Optical interference pigment and method for producing same

A manufacturing method and light interference technology, applied in organic dyes, dyeing physical treatment, etc., can solve problems that have not been studied before, and achieve good light reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8 and comparative example 1~6

[0366] (Preparation of Coating Solution)

[0367] Coating solutions (A) and (B) shown in the table below were prepared, respectively.

[0368] [Table 1]

[0369] Coating solution (A): for producing a layer that reflects right circularly polarized light having a maximum value of reflectance at 380 nm

[0370]

[0371] [Table 2]

[0372] Coating solution (B): for producing a layer that reflects left circularly polarized light having a maximum value of reflectance at 380 nm

[0373]

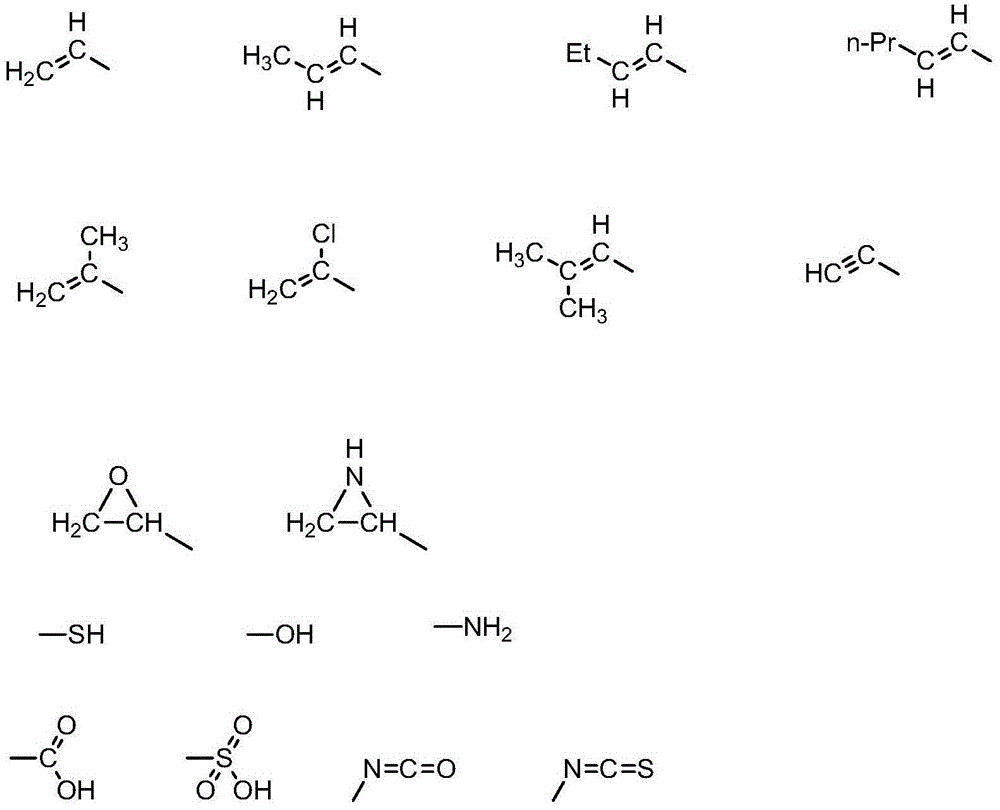

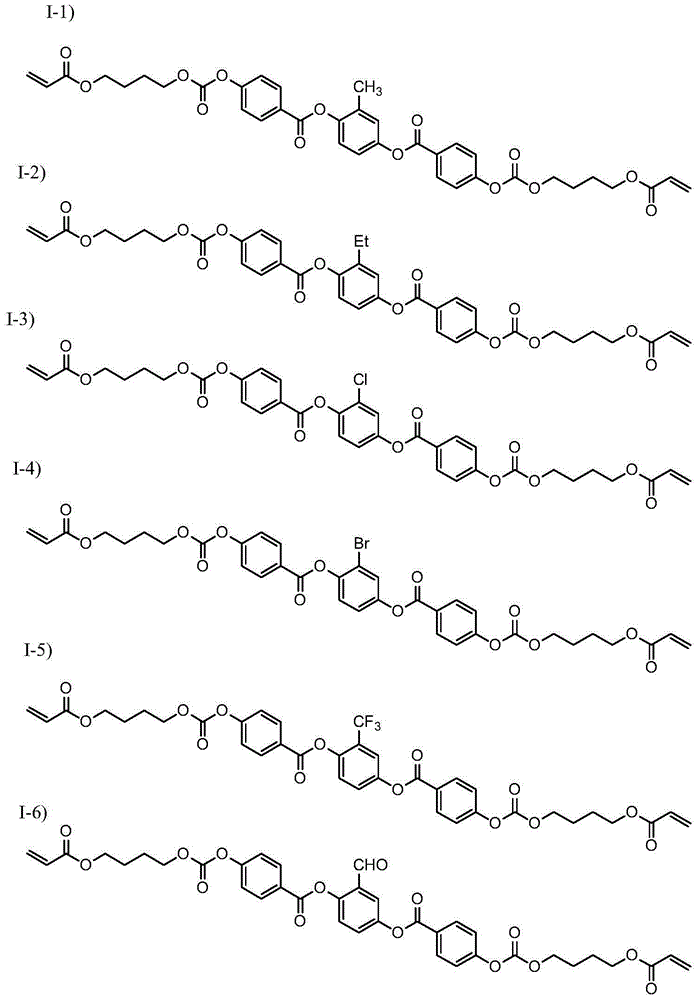

[0374] [chem 35]

[0375] Rod-shaped liquid crystal compound: compound 1

[0376]

[0377] [chem 36]

[0378] Alignment control agent (1): JP-A-2012-211306, compound (2) of paragraph [0022]

[0379]

[0380] [chem 37]

[0381] Orientation Control Agent(2)

[0382]

[0383] [chem 38]

[0384] Chiral agent: Compound (5) of Japanese Patent No. 4287599

[0385]

[0386] (Ultraviolet light with a wavelength of 380nm is irradiated to form a film with a cholesteric liquid crystal ...

Embodiment 9

[0412] As the base film, instead of the PET film, a film formed as follows: a strip-shaped film made of triacetyl cellulose (manufactured by FUJITAC, Fuji Film Co., Ltd., thickness: 100 μm, width: 500 mm, glass transition temperature: 145° C.) was used. One side of the film was coated with a 5% by weight solution of long-chain alkyl-modified polyvinyl alcohol (MP-203, manufactured by KURARAY Co., Ltd.), dried at 90° C. for 4 minutes, and then rubbed to form a 2.0-μm-thick film. As the resin layer for forming an alignment film, a film in which the resin layer for forming an alignment film having a film thickness of 2.0 μm was formed was used as a base film.

[0413] Except for this, the optical interference pigment was produced by the same method as in Example 3, and the evaluation of the optical interference pigment was performed, and the evaluation was also A.

Embodiment 10

[0415] As the substrate, instead of the PET film, a film formed as follows was used: one side of a glass plate with a thickness of 2 mm was coated with long-chain alkyl-modified polyvinyl alcohol (MP-203, manufactured by KURARAY Co., Ltd.) in the same manner as in Example 8. ) 5% by weight solution, dried at 90° C. for 4 minutes, and rubbed to form a resin layer for forming an alignment film with a film thickness of 2.0 μm. The film formed with the resin layer for forming an alignment film with a film thickness of 2.0 μm was used as a substrate film. Except for this, the optical interference pigment was produced by the same method as in Example 3, and the evaluation of the optical interference pigment was performed, and the evaluation was also A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com