Composition of eco-friendly hot melt adhesive

A hot-melt and composition technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of reducing the mechanical strength of hot-melt adhesive compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

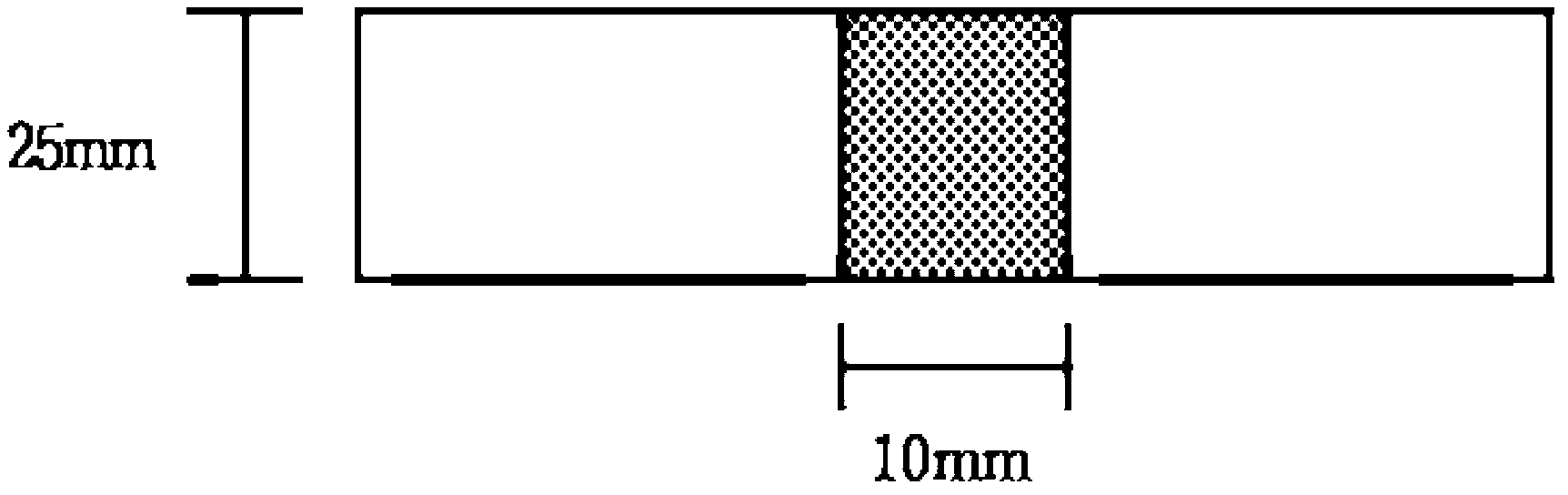

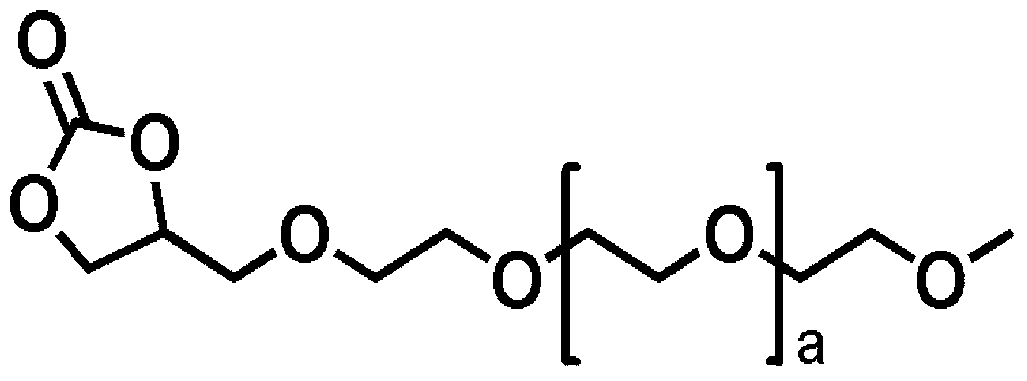

[0033] Polypropylene carbonate resin (GeenPolTM, available from SK energy Co.) having a weight average molecular weight of 30,000 g / mol, to which was added 10 parts by weight (phr) of hydroxymethyldioxolane ketone (methoxy tri-ethylene glycol) ether, and adding 20 parts by weight of phenol-modified terpene resin (DS105, available from DRT Co.) with a softening point of 95° C. °C. Mix in a Brabender mixer for 5 minutes. A sheet having a thickness of 0.7 mm was produced by hot pressing, and various dumbbell-shaped samples were produced, followed by measurement of tensile strength and elongation thereof. In addition, if figure 1 As shown, at a temperature of 140°C, a sample with a size of 25mm10mm was bonded between the wood and the PVC sheet for 1 minute, and then the adhesion force was measured by UTM. Furthermore, two PVC sheets were bonded to each other under the same conditions, and the adhesion force therein was measured. Set the test speed to 50mm / min. The results obta...

Embodiment 2

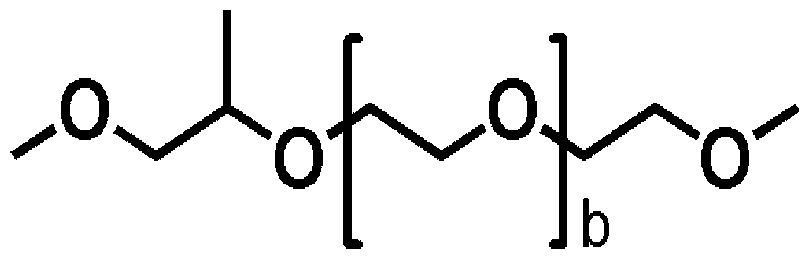

[0035] By the same method, using bis(triethylene glycol methyl ether) glutarate instead of using hydroxymethyldioxolanone (methoxytri-ethylene glycol) ether as the extender in Example 1 Plasticizers for the preparation of hot melt adhesive compositions.

Embodiment 3

[0037] The samples were prepared and evaluated by the same method, but without using the plasticizer in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com