Platinum catalyst and preparing method thereof and preparing method of silicone rubber

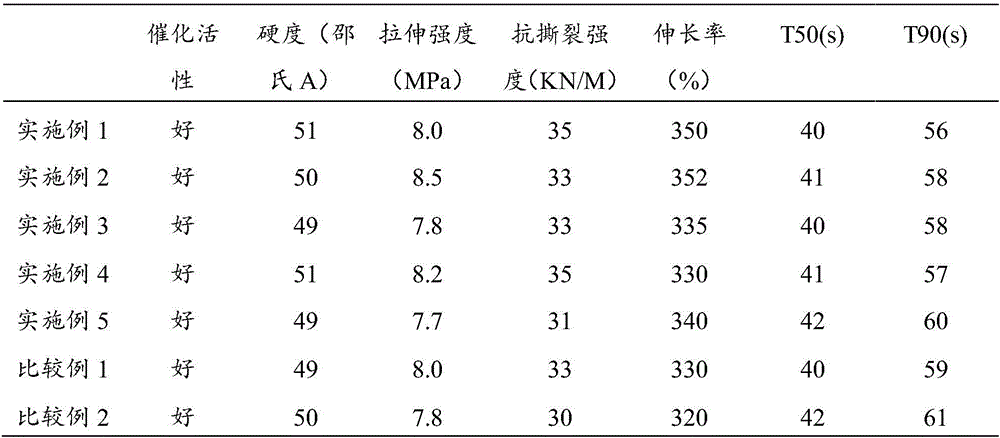

A platinum catalyst and compound technology, which is applied in the preparation of platinum catalysts and silicone rubber, and its preparation field, can solve the problems of poor vulcanization activity and mechanical properties of silicone rubber, poor catalytic activity of platinum complexes, and poor stability of platinum catalysts, and achieves excellent performance. Excellent effect of vulcanization activity and mechanical properties, catalytic activity and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a kind of preparation method of platinum catalyst, comprises the following steps:

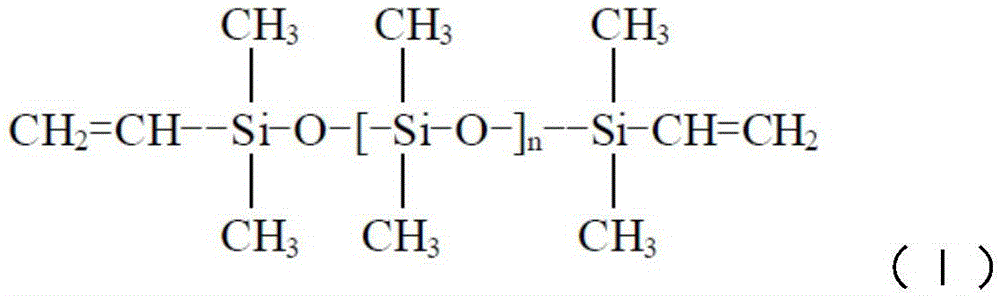

[0037] A) the alcohol solution of chloroplatinic acid is mixed with the compound containing vinyl, and the first reaction is carried out by heating;

[0038] B) mixing the product obtained by the first reaction with the nitrogen-containing organic compound, and heating to carry out the second reaction to obtain a platinum catalyst.

[0039] The present invention has no special limitation on the preparation method of the alcohol solution of chloroplatinic acid, and the preparation method well known to those skilled in the art can be adopted. In the present invention, preferably, chloroplatinic acid is added to liquid alcohol, and mixed to obtain an alcoholic solution of chloroplatinic acid. The liquid alcohol is preferably absolute ethanol or isopropanol. The dosage ratio of the chloroplatinic acid to the liquid alcohol is preferably 50-80g:200-500mL....

Embodiment 1

[0077] 78 grams of chloroplatinic acid are added to 250 milliliters of ethanol, mixed to form an alcoholic solution of chloroplatinic acid, added dropwise to a round-bottomed flask containing 60 grams of tetramethyldivinyldisiloxane, stirred evenly, and Under the condition of nitrogen protection, heat and reflux in 35°C water bath or oil bath for 2 hours, then add 0.5 g of N,N,N',N'-tetramethylethylenediamine, react at 65°C for 1 hour, add 250 grams of sodium bicarbonate were neutralized, and then under a vacuum of 6.66kpa, small molecular substances such as alcohol and water were distilled off under reduced pressure at 50°C, and solid impurities were removed by filtration to obtain a platinum catalyst. The mass content of platinum in the platinum catalyst was 32.51%. .

[0078] The above-mentioned platinum catalyst made with 100mm 2 / s diluted with simethicone oil, the mass content of platinum in the diluted platinum catalyst is 0.25%. Liquid silicone rubber BQ-6250 base ma...

Embodiment 2

[0082] Add 50 grams of chloroplatinic acid to 200 milliliters of isopropanol, mix to form an alcohol solution of chloroplatinic acid, add dropwise to a round-bottomed flask containing 30 grams of tetramethyldivinyldisiloxane, and stir evenly , and under the condition of nitrogen protection, heat and reflux in a water bath or an oil bath at 35°C for 2 hours, then add 0.8 g of N,N-dimethylformamide, react at 65°C for 1 hour, and add 160 g of sodium bicarbonate Neutralize, and then under vacuum 6.66kpa, 50 ℃ under reduced pressure distillation to remove small molecular substances such as alcohol and water, filter to remove solid impurities, to obtain a platinum catalyst, the mass content of platinum in the platinum catalyst is 38.02%.

[0083] The above-mentioned platinum catalyst made with 100mm 2 / s diluted with simethicone oil, the mass content of platinum in the diluted platinum catalyst is 0.25%. Liquid silicone rubber BQ-6250 base material (produced by Dongguan Betley New ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com