Electricity energy regulating-ice melting device and method for railway traction network

A railway traction and ice melting technology, applied in the installation of cables, electrical components, overhead installation, etc., can solve problems such as improvement, waste management of equipment use, etc., and achieve the effect of saving investment and improving equipment utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

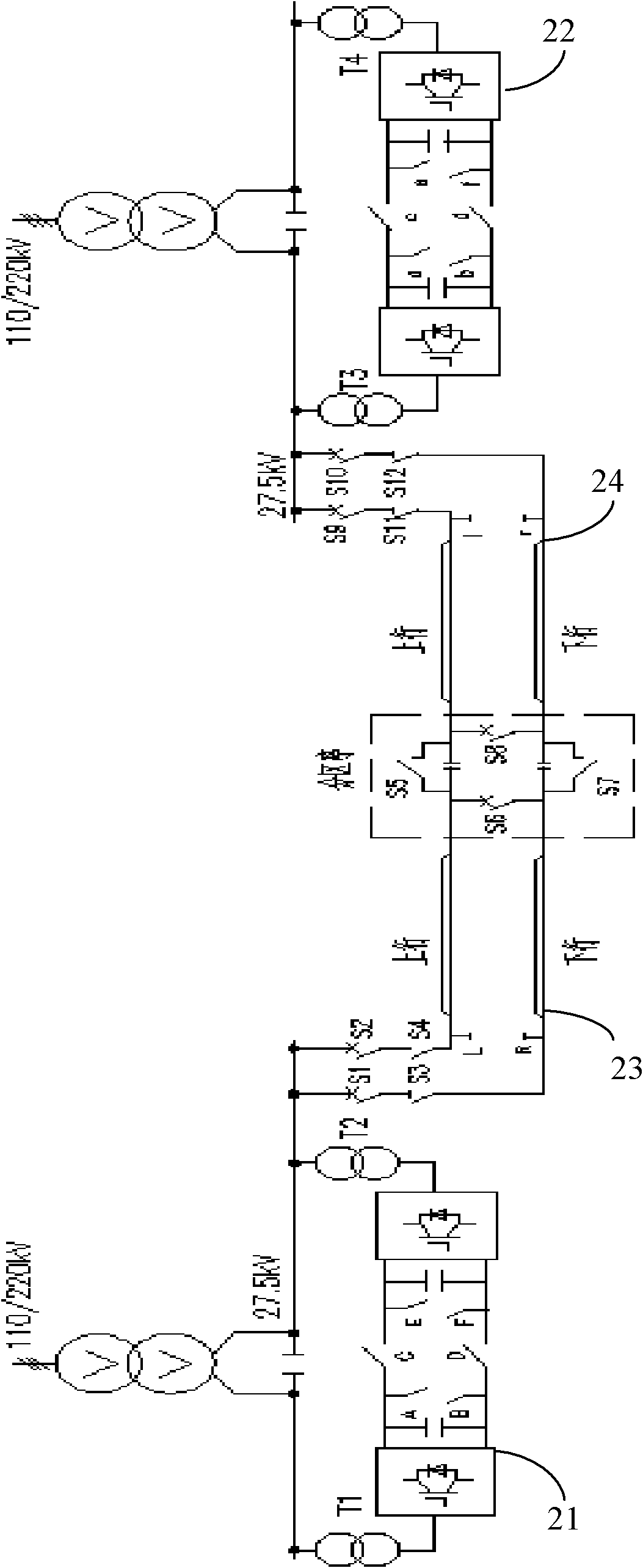

[0026] The invention adopts the topology structure based on the series connection of the DC side of the H bridge, which can not only meet the demand of large-capacity DC ice melting, but also meet the power quality management of electrified railways, so as to realize the ice melting when the ice is coated and the traction substation when the ice is not melting. Power quality management to save investment and improve equipment utilization.

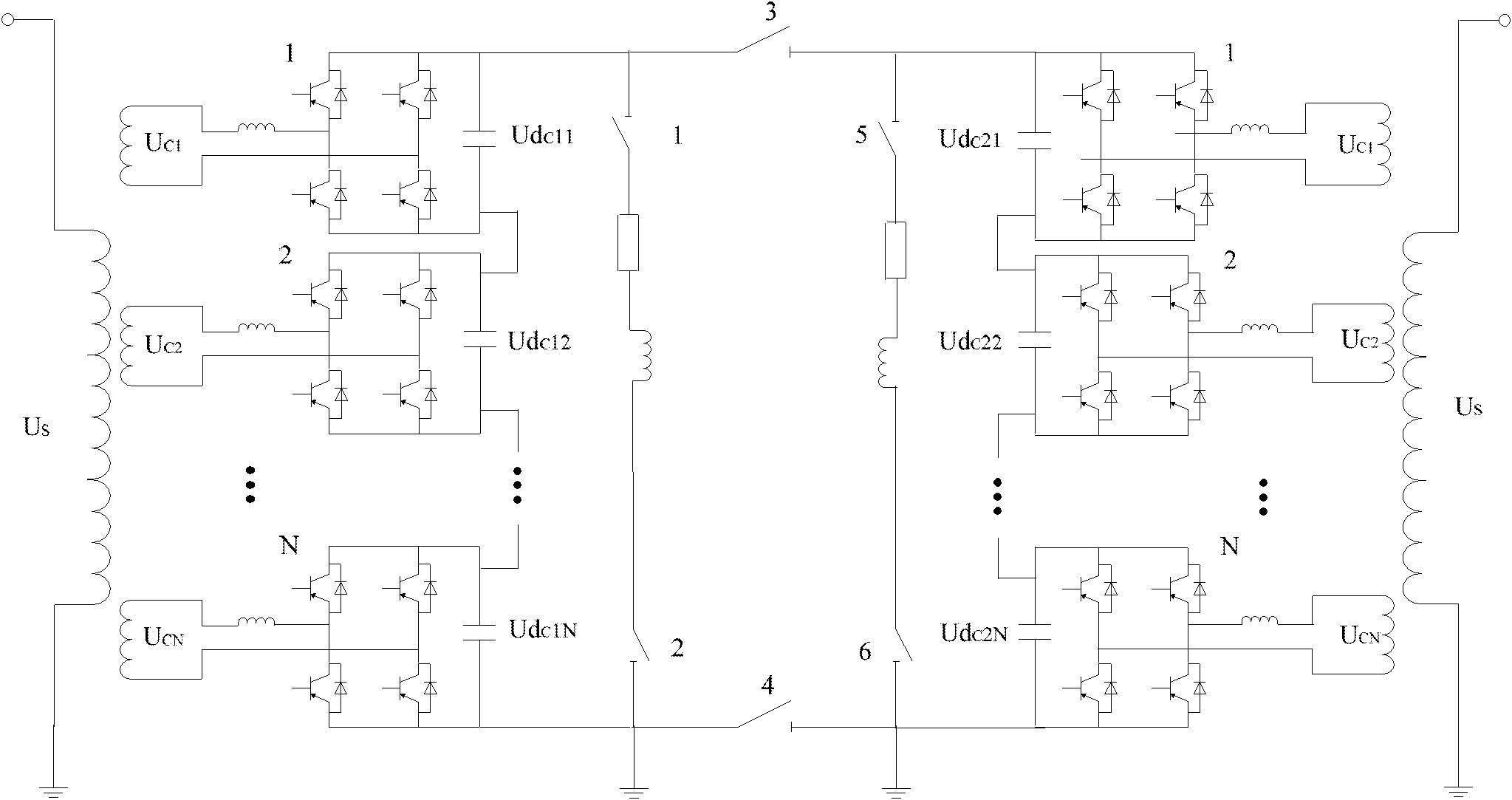

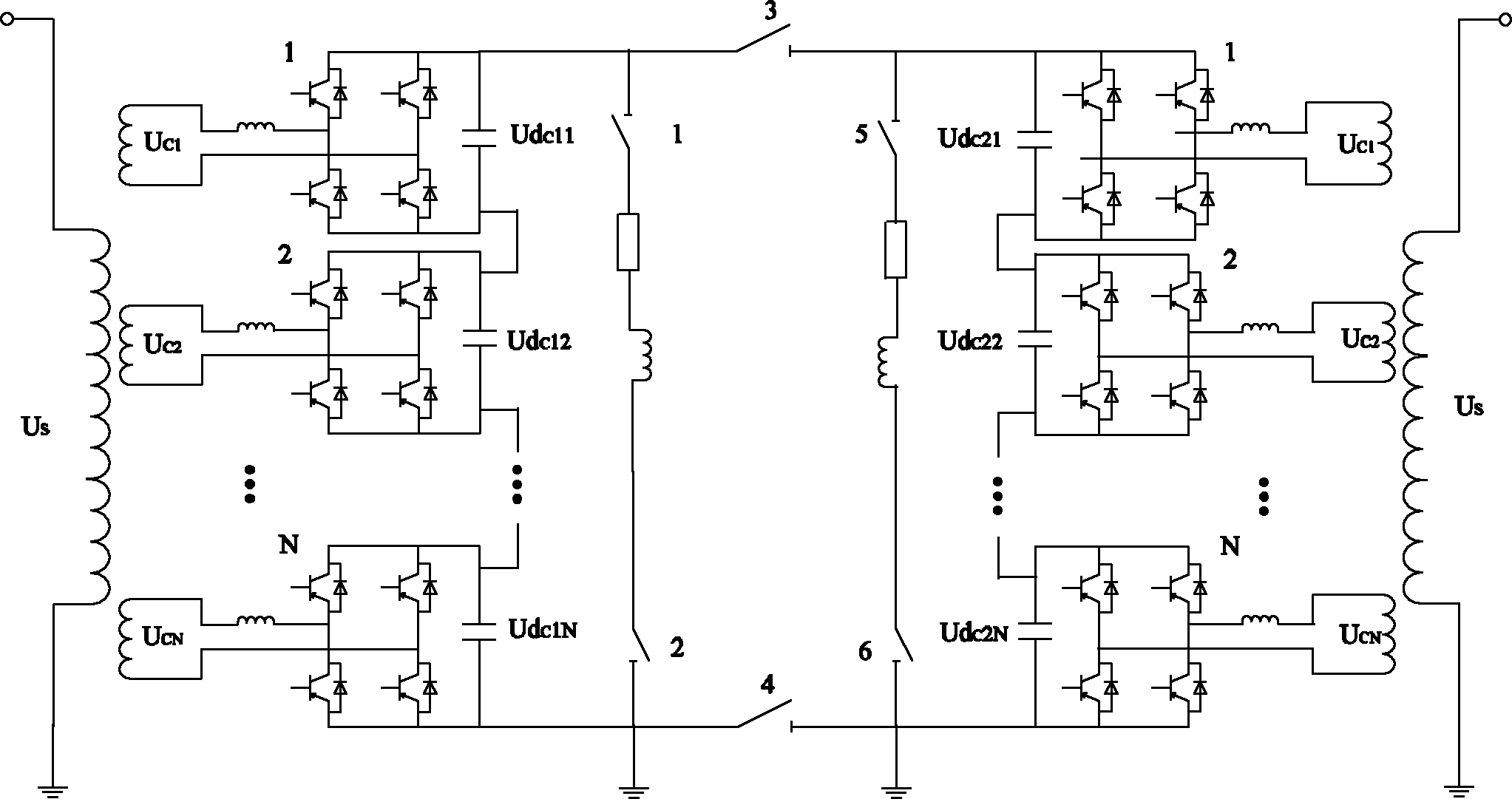

[0027] See figure 1 , Showing the topological structure of the power regulation-anti-icing device of the present invention, as a whole, the device can be divided into two identical converter devices on the left and right. Each converter device includes a multiple winding transformer Us a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com