Dynamic pressure finishing system based on hierarchical structured composite elastic abrasive disk

A hierarchical structure, grinding and polishing technology, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding devices, etc., can solve the problems of low resource utilization, low processing efficiency, low degree of automation, etc., and achieve the degree of automation High, improve the utilization rate, improve the effect of efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

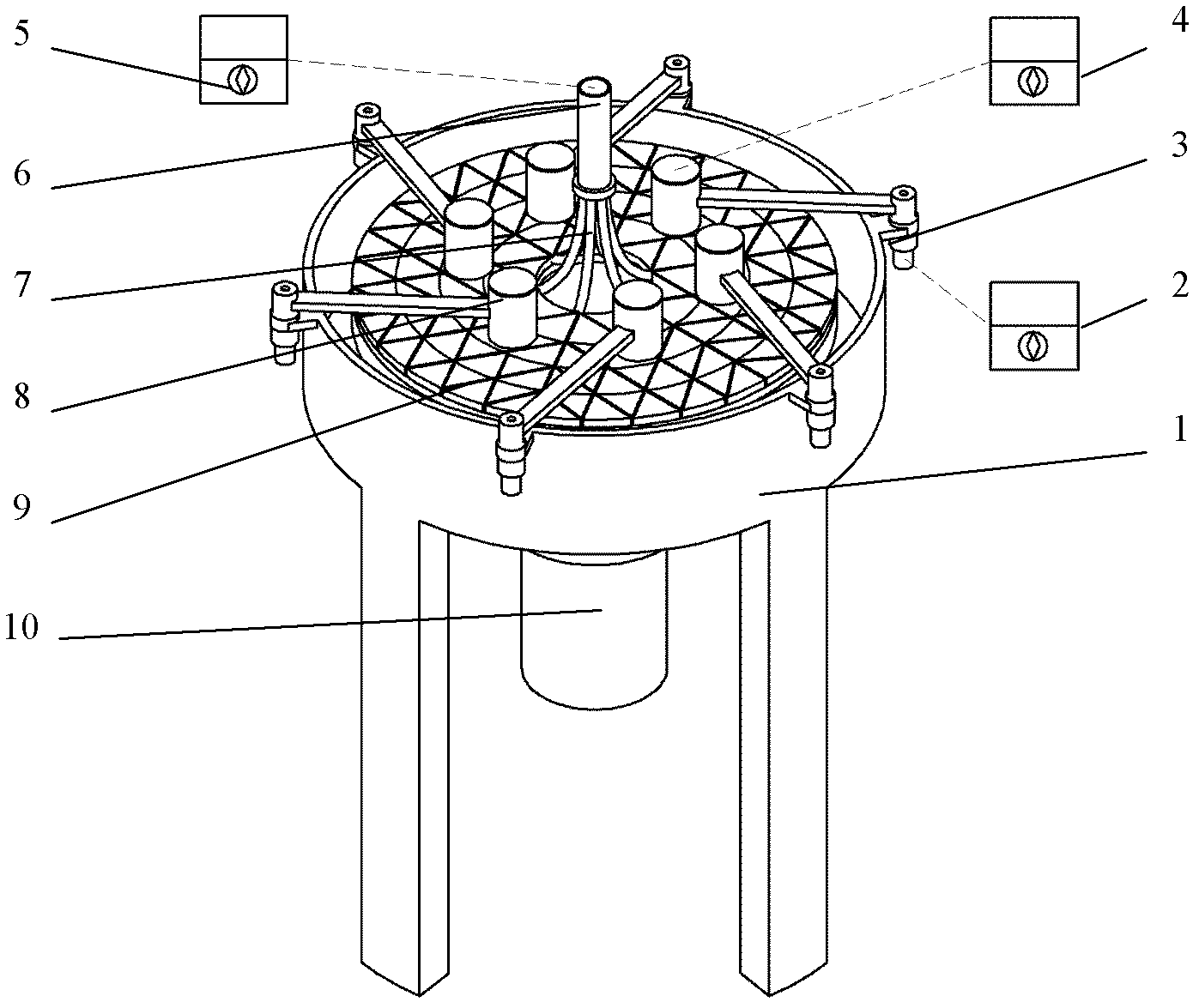

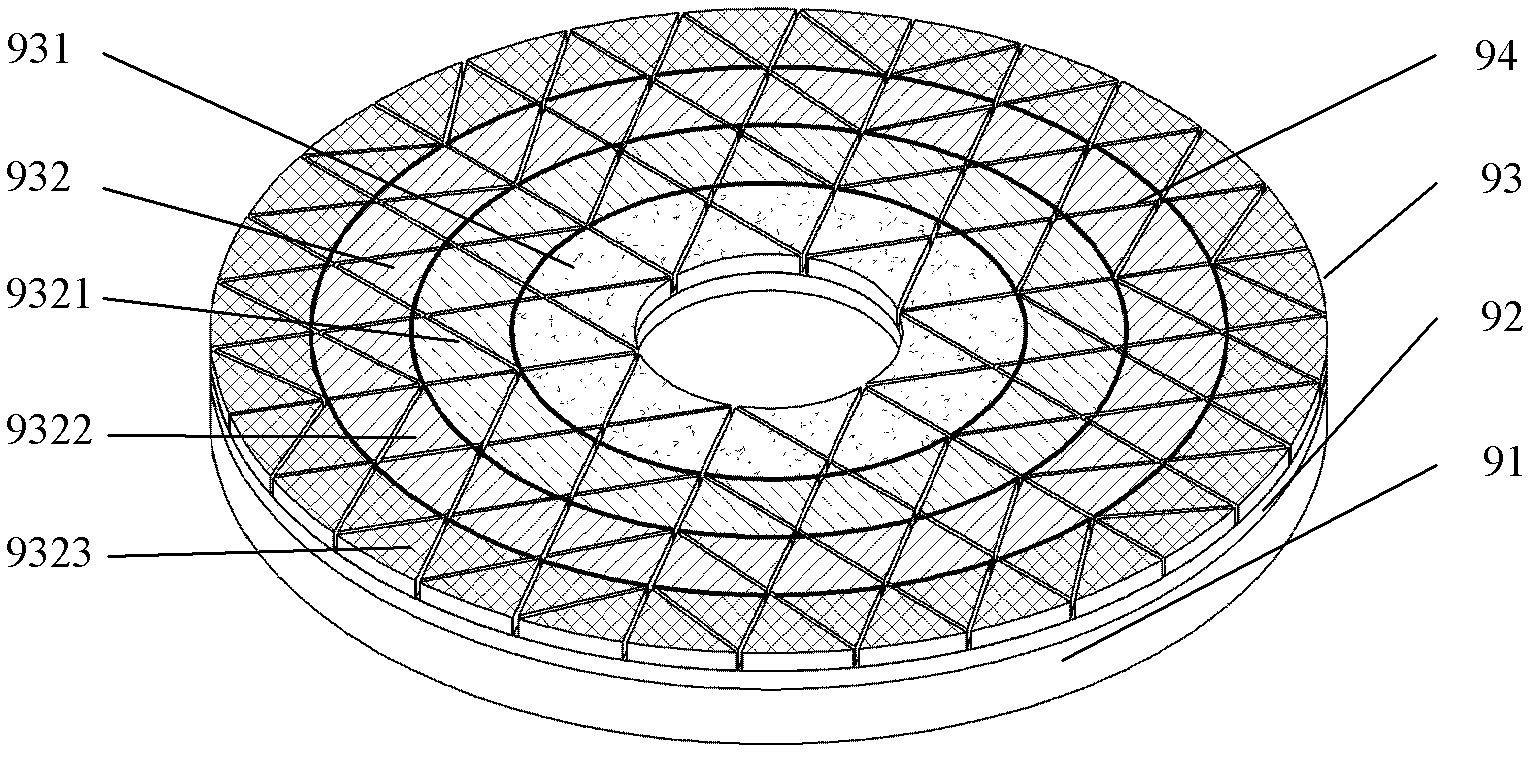

[0017] refer to Figure 1~4 , a dynamic pressure finishing system based on hierarchically structured composite elastic grinding and polishing discs, including a workbench 1 and a grinding and polishing disc 9 erected on the workbench 1, the grinding and polishing disc 9 is connected to a grinding and polishing disc driving device 10, and the grinding and polishing disc driving device 10 is composed of a motor and a reducer, and is used to control the rotation of the polishing disc 9. It is characterized in that: the polishing disc 9 has a rough grinding ring 9323, a fine grinding ring 9322, a fine grinding ring 9321 and a polishing inner ring 931 from the outside to the inside; The polishing disc 9 indicates that a flow channel 94 for circulating the polishing liquid is arranged; the dynamic pressure regulating device 8 presses the workpiece S1 on the polishing disc 9;

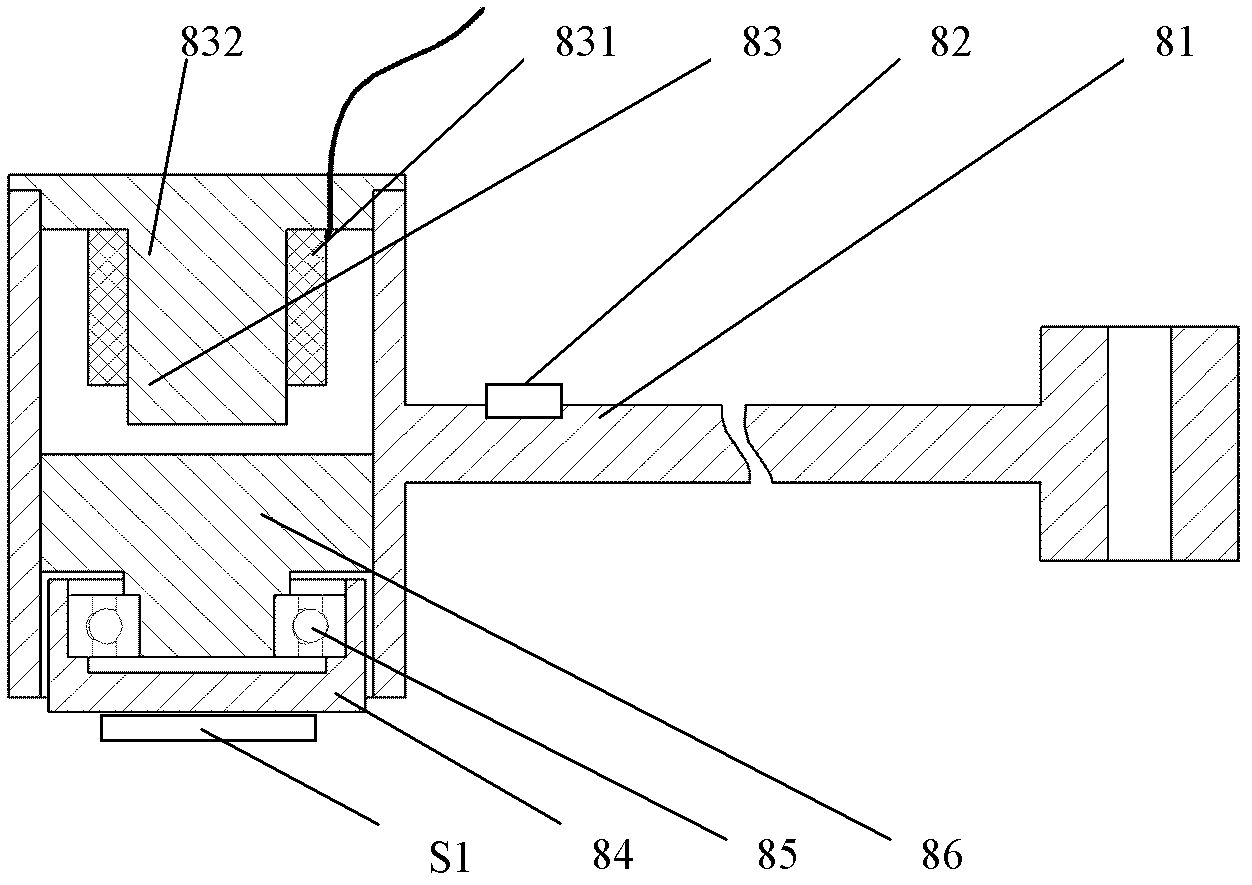

[0018] One end of the support guide body 81 of the dynamic pressure regulating device 8 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com