High-mill-temperature cement grinding aid and preparation method thereof

A cement grinding aid and dispersant technology, applied in the field of cement grinding, can solve the problems of decreased grinding efficiency of the mill, decreased output of the cement mill table, sticking balls, etc., and achieves enhanced adaptability, reduced cost, blending less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

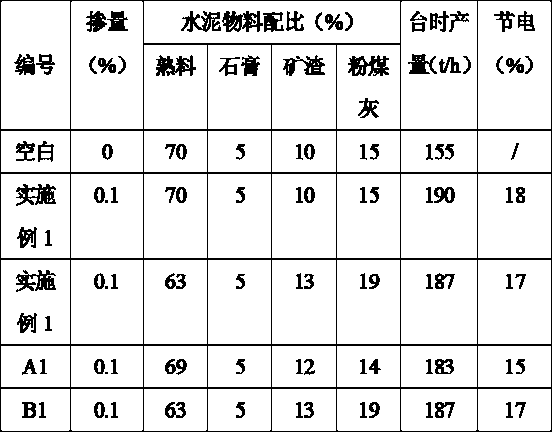

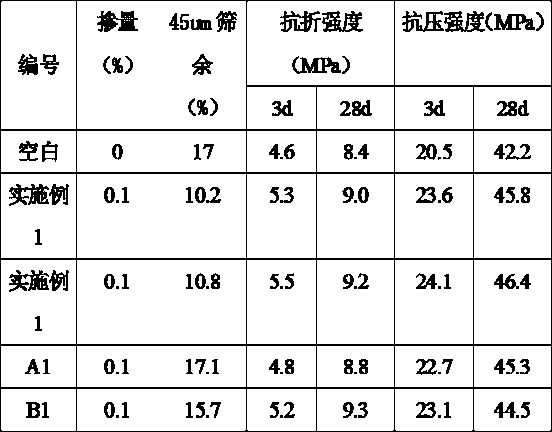

Examples

Embodiment 1

[0015] A high grinding temperature cement grinding aid, comprising 55 parts of aliphatic sodium sulfonate, 5 parts of aluminum sulfate, 2 parts of trihydroxyethylamine, 6 parts of alcohol amines, 3 parts of Sodium tripolyphosphate, 3 parts of sodium gluconate, 1 part of dispersant, 25 parts of water, described aliphatic sodium sulfonate is a straight chain aliphatic alkyl sodium sulfonate with 18 carbon atoms, The sodium alkyl sulfonate is first hydrogenated from petroleum fractions (230-320°C) or treated with concentrated sulfuric acid to remove unsaturated hydrocarbons to obtain pure alkanes, which react with chlorine and sulfur dioxide under ultraviolet light to form monochlorine compounds, and then use It is prepared by saponification of caustic soda; the alcohol amine substance is polyethylene glycol, and the dispersant is sodium dodecylbenzenesulfonate.

[0016] A kind of preparation method of high grinding temperature cement grinding aid is characterized in that, compri...

Embodiment 2

[0020] A high grinding temperature cement grinding aid, comprising 50 parts of aliphatic sodium sulfonate, 8 parts of aluminum sulfate, 3 parts of trihydroxyethylamine, 5 parts of alcohol amines, 6 parts of Sodium tripolyphosphate, 4 parts of sodium gluconate, 0.8 parts of dispersant, 23.2 parts of water, described aliphatic sodium sulfonate is a straight-chain aliphatic alkyl sodium sulfonate with 17 carbon atoms in carbon number, The sodium alkyl sulfonate is first hydrogenated from petroleum fractions (230-320°C) or treated with concentrated sulfuric acid to remove unsaturated hydrocarbons to obtain pure alkanes, which react with chlorine and sulfur dioxide under ultraviolet light to form monochlorine compounds, and then use It is prepared by saponification of caustic soda; the alcohol amine substance is polyethylene glycol, and the dispersant is sodium dodecylbenzenesulfonate.

[0021] A kind of preparation method of high grinding temperature cement grinding aid is charact...

Embodiment 3

[0025] A high grinding temperature cement grinding aid, comprising 46 parts of aliphatic sodium sulfonate, 6 parts of aluminum sulfate, 8 parts of trihydroxyethylamine, 7 parts of alcoholamines, 8 parts of Sodium tripolyphosphate, 7 parts of sodium gluconate, 1.3 parts of dispersant, 14.7 parts of water, described aliphatic sodium sulfonate is a straight chain aliphatic alkyl sodium sulfonate with 18 carbon atoms, The sodium alkyl sulfonate is first hydrogenated from petroleum fractions (230-320°C) or treated with concentrated sulfuric acid to remove unsaturated hydrocarbons to obtain pure alkanes, which react with chlorine and sulfur dioxide under ultraviolet light to form monochlorine compounds, and then use It is prepared by saponification of caustic soda; the alcohol amine substance is polyethylene glycol, and the dispersant is sodium dodecylbenzenesulfonate.

[0026] A kind of preparation method of high grinding temperature cement grinding aid is characterized in that, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com