Inkjet ink and printing method using the same

a technology of inkjet ink and printing method, which is applied in the field of inkjet ink, can solve the problems of inability to print with clear edges, inkjet ink is repelled by or bleeds on the coating surface, and the offset coated media that is suitable for offset printing is not suited for printing using aqueous inkjet ink, so as to improve the drying property, increase the permeability into the coating, and improve the drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Manufacture of the Inkjet Ink

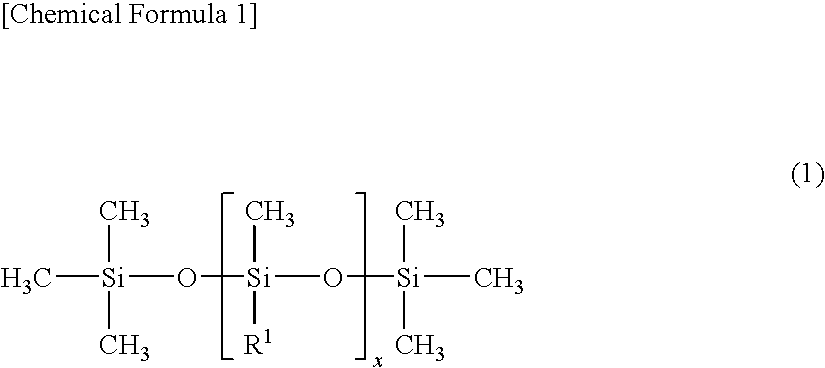

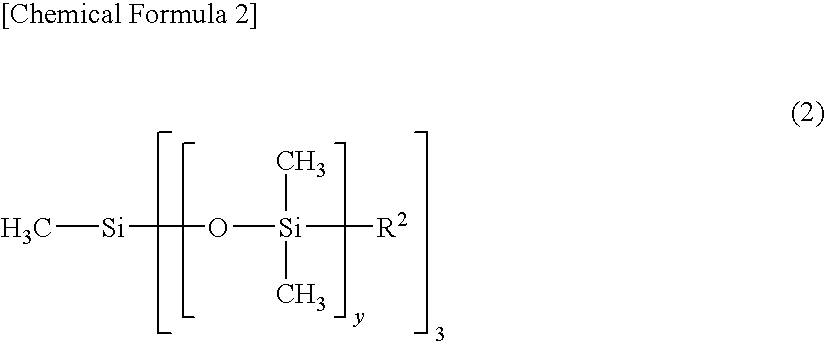

[0099]A carbon black dispersion [Cabojet 300, manufactured by Cabot Corporation, carboxylic group modified, aqueous dispersion, 15 weight % of solids] was used as the pigment, and 1,3-dimethyl-2-imidazolidinone [molecular weight: 114.2, boiling point: 225.5° C.] was used as the polar aprotic solvent. A silicone-based surfactant [Olfine PD-501, manufactured by Nissin Chemical Industry Co., Ltd., dynamic contact angle at 23° C.: 16.1°] was used as the surfactant, and an ethylene oxide adduct of sodium citrate with which the p in the Formula (4) is 6 and all of M1 to M3 are sodium was used as the ethylene oxide adduct of organic acid.

[0100]As the binder resin, an alkali-soluble acrylic resin [NeoCryl B-817, manufactured by Avecia Limited, weight average molecular weight Mw: 23,000] was used, and as the basic substance for dissolving the binder resin in the inkjet ink, 2-amino-2-methyl-1-propanol was used. As the polyoxyethylene phenyl ether, the compound ex...

examples 2 to 8

[0102]In place of 1,3-dimethyl-2-imidazolidinone, except using the same amounts of N-methyl-2-pyrrolidone [molecular weight: 99.1, boiling point: 202° C.] (Example 2), 2-pyrrolidone [molecular weight: 85.1, boiling point: 245° C.] (Example 3), formamide [molecular weight: 45.0, boiling point: 210° C.] (Example 4), N-methylformamide [molecular weight: 59.1, boiling point: 197° C.] (Example 5), N,N-dimethylformamide [molecular weight: 73.1, boiling point: 153° C.] (Example 6), N,N-diethylpropionamide [molecular weight: 129.2, boiling point: 195° C.] (Example 7), and γ-butyrolactone [molecular weight: 86.1, boiling point: 204° C.] (Example 8) as the polar aprotic solvents, inkjet inks were manufactured in the same manner as in Example 1.

example 9

[0103]Except setting the amount of the 1,3-dimethyl-2-imidazolidinone as the polar aprotic solvent to 40 parts by weight, the amount of the silicone-based surfactant to 0.7 parts by weight, the ratio P / S of the two components to 57 / 1, and the amount of the ion-exchanged water to 38.4 parts by weight, an inkjet ink was manufactured in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| dynamic contact angle | aaaaa | aaaaa |

| hydrophobic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com