Powder cosmetic material

A technology of cosmetics and powders, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as agglomeration and difficulty in use, and achieve the effect of good makeup retention and good pick-up characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Hereinafter, examples are given to describe the present invention in detail, but the present invention is not limited by these examples.

reference example 1

[0054] Preparation of flat cellulose particles (1):

[0055] Refined wood pulp-derived cellulose powder (NIPPON PAPER Chemicals: KCFLOCK W-400 (water content in air-dried state: 7%)) was dried under reduced pressure at 40° C., and the adsorbed moisture was sufficiently removed to make it 0.1% or less. 49 g of this cellulose powder was put into a sealable zirconia grinding container (500 ml in volume) together with grinding balls made of zirconia (diameter: 20 mm), and stearic acid was added to make it 2%.

[0056] Thereafter, the pulverization container was set in a planetary ball mill (Germany Fritsch: P-5 type), and pulverization was performed by continuously repeating 72 cycles of rotation pulverization for 10 minutes to pause for 10 minutes. The rotation speed at this time was set to 200 rpm (grinding energy of about 10G (gravitational acceleration)). The pulverized product is obtained in the form of powder.

[0057] The powder was dispersed in water in a flow cell, an...

Embodiment 1

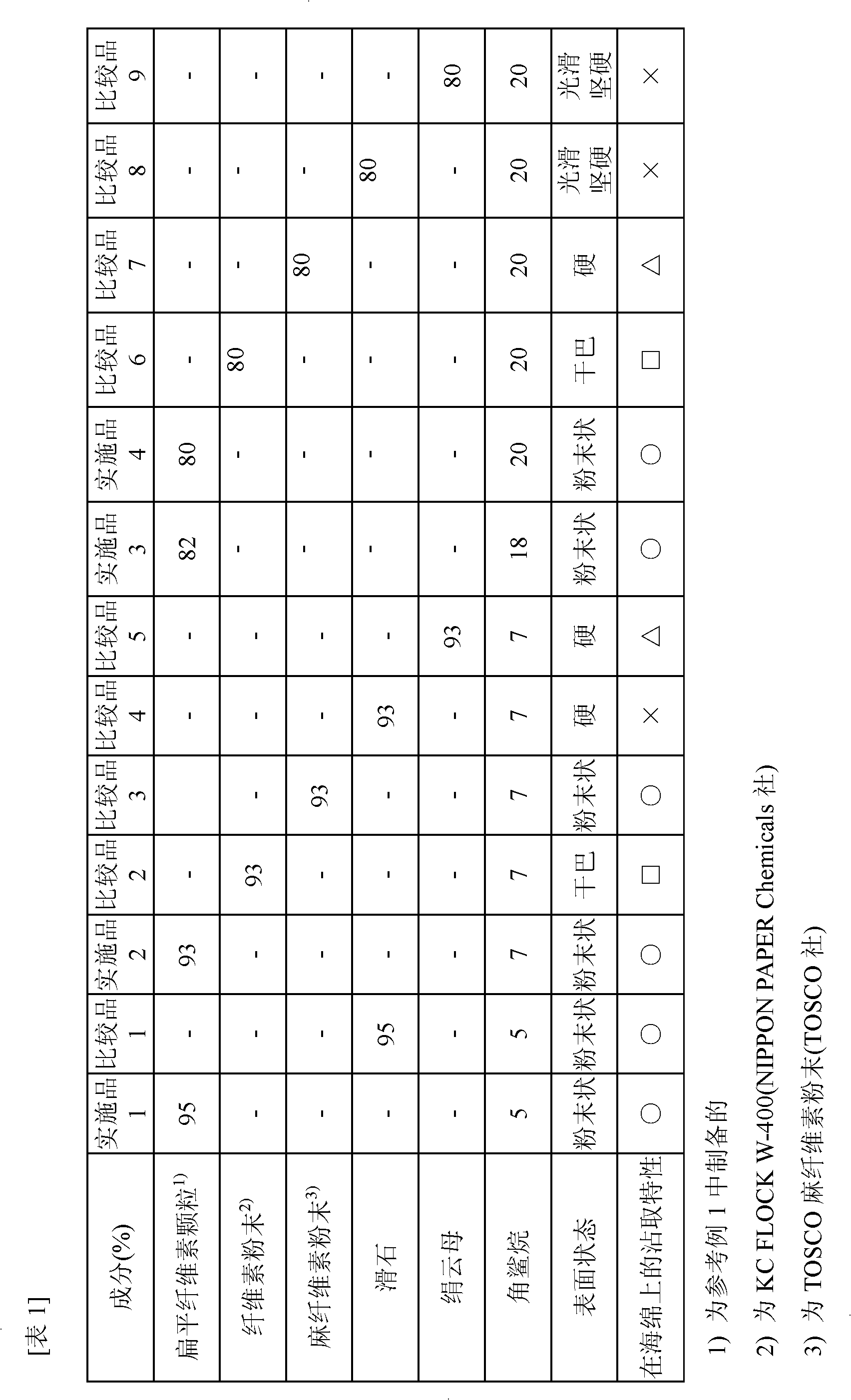

[0069] Comparison with solid substances formed by oil agents (1):

[0070] According to the formulation in Table 1, the flat cellulose particles, cellulose powder, hemp cellulose powder (TOSCO Corporation: TOSCO hemp cellulose powder), talc or sericite prepared in Reference Example 1 were uniformly mixed with the oily component (squalane) Mix, press fill in metal molds to make solid mass. The surface state of the solid matter was visually evaluated, and the pick-up property on the sponge was evaluated according to the following evaluation criteria. Their results are listed in Table 1.

[0071]

[0072]

[0073] (comment content)

[0074] ○: Good pick-up (no lumps even if soaked repeatedly with a sponge)

[0075] ×: Unable to pick up (just rubbing the surface with a sponge 3 to 4 times will cause agglomeration and cannot be picked up)

[0076] △: Difficult to pick up (although not as hard to pick up as when using talc, but firm and hard to pick up)

[0077] □: Excessi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com