Preparation of catalyst for processing industrial wastewater and using method thereof

A technology for industrial wastewater and catalysts, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of energy consumption, high cost, and large energy consumption in electrolytic oxidation processes, and reduce catalyst separation and recovery problems, improve the binding strength, and avoid the effects of decreased activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation steps of the present invention are as follows:

[0012] (1) The molecular sieve powder is placed in a water-soluble metal salt solution that can be decomposed into a P-type semiconductor oxide at a high temperature, and the weight ratio of the two is 1:5 to 1:50, and it is fully stirred at a temperature of 10 to 95°C for 8 to 8. After standing for 48 hours, filter off excess solution, dry at 60-200°C at low temperature, and then bake at 300-800°C for 2-6 hours to obtain a powder with a weight content of 0.5-10% P-type semiconductor oxide catalyst;

[0013] (2) Forming of the catalyst: adding 5-20 wt% binder and 1-3 wt% pore-enlarging agent to the powder catalyst prepared in step (1) in a percentage by weight of 77-94 wt%, and mixing uniformly, in the mixture Add a dilute nitric acid solution with a concentration of 2 to 10% that accounts for 30 to 50 wt% of the mixture, mix well and extrude into strips with an extruder, dry at 80 to 150°C and dry at 400...

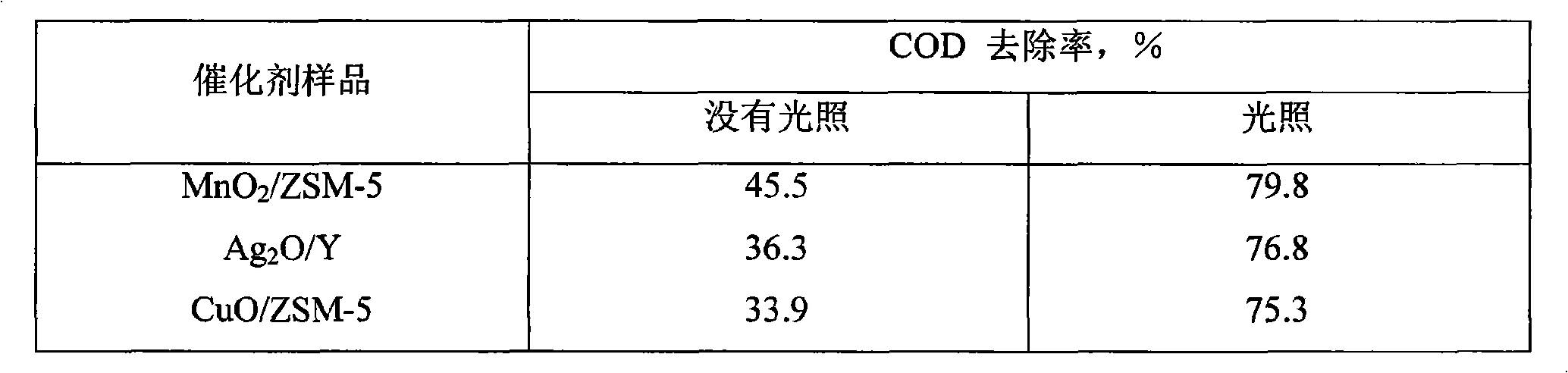

Embodiment 1

[0020] Preparation of MnO by Ion Exchange Method 2 / ZSM-5 catalyst

[0021] Weigh 50 grams of H-ZSM-5 molecular sieve with a silicon-aluminum ratio of 25 into a beaker, add 1.0 L of an aqueous solution containing 6.0 grams of manganese sulfate, stir at 80°C for 24 hours, let it stand and pour off the supernatant, and put it at 120°C After lower drying, the temperature was increased to 300°C at a rate of 2°C / min for 4 hours. Grind the catalyst prepared by roasting into powder, add 15 grams of hydrated alumina (pseudoboehmite), 3 grams of organic pore-enlarging agent, mix well, add 40 mL of dilute nitric acid solution with a concentration of 5.0 V%, and continue kneading to form a block shape, and then extruded into a clover shape of φ=2.0mm with an extruder. After drying at 100°C for 2 hours, the temperature was raised to 500°C at a rate of 2°C / min for 4 hours, and the clover-shaped MnO was obtained after cooling. 2 / ZSM-5 catalyst. MnO in this catalyst 2 The content is ab...

Embodiment 2

[0023] Preparation of Ag by Ion Exchange Method 2 O / Y catalyst

[0024] Take by weighing 50 grams of H-Y molecular sieves in a beaker, add 1.0L of an aqueous solution containing 3.0 grams of silver nitrate, then obtain Ag by the method in Example 1 2 Ag with O content about 3.0w% 2 O / Y catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com