A kind of equipment and method of wood strengthening treatment

A technology for strengthening wood treatment, applied in wood treatment, wood treatment details, electric wood treatment, etc., can solve the problems of wood performance limitations, complex processes, etc., to solve the problem of uneven properties, simple operation, improved strength and dimensional stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

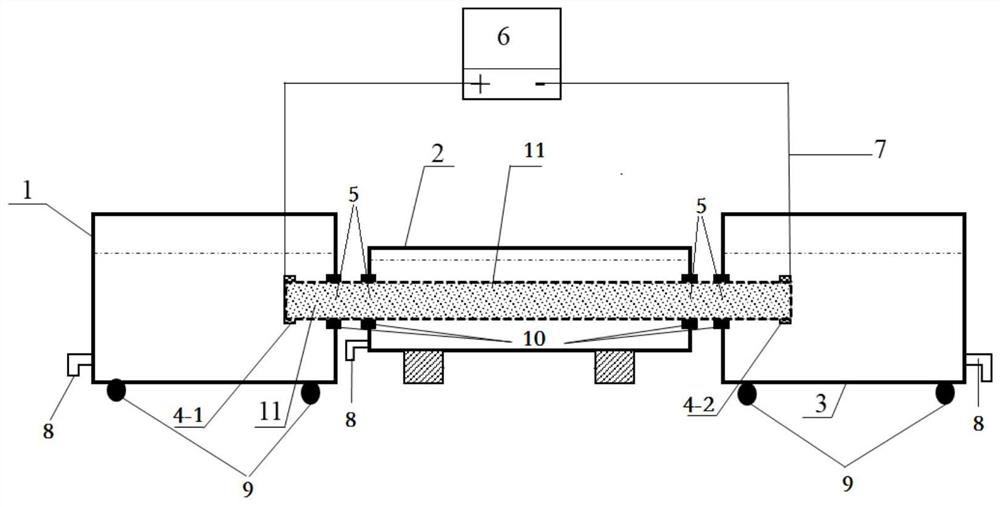

[0072] A device for strengthening wood such as figure 1 As shown, it includes an anode water tank 1 , a soaking water tank 2 and a cathode water tank 3 , and power supply components. A hole 5 is provided on the side walls of the anode water tank 1 , soaking water tank 2 and cathode water tank 3 . The holes 5 are used to support the wood 11 to be treated, and one end of the wood is positioned in the anode water tank 1, the middle section is positioned in the soaking water tank 2, and the other end is positioned in the cathode water tank 3, and the holes 5 are all provided with leak-proof rubber gaskets (liquid-proof pads 10). The bottom of the side walls of the anode water tank 1 , the immersion water tank 2 and the cathode water tank 3 are provided with a drain valve 8 for discharging the liquid in the water tanks, and a pulley 9 is provided at the bottom. The power supply component includes a set of electrodes connected to the DC stabilized output power supply 6 and the wire...

Embodiment 2

[0074] A device for wood strengthening treatment, comprising an anode water tank, a soaking water tank and a cathode water tank, and a power supply component. Three holes are arranged on the side walls of the anode water tank, the soaking water tank and the cathode water tank. One hole in each tank is used to support one piece of wood to be treated (a total of 3 pieces of wood to be treated), and one end of the wood is located in the anode tank, the middle is located in the soaking tank, and the other end is located in the cathode tank. The holes are all set Leak-proof rubber gasket (fluid-proof gasket). The bottoms of the side walls of the anode water tank, the immersion water tank and the cathode water tank are provided with drain valves for discharging the liquid in the water tanks. The power supply part includes 3 sets of electrodes connected to the DC regulated output power supply (power supply) and wires, each set of electrodes includes a positive electrode and a negativ...

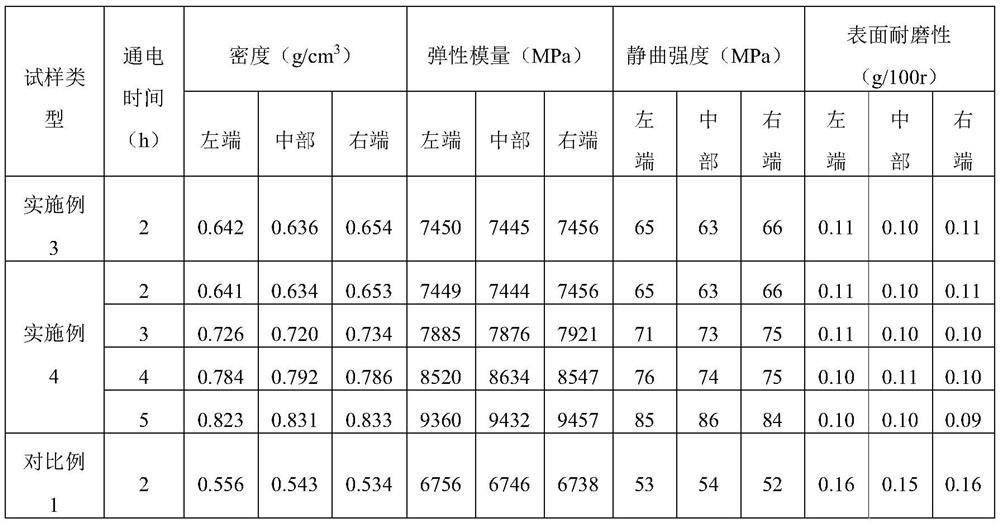

Embodiment 3

[0076] A kind of method that adopts the equipment of wood strengthening treatment of embodiment 1 to carry out wood strengthening treatment, its specific steps are as follows:

[0077] ①Wood pretreatment: select a piece of poplar wood with a diameter D of 13cm and a length of 5m, soak it in a saturated sodium chloride solution for 24 hours, and then take it out to obtain the wood 11 to be treated after soaking in the conductive solution;

[0078] ②Put the wood 11 obtained in step ① through the figure 1 The holes 5 of the anode water tank 1, the soaking water tank 2 and the cathode water tank 3 shown in , and use the leak-proof rubber gasket (leakage-proof gasket 10) to block the gap between the wood and the hole, and fix the wood;

[0079] ③ if figure 1 As shown, the electrodes are fastened to the wood, one end of the wood is fastened to the positive electrode 4-1, and the other end is fastened to the negative electrode 4-2, and the positive electrode 4-1 and the negative ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com