Hyperbranched intumescent flame retardant and preparation method thereof

An intumescent flame retardant and terminal hydroxyl hyperbranched technology, which is applied in the field of flame retardants, can solve the problems of large addition of hyperbranched intumescent flame retardants and unfavorable cost control, so as to improve flame retardant efficiency and charcoal formation rate, the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

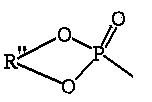

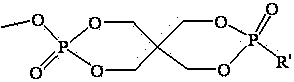

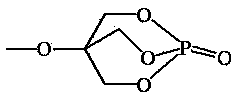

[0058] (1) Accurately weigh 6.665 g (0.045 mol) of phthalic anhydride with an electronic balance, measure 30 mL of N,N-dimethylacetamide (DMAc), put it in a beaker with a capacity of 100 mL, and fully dissolve . Add 4.731 g (0.045mol) of diethanolamine to a three-necked flask with a capacity of 500 mL (pay attention to moisture-proof), then fix the three-necked flask on a magnetic stirrer, and add a clean magnet. Put the fully dissolved phthalic anhydride in a constant pressure dropper with a capacity of 100 mL, then place the constant pressure dropper on a three-neck flask, open the cock, and drop it in about half an hour, then react for 3.5 h, that is Made AB 2 monomer;

[0059] (2) First weigh 4.600 g (0.030 mol) of phosphorus oxychloride and place it in a constant pressure dropper; weigh 4.085 g (0.030 mol) of pentaerythritol and place it in a prepared 40 mL In the three-necked flask with ring (nitrogen protection); put the oil bath on the magnetic stirrer, then put the...

Embodiment approach 2

[0064] (1) Accurately weigh 15.552 g (0.105 mol) of phthalic anhydride with an electronic balance, measure 55 mL of N,N-dimethylacetamide (DMAc), place in a beaker with a capacity of 100 mL, and fully dissolve . Add 11.040 g (0.105 mol) of diethanolamine to a three-necked flask with a capacity of 500 mL (pay attention to moisture-proof), then fix the three-necked flask on a magnetic stirrer, and add a clean magnet. Put the fully dissolved phthalic anhydride in a constant-pressure dropper with a capacity of 100 mL, then place the constant-pressure dropper on a three-neck flask, open the cock, and complete the dropwise addition in about 45 minutes, then react for 3.5 hours, that is Made AB 2 monomer;

[0065] (2) First weigh 9.200 g (0.060 mol) of phosphorus oxychloride and place it in a constant pressure dropper; weigh 8.169 g (0.060 mol) of pentaerythritol and place it in a prepared In the three-necked flask (nitrogen protection); put the oil bath on the magnetic stirrer, t...

Embodiment approach 3

[0070] (1) Accurately weigh 33.325 g (0.225 mol) of phthalic anhydride with an electronic balance, measure 85 mL of N,N-dimethylacetamide (DMAc), place in a beaker with a capacity of 100 mL, and fully dissolve . Add 23.657 g (0.225 mol) of diethanolamine to a three-necked flask with a capacity of 500 mL (pay attention to moisture-proof), then fix the three-necked flask on a magnetic stirrer, and add a clean magnet. Put the fully dissolved phthalic anhydride in a constant pressure dropper with a capacity of 100 mL, then place the constant pressure dropper on the three-necked flask, open the cock, and drop it in about 60 minutes, then react for 3.5 hours, that is Made AB 2 monomer;

[0071] (2) First weigh 18.400 g (0.120 mol) of phosphorus oxychloride and place it in a constant-pressure dropper; weigh 16.338 g (0.120 mol) of pentaerythritol and place it in a prepared 40 mL In the three-necked flask (nitrogen protection); put the oil bath on the magnetic stirrer, then put the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com