Aqueous ink composition for ballpoint pen

A water-based ink and ballpoint pen technology, applied in the directions of ink, application, household appliances, etc., can solve the problems of insufficient drawing line concentration, deterioration of drawing line drying, etc., and achieve the effect of good storage stability and water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

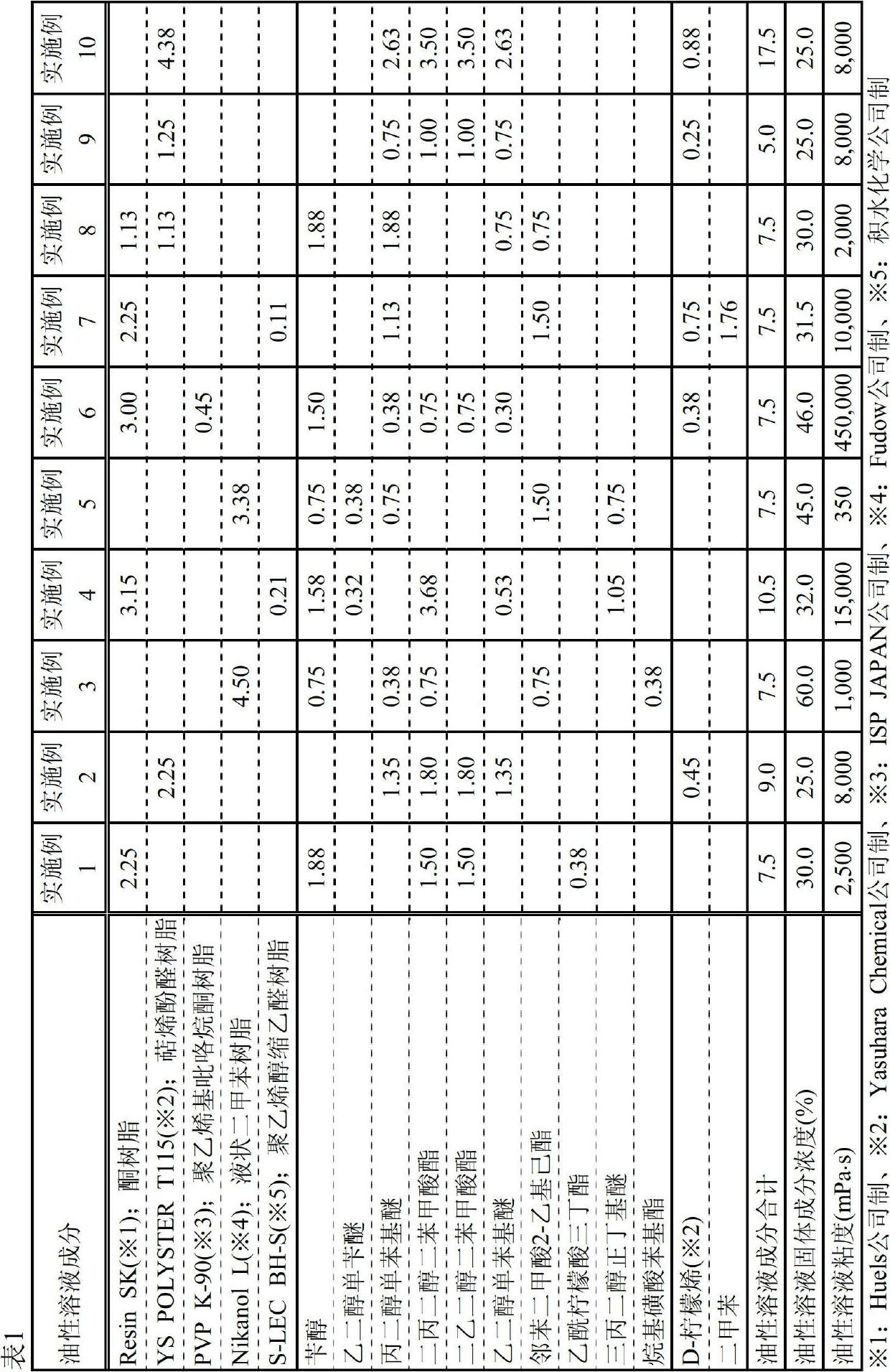

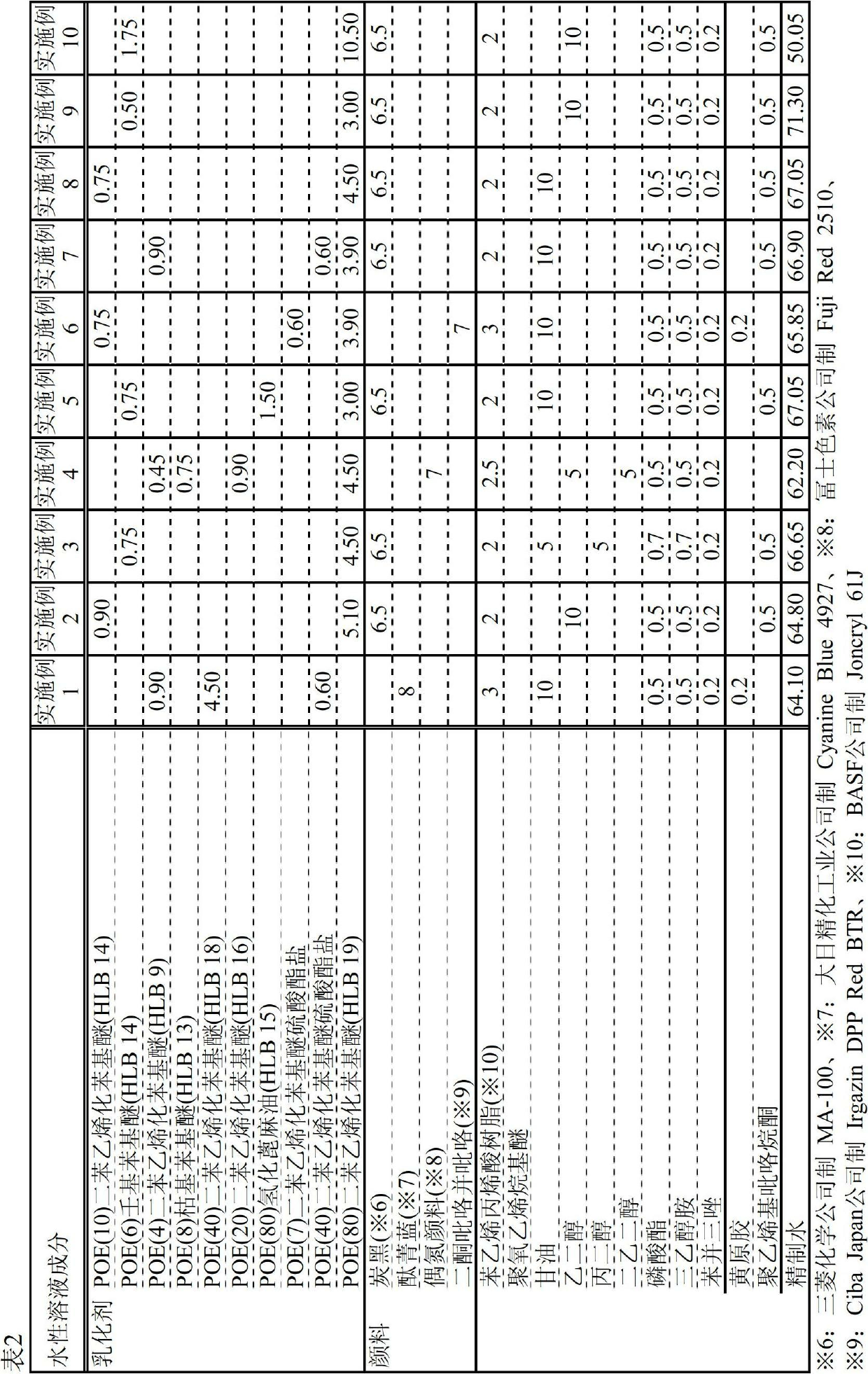

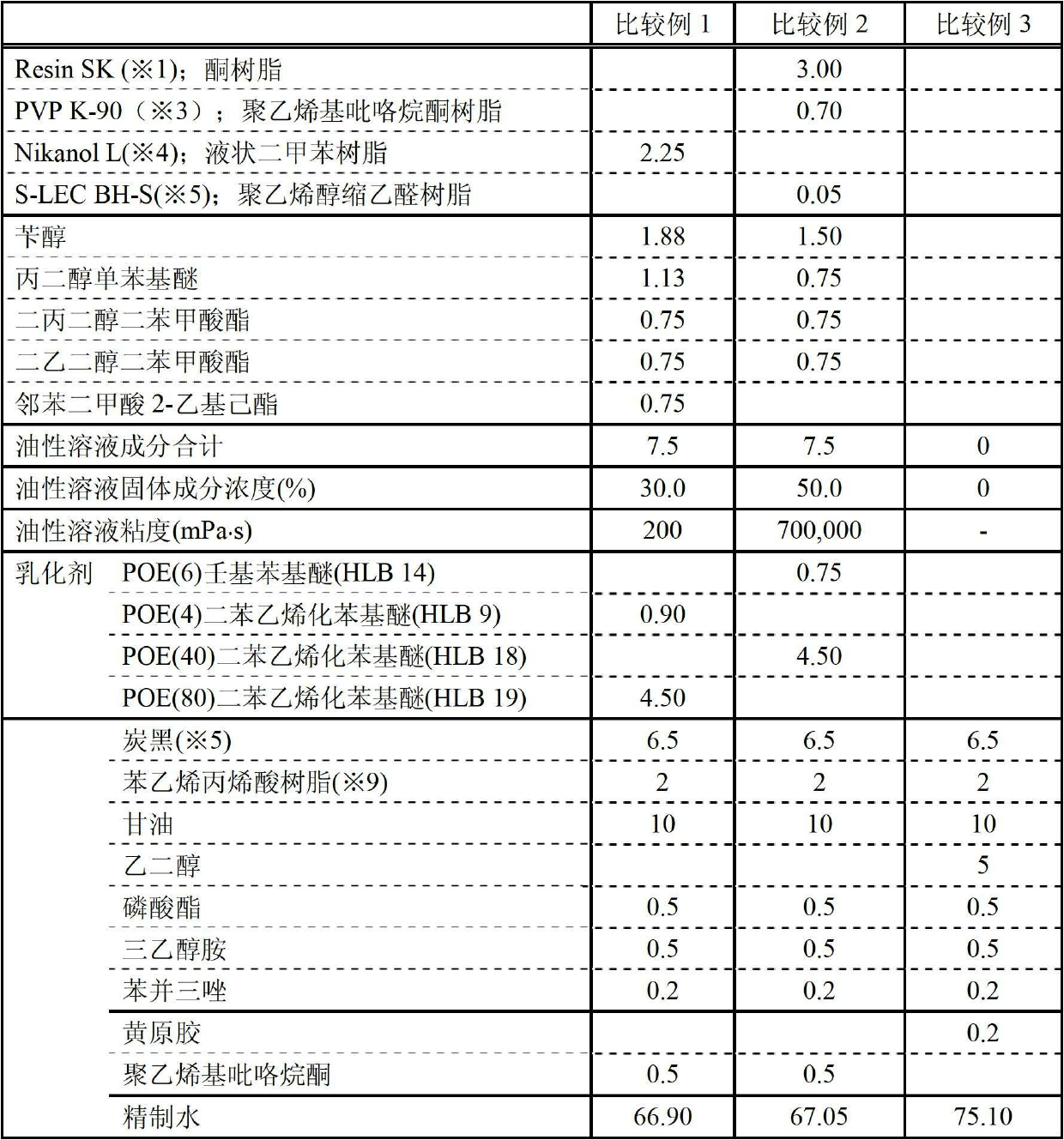

[0091] For Examples 1 to 10, the preparation of the ink composition was carried out as follows.

[0092] First, while stirring the oily solution components described in Table 1, it was heated to a temperature of 50° C. to 60° C. to completely dissolve these components. The viscosity of the oily solution in the table is the value of the solution. On the other hand, differently, the emulsifier described in Table 2 was dissolved in purified water while being stirred, and an emulsifier aqueous solution was produced. In addition, when blending the emulsifier with strong orientation to an oily phase, you may add to this oily solution and stir at normal temperature.

[0093] Next, the aqueous emulsifier solution was slowly added to the oily solution while stirring, thereby changing the phase from W / O to O / W to obtain an oil-in-water emulsion. Thereafter, an emulsification treatment was performed using a commercially available high-pressure homogenizer until reaching a predetermined...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com