Automobile tail gas exhaust device and method for exhausting automobile tail gas

A technology of automobile exhaust and exhaust device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention may be embodied in several forms without departing from the spirit or essential characteristics of the invention. The scope of the invention is determined by the appended claims rather than by the detailed description. All embodiments that come within the intent and range of equivalent features of the claims are therefore to be embraced by the claims.

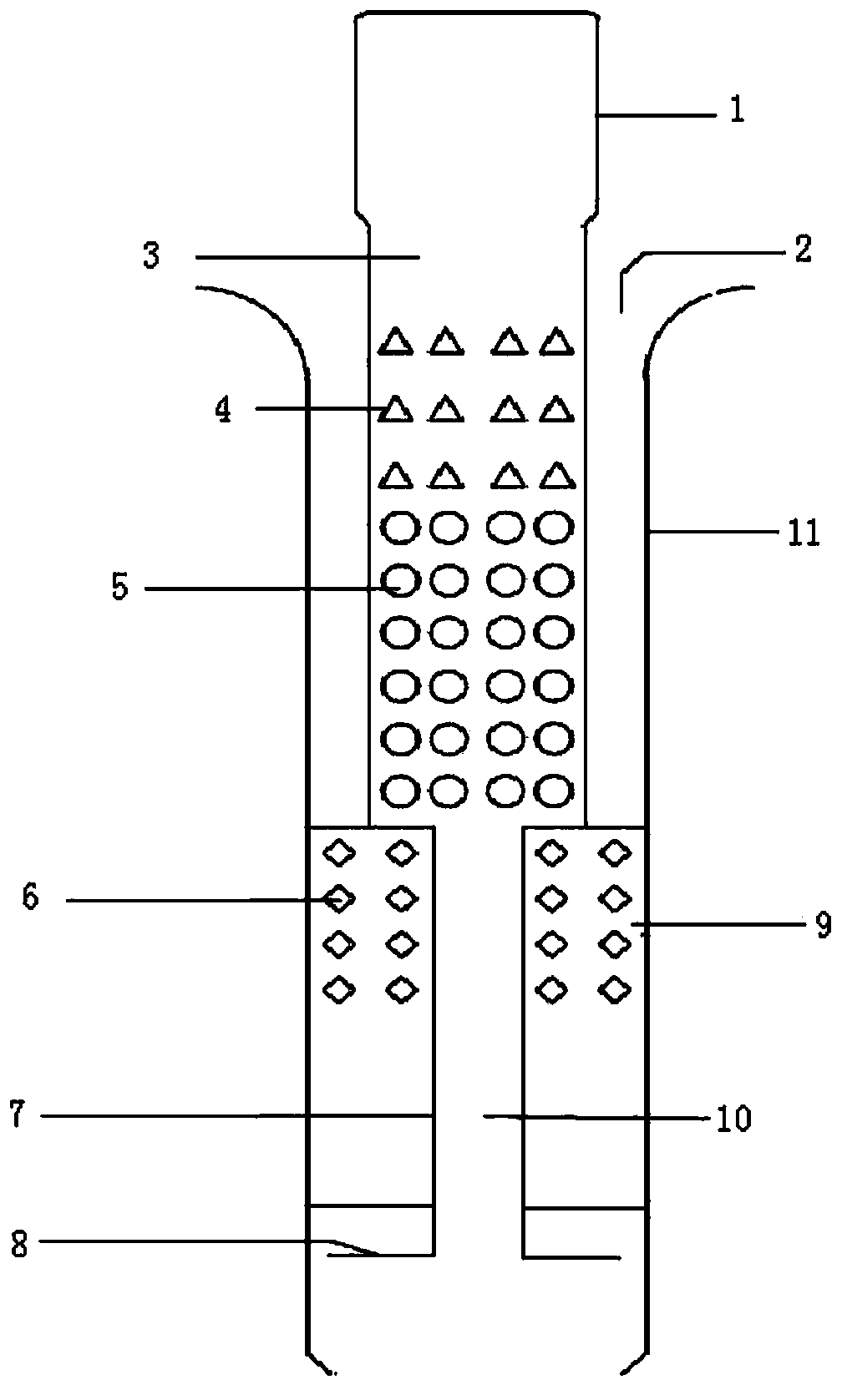

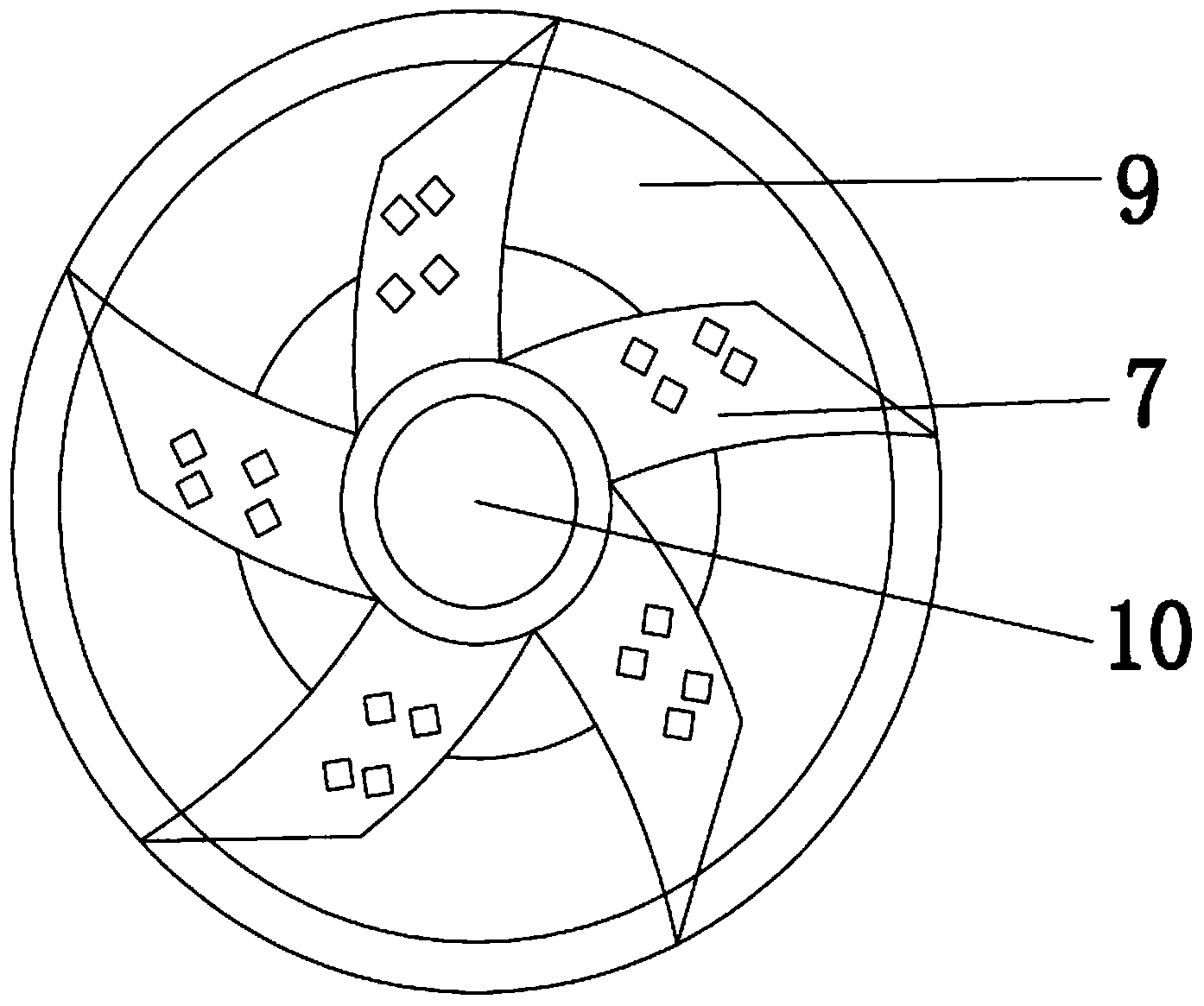

[0026] figure 1 An embodiment of a vehicle exhaust system according to the invention is shown. The connecting body (1) is used to connect the exhaust pipe of the automobile exhaust, and its function is to introduce the exhaust gas of the automobile. The porous honeycomb shunt muffler 3 is sealed and connected with the connector 1, and is mainly used to shunt the imported automobile exhaust gas. Through the wedge-shaped guide port 4 provided on the diverter muffler 3, the automobile exhaust gas can be directed to flow out; and the diverter muffler 3 is also provided with a circular air outlet 5, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com