White cured resin composition and printed circuit board having insulation layer formed with the same

A curable resin, printed circuit board technology, applied in printed circuits, printed circuit parts, circuit substrate materials, etc., can solve the problems of titanium oxide sedimentation and uneven composition, and achieve excellent light reflectivity and storage stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

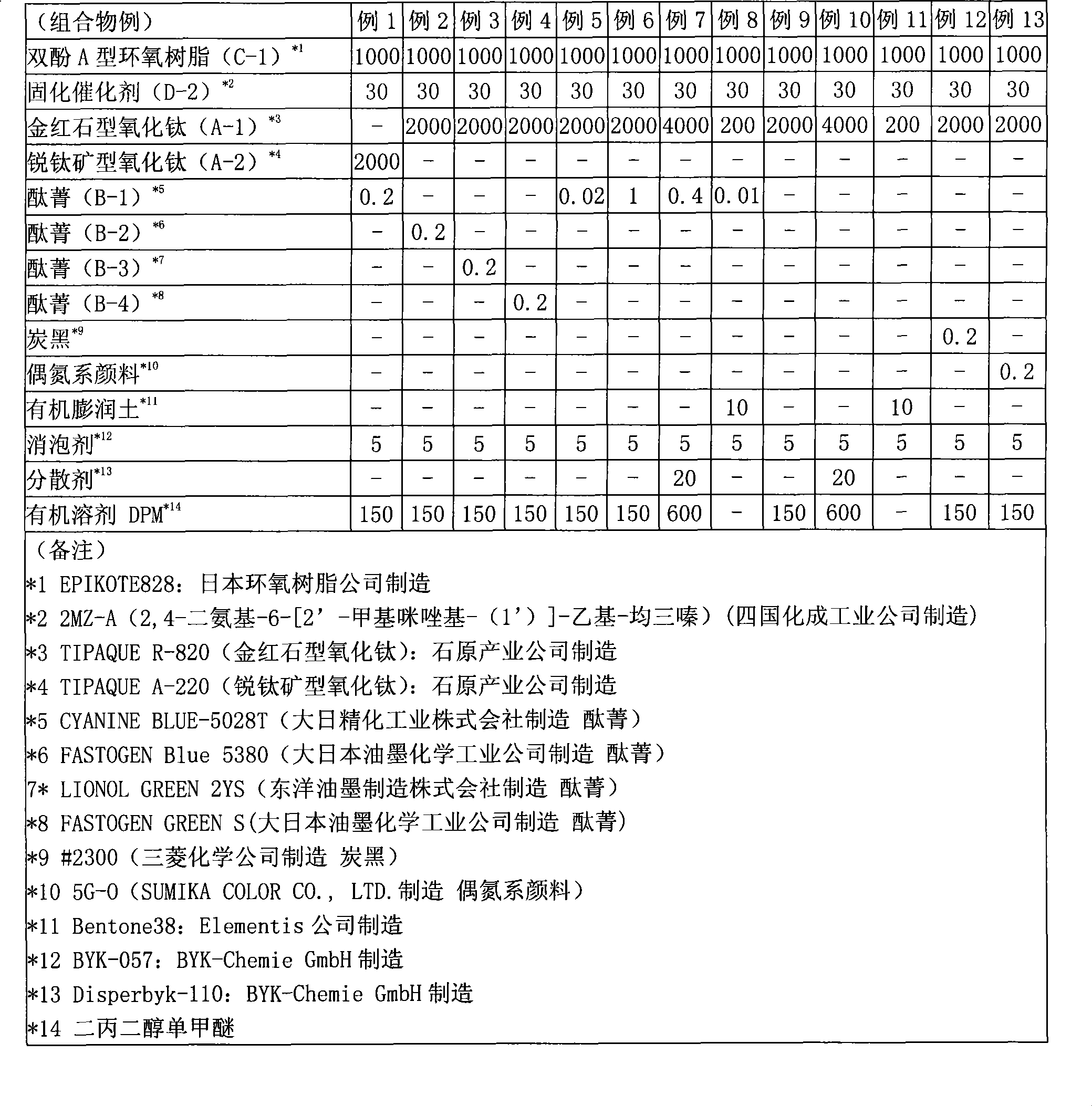

[0070] Each component of Table 1 and Table 2 was kneaded with a three-roll mill to obtain each thermosetting resin composition (composition examples 1 to 24). The numbers in the table represent parts by mass. Among composition examples 1 to 24, examples 9 to 13 and 21 to 24 did not contain phthalocyanine.

[0071] Table 1 (Thermosetting resin composition)

[0072]

[0073] Table 2 (photocurable composition)

[0074]

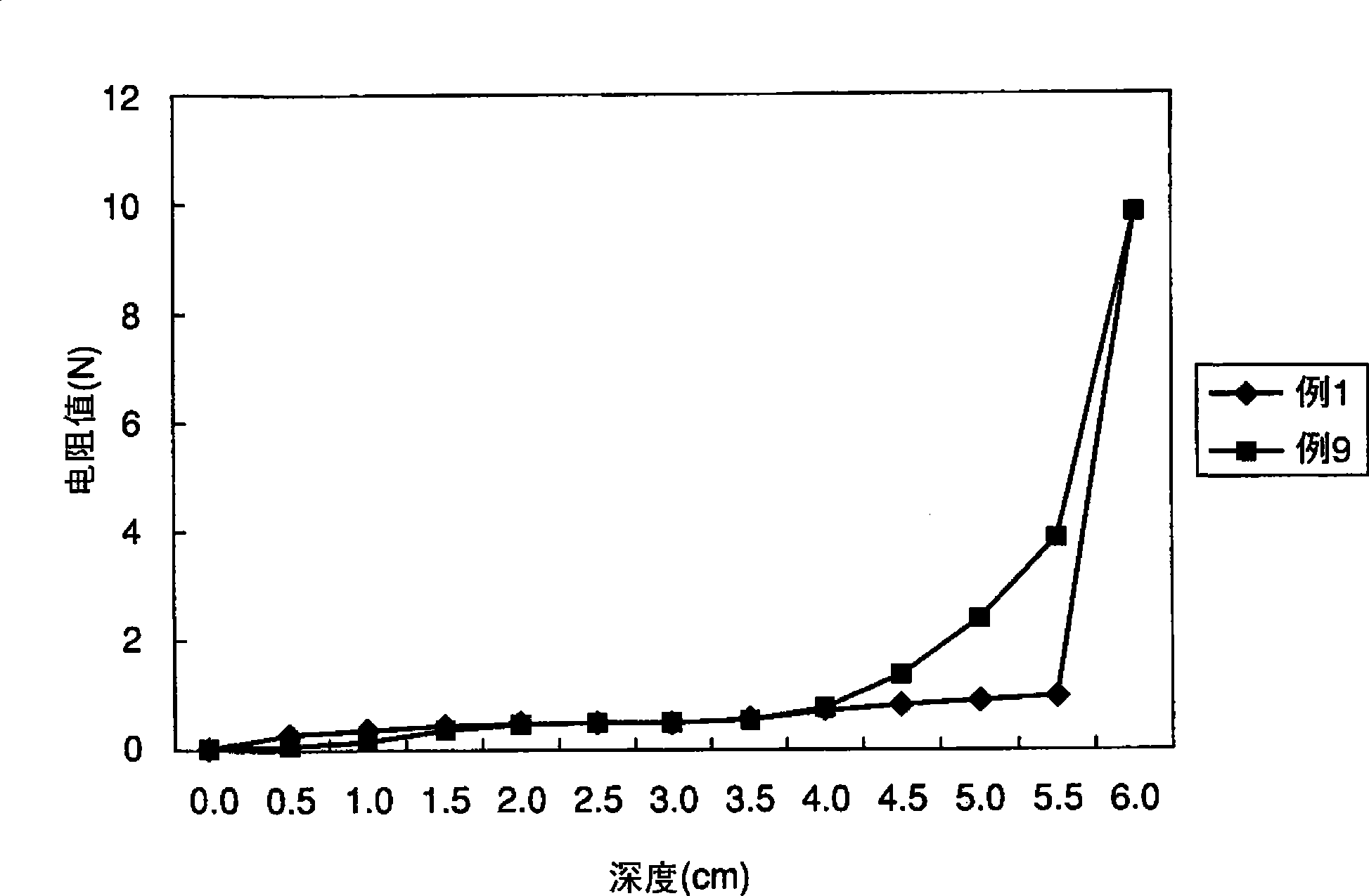

[0075] 〔Sedimentation test〕

[0076] ·Evaluation method

[0077] Put each composition of curable resin composition examples 1 to 24 into a black polyethylene container (Hi-Bessel No. 1100 manufactured by Kinki Container Co., Ltd.) with a capacity of about 1150 ml so that the depth is 6 cm, cover and seal it, and set it at 20 Store in the dark at ℃ for 90 days. About each composition after storage, the state of sedimentation was measured as follows using the Dynometer by Byk-Gardner company.

[0078] Install a rod-shaped probe (for high sensitivity) in...

Embodiment 2

[0102] Example 2 (Physical Properties of Thermosetting Composition)

[0103] After carrying out the sedimentation test of each thermosetting composition of Examples 1 to 8 containing phthalocyanine, it was pattern-printed by screen printing on an FR-4 substrate on which a circuit was formed so that the dry coating film was about 40 μm, and cured at 150°C. After 60 minutes, a substrate for a characteristic test was prepared.

[0104] As a solvent resistance test, the substrate for the property test was immersed in propylene glycol monomethyl ether acetate for 30 minutes, dried, and then subjected to a peeling test of the glass adhesive tape. The solvent resistance was confirmed by the absence of peeling and discoloration of the coating film.

[0105] Next, as a heat resistance test, a rosin-based flux was applied to the substrate for the characteristic test, flowed in a solder tank at 260°C for 10 seconds, washed with propylene glycol monomethyl ether acetate, dried, and then s...

Embodiment 3

[0109] Embodiment 3 (physical property of photocurable composition)

[0110] After carrying out the sedimentation test of each of the photocurable compositions of Examples 14 to 20 containing phthalocyanine, the pattern was printed by screen printing on the FR-4 substrate with the circuit formed so that the dry coating film was about 40 μm, and the metal halide lamp was used to Irradiate 2J / cm at the measurement wavelength centered at 350nm 2 The cumulative amount of light is cured to produce a substrate for characteristic testing.

[0111] As a solvent resistance test, the substrate for the property test was immersed in propylene glycol monomethyl ether acetate for 30 minutes, dried, and then subjected to a peeling test of the glass adhesive tape. The solvent resistance was confirmed by the absence of peeling and discoloration of the coating film.

[0112] Next, as a heat resistance test, a rosin-based flux was applied to the substrate for the characteristic test, flowed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com