Super-high refractive index optical resin composition having high heat deflection temperature and excellent thermal stability, optical lens using same and method for manufacturing the optical lens

An optical lens and monomer composition technology, applied in optics, optical elements, lenses, etc., can solve the problems of easy cracking of multilayer films, deformation of the center of the lens, low refractive index, etc., and achieve good storage stability and good portability. , the effect of high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Mix 16.000g of 1,6-hexamethylene diisocyanate, 11.000g of isophorone diisocyanate, 49.000g of 1,2-bis(2-mercaptoethylsulfide) in 24.000g of toluene diisocyanate base)-3-mercaptopropane, here, 1.500g of 2-(2′-hydroxy-5-methylphenyl)-2H-benzotriazole as a UV absorber, 0.100g of Diisopropyl phosphate, 75ppm of organic dye 1-hydroxyl-4-(p-toluidine) anthraquinone (blue) and 40ppm of perionone dye (red) as a complementary color agent, 0.050g of as a polymerization initiator Put dibutyltin dichloride into a mixing tank equipped with a mixer, replace it with nitrogen, remove the air in the mixing tank and stir it under reduced pressure for 2 hours, stop stirring and then defoam under reduced pressure, and inject it into a polyester bonded In a fixed glass mold (diopter -5.00).

[0040] (2) Put the glass mold filled with the mixture into a steel circulation oven, keep it at 35°C for 2 hours, raise the temperature to 40°C for 3 hours, raise the temperature to 120°C for 12 h...

Embodiment 2~16

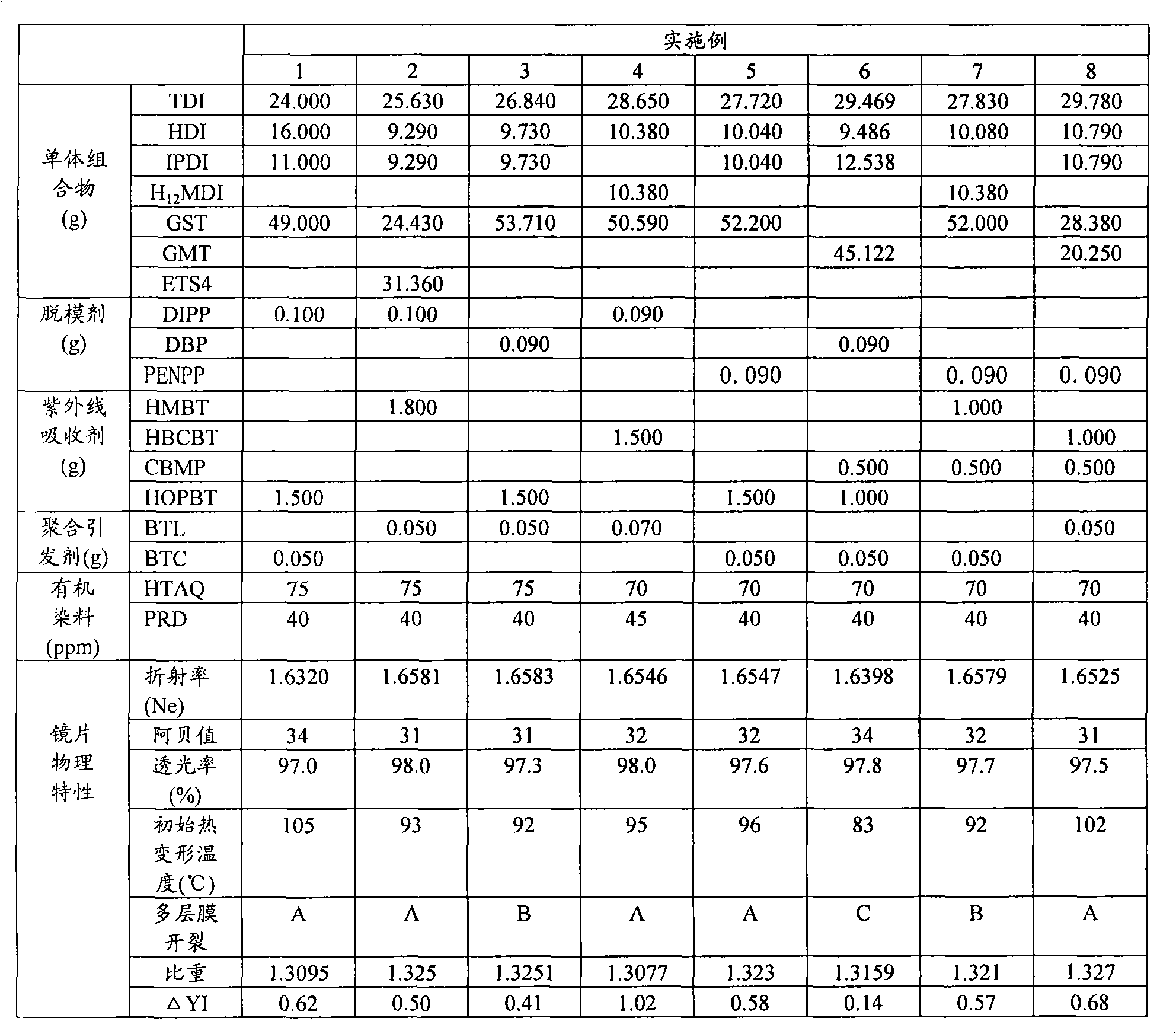

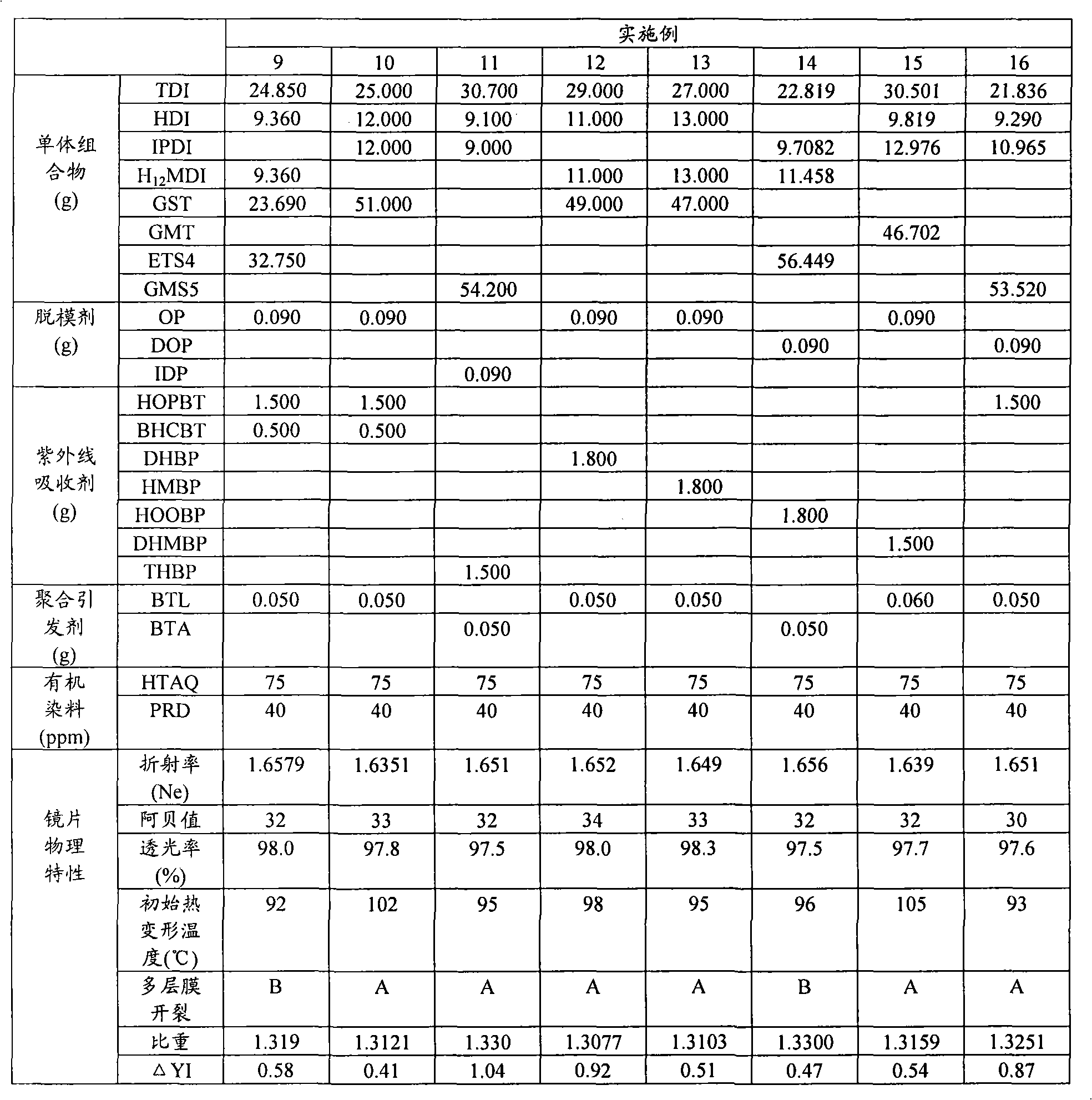

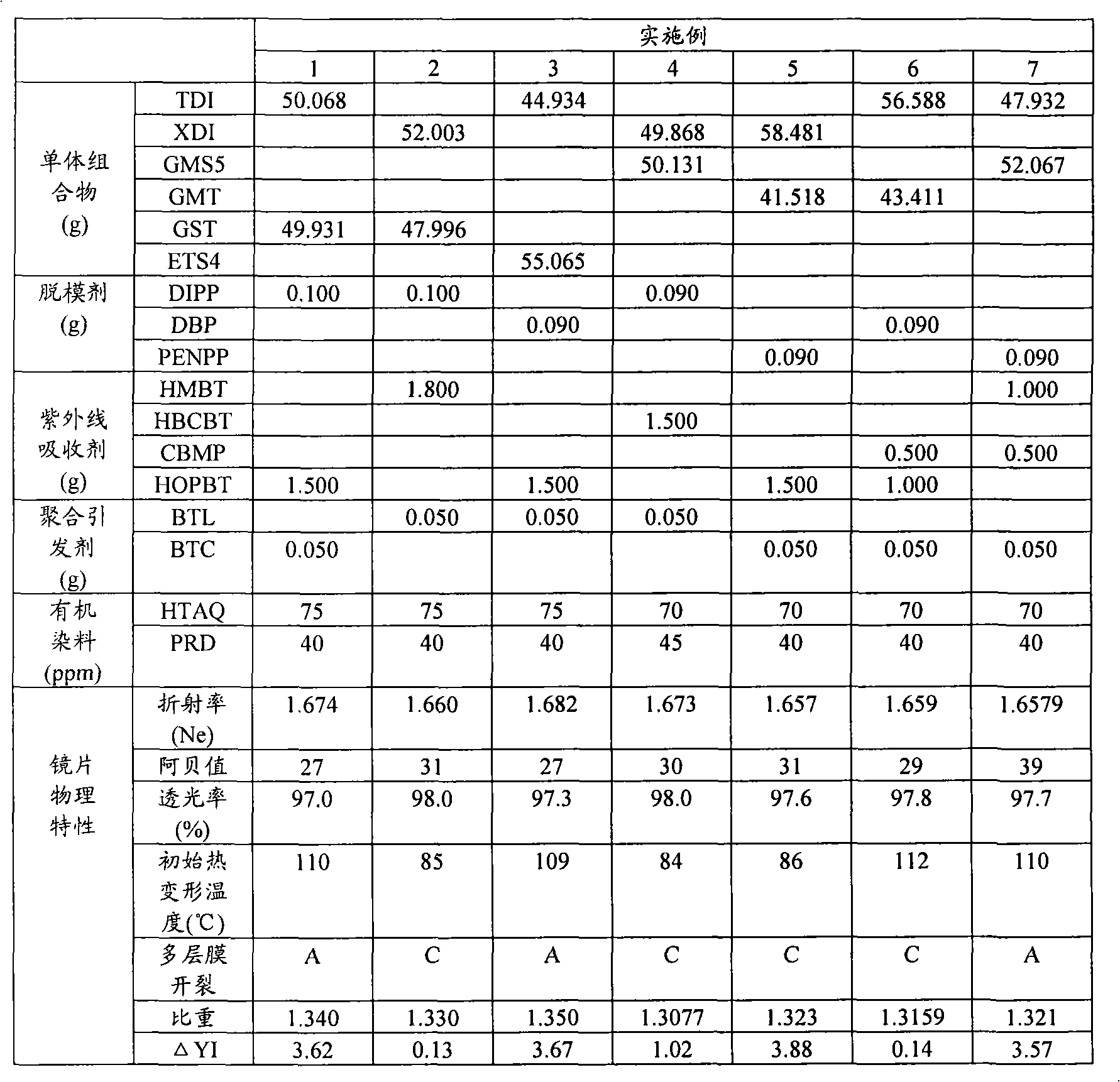

[0052] According to the method of Example 1, monomer compositions and lenses were produced according to the combinations recorded in Tables 1-2, and the experimental results were recorded in Tables 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com