Halogen-free fire-retardant thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer and flame retardant technology, which is applied in the field of halogen-free flame-retardant thermoplastic elastomer materials and its preparation, can solve the problems of limitation, plasticity and mechanical properties decline, and fast flame propagation speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

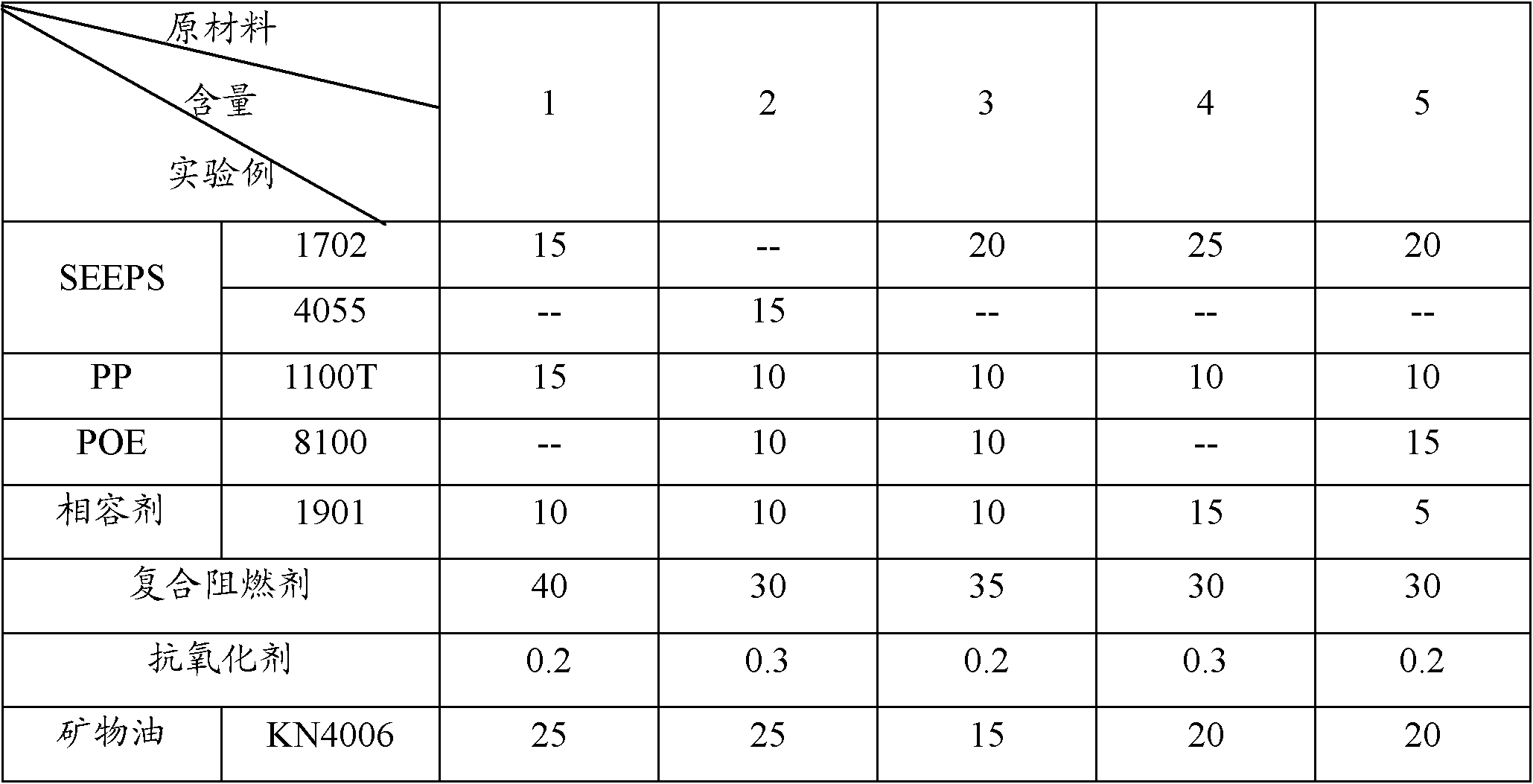

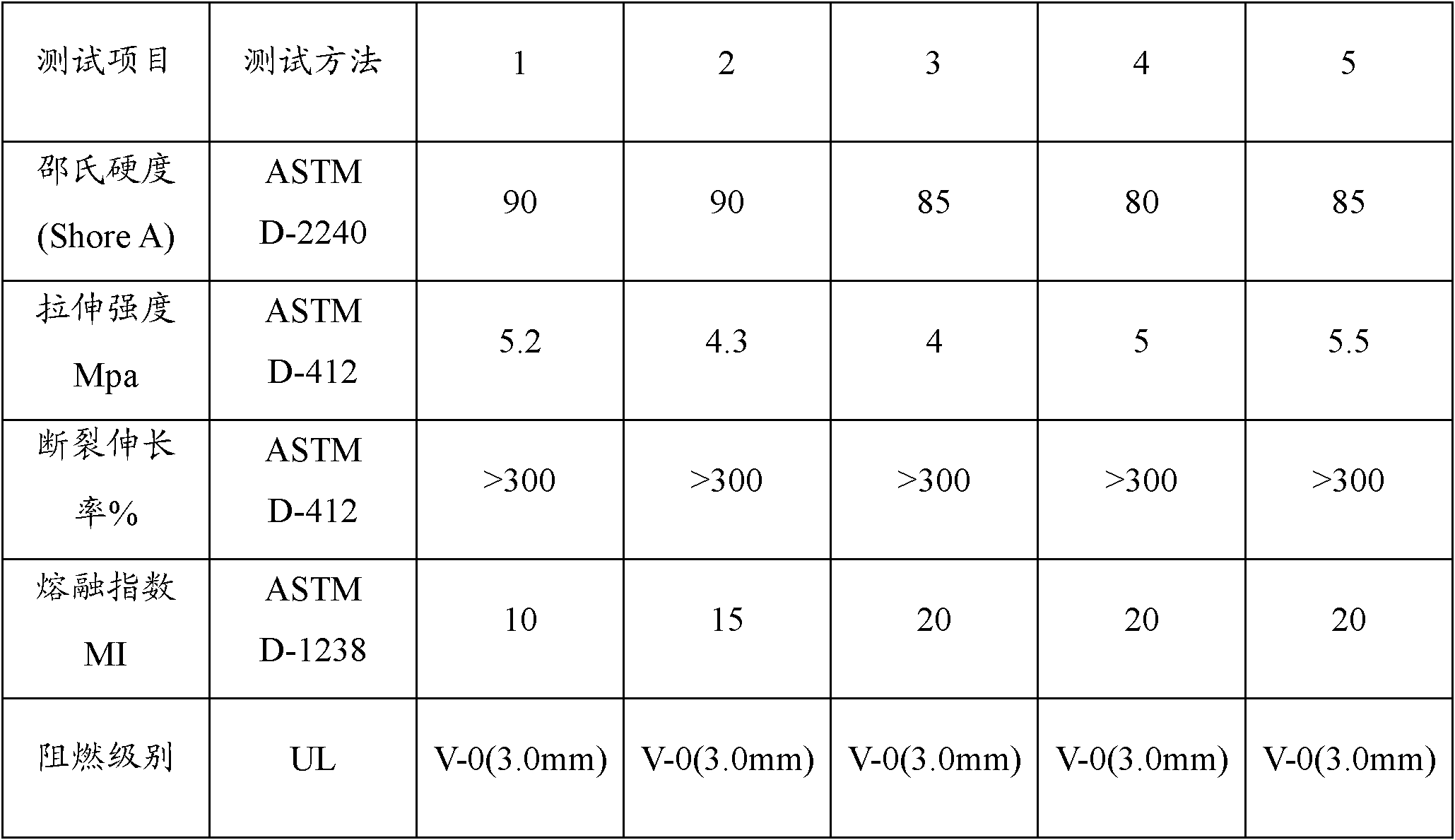

[0028] The halogen-free flame-retardant thermoplastic elastomer and its preparation method will be further described in detail below in conjunction with the embodiments.

[0029] The halogen-free flame-retardant thermoplastic elastomer material of one embodiment includes the raw materials in the following weight ratio:

[0030] SEEPS 15-25 servings;

[0031] 10-20 parts of polypropylene;

[0032] POE 10-15 copies;

[0033] 30-40 parts of halogen-free flame retardant;

[0034] 10-15 parts of compatibilizer;

[0035] Antioxidant 0.1-0.3 parts, and

[0036] 15-25 parts of mineral oil.

[0037] Among them, the SEEPS in this embodiment is low-gel polystyrene-b-poly[ethylene-(ethylene-propylene)]-b-polystyrene. As a matrix resin, its role is to make the material have a good feel and excellent weather resistance.

[0038] Specifically, SEEPS may be Kraton1702 from the United States or at least one of SEPTON4055, SEPTON4077 and SEPTON4033 from Kuraray, Japan.

[0039] Among th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com