Preparation method and application of dummy template molecularly imprinted polymer

A technology that replaces templates and molecular imprinting. It is used in chemical instruments and methods, material separation, and material analysis. It can solve problems such as template leakage and inaccuracy, and achieve high-efficiency detection and ultra-high specific selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

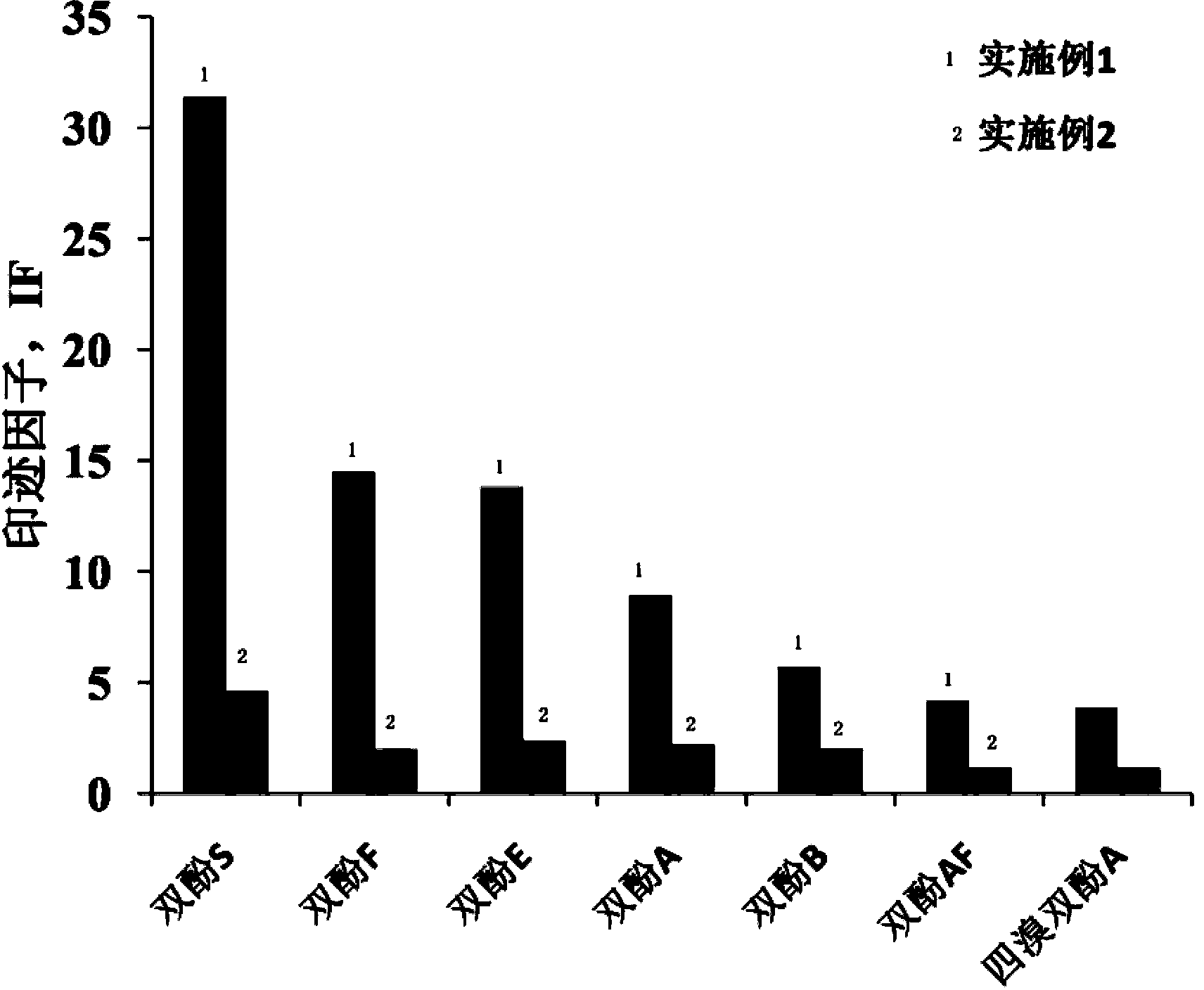

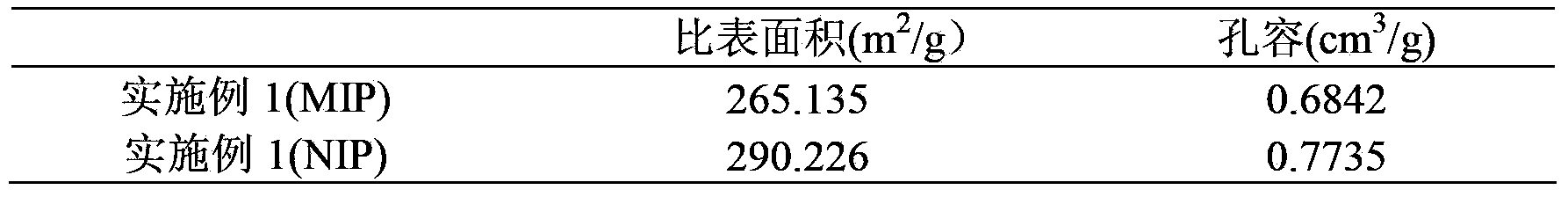

[0023] Dissolve 1 mmol of the surrogate template molecule bisphenol S into acetonitrile (5.6 mL) to prepare a pre-polymerization solution, place the mixture in an ice bath for 10-15 minutes of ultrasonic mixing, then pass nitrogen gas for 10 minutes to remove the oxygen in the system, seal it and refrigerate it at 4°C for 2 hours, then place it at 60°C for 24 hours . The white massive polymer produced by the reaction is pulverized, ground, sieved and settled to obtain a polymer with a particle size of 45-63 μm. The obtained polymer was subjected to Soxhlet extraction using methanol acetic acid (9:1, v / v) and methanol as extraction solvents in order to remove template molecules and other interfering substances, and the obtained polymer was dried in a vacuum oven at 60°C A white molecularly imprinted polymer (MIP) was obtained overnight.

[0024] A control non-imprinted polymer (NIP) was prepared and treated the same as above except that no template molecules were added. The ...

Embodiment 2

[0030]Dissolve 1 mmol of the surrogate template molecule bisphenol S into acetonitrile (5.6 mL) containing 4 mmol of the functional monomer methacrylic acid, 20 mmol of the crosslinker ethylene glycol-based dimethacrylate, and 0.04 g of the initiator azobisisobutyronitrile Prepare a pre-polymerization solution in an ice bath, put the mixed solution in an ice bath for 10-15 minutes and mix it uniformly, then pass nitrogen gas for 10 minutes to remove the oxygen in the system, seal it and refrigerate it at 4°C for 2h, then place it at 60°C for 24h. The white massive polymer produced by the reaction is pulverized, ground, and sieved to obtain a polymer with a particle size of 45-63 μm. The obtained polymer was sequentially Soxhlet extracted using methanol acetic acid (9:1, v / v) and methanol as the extraction solvent to remove template molecules and interfering substances, and the obtained polymer was dried overnight in a vacuum oven at 60°C A white molecularly imprinted polymer w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com