Method for preparing pyrolysis oil by using waste polyolefin plastics and brominated flame-retardant waste plastics

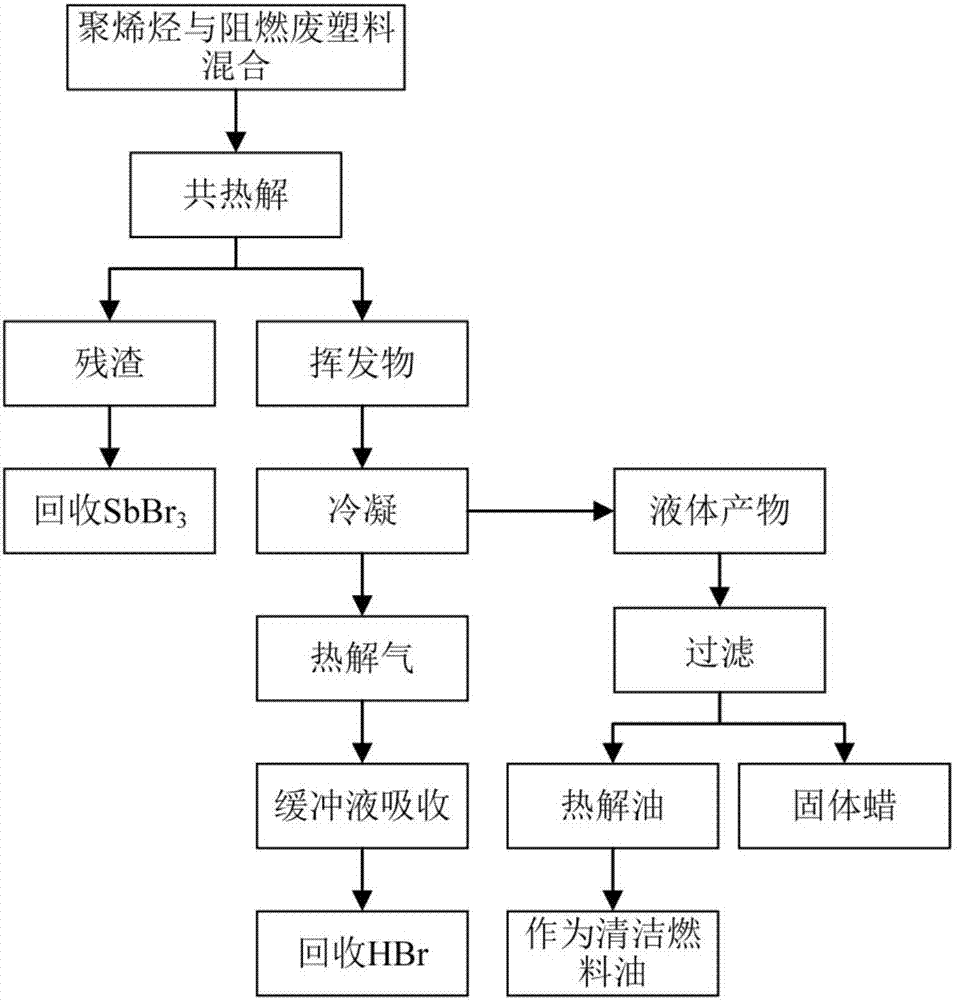

A bromine-based flame retardant and waste polyolefin technology, which is applied in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oils, and the petroleum industry to achieve the effects of reducing organic bromine content, realizing efficient recycling, and realizing synergistic resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In Example 1, the bromine-containing flame-retardant electronic waste plastic HIPS is used alone as the reaction raw material, and the method for preparing pyrolysis oil by pyrolysis includes the following steps:

[0031] Step (1): Bromine-containing flame-retardant electronic waste plastic HIPS is broken into small particles with a particle size between 75 μm and 250 μm.

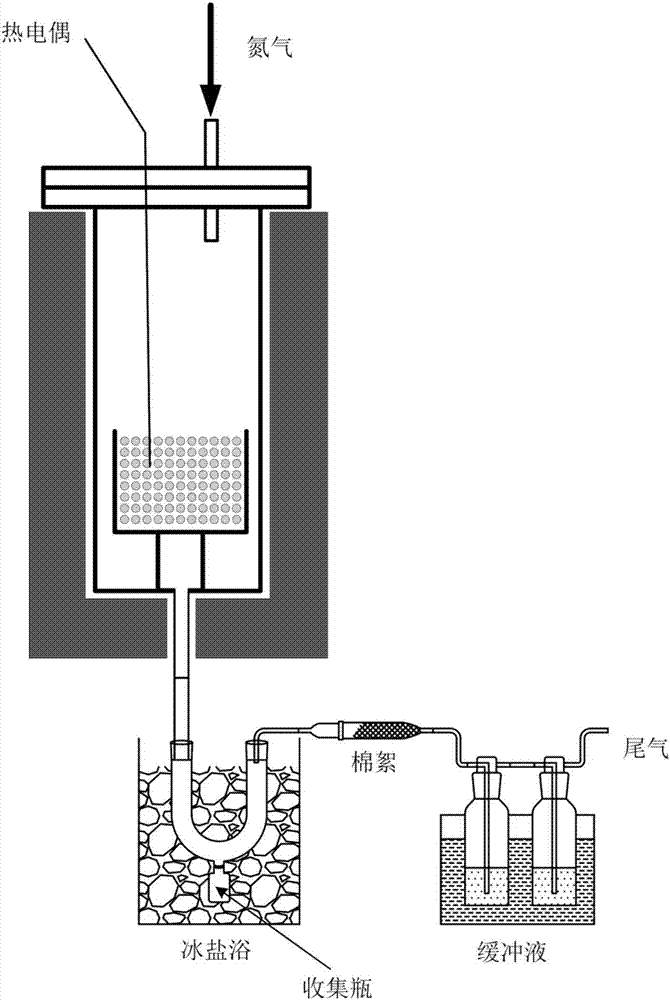

[0032] Step (2): Weigh 10 g of small plastic particles obtained in step (1) and place in figure 1 in the fixed bed reactor shown.

[0033] Step (3): Flow at 500ml / min to figure 1 The device system shown is fed with high-purity nitrogen (purity not less than 99.999%) for 40 minutes to remove oxygen, water vapor and other impurity gases that affect pyrolysis in the system.

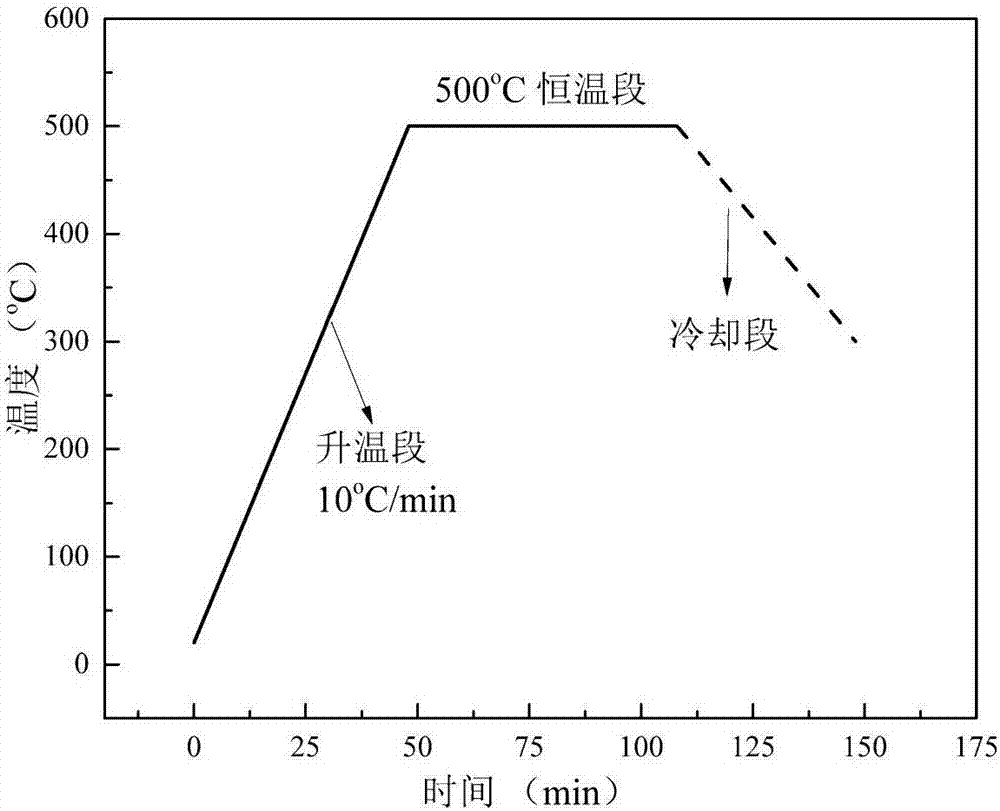

[0034] Step (4): Adjust the nitrogen flow rate to 100ml / min, and press figure 2The temperature curve shown (that is, first heat the reactor to 500 °C at a heating rate of 10 °C / min, keep the temperature for 1 hour, and then coo...

Embodiment 2

[0040] This embodiment 2 uses ABS waste plastics alone as the reaction raw material, and the specific steps are similar to those in embodiment 1, except that the HIPS in step (1) is replaced by ABS, and other steps are the same as in embodiment 1; the obtained ABS is heated separately The distribution of hydrolysis products and the content of bromine in pyrolysis oil are shown in Table 2.

[0041] Table 2 ABS separate pyrolysis product distribution and content of bromine in pyrolysis oil (wt%)

[0042] sample oil yield wax yield gas production rate Coke yield bromine content in oil ABS 57.5 18.3 11 13.2 7.1

Embodiment 3

[0044] In Example 3, waste olefin polymer plastic polypropylene PP and bromine-containing flame-retardant electronic waste plastic HIPS are used together as reaction raw materials, and the method for preparing pyrolysis oil by pyrolysis includes the following steps:

[0045] Step (1): The olefin polymer plastic polypropylene (PP) is crushed into small particles with a particle size between 75-250 μm.

[0046] Step (2): The bromine-containing flame-retardant electronic waste plastic HIPS obtained in step (1) in Example 1 and the olefin polymer plastic PP particles obtained in step (1) in Example 3 are mechanically processed according to a mass ratio of 9:1. Mix and mix evenly; then, place 10g of the evenly mixed plastic mixture in figure 1 in the fixed bed reactor shown.

[0047] Subsequent step (3), step (4), and step (5) are respectively consistent with step (3), step (4), and step (5) in Embodiment 1.

[0048] Table 3 shows the distribution of pyrolysis products of HIPS an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com