Internal operation image real-time monitoring system for high-voltage electric apparatus

A technology for high-voltage electrical equipment and image monitoring, applied in closed-circuit television systems, television systems adapted to optical transmission, radiation pyrometry, etc., can solve the shortage of monitoring techniques, indirect diagnostic methods, and inability to meet the technical requirements of equipment condition maintenance To prevent and control abnormalities and accidents, improve operation level and power supply reliability, and have strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

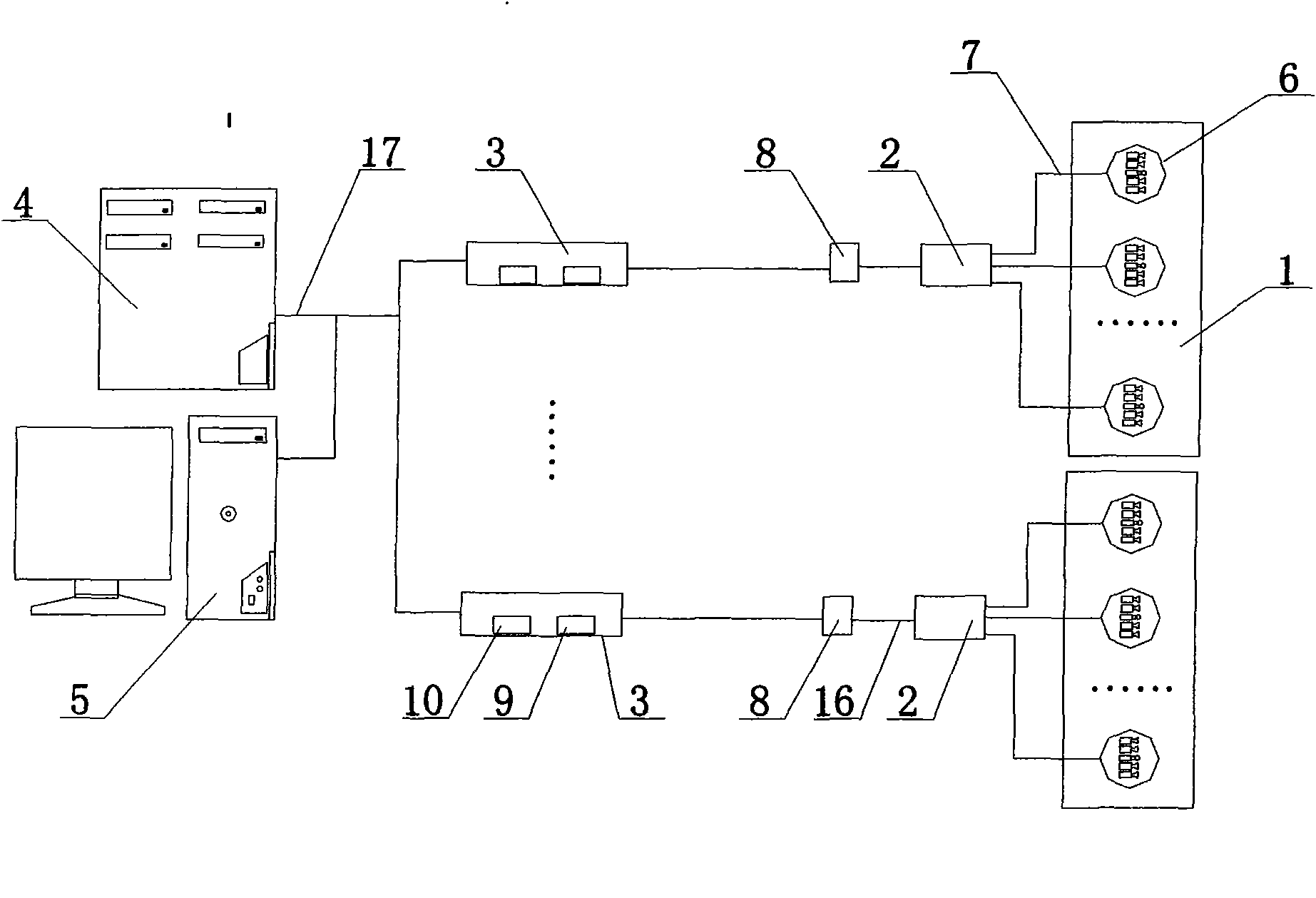

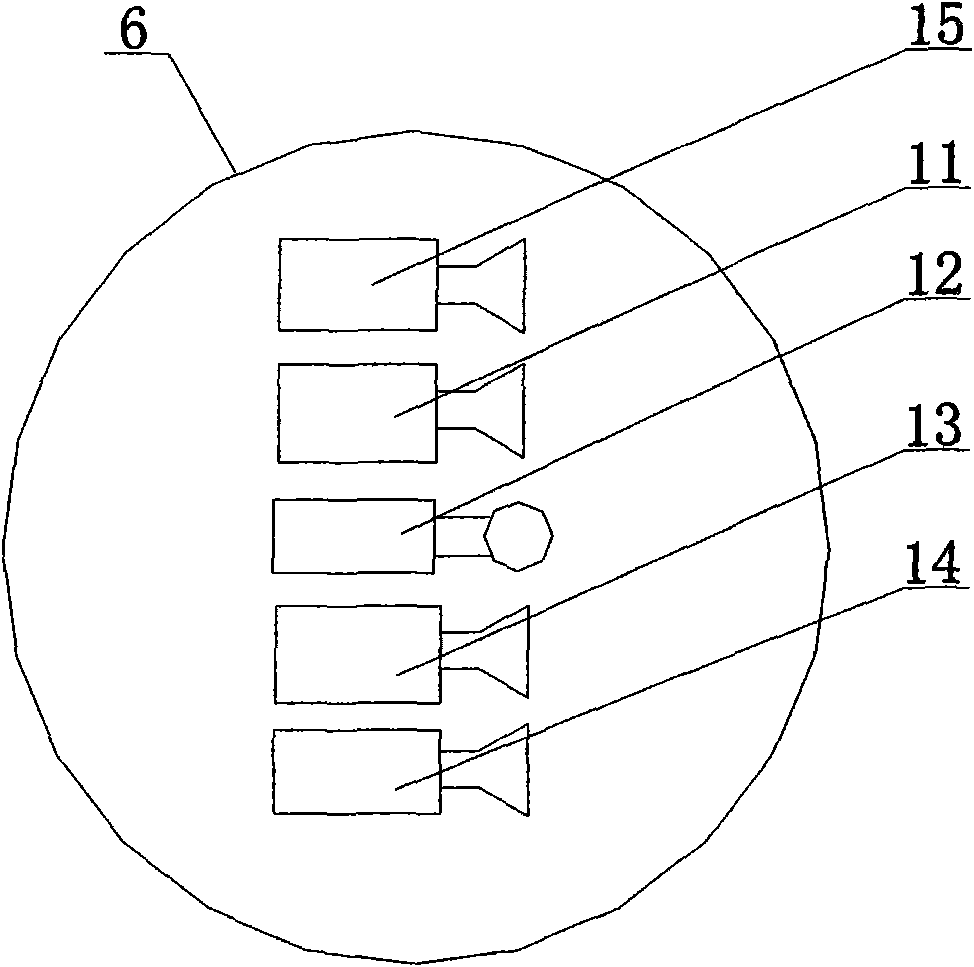

[0019] Depend on figure 1 It can be seen that the real-time monitoring system for the internal operation image of the high-voltage electrical equipment mainly includes high-voltage equipment 1, an optical cable hub 2, an industrial computer 3, a computer server 4, and a computer terminal 5. The monitoring point 6 is connected with the high-voltage insulated optical cable 7 between each monitoring point 6 and the optical cable hub 2. In the optical cable hub 2, each high-voltage insulated optical cable 7 is connected, and the high-voltage insulated optical cable is connected through the optical cable outlet sleeve 8. 7 is led out of the high-voltage equipment 1, and is connected to the industrial computer 3 in the main control room of the substation through an insulated optical cable 16. The industrial computer 3 is equipped with a light source device 10 and a photoelectric conversion device 9, and the industrial computer 3 is connected to the computer server 4 and the computer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com