Epoxystyrene-isoprene-styrene segmented copolymer medicine paster and preparation method thereof

A technology of epoxidizing styrene and styrene blocks, which is used in pharmaceutical formulations, medical preparations with non-active ingredients, and sheet transportation, etc., can solve the problems of easy occurrence of allergies, impact on sticking performance, poor adhesion ability, etc. , to avoid skin whitish allergy, improve the mixing amount of the drug, and enhance the adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Preparation of epoxidized styrene-isoprene-styrene block copolymer medical patch

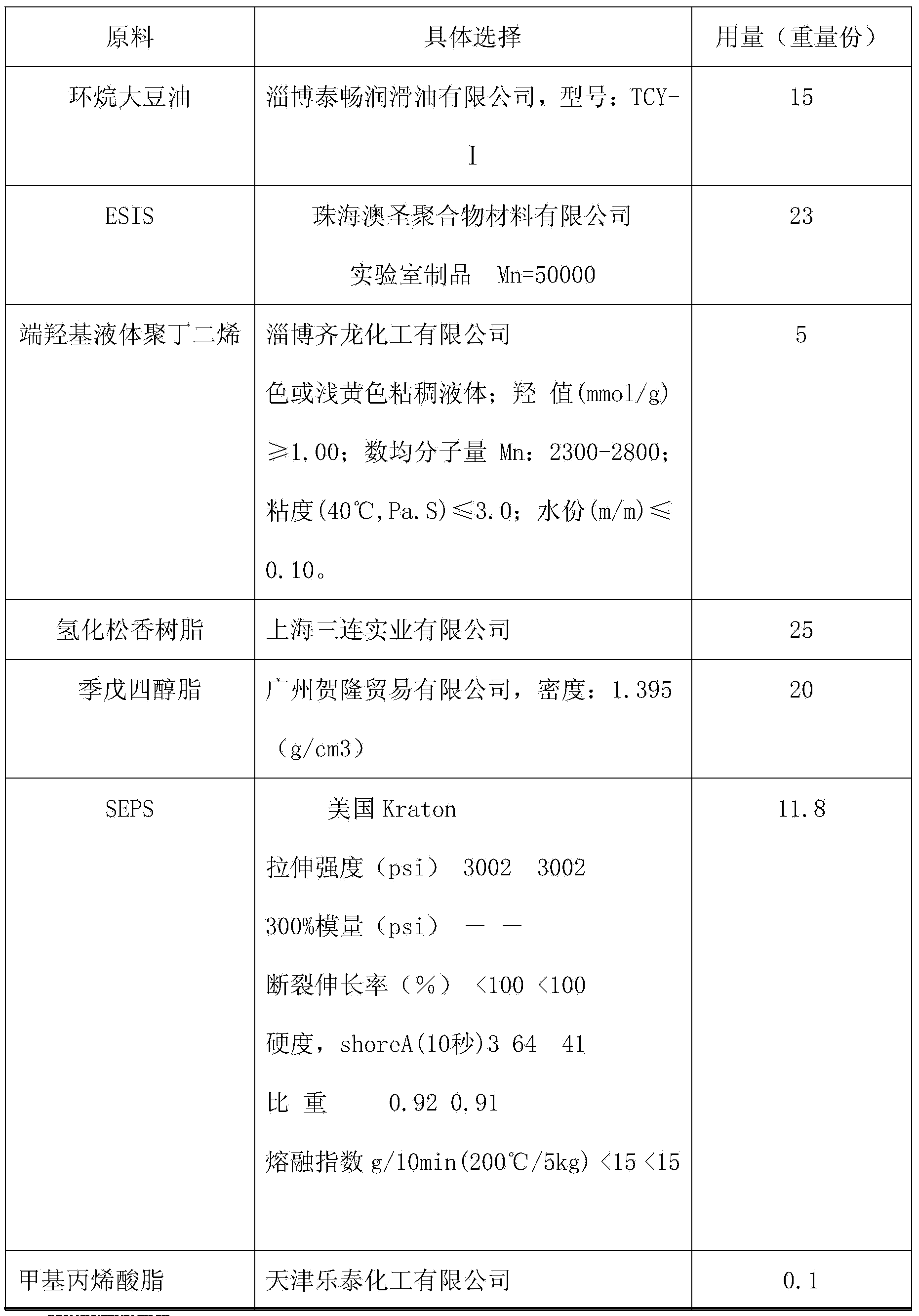

[0022] raw material:

[0023]

[0024]

[0025] (1) Preparation method:

[0026] Add part of naphthenic soybean oil to the reactor first, add ESIS and SEPS according to the weight ratio, then add antioxidant, heat to 160°C, start stirring, and pass nitrogen to replace the gas in the reactor.

[0027] After the ESIS is completely dissolved, add rosin pentaerythritol resin in proportion, and then add hydrogenated rosin resin after the temperature is constant.

[0028] Vacuum the kettle to keep it at -0.02mPa, stir for about 20 minutes to lower the temperature of the kettle, and use the internal cooling of the reactor to drop the temperature to 120°C before discharging.

[0029] (2) Product performance parameters:

[0030] Appearance: with light yellow transparent solid glue

[0031] Non-volatile matter: 100%

[0032] Purity: Heated to 160°C, all 100-mesh sieves pass...

Embodiment 2

[0039] Embodiment 2: Preparation of epoxidized styrene-isoprene-styrene block copolymer medical patch

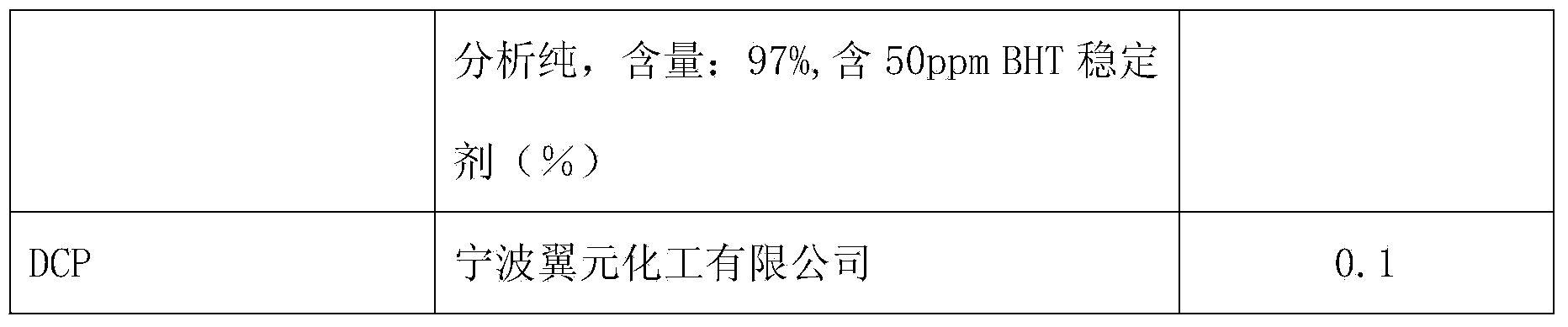

[0040] raw material:

[0041]

[0042]

[0043] (4) Preparation method:

[0044] Add part of naphthenic soybean oil to the reactor first, add ESIS and SEPS according to the weight ratio, then add antioxidant, heat to 160°C, start stirring, and pass nitrogen to replace the gas in the reactor.

[0045] After the ESIS is completely dissolved, add rosin pentaerythritol resin in proportion, and then add hydrogenated rosin resin after the temperature is constant.

[0046] Vacuum the kettle to keep it at -0.05mPa, stir for about 20 minutes to lower the temperature of the kettle, and use the internal cooling of the reactor to drop the temperature to 120°C before discharging.

[0047] (5) Product performance parameters:

[0048] Appearance: with light yellow transparent solid glue

[0049] Non-volatile matter: 100%

[0050] Purity: Heated to 160°C, all 100-mesh sieves pass...

Embodiment 3

[0057] Embodiment 3: Preparation of epoxidized styrene-isoprene-styrene block copolymer medical patch

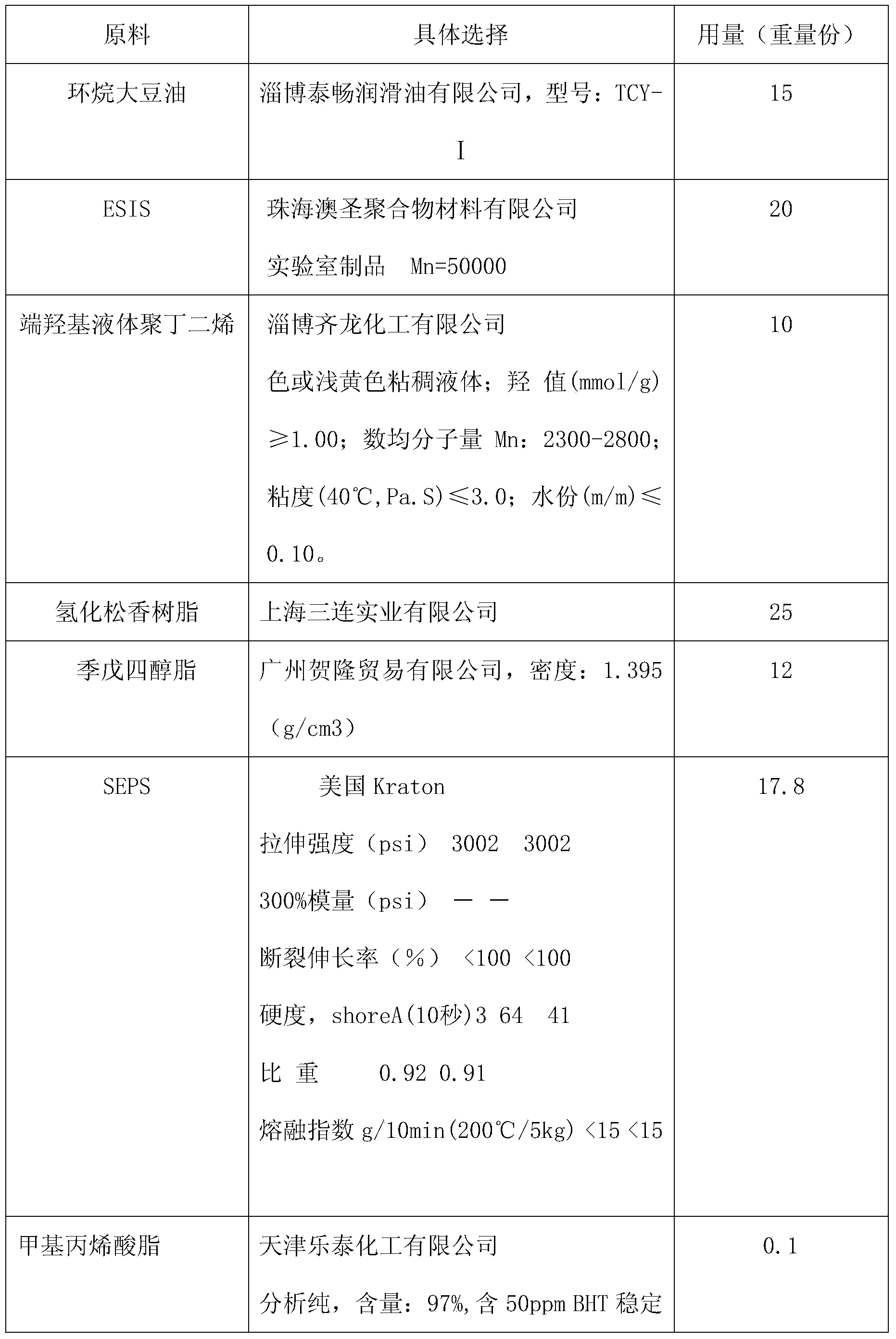

[0058] raw material:

[0059]

[0060]

[0061] (7) Preparation method:

[0062] Add part of naphthenic soybean oil to the reactor first, add ESIS and SEPS according to the weight ratio, then add antioxidant, heat to 160°C, start stirring, and pass nitrogen to replace the gas in the reactor.

[0063] After the ESIS is completely dissolved, add rosin pentaerythritol resin in proportion, and then add hydrogenated rosin resin after the temperature is constant.

[0064] Vacuum the kettle to keep it at -0.03mPa, stir for about 20 minutes to lower the temperature of the kettle, and use the internal cooling of the reactor to drop the temperature to 120°C before discharging.

[0065] (8) Product performance parameters:

[0066] Appearance: with light yellow transparent solid glue

[0067] Non-volatile matter: 100%

[0068] Purity: Heated to 160°C, all 100-mesh sieves pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com