Macromolecule triazine charring agent and preparation method thereof

A triazine carbon-forming agent, macromolecular technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc. Short time, simple synthesis process, and the effect of preventing migration and uneven dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step (1). With 216 grams of H 2 N(CH 2 ) 5 COO(CH 2 ) 5 NH 2 (1mol) mixed with 100 grams of potassium bicarbonate (1mol), in a nitrogen atmosphere, stirred at 25°C for 1 hour to obtain a difunctional active hydrogen compound;

[0032] Step (2). Add 1L of N-methylpyrrolidone solution of cyanuric chloride with a concentration of 1mol / L to the difunctional active hydrogen compound, and react at 25°C for 8 hours;

[0033] Step (3). Adding 1L concentration to the reaction solution is the I(CF of 1mol / L 2 ) 5 SO 3The N-methylpyrrolidone solution of H, then add 127 grams of metal copper (2mol), raise the temperature to 80°C, and react for 12 hours;

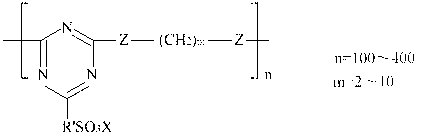

[0034] Step (4). After the reaction, suction filtration, water washing, and drying were performed to obtain a macromolecular triazine char-forming agent with the following structure. The macromolecular triazine char-forming agent had an average molecular weight of 62,300.

[0035]

[0036]

Embodiment 2

[0038] Step (1). 138 grams of HSCH 2 COOCH 2 SH (1mol) was mixed with 168 grams of sodium bicarbonate (2mol), and stirred at 45°C for 0.5 hours in an argon atmosphere to obtain a difunctional active hydrogen compound;

[0039] Step (2). Add 5L of N-N dimethylformamide solution of cyanuric chloride with a concentration of 0.1mol / L to the difunctional active hydrogen compound, and react at 45°C for 4 hours;

[0040] Step (3). Adding 7.5L concentration to the reaction solution is the ICF of 0.1mol / L 2 OCF 2 CF 2 SO 3 Na's N-N dimethylformamide solution, then add 177 grams of nickel metal (3mol), raise the temperature to 150°C, and react for 8 hours;

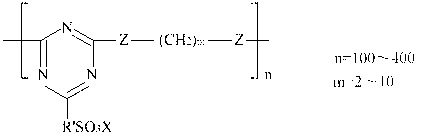

[0041] Step (4). After the reaction, suction filtration, water washing, and drying were performed to obtain a macromolecular triazine char-forming agent with the following structure. The macromolecular triazine char-forming agent had an average molecular weight of 48,300.

[0042]

[0043]

Embodiment 3

[0045] Step (1). 134 grams of HO (CH 2 ) 2 COO(CH 2 ) 2 OH (1mol) was mixed with 60 grams of sodium hydroxide (1.5mol), and stirred at 30°C for 45 minutes in a nitrogen atmosphere to obtain a difunctional active hydrogen compound;

[0046] Step (2). Add 5L of N-N dimethylacetamide solution of cyanuric chloride with a concentration of 0.3mol / L to the difunctional active hydrogen compound, and react at 30°C for 6 hours;

[0047] Step (3). Adding 2.5L concentration in the reaction solution is the Br(CF of 0.3mol / L 2 ) 2 SO 3 K's N-N dimethylacetamide solution, then add 212 grams of metal palladium (2mol), raise the temperature to 100 ° C, and react for 10 hours;

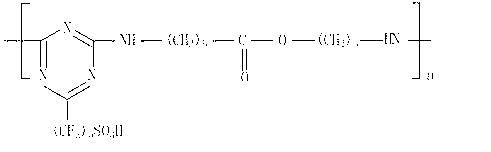

[0048] Step (4). After the reaction, suction filtration, washing with water, and drying, the macromolecular triazine char-forming agent with the following structure was obtained. The average molecular weight of the macromolecular triazine char-forming agent was 47190.

[0049]

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com