Optical resin monomer material

A technology of optical resin and monomer, which is applied in optics, optical components, instruments, etc., can solve the problems of thermal resistance, poor visible light transmittance, thick thickness, etc., achieve good visible light transmittance, improve refractive index, The effect of high refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

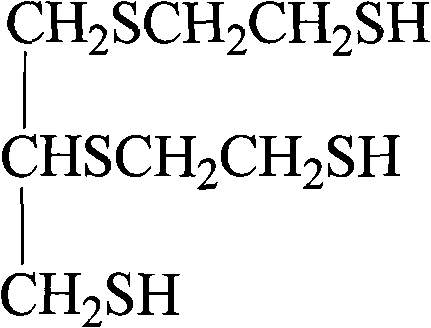

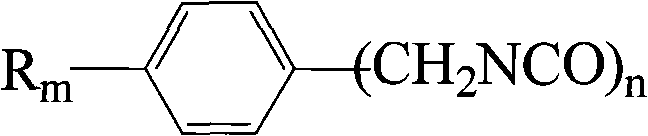

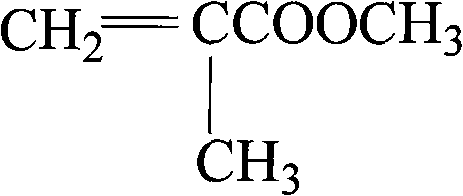

[0028] With 1,2-bis(2-mercaptoethylthio)-3-mercaptopropane 15%, m-xylylene diisocyanate 20%, a-methyl methacrylate 10%, tetrabromobisphenol A bis(hydroxyl 12% of methyl) ether, 23% of 2-hydroxy-3-phenoxy propyl acrylate, and 20% of p-phenylene diethylene are formulated into optical resin monomer materials. Its refractive index is 1.571, and the refractive index of the lens is 1.597.

[0029] Experiment two:

[0030] Take 1,2-bis(2-mercaptoethylthio)-3-mercaptopropane 18%, m-xylylene diisocyanate 25%, a-methyl methacrylate 8%, tetrabromobisphenol A bis(2 -Hydroxyethyl)ether 15%, 2-hydroxy-3-phenoxy propyl acrylate 20%, and a-methylstyrene 14% are formulated into optical resin monomer materials. Its refractive index is 1.568, and the refractive index of the lens is 1.601.

example 3

[0032] With 1,2-bis(2-mercaptoethylthio)-3-mercaptopropane 12%, 5-ethyl-1,3-xylylene diisocyanate 18%, a-methyl methacrylate 10%, Tetrabromobisphenol A bis(3-hydroxypropyl) ether 15%, 2-hydroxy-3-phenoxy propyl acrylate 28%, and m-phenylene diethylene 17% are formulated into optical resin monomer materials. Its refractive index is 1.570, and the refractive index of the lens is 1.598.

example 4

[0034] With 1,2-bis(2-mercaptoethylthio)-3-mercaptopropane 20%, p-xylylene diisocyanate 15%, a-methyl methacrylate 10%, tetrabromobisphenol A bis(3 -Hydroxypropyl ether 10%, 2-hydroxy-3-phenoxy propyl acrylate 25%, and m-bromostyrene 20% are formulated into optical resin monomer materials. Its refractive index is 1.571, and the refractive index of the lens is 1.600.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com