Biomass fuel particle and preparation method thereof

A technology of biomass fuel and pellets, which is applied in the direction of biofuel, waste fuel, fuel, etc., can solve problems such as complex process, achieve the effect of low crushing rate, small wear, and increase mold release speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

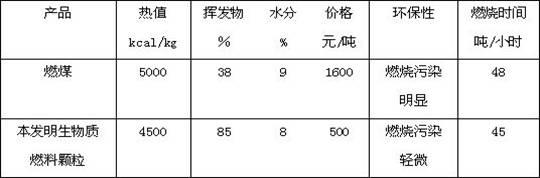

Embodiment 1

[0033] Composition: Biomass fuel raw material 75% (corn stalk or straw), palm meal 15% (by-product after palm kernel husking and oil extraction; contains 16.21% crude protein, 8.15% crude fat, 21.49% crude fiber, 6.21% moisture, Crude ash 4.76%, total energy 17.15 MJ / kg); medicinal mud alcohol precipitation 10% (the waste paste-like sediment produced in the modern Chinese medicine water extraction and alcohol precipitation process of the Chinese herbal medicine cassia seed, the composition is macromolecular polysaccharide , 80% alcohol, 5.34% ash). The properties of the prepared biomass particles are described in Table 1.

Embodiment 2

[0035] Biomass fuel 80% (wheat straw or cotton straw), palm meal 10% (by-product of palm kernel shelling and oil extraction; contains 16.21% crude protein, 8.15% crude fat, 21.49% crude fiber, 6.21% moisture, 4.76% crude ash %, total energy 17.15 MJ / kg); medicinal mud alcohol precipitation 10% (the waste paste-like sediment produced during the extraction process of the Chinese herbal medicine Panax notoginseng in the modern Chinese medicine water extraction and alcohol precipitation process, the composition is macromolecular polysaccharide, containing Alcohol 85%, ash 5.34%). The properties of the prepared biomass particles are described in Table 1.

Embodiment 3

[0037] Biomass fuel raw material 80% (pine wood chips or tree roots), palm meal 5% (by-product after palm kernel shelling and oil extraction; contains 16.21% crude protein, 8.15% crude fat, 21.49% crude fiber, 6.21% moisture, crude Ash content 4.76%, total energy 17.15 MJ / kg); 15% medicinal mud alcohol precipitation (Chinese medicinal material Chuanqiong is a waste paste-like sediment produced during the extraction process of modern Chinese medicine water extraction and alcohol precipitation, and the composition is macromolecular polysaccharide , 75% alcohol, 5.34% ash). The properties of the prepared biomass particles are described in Table 1.

[0038]

[0039] The preparation method of 1-3 embodiment

[0040] Biomass fuel raw materials such as crop straw (such as corn straw, rice straw, wheat straw, cotton straw, sorghum straw, etc.), wood processing waste (pine wood chips, sawdust, branches, roots), industrial organic waste, and municipal solid organic waste After cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com