Method for manufacturing CTI copper-clad laminate

A technology of copper clad laminates and manufacturing methods, applied in lamination, bonding methods of adhesive heating, lamination devices, etc., can solve the problems of resin component aging, poor insulation performance of substrates, etc., and prolong the service life , Improve the effect of tracking voltage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Mixing formula:

[0057] Low bromine epoxy resin (Br: 10%) 125

[0058] Dicyandiamide 3.0

[0059] Dimethylformamide 30

[0060] Dimethylimidazole 0.070

[0061] Aluminum hydroxide 30

[0062] 2. Prepreg control parameters

[0063] Gluing machine oven temperature: 190°C

[0064] Gluing speed: 15m / min

[0065] Resin content: 43%

[0066] Gel time: 105s

[0067] Liquidity: 21%

[0068] Volatile matter: 0.35%;

[0069] 3. Arranging boards

[0070] 8 pieces of 7628 prepreg (1.6mm board material), the copper foil is H OZ.

[0071] 4. Thermoforming

[0072] Hot pressing temperature: 185°C

[0073] Pressure: 30kg / cm 2

[0074] Hot pressing time: 90min

[0075] 5. The basic performance parameters are as follows in Table 2:

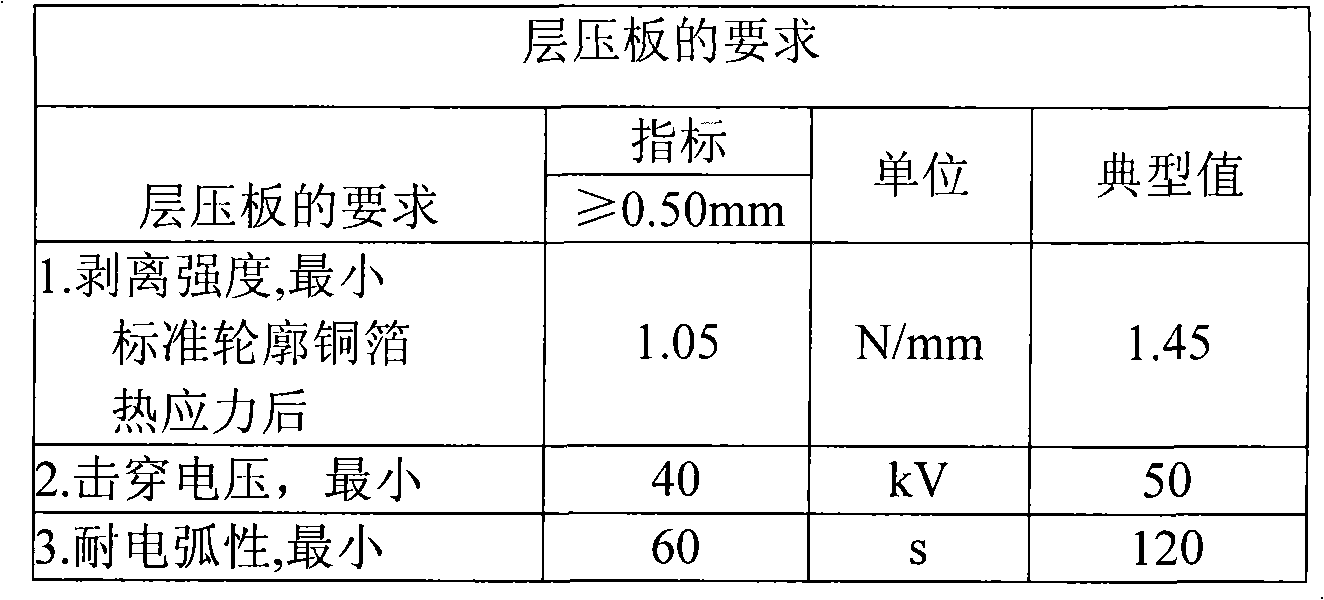

[0076] Table 2

[0077]

[0078] 4. Thermal stress at 288°C

Embodiment 2

[0080] 1. Mixing formula:

[0081] Low bromine epoxy resin (Br: 14%) 125

[0082] Dicyandiamide 3.2

[0083] Dimethylformamide 32

[0084] Dimethylimidazole 0.065

[0085] Aluminum hydroxide 45

[0086] 2. Prepreg control parameters

[0087] Gluing machine oven temperature: 200°C

[0088] Gluing speed: 17m / min

[0089] Resin content: 46%

[0090] Gel time: 95s

[0091] Liquidity: 22%

[0092] Volatile matter: 0.35%;

[0093] 3. Arranging boards

[0094] 8 pieces of 7628 prepreg (1.6mm board material), copper foil is 1OZ.

[0095] 4. Thermoforming

[0096] Hot pressing temperature: 200°C

[0097] Pressure: 30kg / cm 2

[0098] Hot pressing curing time: 60min

[0099] 5. The basic performance parameters are as follows in Table 3:

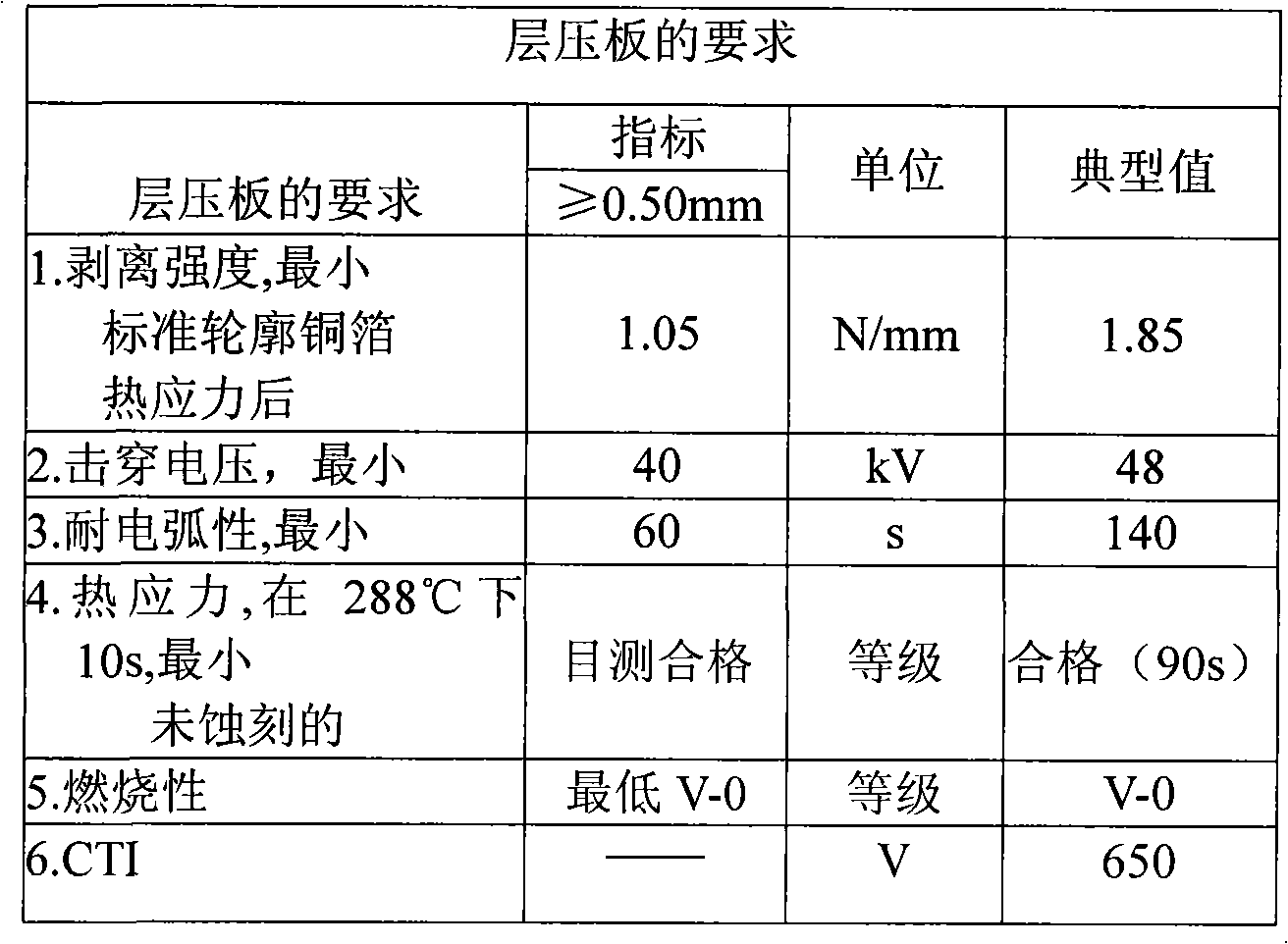

[0100] table 3

[0101]

Embodiment 3

[0103] 1. Mixing formula:

[0104] Low bromine epoxy resin (Br: 12%) 133

[0105] Dicyandiamide 3.4

[0106] Dimethylformamide 34

[0107] Dimethylimidazole 0.060

[0108] Aluminum hydroxide 30

[0109] 2. Prepreg control parameters

[0110] Gluing machine oven temperature: 210°C

[0111] Gluing speed: 20m / min

[0112] Resin content: 45%

[0113] Gel time: 100s

[0114] Liquidity: 22%

[0115] Volatile matter: 0.30%;

[0116] 3. Arranging boards

[0117] 6 pieces of 7628 prepreg (1.2mm board material), copper foil is 2OZ.

[0118] 4. Thermoforming

[0119] Hot pressing temperature: 210°C

[0120] Pressure: 30kg / cm 2

[0121] Hot pressing time: 40min

[0122] 5. The basic performance parameters are as follows in Table 4:

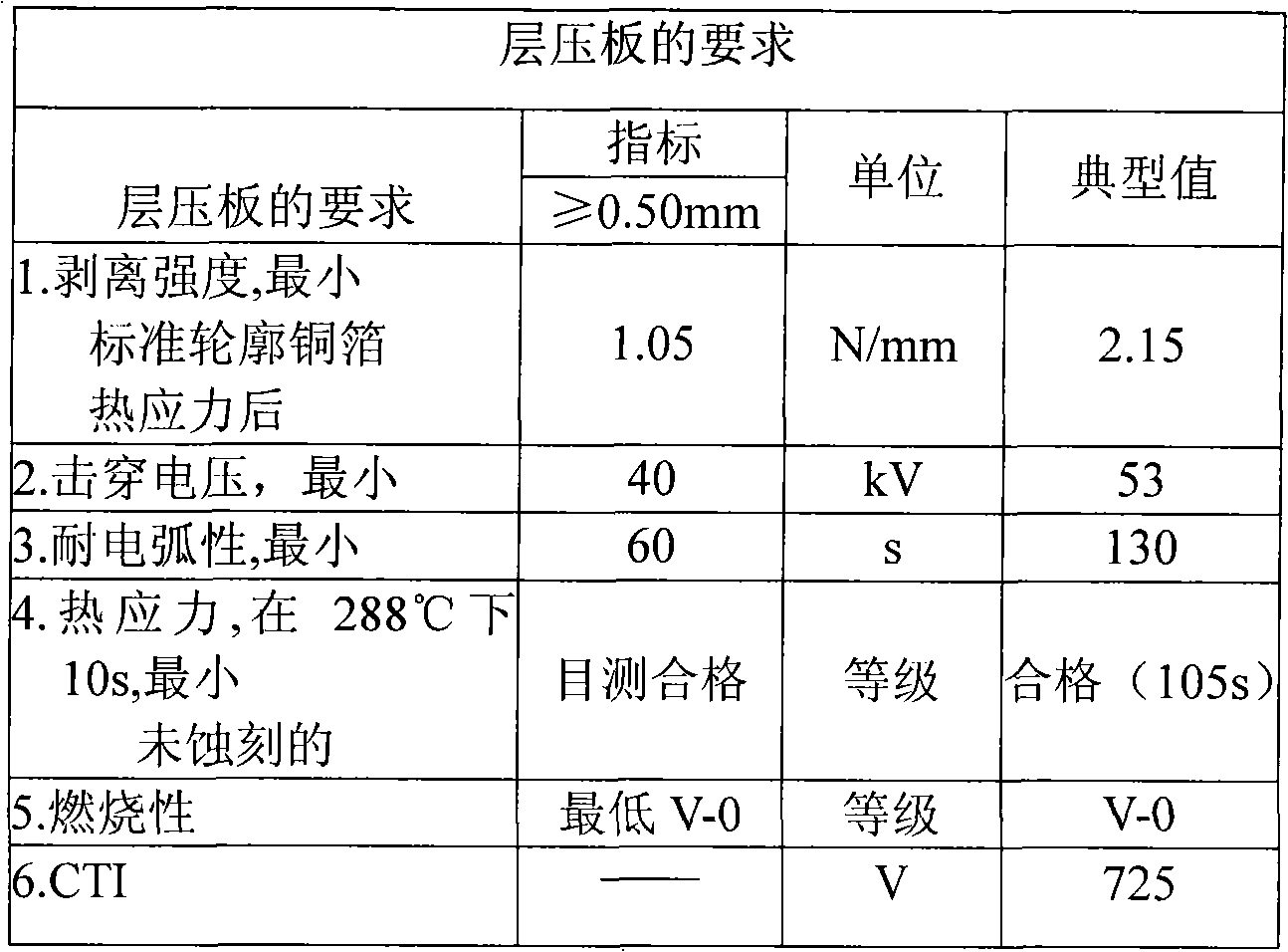

[0123] Table 4

[0124]

[0125] The present invention focuses on the research of the epoxy resin system used in copper-clad laminates: FR-4 laminates usually use brominated epoxy resin, and the Br---C bond often makes the polarity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com