Chemical enterprise intelligent production plan control system based on quantum particle swarm algorithm

A quantum particle swarm and control system technology, applied in the field of intelligent production planning control system of chemical enterprises, can solve the problems of low utilization rate of resources and equipment, inability to effectively share collaborative production workshops, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

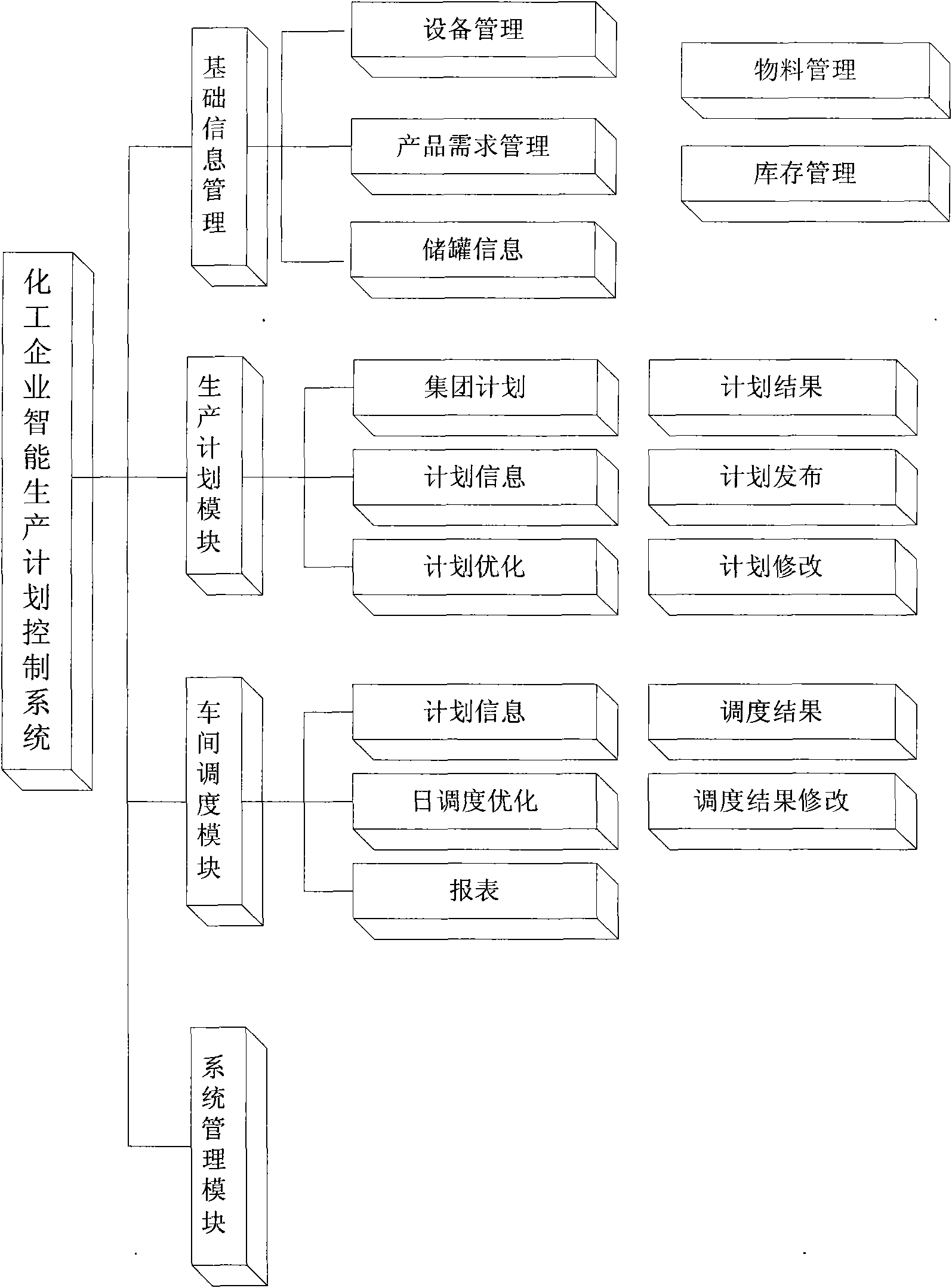

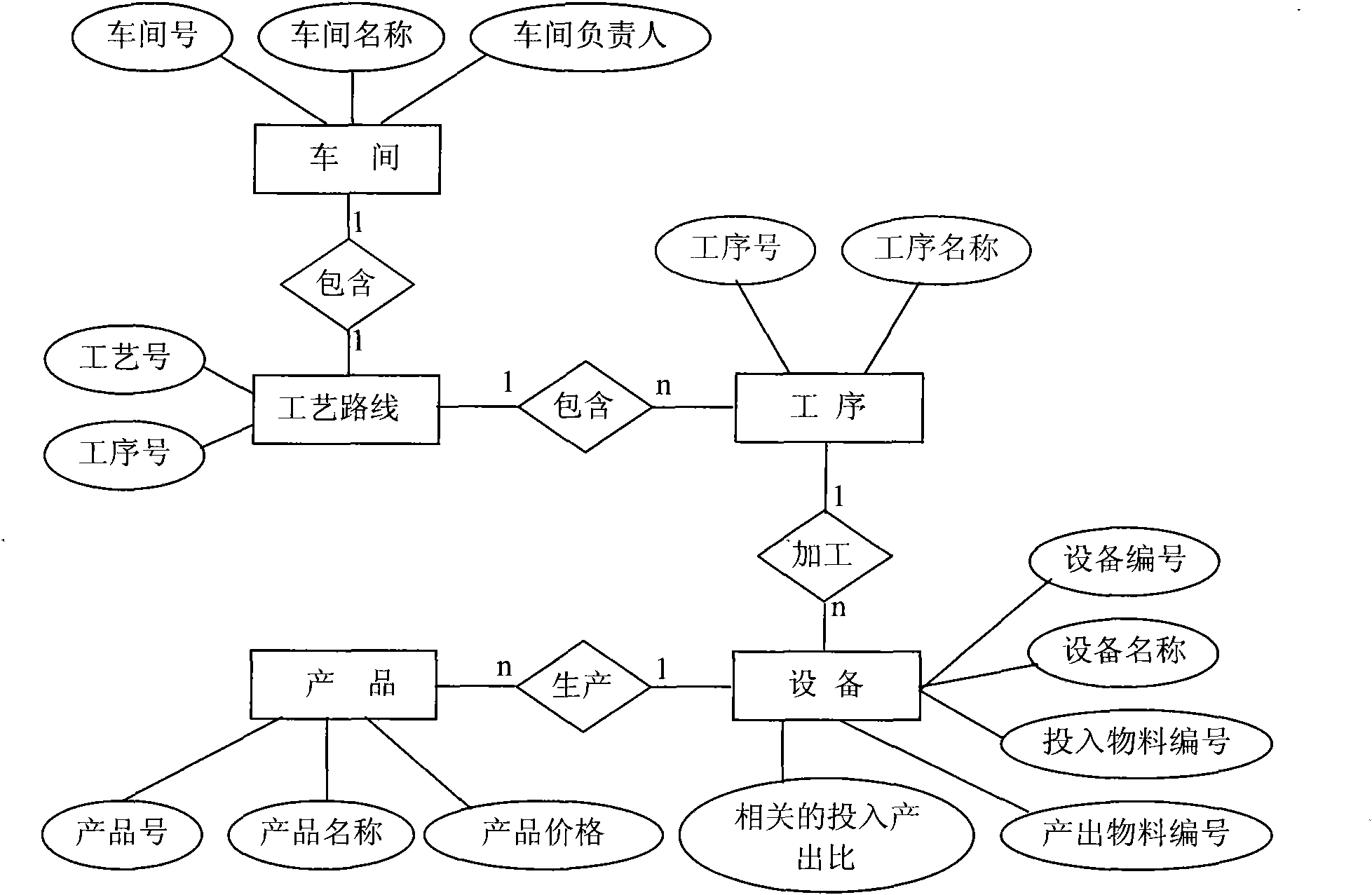

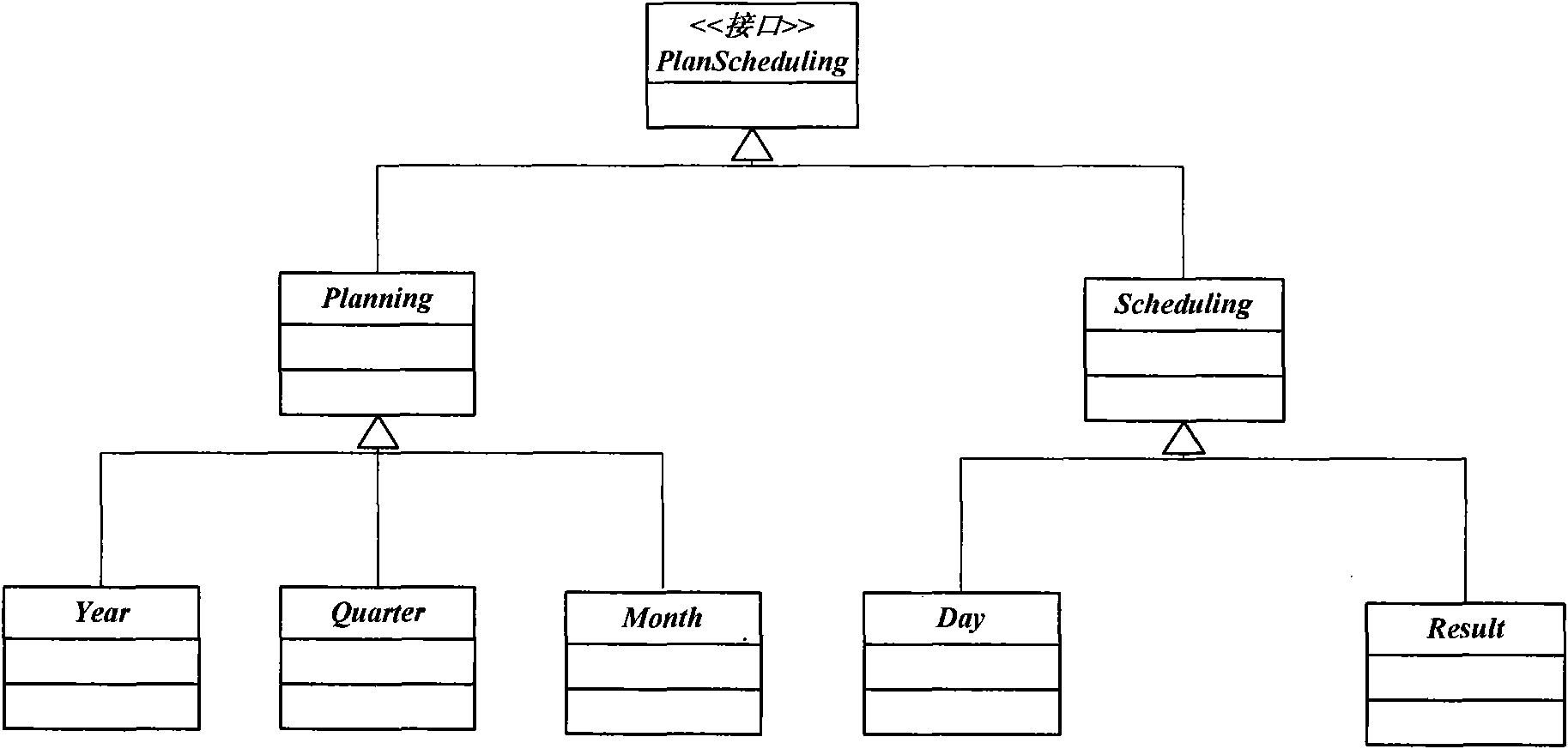

[0054] refer to Figure 1 to Figure 5 , a chemical enterprise intelligent production planning control system based on quantum particle swarm algorithm, the overall framework of the system is:

[0055] According to the actual production situation of the enterprise, when the enterprise receives the annual production plan issued by the group, the enterprise management department of the enterprise will decompose the plan of the group according to various constraints such as the supply of raw materials, the state of equipment and production capacity, etc. Form a monthly plan and distribute it to each workshop. The workshop evaluates whether the plan can be completed on schedule according to the actual production situation of its own workshop. If it can be completed on schedule, it will carry out workshop scheduling and arrange production according to the plan. Otherwise, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com