Reshaping and ejecting device for automobile rear axle

A technology for the rear axle and ejection device of an automobile, which is applied in the field of automobiles and vehicles. It can solve the problems of affecting the surface quality of the middle section of the rear axle, limiting the prospect of market promotion, and low degree of automation, etc., and achieves the effects of small deformation, flexible integration, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

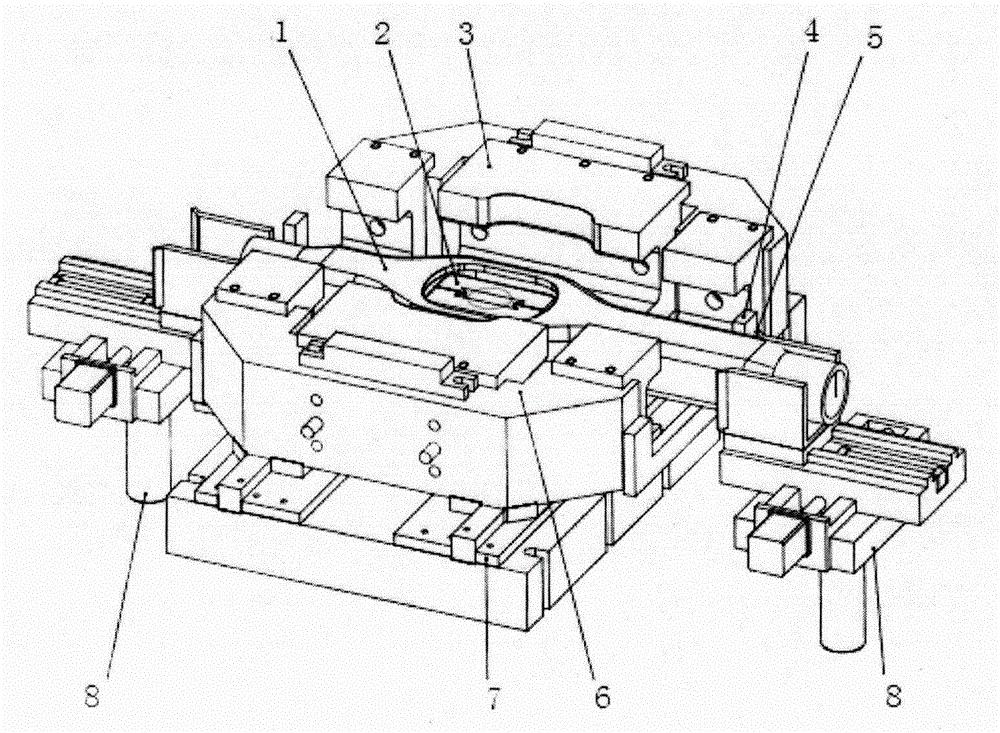

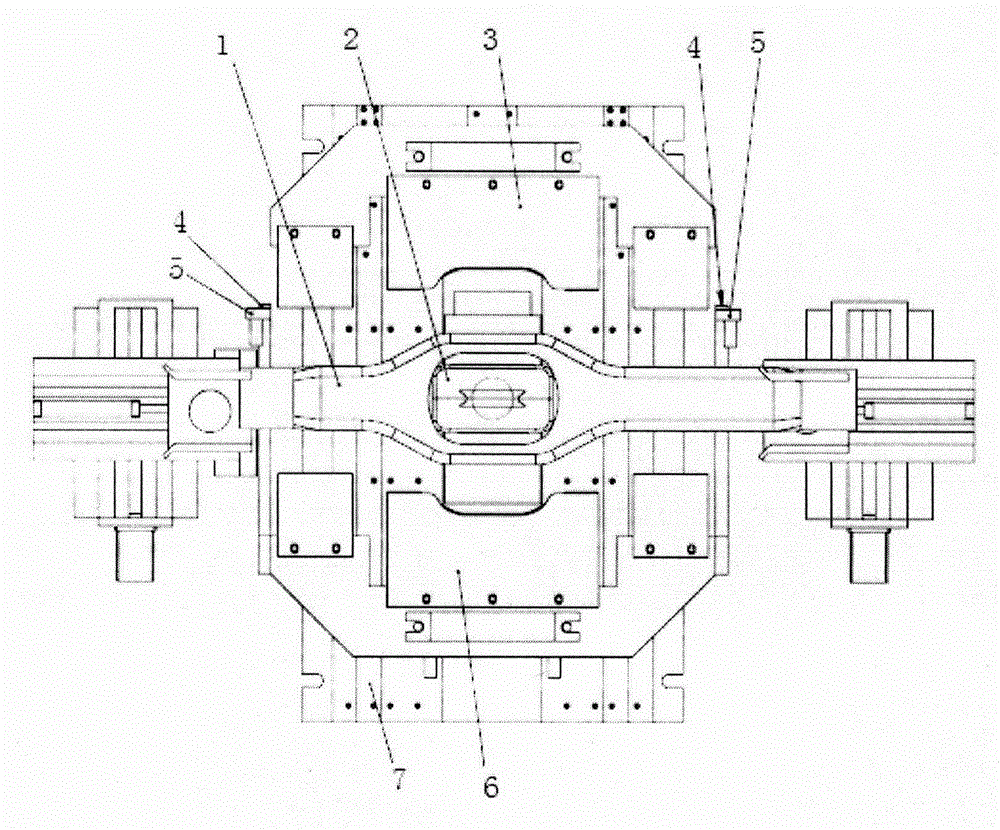

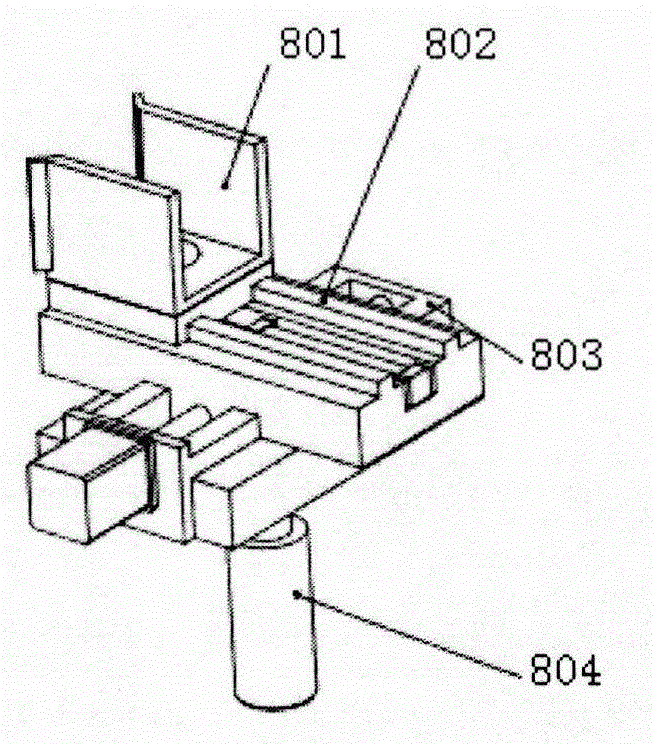

[0024] Such as figure 1 with figure 2 A kind of plastic mold ejecting device for automobile rear axle shown, comprises rear axle 1, plastic center positioning device 2, plastic external mold fixed mold 3, plastic external mold mobile mold 6 and plastic guiding mobile platform 7, also includes setting The rear axle ejectors 8 at both ends of the rear axle 1 are symmetrically distributed, and the two rear axle ejectors 8 push the rear axle 1 to move in the opposite direction along the radial direction of the rear axle 1 to speed up the movement of the rear axle. The rear axle 1 is separated from the shaping center positioning device 2. It also includes an end positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com