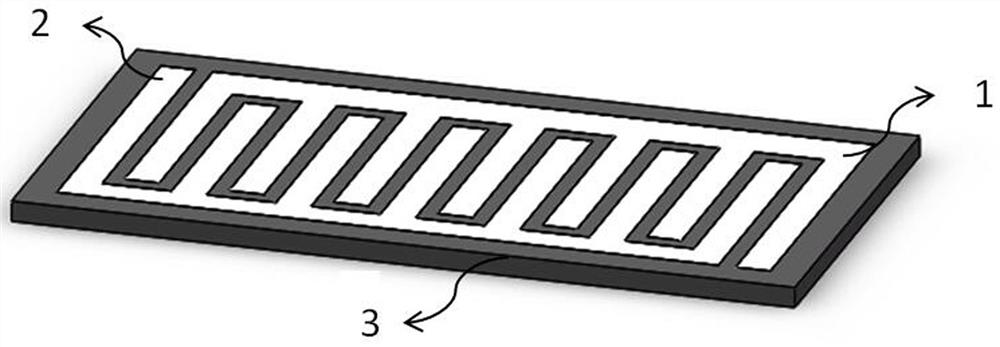

Flexible and stretchable piezoelectric nanogenerator based on interdigitated electrode structure and its preparation method

A technology of nanogenerators and interdigitated electrodes, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of flexible Problems such as high polymer viscosity, breakage and drop of the piezoelectric film, good flexibility and stretchability, increased output voltage, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

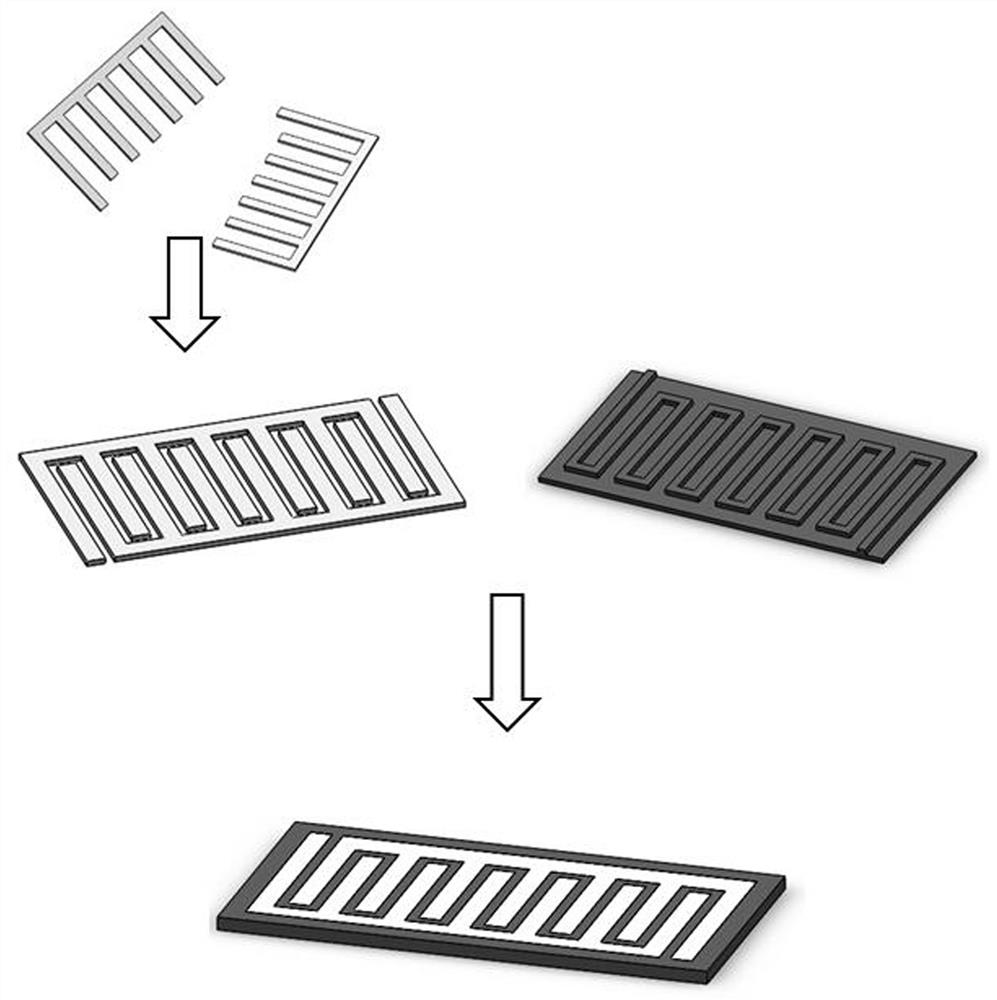

[0045] The specific fabrication steps of the flexible and stretchable piezoelectric nanogenerator based on the interdigitated electrode structure are as follows:

[0046] Step 1: Preparation of flexible polymer materials: mix the raw rubber and vulcanizing agent in a ratio of 100:2, and knead on a mixer for 1 to 3 hours to mix the raw rubber and vulcanizing agent evenly.

[0047] Step 2: Preparation of interdigitated electrode film layer: take copper powder (40%) and mix it evenly into the flexible polymer material (60%) prepared in step 1, and knead on a mixer for 1-3 hours , After kneading, it is vulcanized by a flat vulcanizer for 20 minutes. The vulcanization temperature is 180 ° C. During the vulcanization process, the mold is used to control its shape, size and thickness.

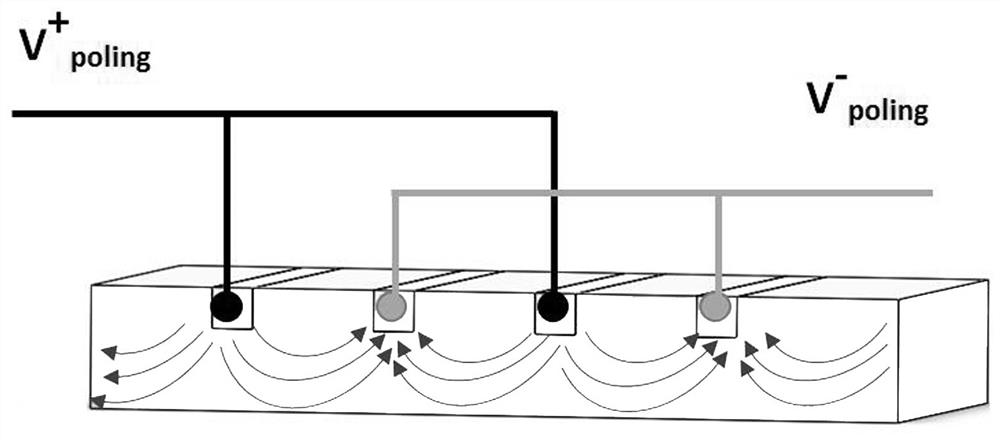

[0048] Step 3: Preparation of piezoelectric film based on interdigitated electrodes: Take lead zirconate titanate (80%) and mix it evenly into the flexible polymer material (20%) prepared in step 1, a...

Embodiment 2

[0053] The specific fabrication steps of the flexible and stretchable piezoelectric nanogenerator based on the interdigitated electrode structure are as follows:

[0054] Step 1: Preparation of flexible polymer materials: mix the raw rubber and vulcanizing agent in a ratio of 100:1, and knead on a mixer for 1 to 3 hours to make the raw rubber and vulcanizing agent evenly mixed.

[0055] Step 2: Preparation of interdigitated electrode film layer: Take silver powder (80%) and mix it evenly into the flexible polymer material (20%) prepared in step 1, and knead on a mixer for 1 to 3 hours, After kneading, vulcanize it with a flat vulcanizer for 25 minutes at a vulcanization temperature of 180°C. During the vulcanization process, use a mold to control its shape, size and thickness.

[0056] Step 3: Preparation of piezoelectric film based on interdigitated electrodes: take barium titanate (50%) and mix it evenly into the flexible polymer material (50%) prepared in step 1, and knead ...

Embodiment 3

[0061] The specific fabrication steps of the flexible and stretchable piezoelectric nanogenerator based on the interdigitated electrode structure are as follows:

[0062] Step 1: Preparation of flexible polymer materials: mix the raw rubber and vulcanizing agent in a ratio of 100:2, and knead on a mixer for 1 to 3 hours to mix the raw rubber and vulcanizing agent evenly.

[0063] Step 2: Preparation of interdigitated electrode film layer: take silver copper powder (60%) and mix it evenly into the flexible polymer material (40%) prepared in step 1, and knead on a mixer for 1~3 After mixing, it is vulcanized for 25 minutes with a flat vulcanizer, and the vulcanization temperature is 170 ° C. During the vulcanization process, the mold is used to control its shape, size and thickness.

[0064] Step 3: Preparation of piezoelectric film based on interdigitated electrodes: Take lead magnesium niobate-lead titanate (70%) and mix it evenly into the flexible polymer material (30%) prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com