Antisoil and anti-graffiti coatings and method for preparing same

An anti-graffiti and coating technology, applied in the direction of anti-fouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of anti-graffiti and anti-fouling coatings that need to be updated, and achieve anti-fouling and anti-graffiti effects Better, stable internal structure, less cleaning difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

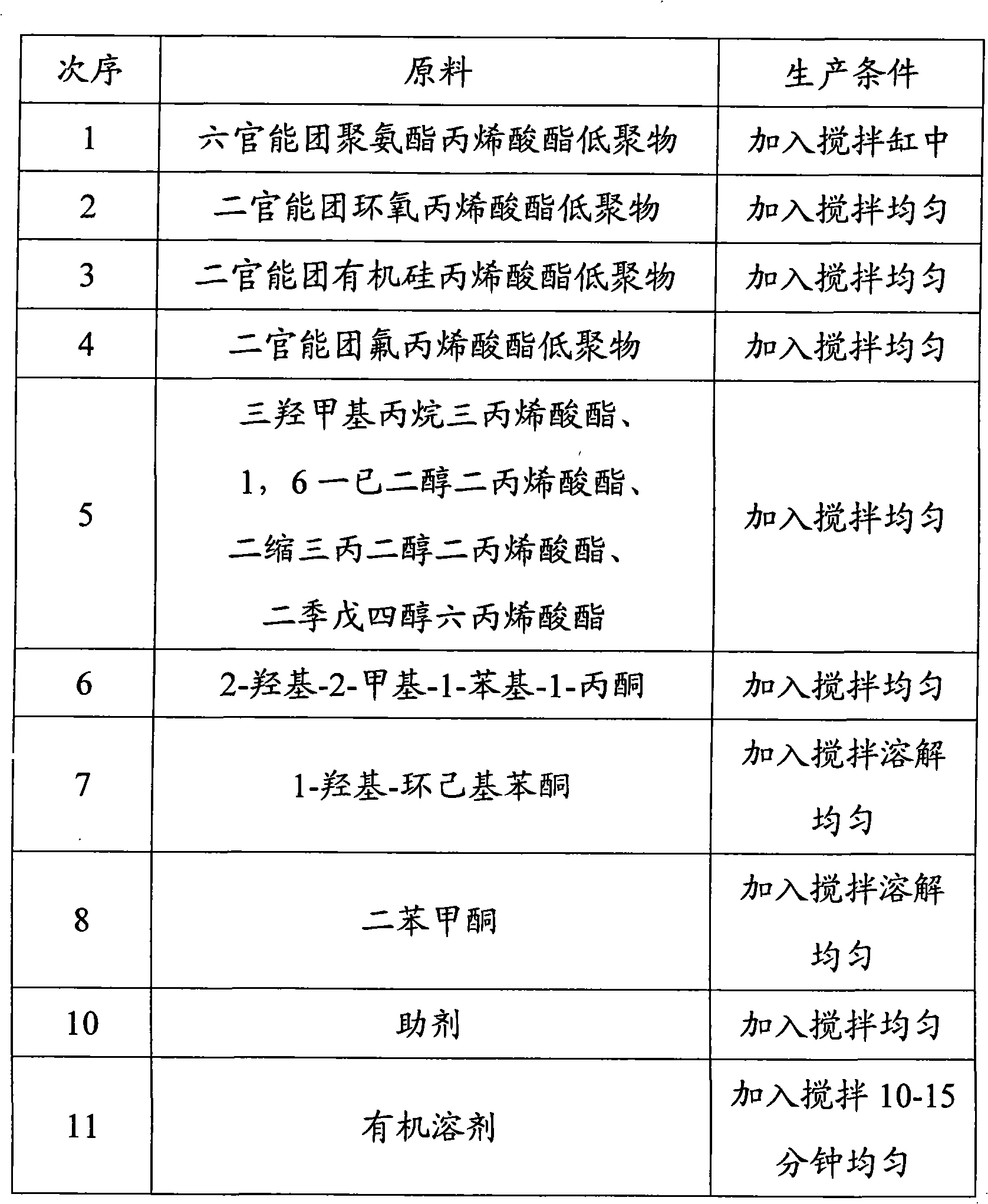

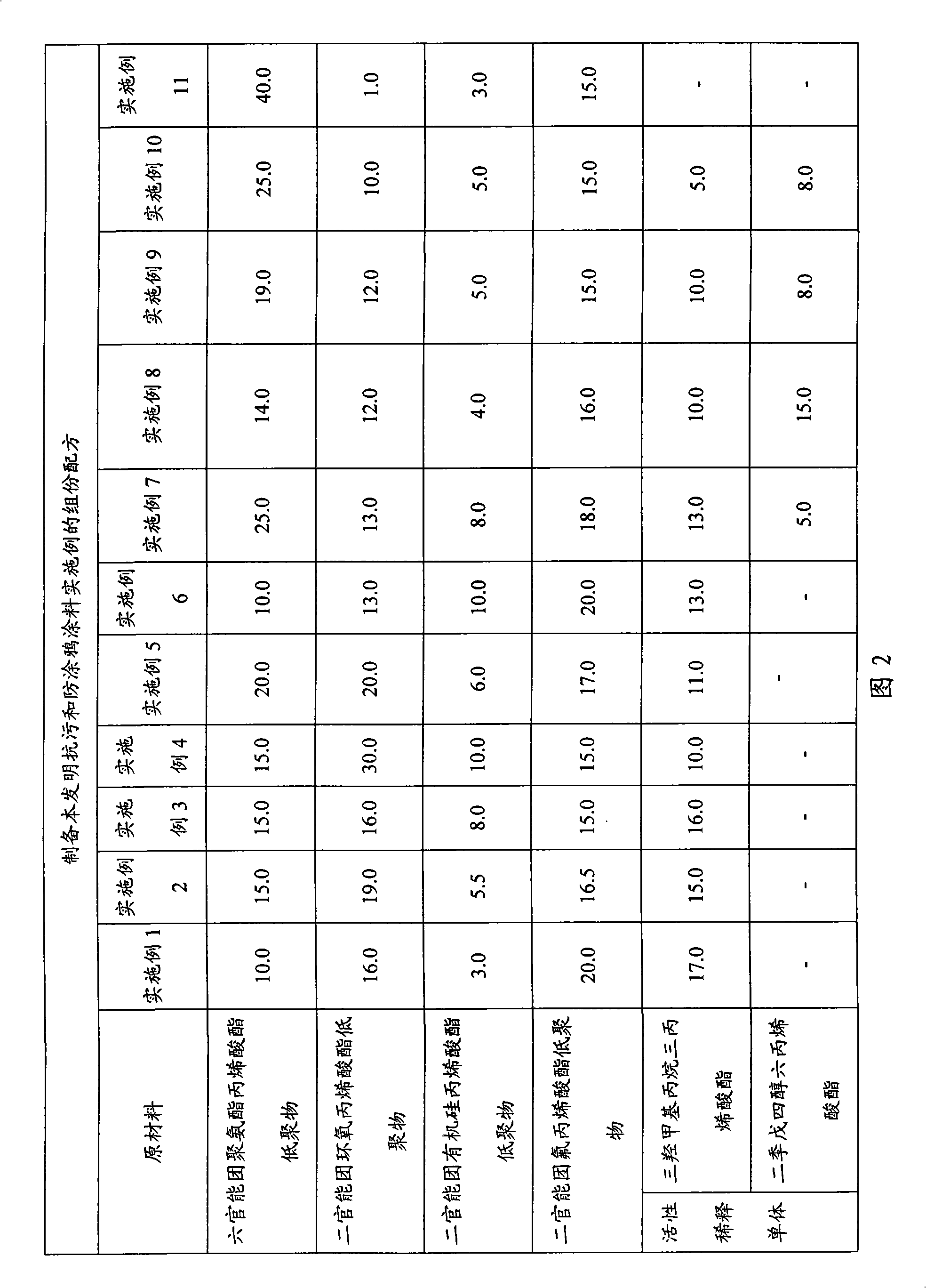

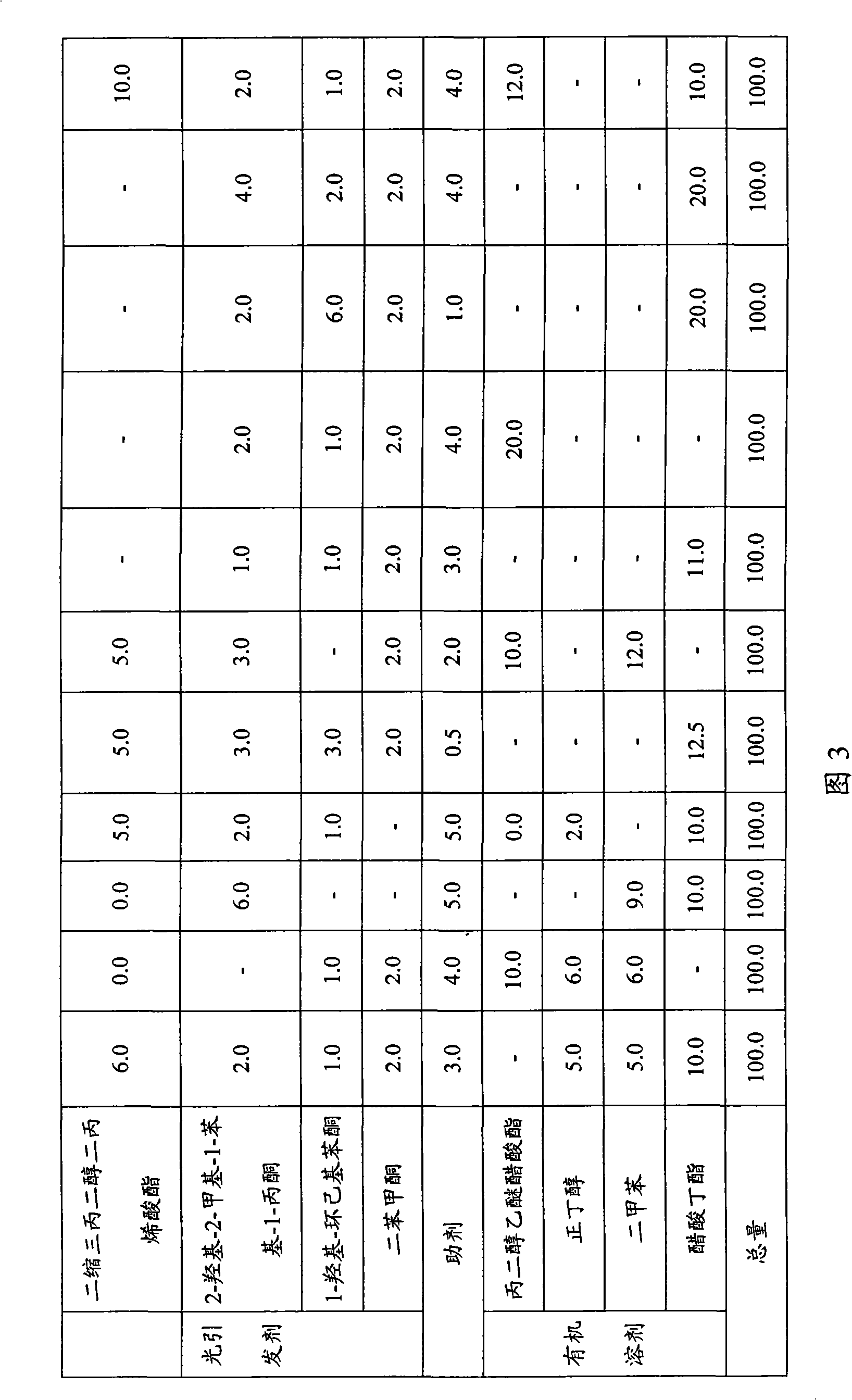

[0047] The following components: 10.0 parts of hexafunctional urethane acrylate oligomer; 16.0 parts of difunctional epoxy acrylate oligomer; 3.0 parts of difunctional silicone acrylate oligomer; 20.0 parts of difunctional fluoroacrylate oligomer ; 23.0 parts of reactive diluent monomers, including 17.0 parts of trimethylolpropane triacrylate, 6.0.0 parts of tripropylene glycol diacrylate; 5.0 parts of photoinitiators, of which, 2-hydroxyl-2-methyl-1 2.0 parts of -phenyl-1-acetone, 1.0 parts of 1-hydroxy-cyclohexyl phenone, 2.0 parts of benzophenone; 3.0 parts of additives; 20.0 parts of organic solvents, including 5.0 parts of n-butanol and 5.0 parts of xylene 10.0 parts of butyl acetate were added into a mixing tank for mixing, and stirred to dissolve evenly.

[0048] In a specific embodiment, the ratio of the photoinitiator can be between 1.0 part and 10.0 parts, wherein, when the ratio of the photoinitiator is 5.0 parts, it is the best choice.

[0049] Prepare the operati...

Embodiment 2

[0063] Repeat the corresponding operation of embodiment 1 according to the specified components of embodiment 2 in Fig. 2 and Fig. 3, obtain the cured paint film, and measure its technical performance as described in embodiment 1, and the test index is as shown in table 1 , The comparison results of the test show that the performance of each technology of the present invention is good, as shown in Fig. 4 to Fig. 6 .

[0064] Table 1

[0065]

[0066]

[0067]

Embodiment 3

[0069] Repeat the corresponding operation of embodiment 1 according to the specified components of embodiment 3 in Fig. 2 and Fig. 3, obtain the cured paint film, and measure its technical performance as described in embodiment 1, and the test index is as shown in table 1 , the test results show that the technical performance of the present invention is good, as shown in Figures 4 to 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com