Flame-retardant rubber

A flame retardant rubber and rubber technology, applied in the field of flame retardant rubber, can solve problems such as easy agglomeration, and achieve the effects of improving mechanical properties, increasing carbon formation rate, and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

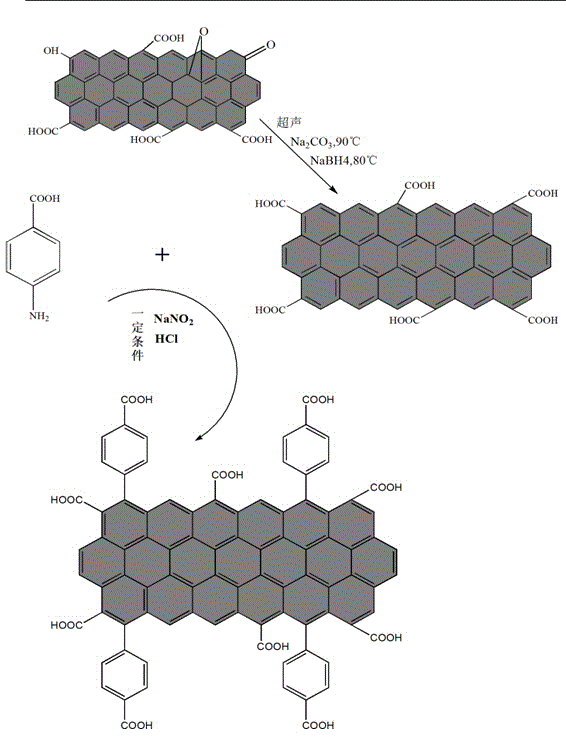

[0021] Ultrasonic disperse 1g of graphene oxide in 300ml of aqueous solution, add 600mg of sodium borohydride, prepare 5% sodium carbonate solution to adjust the pH of the graphene aqueous solution to a pH of 9-10, and stand at 80°C for 1 hour. The product was obtained by centrifugation. Centrifuge the product into 100ml of aqueous solution, adjust the pH to 5-6 with 1mol / L hydrochloric acid solution, add 18mg of sodium nitrite and 46mg of benzoic acid, stir for 2 hours in an ice-water bath, and centrifuge to obtain functionalized graphene. .

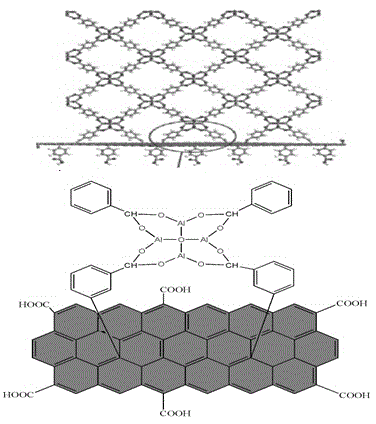

[0022] 0.5 g of functionalized graphene was ultrasonically dispersed in 100 ml of aqueous solution, and AL-MOFs metal-organic framework was added at room temperature and stirred for 4 hours at room temperature to prepare a metal-organic framework grafted functionalized graphene synergistic flame retardant.

[0023] 100 parts of natural rubber; 1.2 parts of sulfur; 0.8 parts of accelerator CZ; 0.35 parts of accelerator TMTD;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com