Strong-laser-ablation-resistant protective coating and preparation method thereof

A protective coating and strong laser technology, applied in coatings, reflection/signal coatings, etc., can solve the problems of low coating strength and difficulty in engineering applications, and achieve high curing strength, low price, and good reflection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

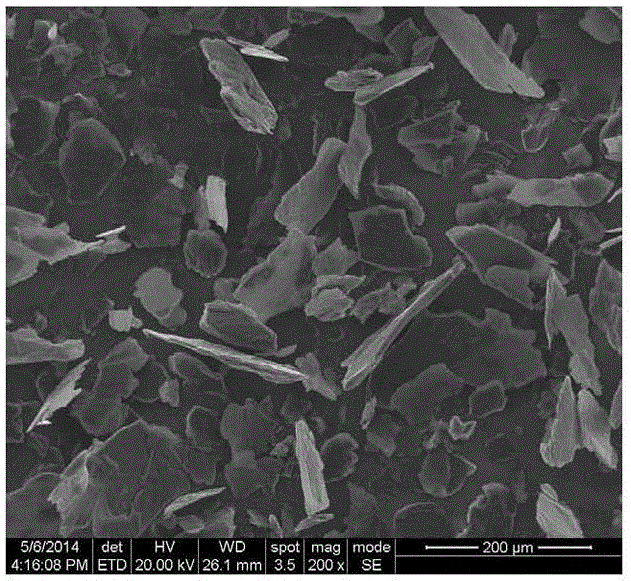

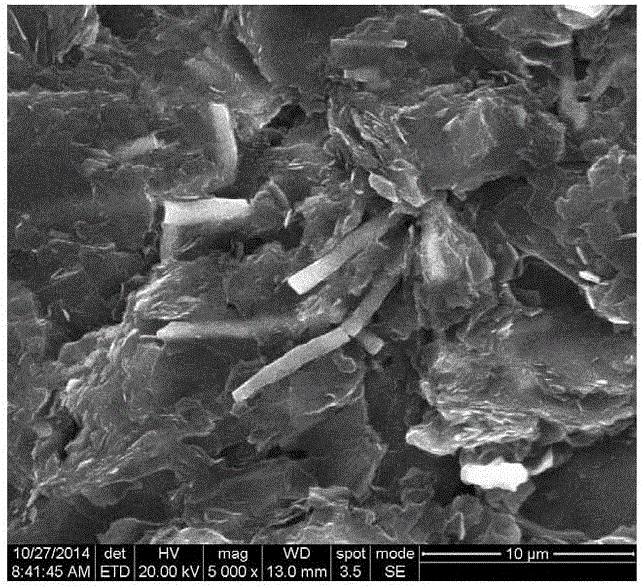

[0030] A protective coating against strong laser ablation of the present invention, the protective coating is prepared from flake graphite, SiC whiskers, epoxy-modified silicone resin and phenolic resin, wherein, by mass fraction, Flake graphite is 50%, SiC whisker is 10%, epoxy-modified silicone resin is 32%, phenolic resin is 8%, and the mass ratio of epoxy-modified silicone resin to phenolic resin is 4:1.

[0031] In this embodiment, the diameter of the flake graphite is 80 microns to 100 microns.

[0032] In this example, the epoxy-modified silicone resin comes from epoxy-modified silicone resin solution, specifically the epoxy-modified silicone resin solution produced by Jiangsu Jiangyin Osaka Paint Co., Ltd., the trade name is TR613, and its solid The content is 50%. That is to say, the mass of the epoxy-modified silicone resin contained in the epoxy-modified silicone resin solution accounts for 32% of the total mass of the above four kinds of coating raw materials.

...

Embodiment 2

[0043] A protective coating against strong laser ablation of the present invention, the protective coating is prepared from flake graphite, SiC whiskers, epoxy-modified silicone resin and phenolic resin, wherein, by mass fraction, Flake graphite is 60%, SiC whisker is 5%, epoxy-modified silicone resin is 25%, phenolic resin is 10%, and the mass ratio of epoxy-modified silicone resin to phenolic resin is 2.5:1.

[0044] In this embodiment, the diameter of the flake graphite is 50 microns to 80 microns.

[0045] In this example, the epoxy-modified silicone resin comes from epoxy-modified silicone resin solution, specifically the epoxy-modified silicone resin solution produced by Jiangsu Jiangyin Osaka Paint Co., Ltd., the trade name is TR613, and its solid The content is 50%. That is to say, the mass of the epoxy-modified silicone resin contained in the epoxy-modified silicone resin solution accounts for 25% of the total mass of the above four kinds of coating raw materials.

...

Embodiment 3

[0050] A protective coating against strong laser ablation of the present invention, the protective coating is prepared from flake graphite, SiC whiskers, epoxy-modified silicone resin and phenolic resin, wherein, by mass fraction, Flake graphite is 50%, SiC whisker is 5%, epoxy-modified silicone resin is 38%, phenolic resin is 7%, and the mass ratio of epoxy-modified silicone resin to phenolic resin is about 5.5:1 .

[0051] In this embodiment, the diameter of the flake graphite is 60 microns to 90 microns.

[0052] In this example, the epoxy-modified silicone resin comes from epoxy-modified silicone resin solution, specifically the epoxy-modified silicone resin solution produced by Jiangsu Jiangyin Osaka Paint Co., Ltd., the trade name is TR613, and its solid The content is 50%. That is to say, the mass of the epoxy-modified silicone resin contained in the epoxy-modified silicone resin solution accounts for 38% of the total mass of the above four kinds of coating raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com