Anti-pollution photocatalytic degradation blended membrane

A technology of blended membrane and photocatalysis, which is applied in the direction of water pollutants, membrane, membrane technology, etc., can solve the problems of PVDF membrane strength, poor anti-pollution, small addition of inorganic nanoparticles, and reduced stability of casting solution. , to achieve the effects of easy large-scale processing, improved blending stability, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

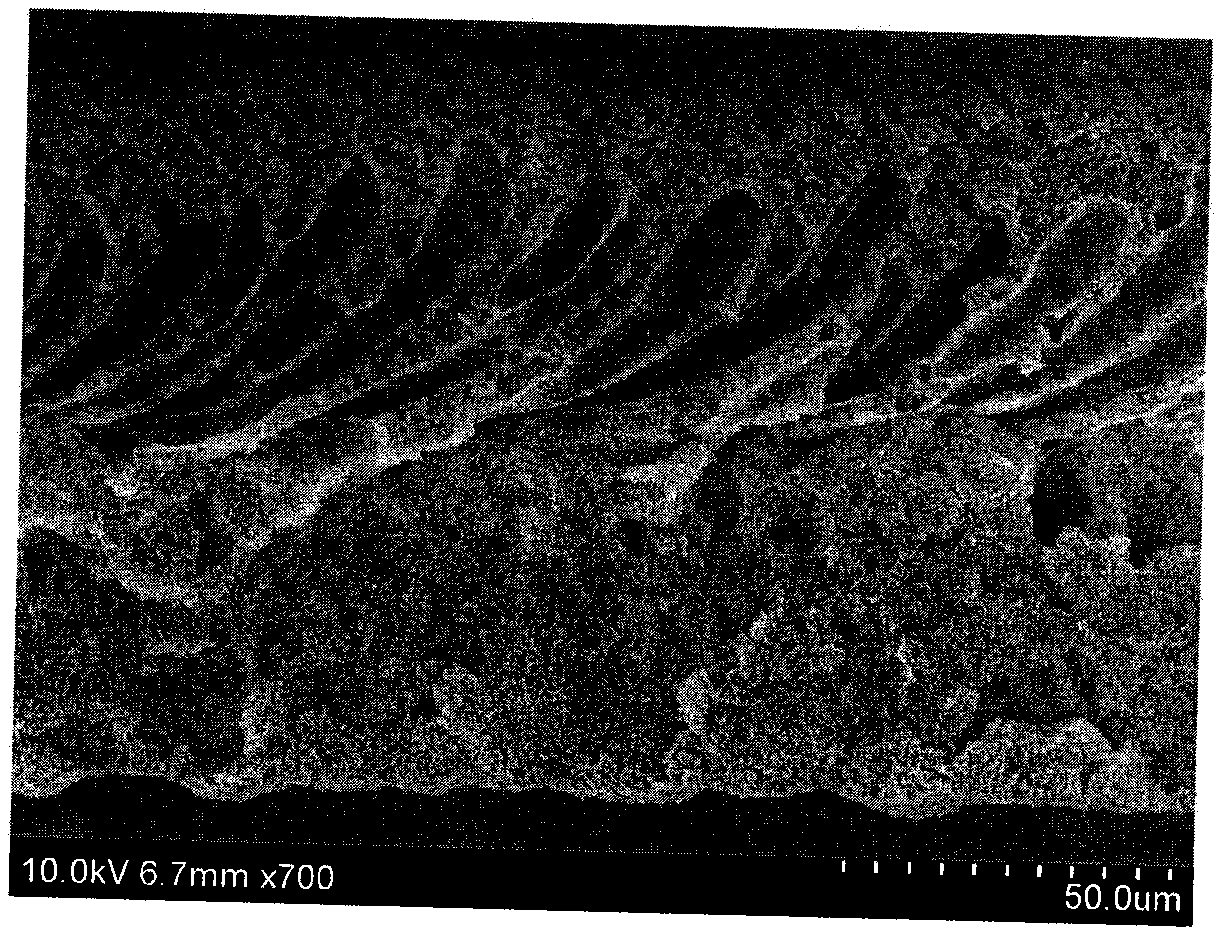

[0028] This example shows a MWCNTS-ZnO / PVDF blend membrane with high hydrophilic self-cleaning properties. The specific implementation steps are as follows:

[0029] (1) Dissolve PVDF in TEP at 180°C to form a PVDF casting solution;

[0030] (2) adding zinc oxide (ZnO) and carboxylated carbon nanotubes (MWCNTS) into the diluent respectively and performing ultrasonic treatment for 30min to obtain MWCNTS mixed solution (A) and ZnO mixed solution (B);

[0031] (3) Add A and B in turn to the PVDF casting solution and stir for 6 hours;

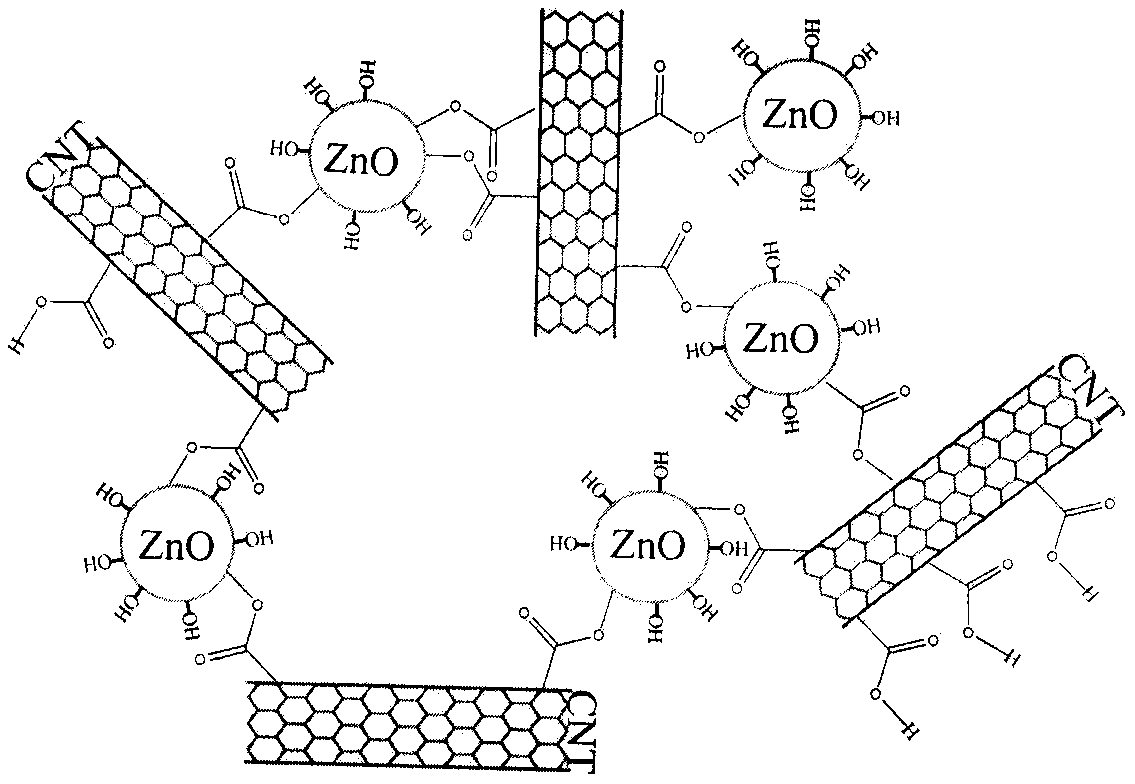

[0032] (4) In PVDF casting solution, MWCNTS and ZnO react to obtain MWCNTS-ZnO composite;

[0033] (5) Scrape-coat the casting solution obtained in step (4) on a glass plate under an atmosphere of 190° C.;

[0034] (6) Put the glass plate with the casting solution obtained in step (5) into a water coagulation bath at 0° C. and prepare the MWCNTS-ZnO / PVDF blend film by thermal phase inversion method;

[0035] (7) Measure the MWCNTS-ZnO / PVDF blend...

Embodiment 2

[0039] This example shows a MWCNTS-ZnO / PVDF blend membrane with high hydrophilic self-cleaning properties. The specific implementation steps are as follows:

[0040] (1) Dissolve PVDF in TEP at 190°C to form a PVDF casting solution;

[0041] (2) adding zinc oxide (ZnO) and carboxylated carbon nanotubes (MWCNTS) into the diluent respectively and performing ultrasonic treatment for 30min to obtain MWCNTS mixed solution (A) and ZnO mixed solution (B);

[0042] (3) Add A and B in turn to the PVDF casting solution and stir for 6 hours;

[0043] (4) In PVDF casting solution, MWCNTS and ZnO react to obtain MWCNTS-ZnO composite;

[0044] (5) Scrape-coat the casting solution obtained in step (4) on a glass plate under an atmosphere of 200° C.;

[0045] (6) Put the glass plate with the casting liquid that step (5) obtains into the water coagulation bath of 40 DEG C and prepare MWCNTS-ZnO / PVDF blend film by thermal phase inversion method;

[0046] (7) Measure the MWCNTS-ZnO / PVDF blend...

Embodiment 3

[0050] This example shows a MWCNTS-ZnO / PVDF blend membrane with high hydrophilic self-cleaning properties. The specific implementation steps are as follows:

[0051] (1) Dissolve PVDF in TEP at 200°C to form a PVDF casting solution;

[0052] (2) adding zinc oxide (ZnO) and carboxylated carbon nanotubes (MWCNTS) into the diluent respectively and performing ultrasonic treatment for 30min to obtain MWCNTS mixed solution (A) and ZnO mixed solution (B);

[0053] (3) Add A and B in turn to the PVDF casting solution and stir for 6 hours;

[0054] (4) In PVDF casting solution, MWCNTS and ZnO react to obtain MWCNTS-ZnO composite;

[0055](5) The casting solution obtained in step (4) is scraped and coated on a glass plate under an atmosphere of 210° C.;

[0056] (6) Put the glass plate with the casting liquid that step (5) obtains into the water coagulation bath of 80 DEG C and prepare the MWCNTS-ZnO / PVDF blend film by thermal phase inversion method;

[0057] (7) Measure the MWCNTS-Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com