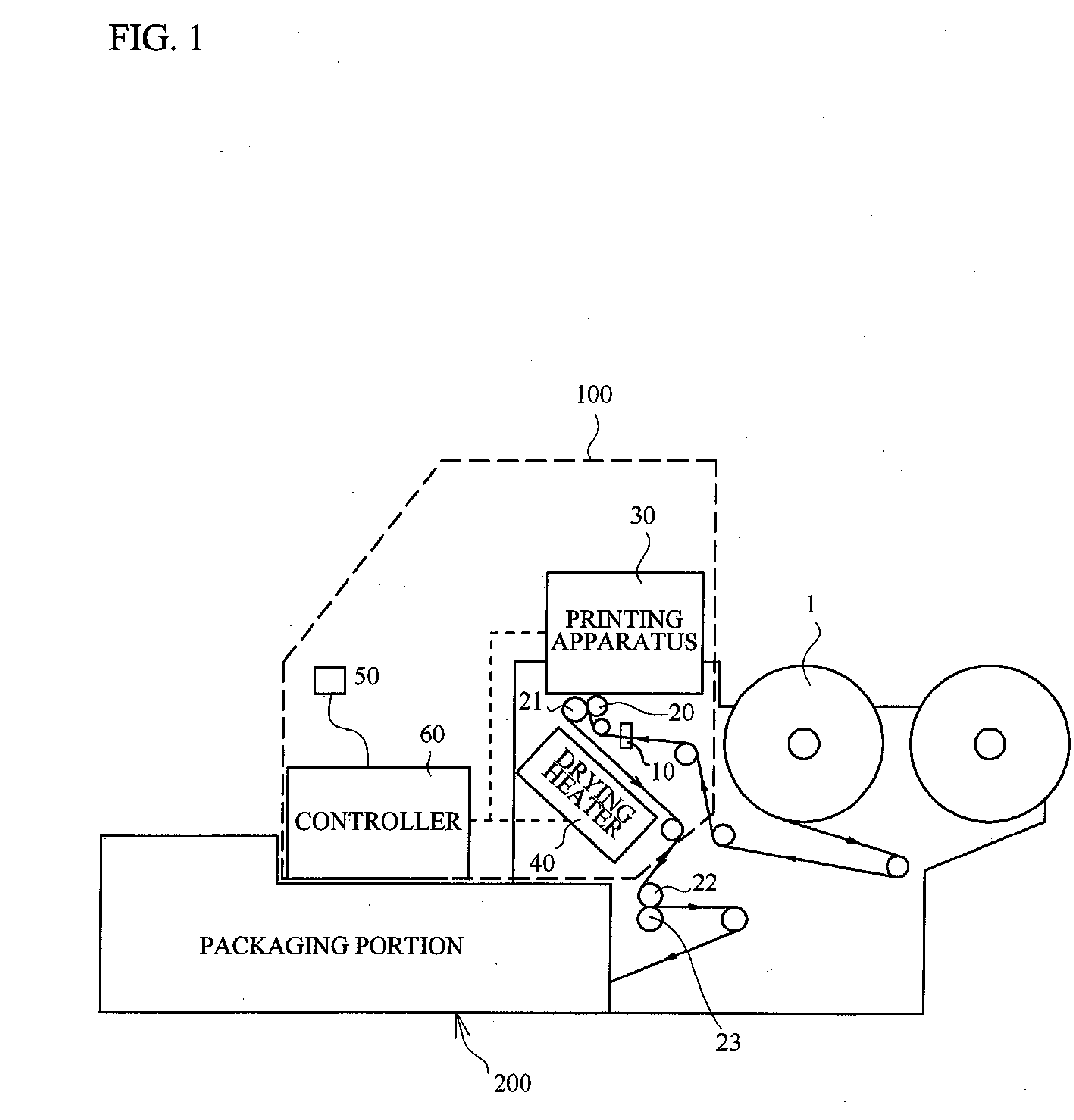

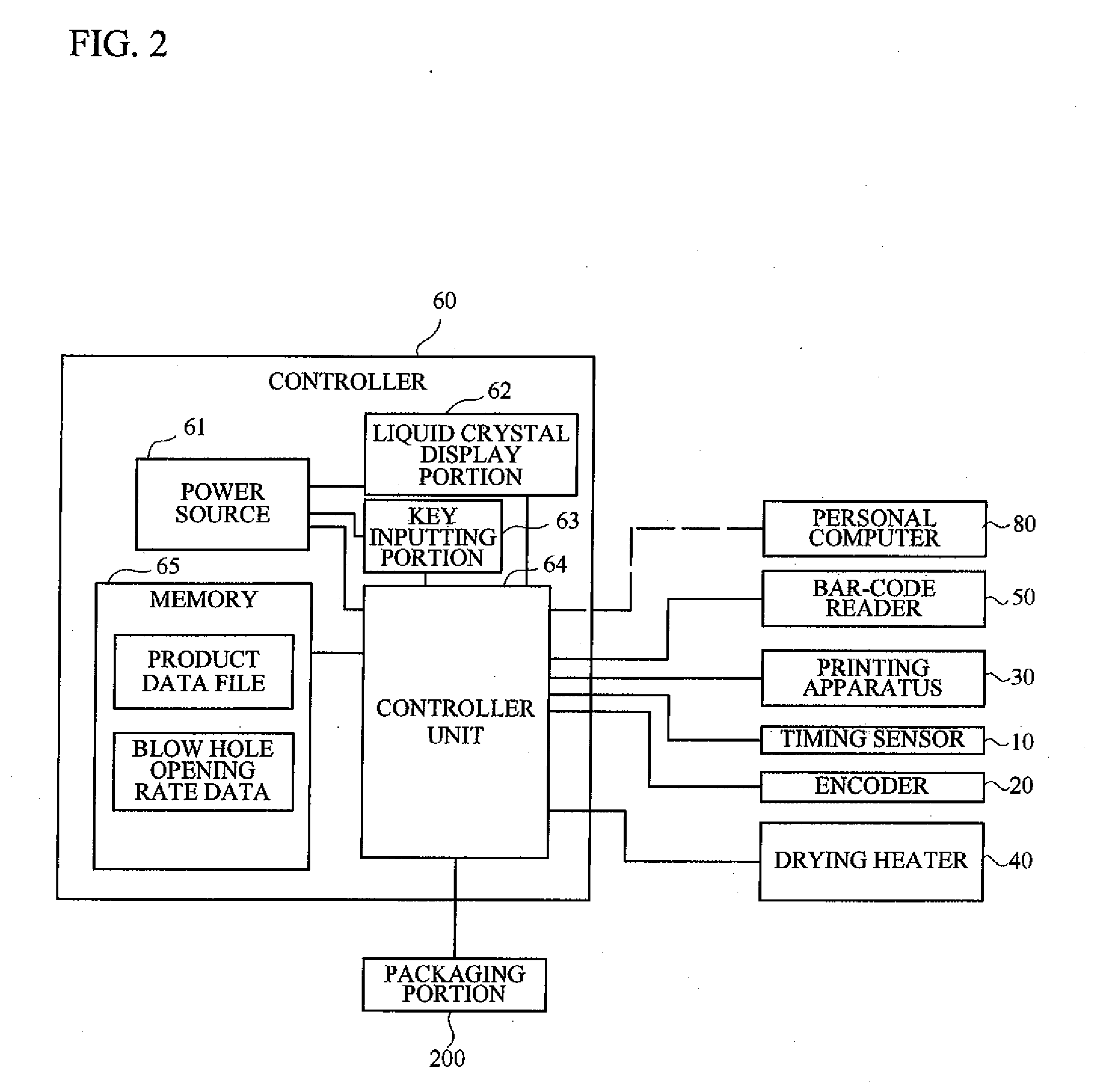

Printer

InactiveUS20090244160A1Improve rendering capabilitiesImprove workabilityOther printing apparatusAir volumeEngineering

A printer includes: a print head for ejecting ink on a print medium; a drying portion for blowing hot air to the printed print medium so as to expedite drying of the ink applied on the printed print medium, the drying portion including a blowing amount changing portion changeable a blowing amount of the hot air blown to the print medium; a detecting portion for detecting a feeding speed of the print medium; and a controller unit for controlling the blowing amount changing portion in response to the feeding speed of the print medium detected by the detecting portion.

Owner:SEIKO PRECISION CO LTD

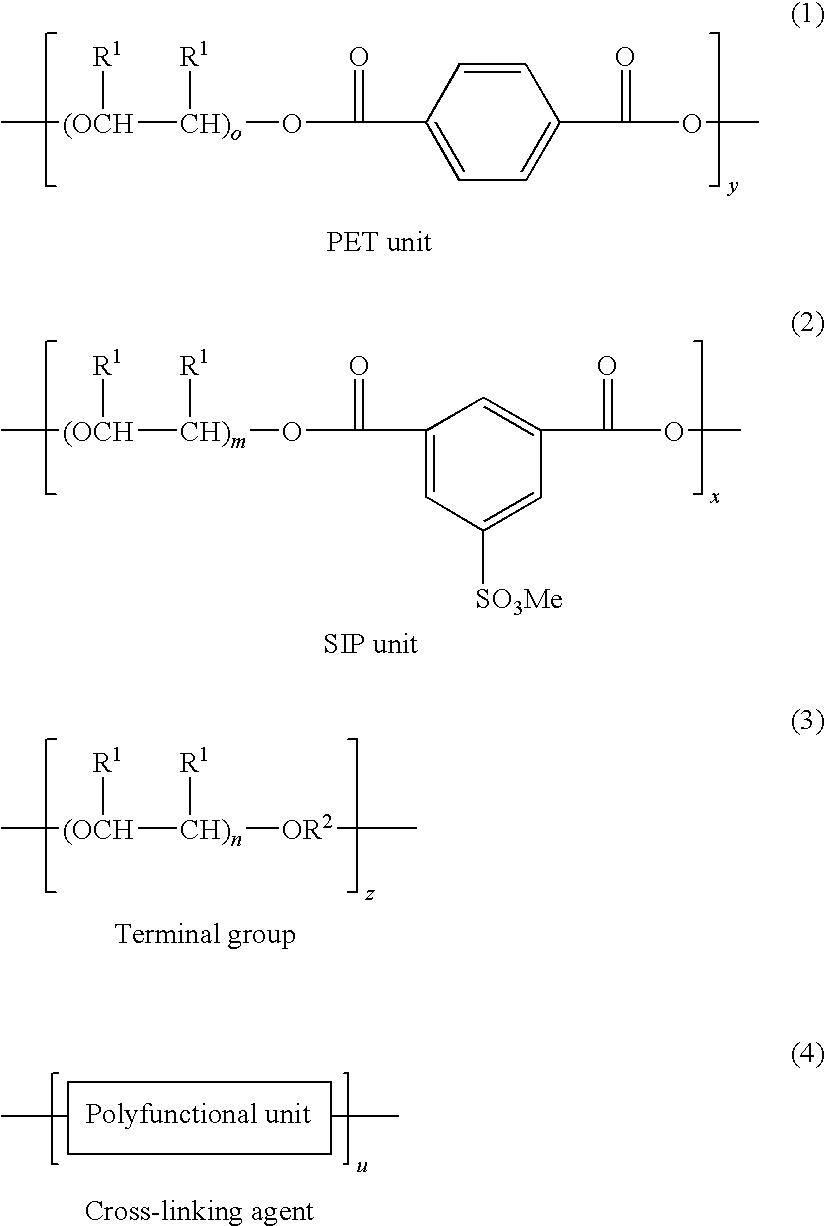

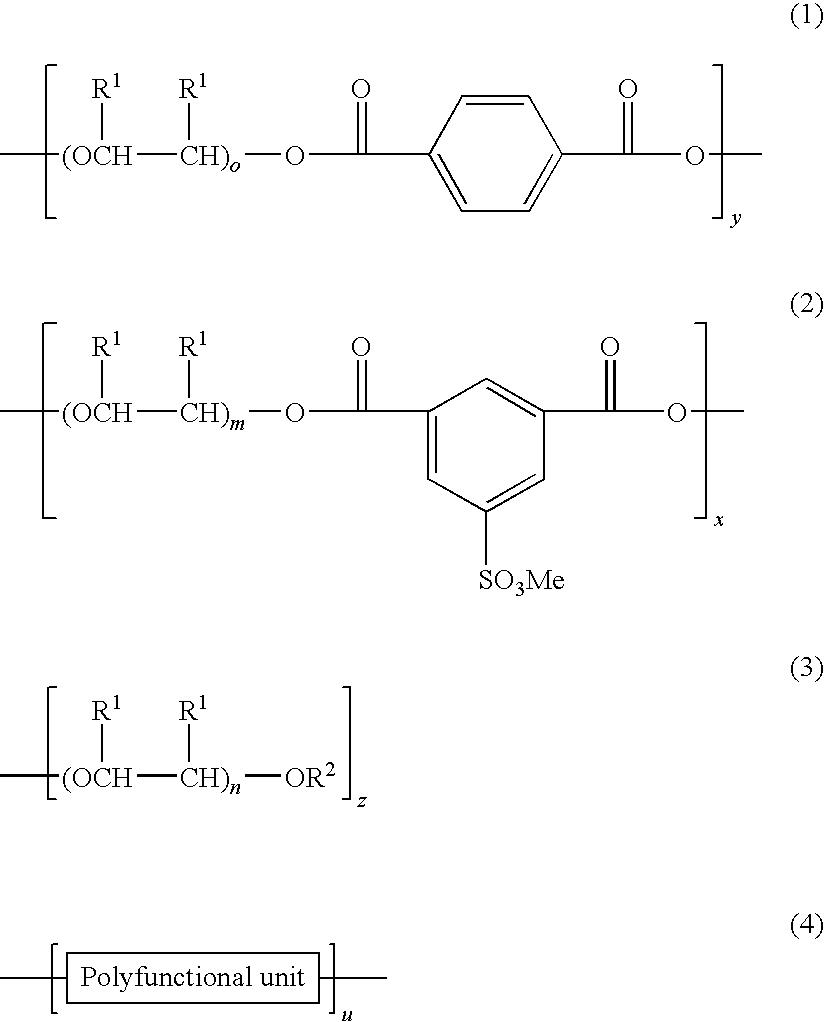

Detergent Composition

InactiveUS20100197546A1Accelerated dryingImproved soil release effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPolyester

Owner:RECKITT BENCKISER VANISH BV

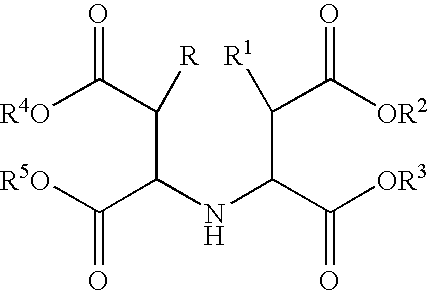

Liquid carboxy-containing polyester oligomer, water-compatible polyurethane resin, and process for producing the same

InactiveUS20060167203A1Without deteriorating working environmentKeep a humid environmentPolyurea/polyurethane coatingsPolyesterPolyol

A carboxy-containing polyester polyol which is obtained by polymerizing ε-caprolactone by ring-opening polymerization with a compound represented by the formula (1): HOCH2C(COOH)RCH2OH (1) (wherein R is C2 or higher alkyl) and which has a number-average molecular weight of 550 to 950 and is liquid at ordinary temperature. This polyol can give a water-compatible polyurethane resin which is excellent in the preservation of a working atmosphere during handling and application and has excellent drying properties after application, and which has homogeneity and excellent stability and is useful in a wide range of applications such as a binder for coating materials, printing inks, etc. and an adhesive. By the production process, a water-compatible polyurethane resin which is excellent in the preservation of a working atmosphere and drying property and is homogeneous and stable can be easily produced.

Owner:DAICEL CHEM IND LTD

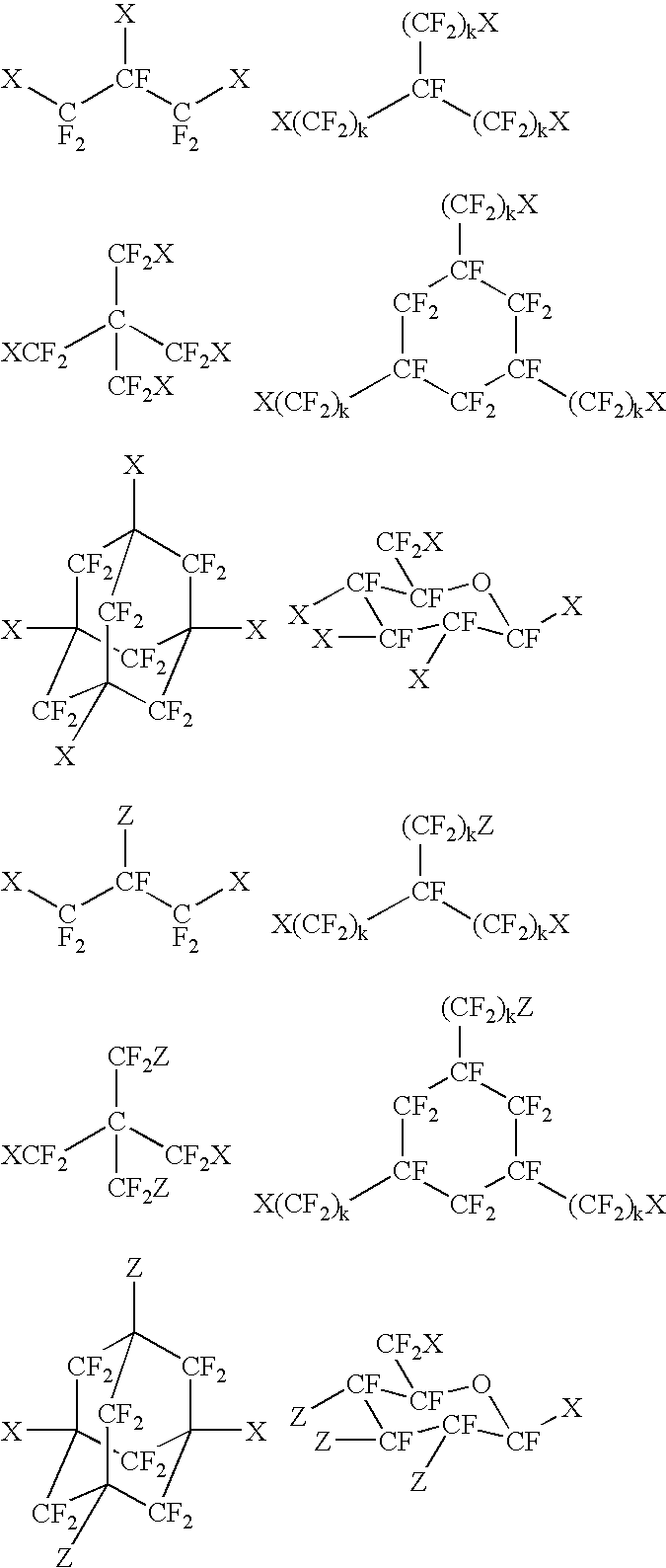

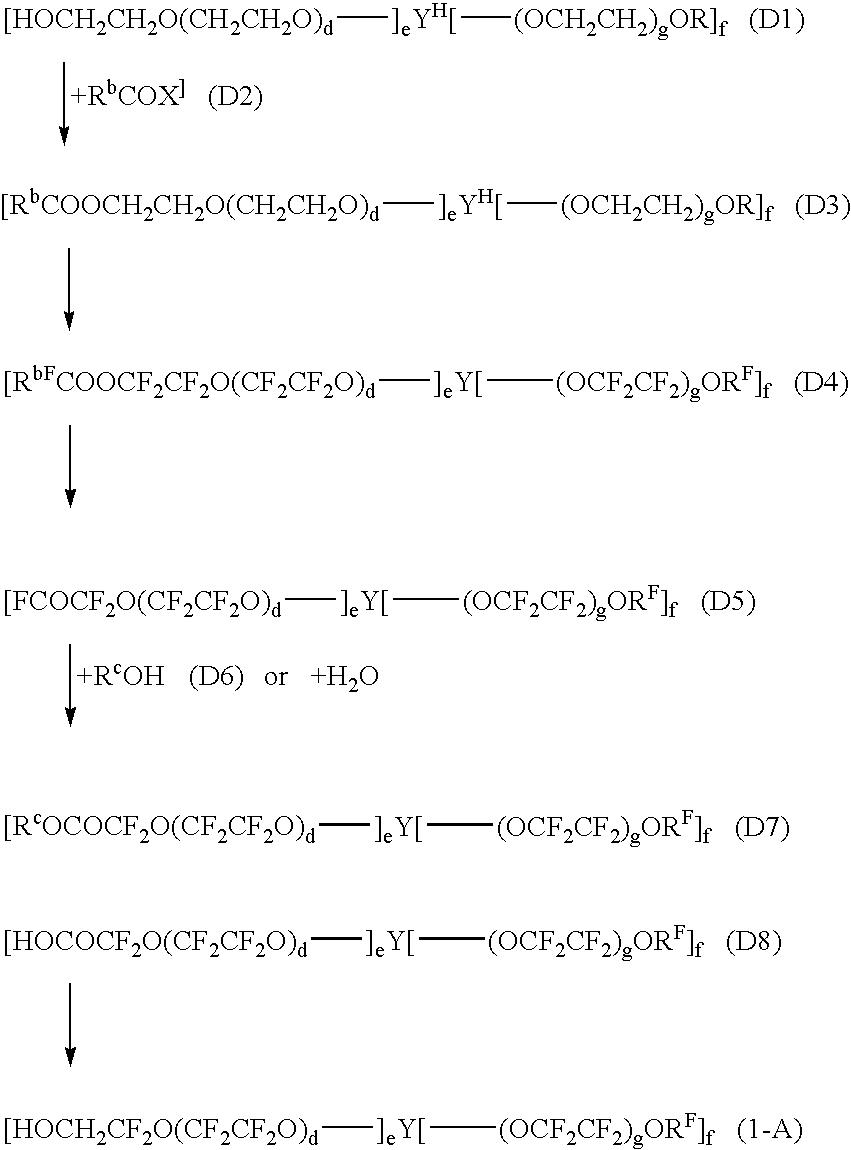

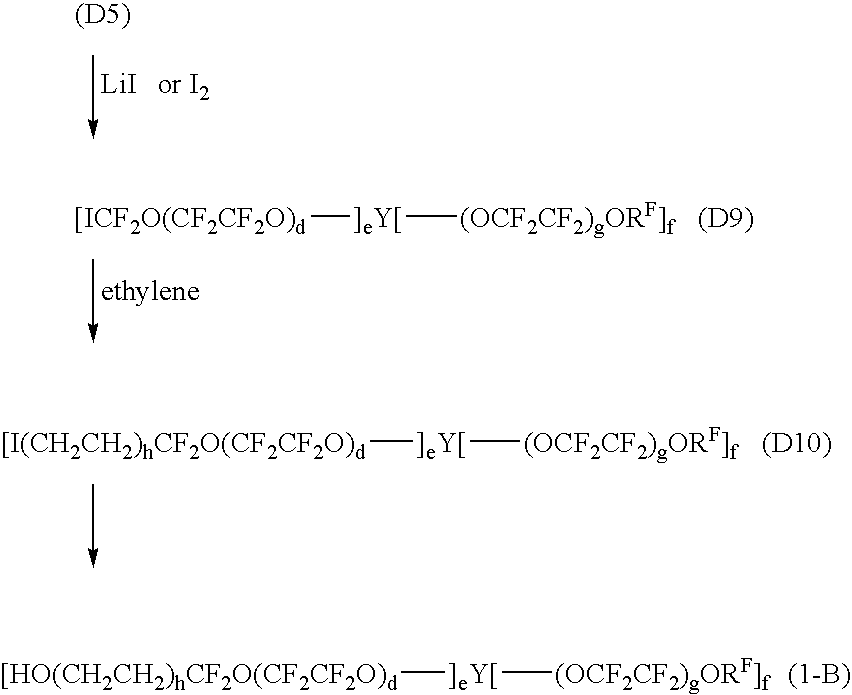

Lubricant solution for magnetic recording media, containing fluorinated polyether compound as lubricant

InactiveUS20070116990A1Low vapor pressureLow viscosityOrganic chemistryOrganic compound preparationOzone layerSolvent

To present a lubricant solution for magnetic recording media, which comprises a lubricant excellent in chemical stability and capable of imparting excellent lubricity, and a solvent having a suitable dissolving power for the lubricant and being excellent in drying properties and not influential over the ozone layer. A lubricant solution comprising a lubricant and a fluorinated alkyl ether. For example, as the lubricant, a compound of the formula (HO—CH2—CF2(OCF2CF2)dO—)3Y wherein Y is a trivalent perfluorohydrocarbon group, is used, and as the fluorinated alkyl ether, 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether is used.

Owner:ASAHI GLASS CO LTD

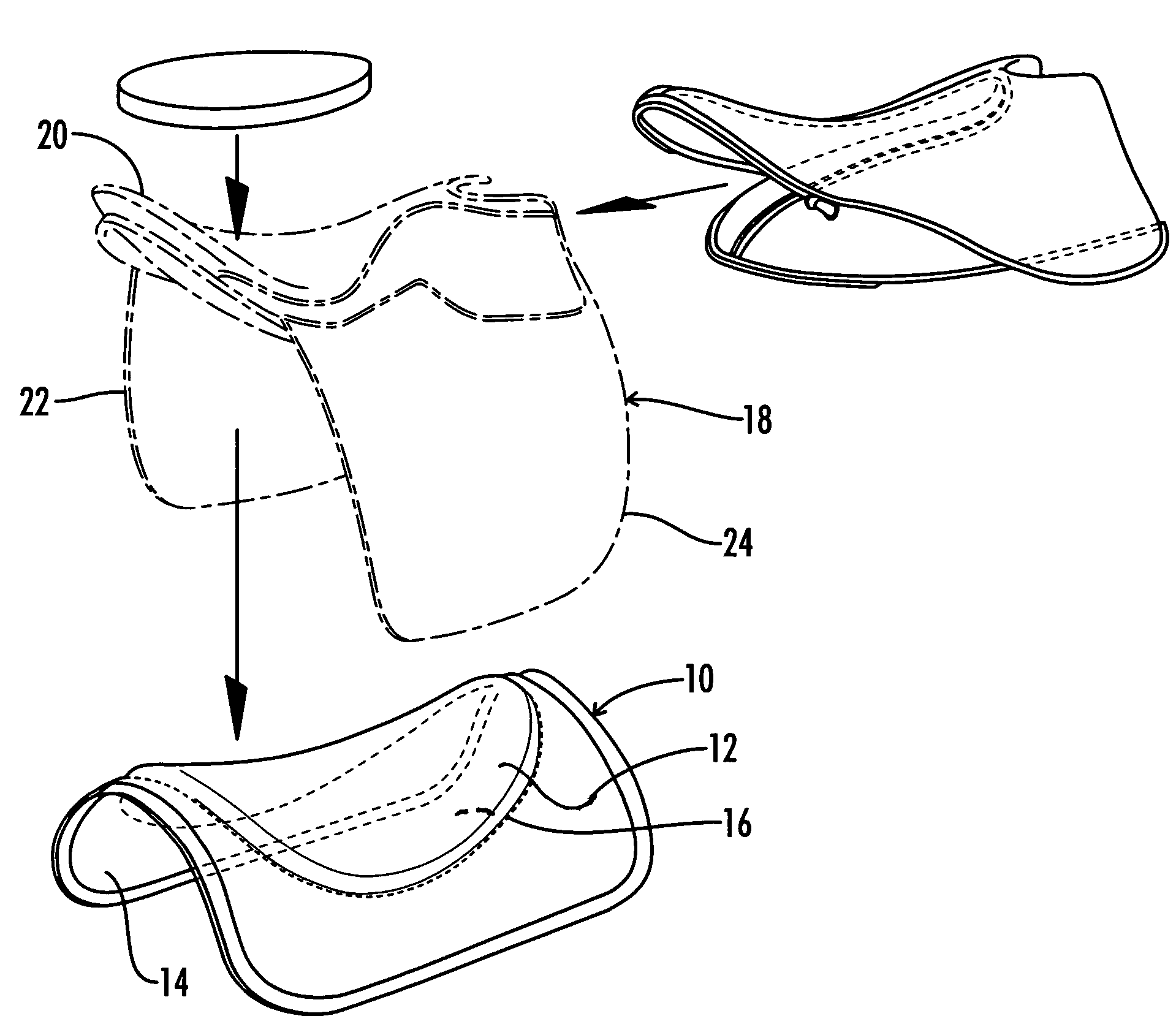

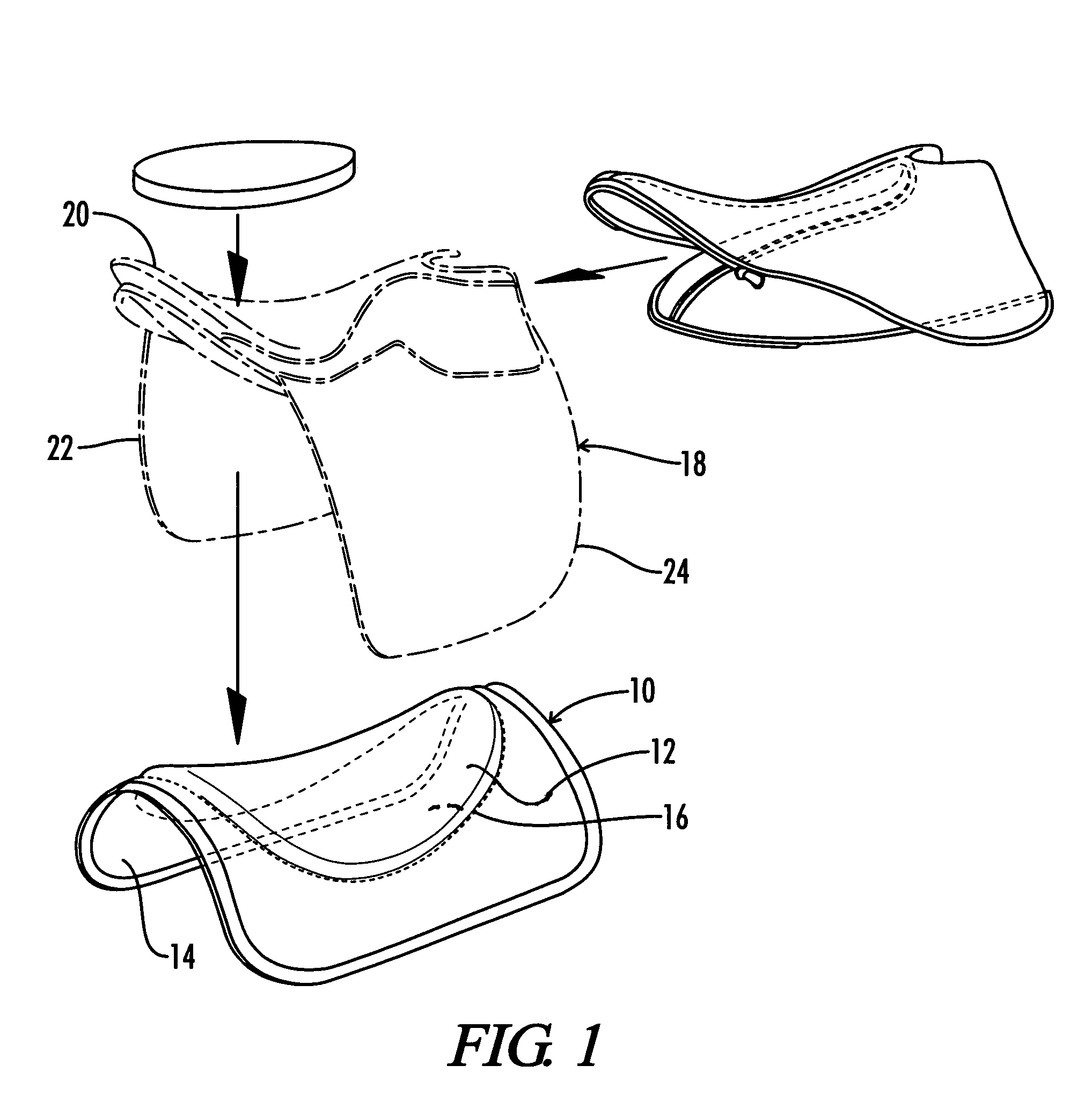

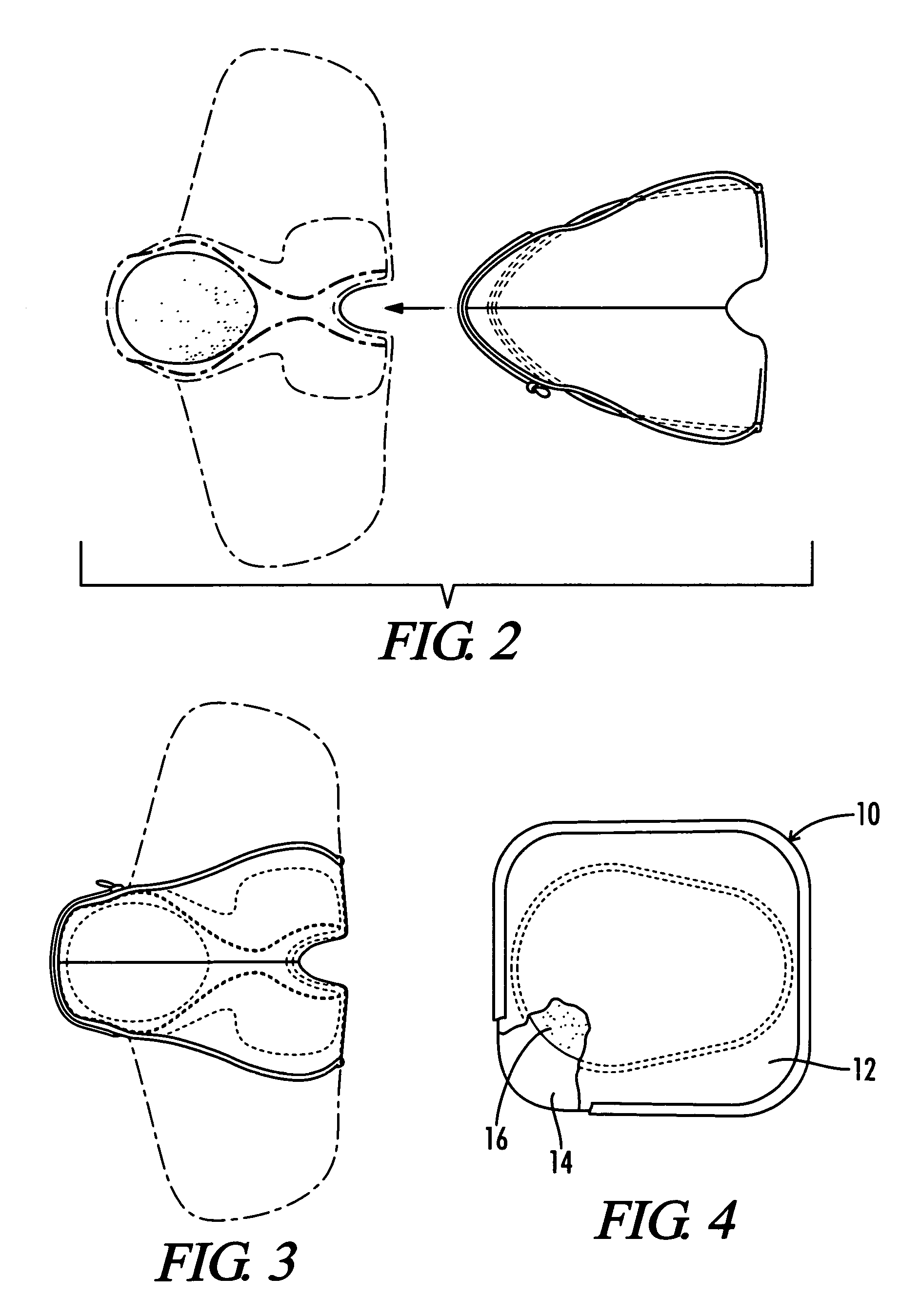

Non-slip horse saddle pad

A saddle pad apparatus constructed from a first non-slip top layer which is stitched or welded to a second non-slip bottom layer with a stiffening layer contained between the top and bottom layers. Each layer is constructed from a poly vinyl chloride impregnated scrim. Each scrim is constructed with ventilation openings to allow for proper ventilation between the load being carried and the animal. The scrims are manufactured by applying a poly vinyl chloride material onto a fiber network with fibers areas and open areas to create a scrim with appropriate stiffness, softness, and ventilation while maintaining other appropriate characteristics.

Owner:EQUI TECH LABS

Aqueous ink composition

InactiveUS20180237646A1Excellent color development and image qualityReduce viscosityDuplicating/marking methodsInksBoiling pointTitanium

An aqueous ink composition containing, at least, water, a pigment (but excluding titanium oxides in which the pigment surface has been treated with an organic compound), a pigment dispersing resin, and two or more types of alkyl polyols having boiling points of at least 180° C. but not more than 250° C. at 1 atmosphere, wherein the pigment dispersing resin has an alkyl group of 10 to 36 carbon atoms, and the total amount of the alkyl polyols, relative to the total weight of the aqueous ink composition, is at least 10% by weight but not more than 30% by weight.

Owner:TOYOCOLOR CO LTD +1

Inkjet ink and printing method using the same

InactiveUS20100110122A1Improve breathabilityKeep dryMeasurement apparatus componentsDuplicating/marking methodsProtic solventSURFACTANT BLEND

A inkjet ink and a method for printing on hydrophobic media such as offset coated media using the inkjet ink. An inkjet contains a pigment, water, a surfactant and 40 to 75 weight % of a polar non-protic solvent with a molecular weight of 40 to 130 which has permeability to a hydrophobic surface such as the coating of an offset coated medium.

Owner:GENERAL CO LTD

Inkjet ink and printing method using the same

InactiveUS20100110121A1Improve breathabilityKeep dryMeasurement apparatus componentsDuplicating/marking methodsProtic solventSURFACTANT BLEND

An inkjet ink and a method for printing on hydrophobic media such as offset coated media, using the inkjet ink, including an inkjet containing a pigment, water, a surfactant and 40 to 75 weight % of a polar non-protic solvent with a molecular weight of 40 to 130 which has permeability to a hydrophobic surface such as the coating of an offset coated medium.

Owner:GENERAL CO LTD

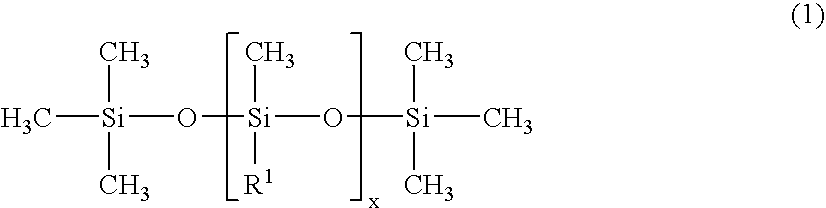

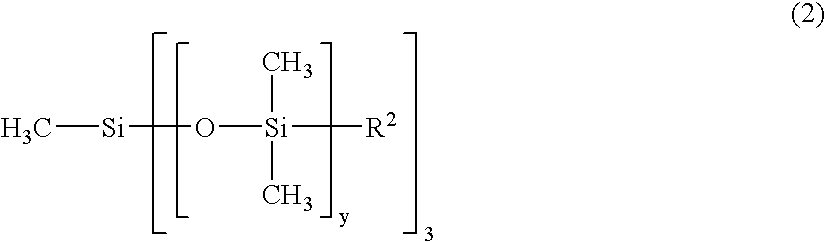

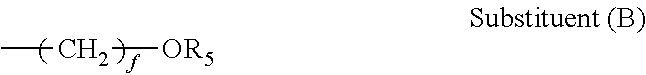

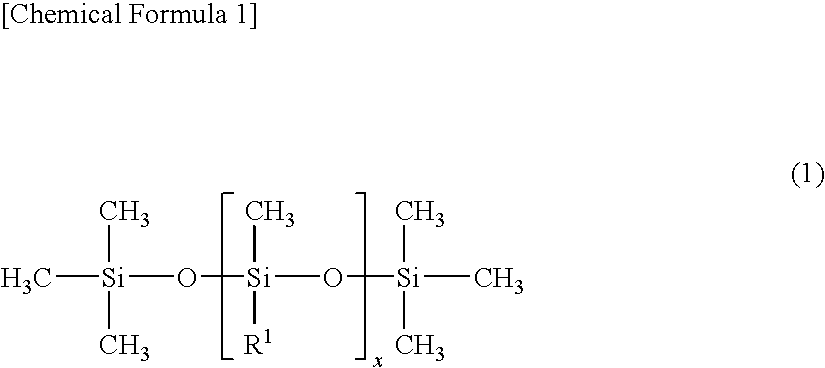

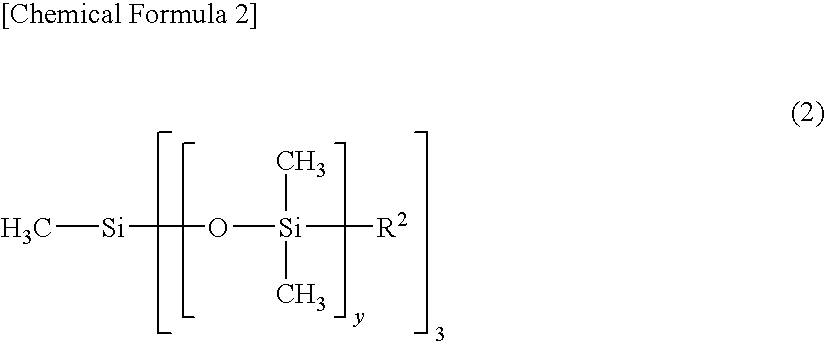

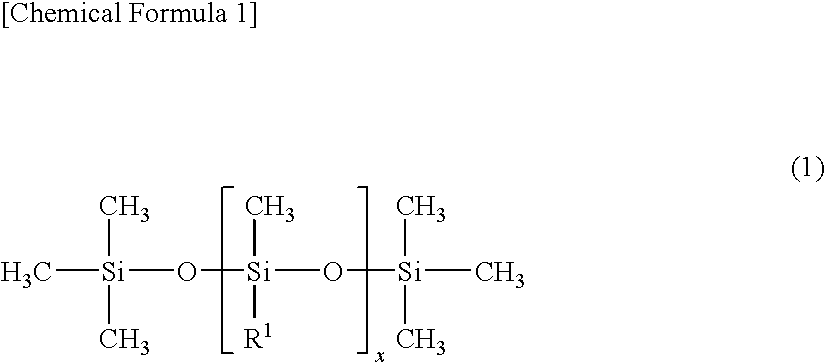

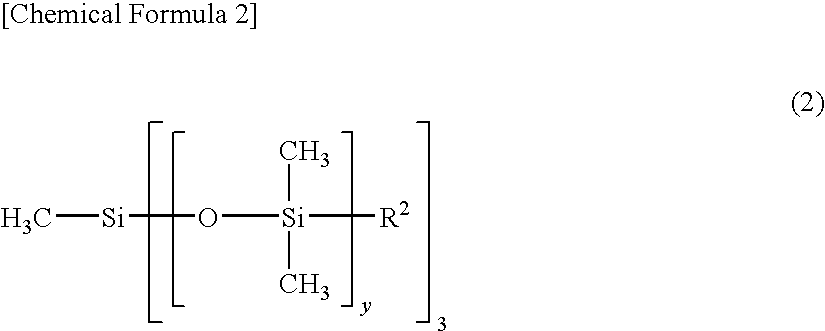

Curing composition and method for applying alkyd coating material with the same

An object of the present invention is to improve a drying property of paint in application of alkyd paint to the surface of a cured material resulting from the curable composition containing an oxyalkylene polymer having at least one silicon-containing functional group capable of cross-linking by formation of at least one siloxane bond, and to provide a composition that contains an oxyalkylene polymer (A) having at least one silicon-containing functional group capable of cross-linking by formation of at least one siloxane bond and 2,6-di-t-butylhydroxytoluene wherein the content of the above-described 2,6-di-t-butylhydroxytoluene is 350 ppm or less relative to the above-described polymer (A).

Owner:KANEKA CORP

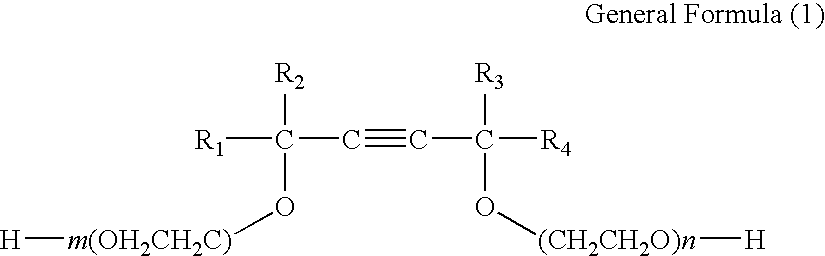

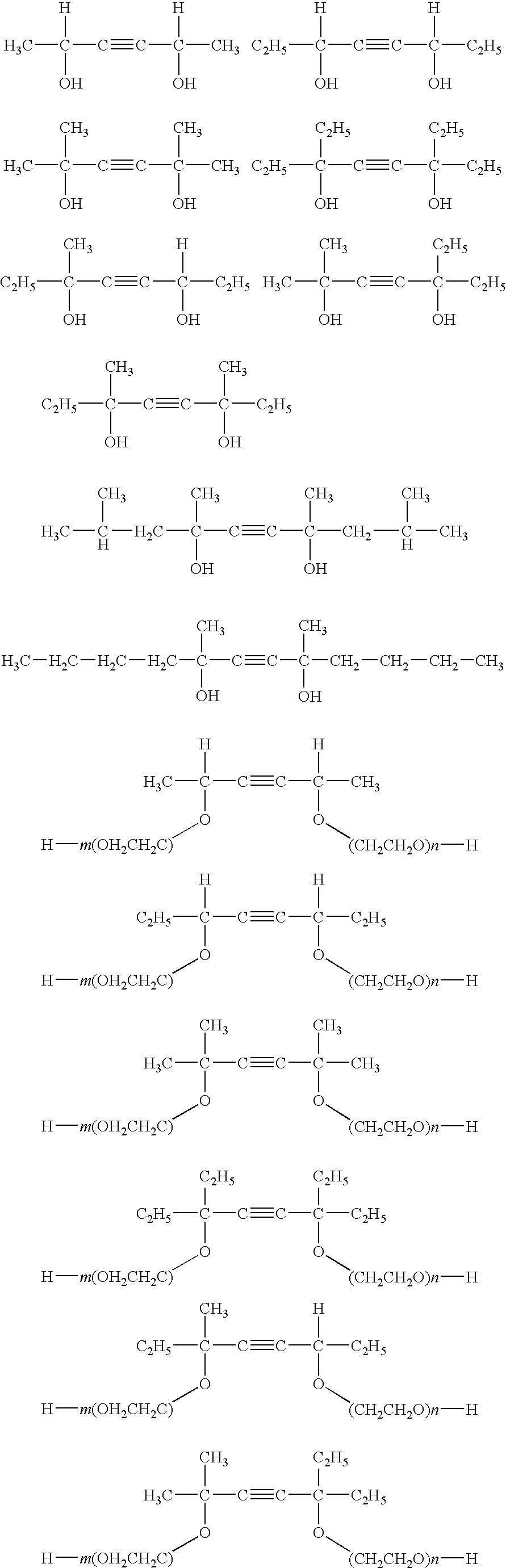

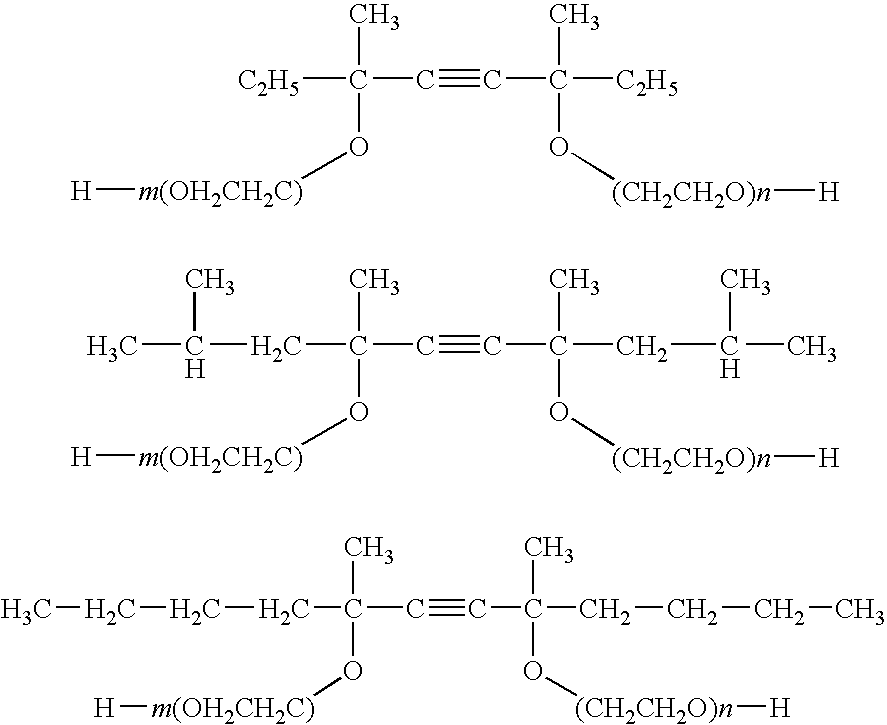

Ink composition, ink set and recording method

InactiveUS7540910B2Drying property of imageDeterioration can be suppressedMeasurement apparatus componentsDuplicating/marking methodsEthylene oxideDiol

An ink composition includes: a coloring material having an azo group bound to a heterocyclic group; an aqueous medium; and at least one of an acetylene diol and an ethylene oxide adduct of the acetylene diol, wherein an average value of an addition molar number of the at least one of the acetylene diol and the ethylene oxide adduct of the acetylene diol is 0 or more and less than 4.

Owner:FUJIFILM HLDG CORP +1

Slow-curing, quick-drying aqueous paint usable in combination with oil-based paint

InactiveUS20090163644A1Improve liquidityReduce defectsArtist's paintsEmulsion paintsWater dispersibleBULK ACTIVE INGREDIENT

A paint which can be used in combination with either an aqueous paint or an oil-based paint, and which has a quick-drying property and a slow-curing property may comprise a water-dispersible acryl-modified alkyd resin as an active ingredient. The paint may comprise a water-dispersible acryl-modified alkyd resin and a water-dispersible polymer as active ingredients. The paint may comprise a water-dispersible acryl-modified alkyd resin and a surfactant as active ingredients. The paint may comprise a water-dispersible acryl-modified alkyd resin, a pigment, an extender pigment, a surfactant and water as active ingredients.

Owner:KUSAKABE

Aqueous polyurethane resin dispersion and process for preparing the same

An object of this invention is to obtain an aqueous polyurethane resin dispersion having excellent drying property, which can provide a coating film having high hardness. The aqueous polyurethane resin dispersion comprises a polyurethane resin obtained by reacting (a) a polyol compound, (b) a polyisocyanate compound, (c) an acidic group-containing polyol compound and (d) a chain-elongating agent, which is being dispersed in an aqueous medium, wherein the above-mentioned (a) polyol compound contains at least (a1) a polycarbonate polyol having an alicyclic structure at the main chain and (a2) a polymer polyol having a number average molecular weight of 500 to 5000 and having no alicyclic structure.

Owner:UBE IND LTD

Pretreatment liquid and ink set

ActiveUS20210130639A1Improve adhesionImprove the immunityDuplicating/marking methodsInksPolymer scienceActive agent

A pretreatment liquid that is used together with an aqueous inkjet ink containing a pigment and water, wherein the pretreatment liquid contains resin microparticles (A), a surfactant (B), a coagulant (C) and water, the surfactant (B) contains a polyoxyalkylene alkyl ether (b-1), and the coagulant (C) contains a polyvalent metal salt and / or a cationic polymer compound and has a water absorptivity at a temperature of 40° C. and a relative humidity of 80% of 75% by mass or less.

Owner:TOYOCOLOR CO LTD +1

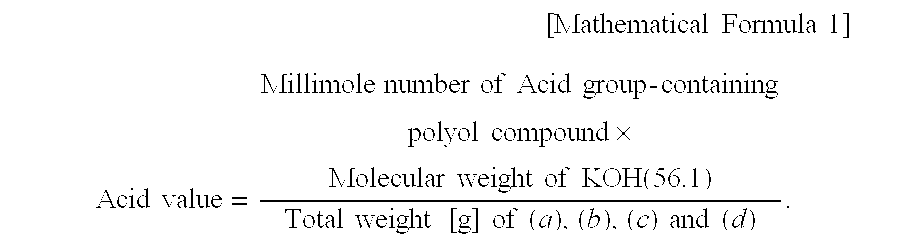

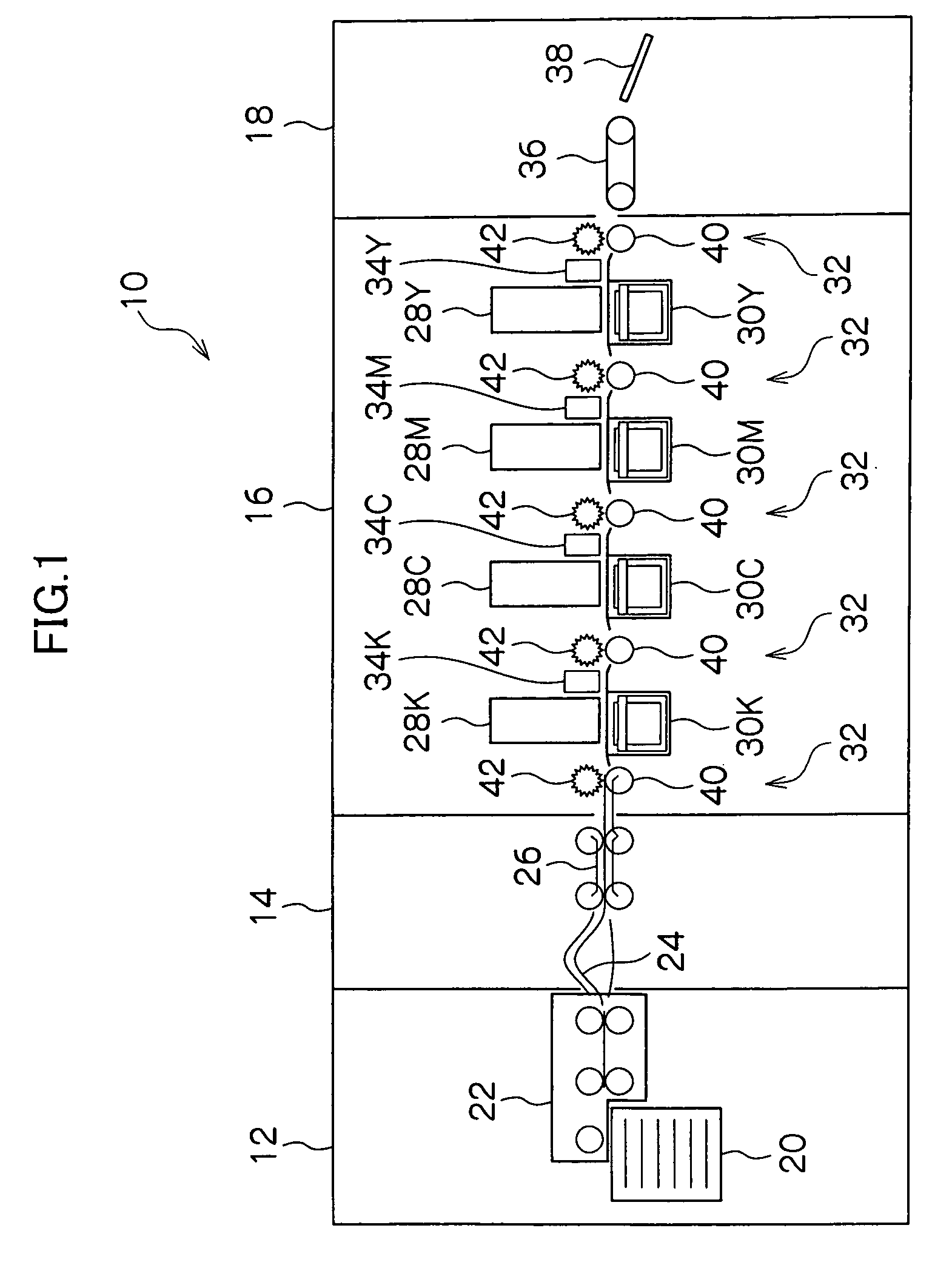

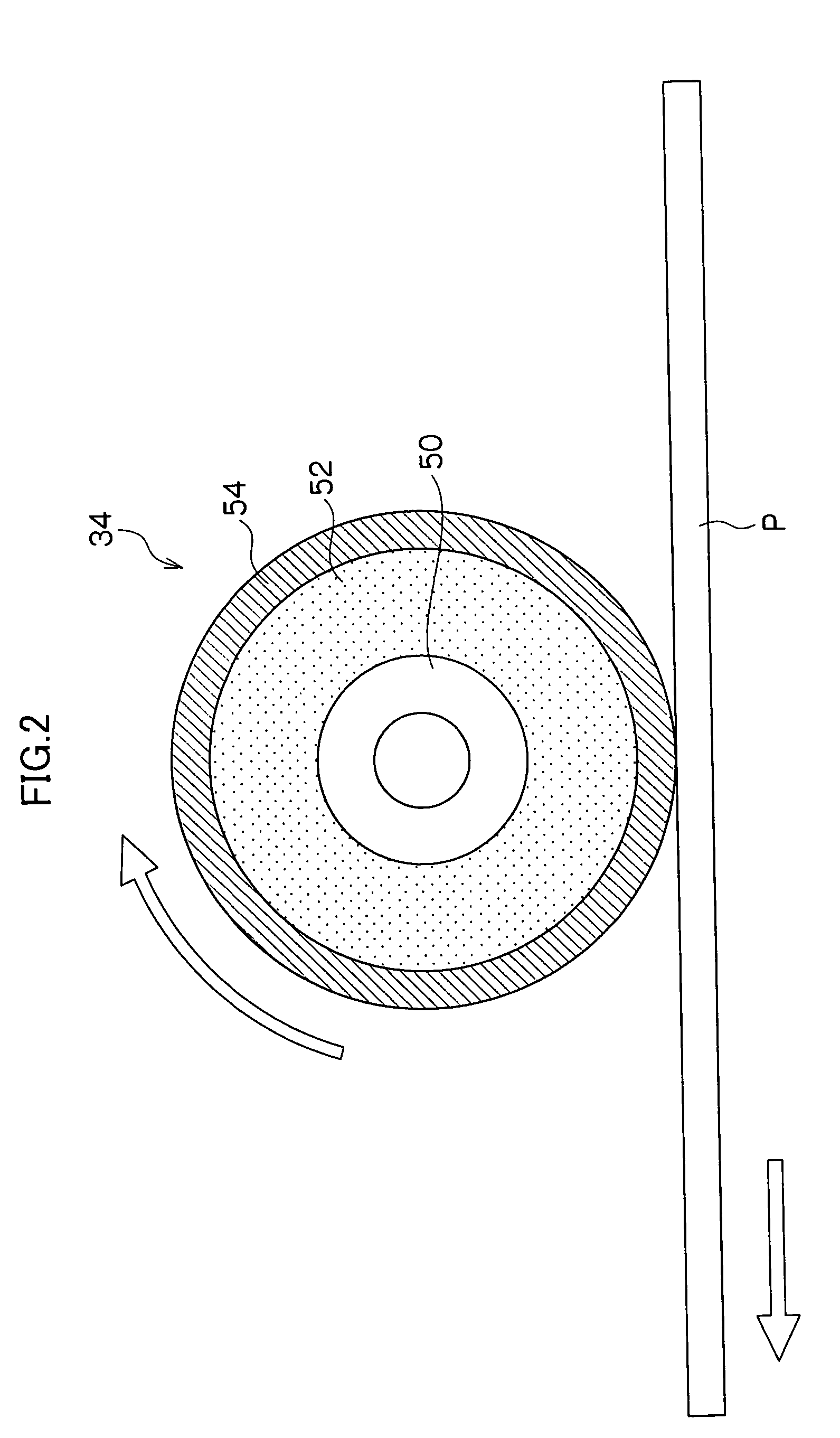

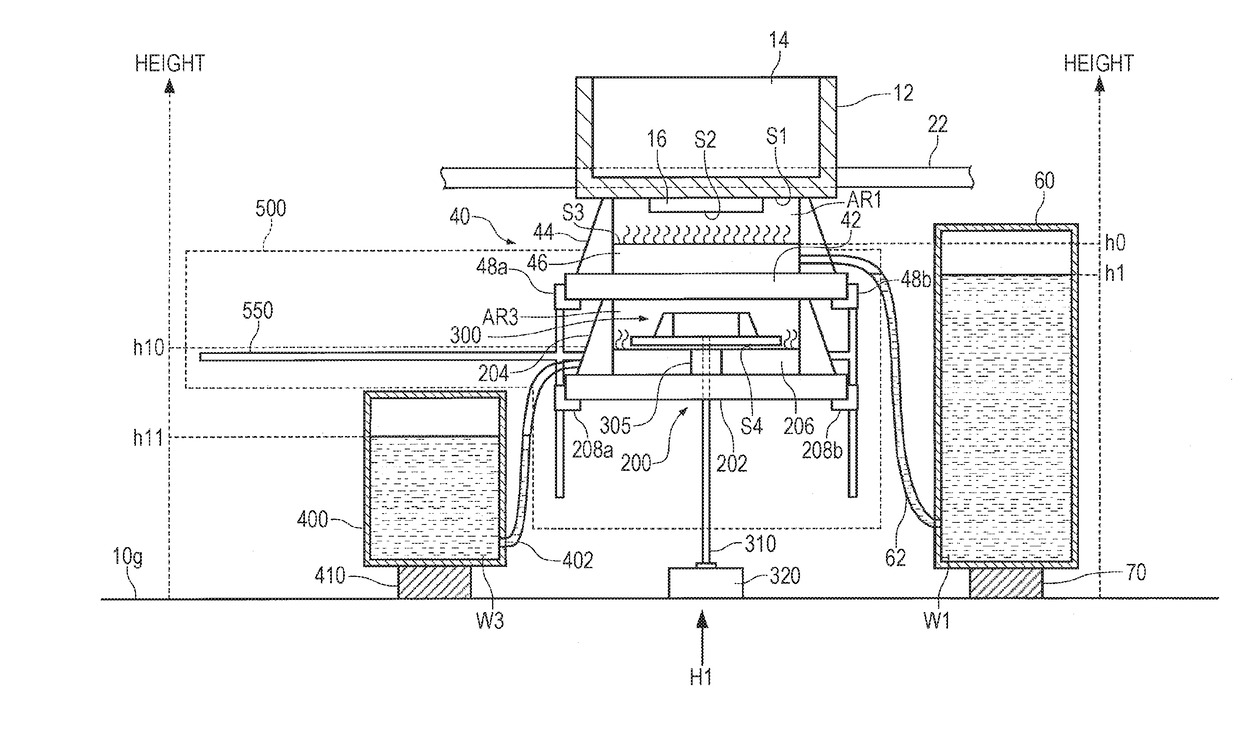

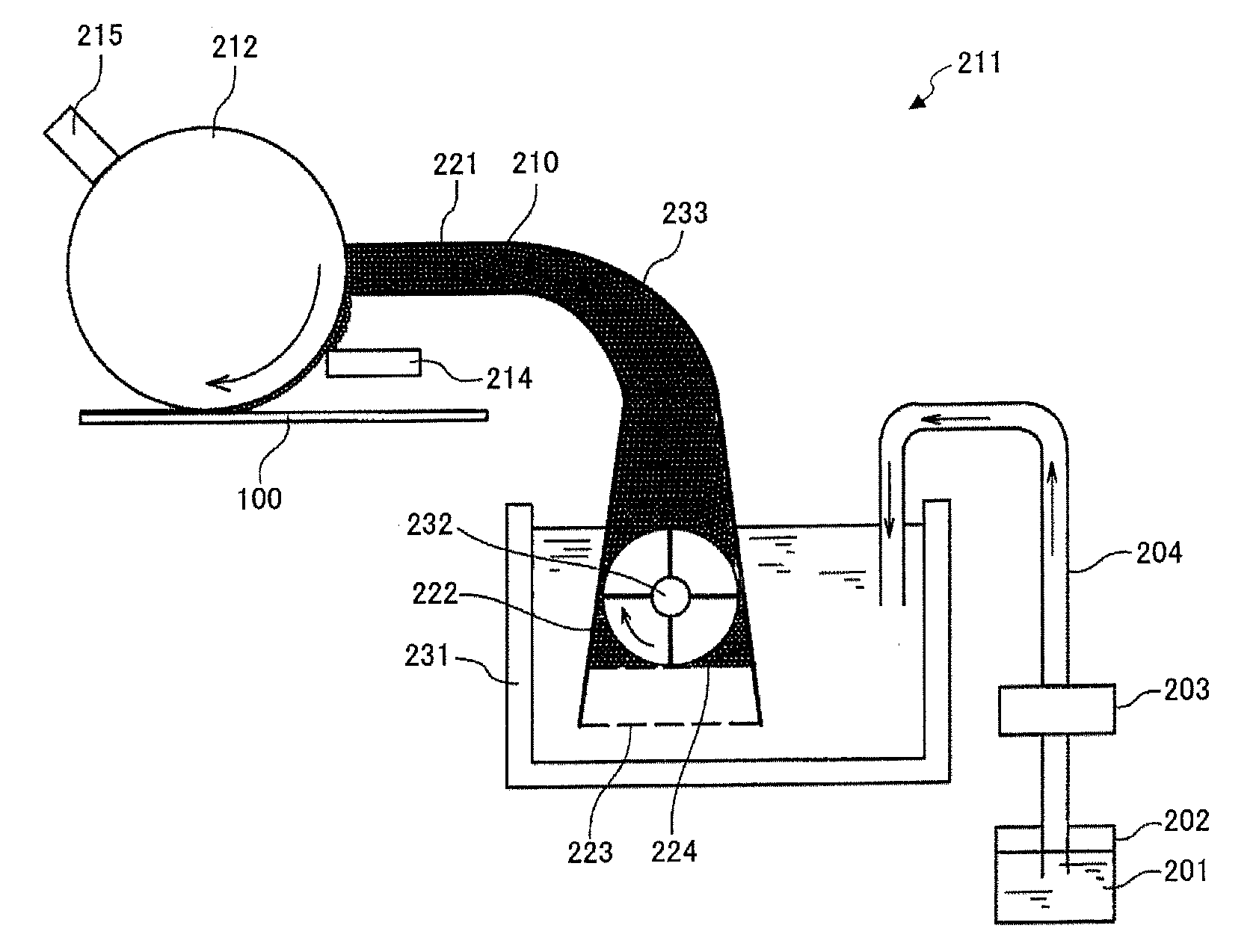

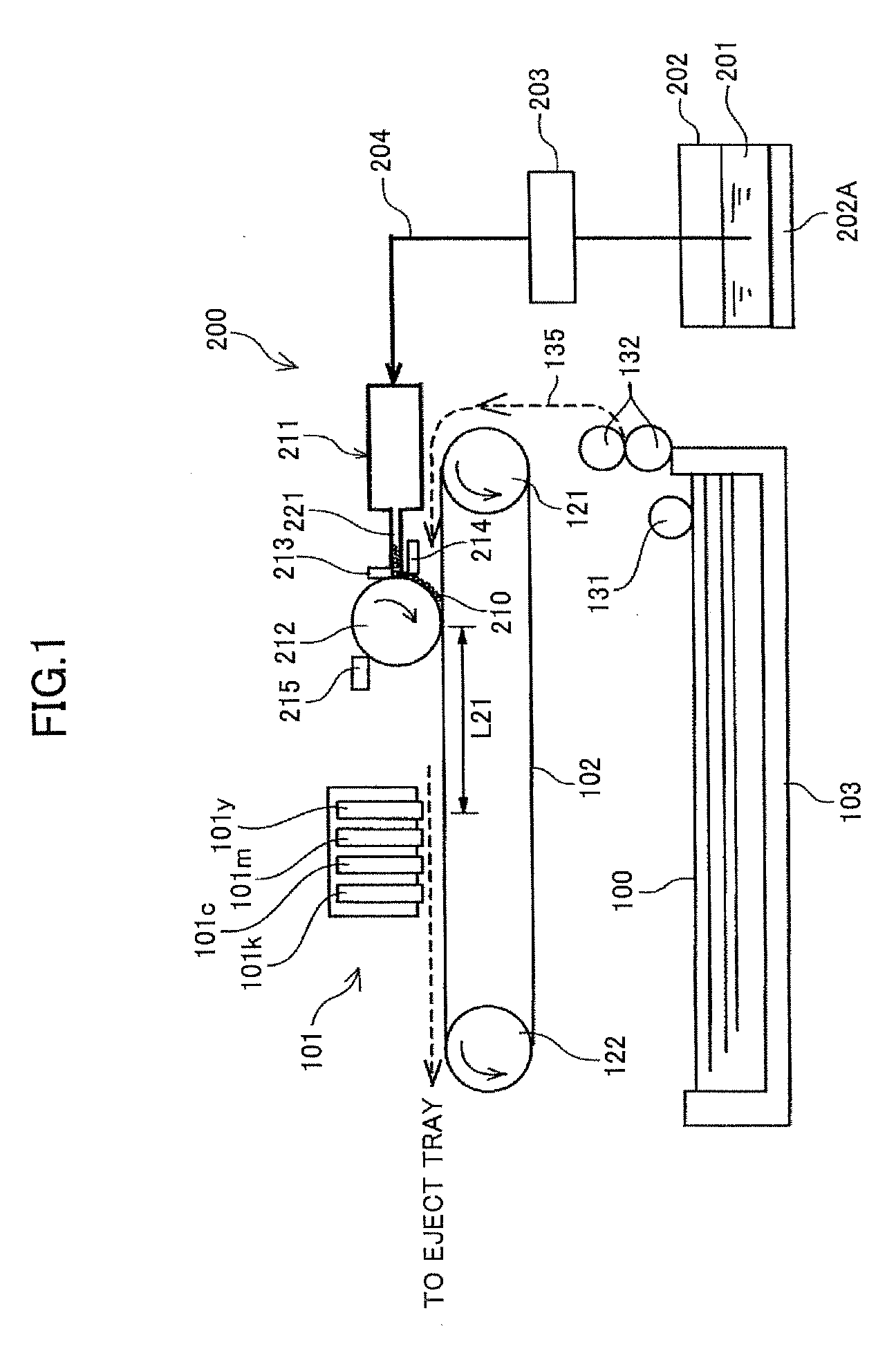

Image forming apparatus and apparatus for coating foam on coating target member

InactiveUS20100218718A1Improve drying propertyUniform coatingLiquid surface applicatorsElectrographic process apparatusImaging equipmentMechanical engineering

An image forming apparatus includes a generating mechanism to generate foam from a liquid or gel which may take a foam state, a coating roller having a peripheral surface supplied with the foam to coat the foam on the peripheral surface onto a surface of a recording medium, and a transport passage to transport the foam from the generating mechanism to the coating roller by an accumulation force of the foam.

Owner:RICOH KK

Water-based ink composition for ballpoint pen and water-based ballpoint pen using the same

ActiveUS20200248019A1No blurring and line splittingAvoid bleedingInksBall-point pensOrganic chemistryColoring agents

The present invention provides a water-based ink composition for a ballpoint pen that is less likely to cause bleeding of a written trace in writing, provides a favorable written trace without causing no blurring or line splitting, and excels in the storage stability of the ink composition; and a water-based ballpoint pen using the ink composition.A water-based ink composition for a ballpoint pen comprising water, a coloring agent, a copolymer having a specific structure; and a water-based ballpoint pen using the ink composition.

Owner:PILOT PEN CO LTD

Water-Based Ink for Ink-Jet Recording, Ink Cartridge and Method for Producing Water-Based Ink for Ink-Jet Recording

A water-based ink for ink-jet recording contains a water-soluble colorant; water; and a water-insoluble liquid which is dispersed in the water and of which boiling point is not less than 250 degrees Celsius. The water-based ink may further contain a surfactant. The drying property of the water-based ink is improved and any odor can be lowered.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com