Flame retardant composition copper clad laminate and preparation thereof

A composition and flame retardant technology, applied in the field of flame retardant composition and copper clad laminates and their preparation, can solve the problems of poor heat resistance, low water absorption, high water absorption, etc., to solve glue flow and reduce fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the flame retardant composition provided by the invention comprises mixing a main resin, a curing agent and tetrabromobisphenol A. With respect to the host resin of 100 parts by weight, the consumption of curing agent is preferably 50-120 parts by weight, more preferably 70-90 parts by weight; the consumption of tetrabromobisphenol A is preferably 5-30 parts by weight, more preferably 10- 20 parts by weight.

[0040] Compared with the polymerization of tetrabromobisphenol A and the main resin to form low-bromine or high-bromine epoxy resin, the present invention directly mixes tetrabromobisphenol A with the main resin and curing agent, and the tetrabromobisphenol A is not mixed with the main resin. reaction, therefore, tetrabromobisphenol A can also play a role in curing the bisphenol A novolac epoxy resin while playing a flame retardant effect, and can reduce the fluidity of the bisphenol A novolak epoxy resin. Effectively solve the glue flow...

Embodiment 1

[0056] This example is used to illustrate the flame retardant composition provided by the present invention and its preparation method.

[0057] 100 parts by weight of bisphenol A novolac epoxy resin (produced by Yueyang Petrochemical Epoxy Resin Factory, trade mark: CYDBN-240, number average molecular weight: 4500, epoxy equivalent: 220), 120 parts by weight of phenolic resin (Chuang Mingda Produced by the company, brand name: RI-3500, number average molecular weight: 3550, free phenol content: 0.1%) and 16 parts by weight of tetrabromobisphenol A (Jiahe Chemical Factory, TBBA) were mixed to obtain flame retardant composition Z1.

Embodiment 2

[0059] This example is used to illustrate the flame retardant composition provided by the present invention and its preparation method.

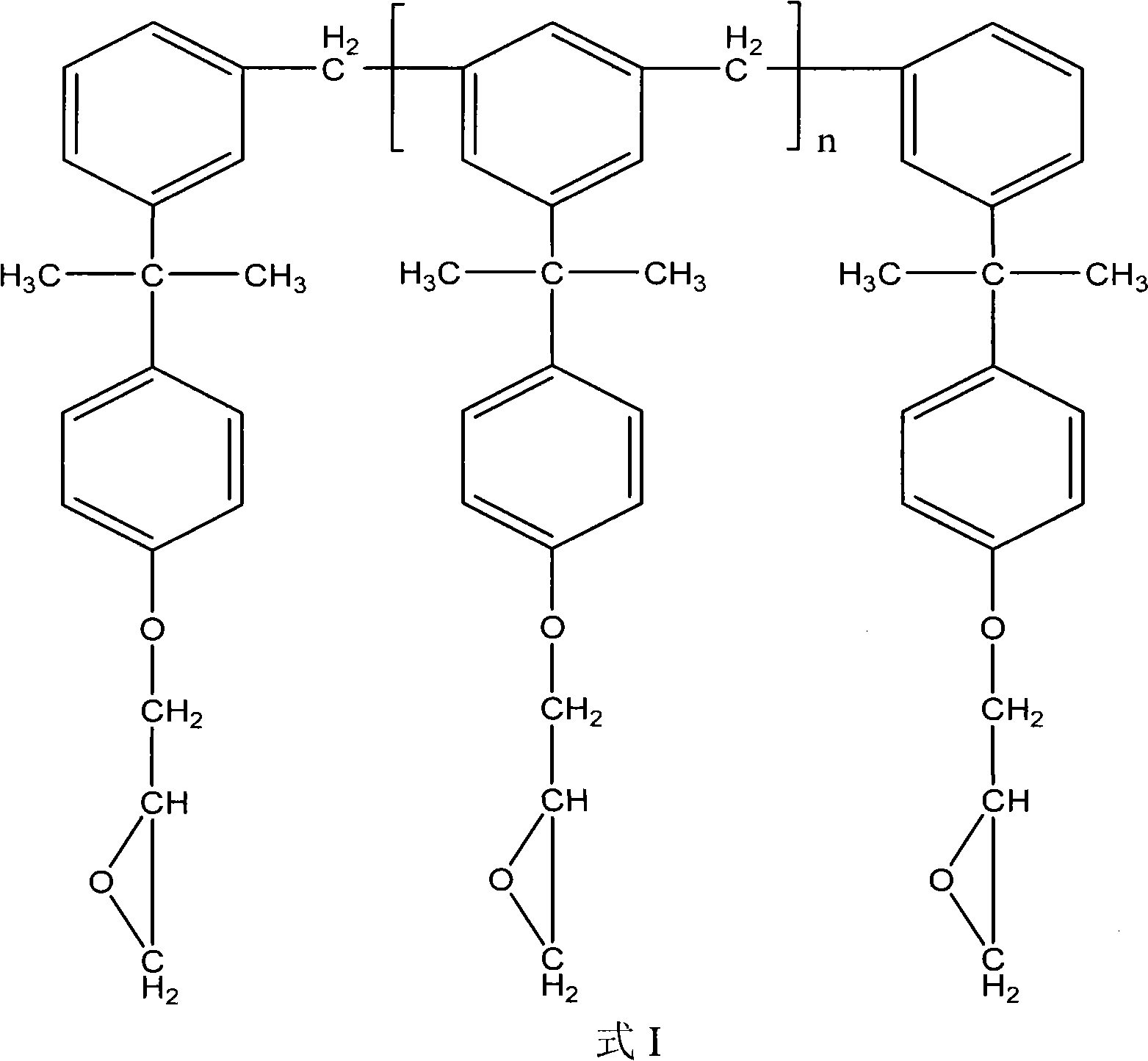

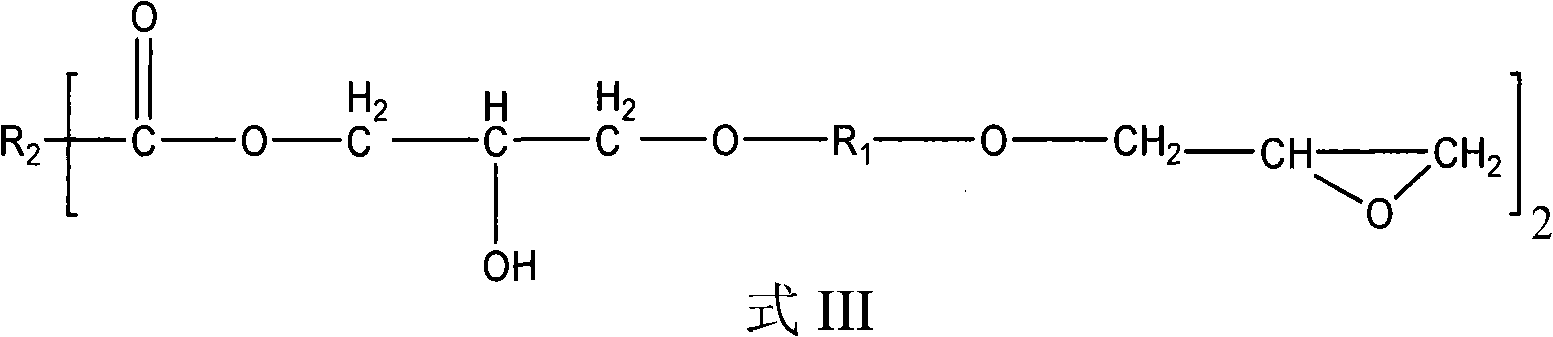

[0060] Carboxyl-terminated liquid nitrile rubber (Nuoyu, CTBN1300*13) with a weight ratio of 4:6 and brominated epoxy resin (produced by Guangzhou Hongchang Epoxy Resin Company, brand: 454A80, number average molecular weight is 3100, bromine content is 20%, and the epoxy equivalent is 465) at 90°C for 1 hour to obtain a prepolymer of carboxyl-terminated liquid nitrile rubber and brominated epoxy resin. The structural formula of this prepolymer is shown in formula III, wherein in R 1 In, m is 9; in R 2 Among them, x1 is 4, x2 is 2, y is 4, and n is 6.

[0061] 100 parts by weight of bisphenol A novolac epoxy resin (produced by Yueyang Petrochemical Epoxy Resin Factory, trade mark: CYDBN-240, number average molecular weight: 4500, epoxy equivalent: 220), 120 parts by weight of phenolic resin (Chuang Mingda Produced by the company, brand: RI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com