Composite capable of efficiently degrading tetrabromobisphenol A, as well as preparation method and application method of composite

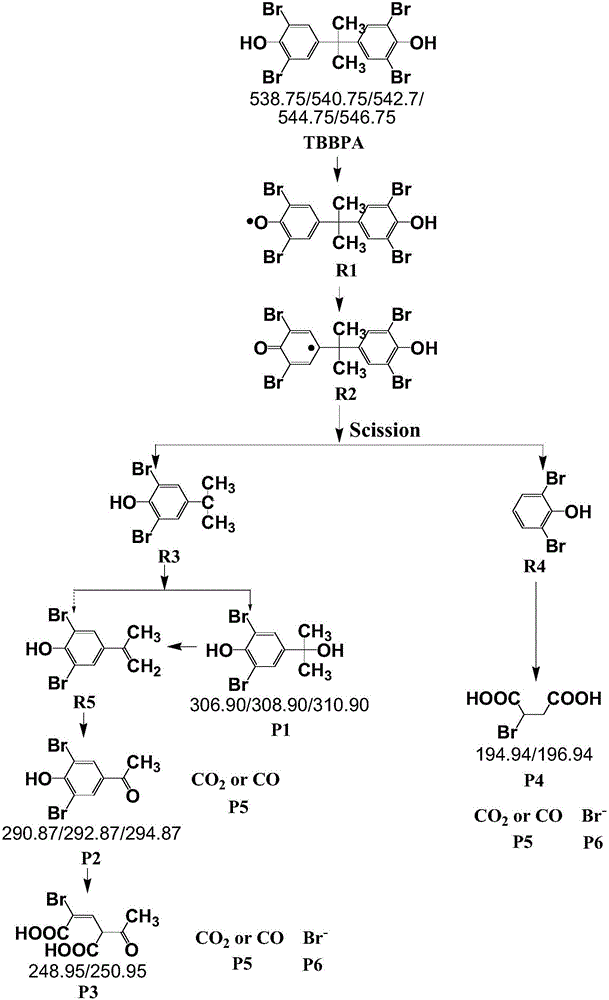

A technology of tetrabromobisphenol and composite materials, which is applied in chemical instruments and methods, catalyst activation/preparation, organic compound/hydride/coordination complex catalysts, etc., can solve high energy consumption, low efficiency, and secondary pollution and other problems, to achieve high degradation efficiency, high removal efficiency, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

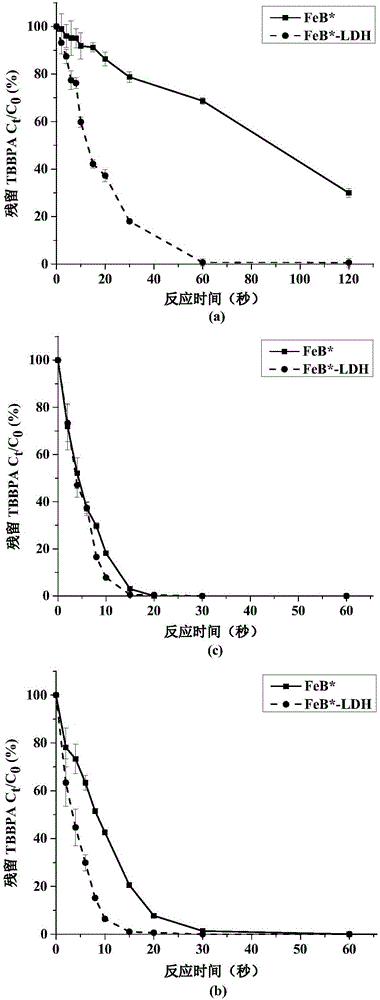

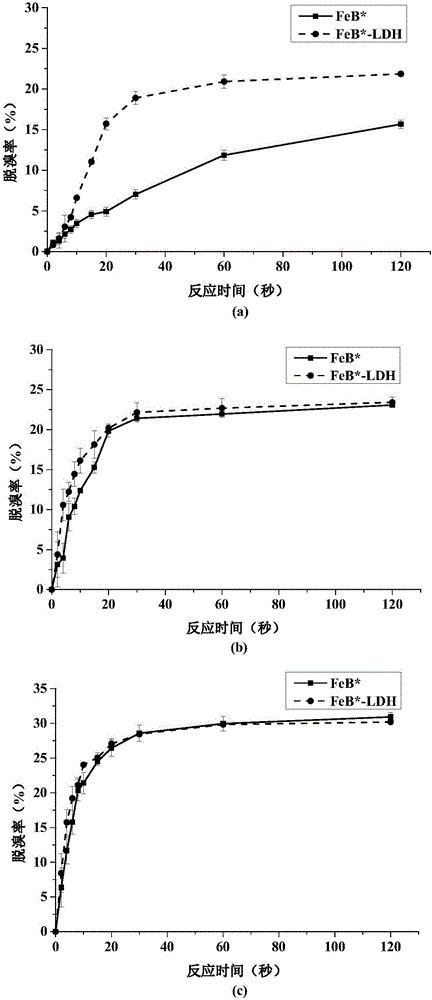

[0063] A method for improving tetraamidohexamethylphenyl ring iron degradation tetrabromobisphenol A efficiency and reutilization rate, the steps are:

[0064] (1) Prepare MgCl containing 3.0mmol 2 and 1.0 mmol AlCl 3 10 milliliters of the mixed solution, and the prepared mixed solution was added to 40 milliliters of 0.15M NaOH solution under vigorous stirring (stirring speed is 1000 rpm) within 5 seconds, then isolated from the air and shaken for 30 minutes, and then centrifuged repeatedly three times. The centrifuged LDH slurry was dispersed into 40 ml of deionized water, and placed in a sterilized pot for hydrothermal treatment at 100 degrees Celsius for 16 hours to obtain a homogeneous suspension of LDH. Quantify the LDH homogeneous suspension, the quantitative method is: weigh the mass of the 20mL glass tube as m 1; Draw 10mL of LDH suspension into a 20mL glass tube, and then place it in a vacuum drying oven at 50°C for 48 hours to ensure that the LDH is absolutely dry...

Embodiment 2

[0070] A method for improving tetraamidohexamethylphenyl ring iron degradation tetrabromobisphenol A efficiency and reutilization rate, the steps are:

[0071] (1) Prepare MgCl containing 3.0mmol 2 and 1.0 mmol AlCl 3 10 milliliters of the mixed solution, the prepared mixed solution was added to 40 milliliters of 0.15M NaOH solution under vigorous stirring (stirring speed is 1200 rpm) within 5 seconds, then isolated from the air and shaken for 35 minutes, then centrifuged and washed repeatedly three times. The centrifuged LDH slurry was dispersed into 40 ml of deionized water, and placed in a sterilized pot for hydrothermal treatment at 150 degrees Celsius for 10 hours to obtain a homogeneous suspension of LDH. The LDH homogeneous suspension was quantified, the quantification method was the same as in Example 1, and the concentration of LDH obtained by quantification was 30 mg / mL.

[0072] (2) 100 mg of freshly prepared LDH was placed in 10 mL of FeB* solutions of different...

Embodiment 3

[0075] A method for improving tetraamidohexamethylphenyl ring iron degradation tetrabromobisphenol A efficiency and reutilization rate, the steps are:

[0076] (1) Prepare MgCl containing 3.0mmol 2 and 1.0 mmol AlCl 3 10 milliliters of the mixed solution, the prepared mixed solution was added to 40 milliliters of 0.15M NaOH solution under vigorous stirring (stirring speed was 1500 rpm) within 5 seconds, then isolated from the air and shaken for 30 minutes, then centrifuged repeatedly three times. The centrifuged LDH slurry was dispersed into 40 ml of deionized water, and placed in a sterilized pot for hydrothermal treatment at 130 degrees Celsius for 12 hours to obtain a homogeneous suspension of LDH. The LDH homogeneous suspension was quantified, and the concentration was 30 mg / mL.

[0077] (2) 100 mg of freshly prepared LDH was placed in 10 mL of FeB* solutions of different concentrations (10, 25, 50, 103, 251, 504, 1038, 2512, 5024, 10541 μmol / L) and stirred for 24 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com