Bacterium agent for fermentation treatment of waste organic matters and preparation method

A technology of organic substances and fermentation bacteria, which is applied in the direction of organic fertilizers, bacteria, fungi, etc., can solve problems such as unsatisfactory, affecting the activity of fermentation bacteria, reducing fermentation efficiency, etc., to reduce the amount of oxygen mixed, promote the growth of bacterial micelles, The effect of prolonging the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

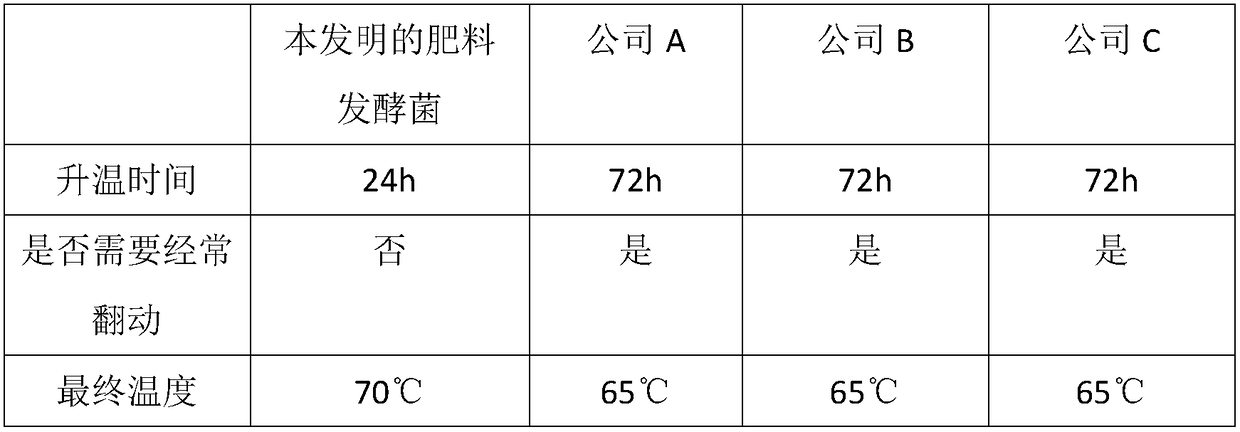

Image

Examples

preparation example Construction

[0024] A method for preparing an inoculant for fermentation treatment of waste organic matter, comprising the steps of:

[0025] A. Preparation of sterilized culture solution: After mixing beef extract, peptone, glucose and sodium chloride with 1.2-1.8 parts of distilled water, adjust the pH value to 7-8, and sterilize to obtain a sterilized culture solution;

[0026] B. Preparation of liquid bacteria: mix sterilized culture fluid, egg white, sheep serum, brown sugar, metabolites of photosynthetic bacteria, metabolites of saccharomyces and EM bacteria, and ferment to obtain liquid bacteria;

[0027] One embodiment further includes step C: C, preparing the fertilizer fermentation bacteria: spraying the liquid bacteria evenly on the surface of the carrier to obtain the fertilizer fermentation bacteria.

[0028] Further, the step C also includes step S: S, preparation of carrier: after mixing soybean meal, corn flour, wheat bran, malt powder, stale rice and old noodles, steaming,...

Embodiment 1

[0036] A bacterial agent for the fermentation treatment of waste organic matter, including a liquid bacterial agent; the liquid bacterial agent includes the following components in parts by weight: 0.005 parts of beef extract, 0.02 parts of peptone, 0.04 parts of glucose, and 0.002 parts of sodium chloride , 101.2 parts of distilled water, 2 parts of egg whites, 0.05 parts of sheep serum, 2 parts of brown sugar, 0.02 parts of metabolites of photosynthetic bacteria, 0.02 parts of metabolites of yeasts, and 0.2 parts of EM bacteria.

[0037] A method for preparing an inoculant for fermentation treatment of waste organic matter, comprising the steps of:

[0038] A, preparation of sterilized culture solution: After mixing beef extract, peptone, glucose and sodium chloride with 1.2 parts of distilled water, adjust the pH value to 7, and sterilize to obtain the sterilized culture solution;

[0039] B. Preparation of liquid bacteria: mix sterilized culture fluid, egg white, sheep ser...

Embodiment 2

[0042]A bacterial agent for the fermentation treatment of waste organic matter, including a liquid bacterial agent; the liquid bacterial agent includes the following components in parts by weight: 0.015 parts of beef extract, 0.04 parts of peptone, 0.06 parts of glucose, and 0.006 parts of sodium chloride , 101.8 parts of distilled water, 4 parts of egg whites, 0.2 parts of sheep serum, 4 parts of brown sugar, 0.06 parts of metabolites of photosynthetic bacteria, 0.06 parts of metabolites of yeast, and 0.6 parts of EM bacteria.

[0043] The bacterial agent used for the fermentation treatment of waste organic matter also includes a carrier; the weight ratio of the carrier to the liquid bacterial agent is 20:1, and the carrier is organic particles with a mesh number of 10.

[0044] The organic matter granule is composed of the following components in parts by weight: equal parts of soybean meal, corn flour, wheat bran, malt powder, aged rice and old noodles.

[0045] A method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com