Lignin inrumescent flame retardant preparation method

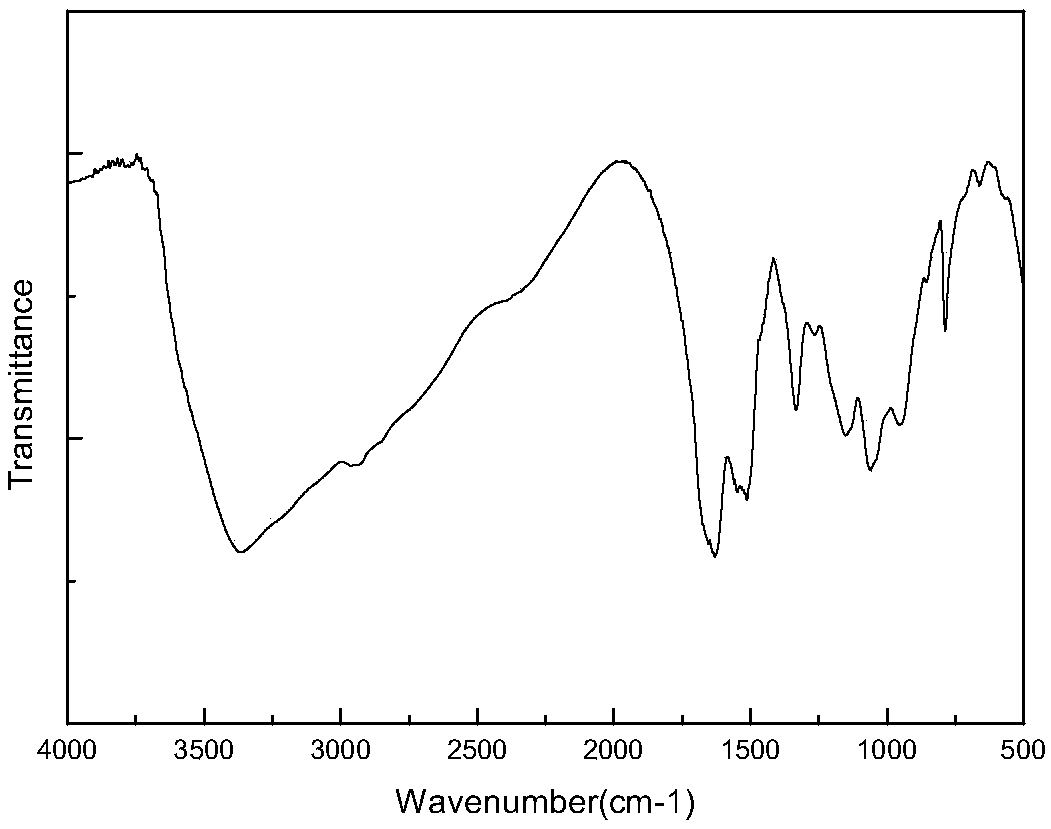

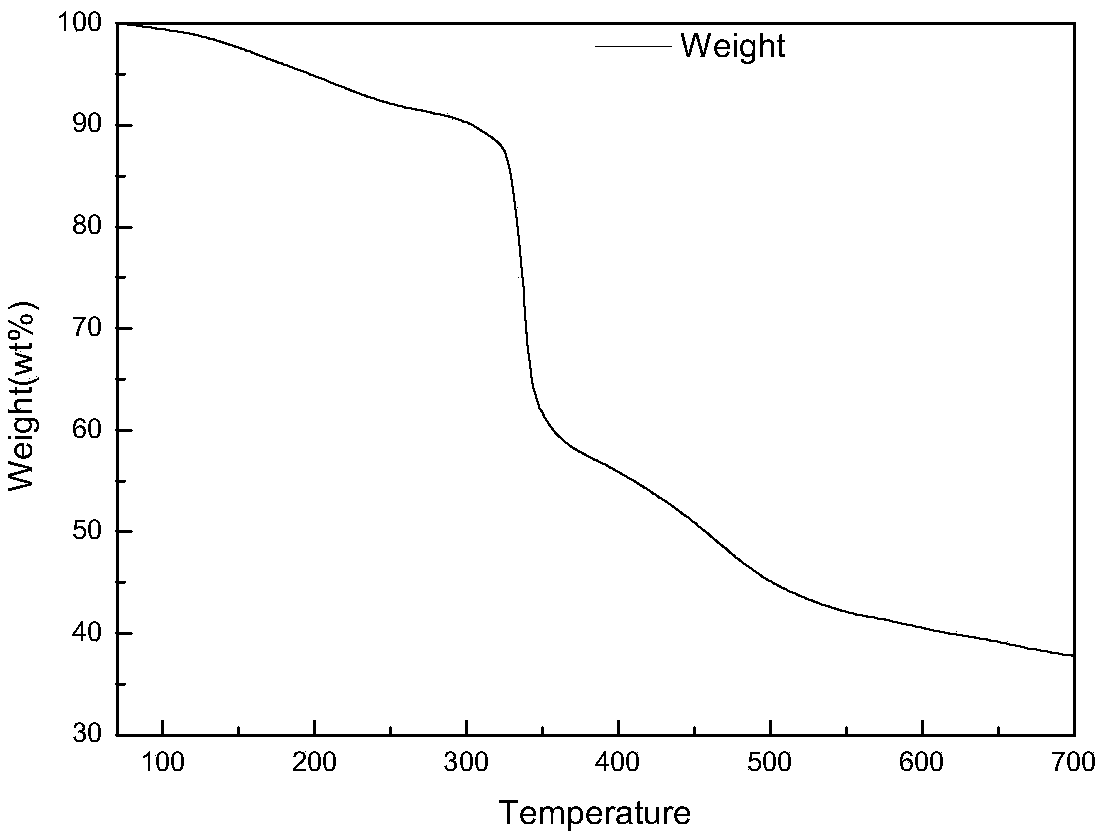

An intumescent flame retardant, lignin-based technology, applied in the field of flame retardant, can solve the problems of environmental pollution, resource waste, etc., and achieve thermal stability, good char formation, high char formation rate, and strong flame retardant effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

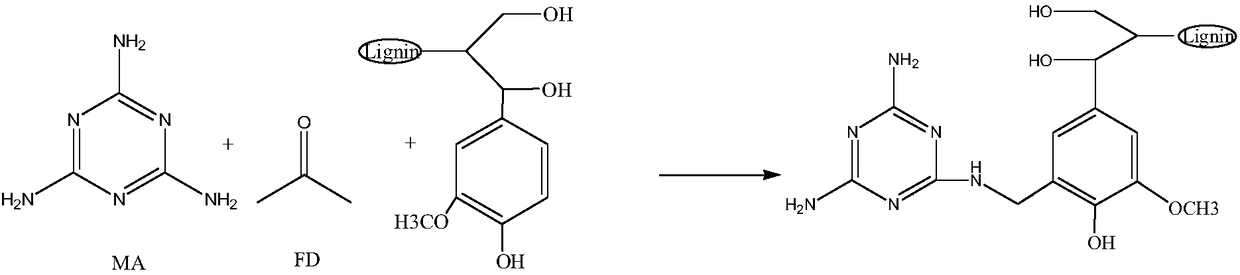

Method used

Image

Examples

Embodiment 1

[0036] Put 8.07g of alkali lignin into a 500ml three-necked bottle and add 80g of deionized water, pass through the condensed water, stir, raise the temperature to 70°C, add 12.906g of melamine into the system, stir for 10min; The formaldehyde solution (37wt%) was slowly added dropwise into the three-necked flask for 1 hour, and the temperature was maintained for 6 hours of reaction. After the reaction, add 20.88g phytic acid solution (50wt%) into the there-necked flask, filter, wash the filter residue with deionized water 3 times, then dry the filter residue and place it in a vacuum oven at 80°C for 24h. Grinding and pulverizing the product, and then putting the product into a ball mill for 24 hours to finally obtain an intumescent flame retardant containing phosphorus and nitrogen elements.

Embodiment 2

[0038] Put 16.14 alkali lignin into a 500ml three-necked bottle and add 160g deionized water, pass condensed water, stir, heat up to 70°C, add 25.818g melamine into the system, stir for 10min; heat up to 90°C, add 26.16g formaldehyde The solution (37wt%) was slowly added dropwise into the three-necked flask for 2 hours, and the temperature was maintained for 7 hours. After the reaction, add 83.52g phytic acid solution (50wt%) into the there-necked flask, filter, wash the filter residue three times with deionized water, then dry the filter residue, and place it in a vacuum oven at 80°C for 24h. Grinding and pulverizing the product, and then putting the product into a ball mill for 36 hours to finally obtain an intumescent flame retardant containing phosphorus and nitrogen elements.

Embodiment 3

[0040] Put 8.07g of alkali lignin into the three-necked flask and add 80g of deionized water, pass through the condensed water, stir, stir, raise the temperature to 70°C, add 12.906g of melamine into the system, stir for 10min; raise the temperature to 90°C, put 13.08g The formaldehyde solution (37wt%) was slowly added dropwise into the three-necked flask for 1 hour, and the temperature was maintained for 6 hours of reaction. After the reaction, add 41.76g phytic acid solution (50wt%) into the there-necked flask, filter, wash the filter residue with deionized water 3 times, then dry the filter residue, and place it in a vacuum oven at 80°C for 24h. Grinding and pulverizing the product, and then putting the product into a ball mill for 24 hours to finally obtain an intumescent flame retardant containing phosphorus and nitrogen elements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com