PDMS elastomer micro-nano processing method based on crosslinking control control transfer printing

A technology of micro-nano processing and controlled transfer, which is applied in the process of producing decorative surface effects, manufacturing micro-structure devices, micro-structure technology, etc., can solve the problem of limited processing forms, limited micro-nano processing technology, and difficulty in preparing complex and fine materials. Surface pattern structure and other issues, to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: prepare the PDMS membrane of surface patterning, the steps are as follows:

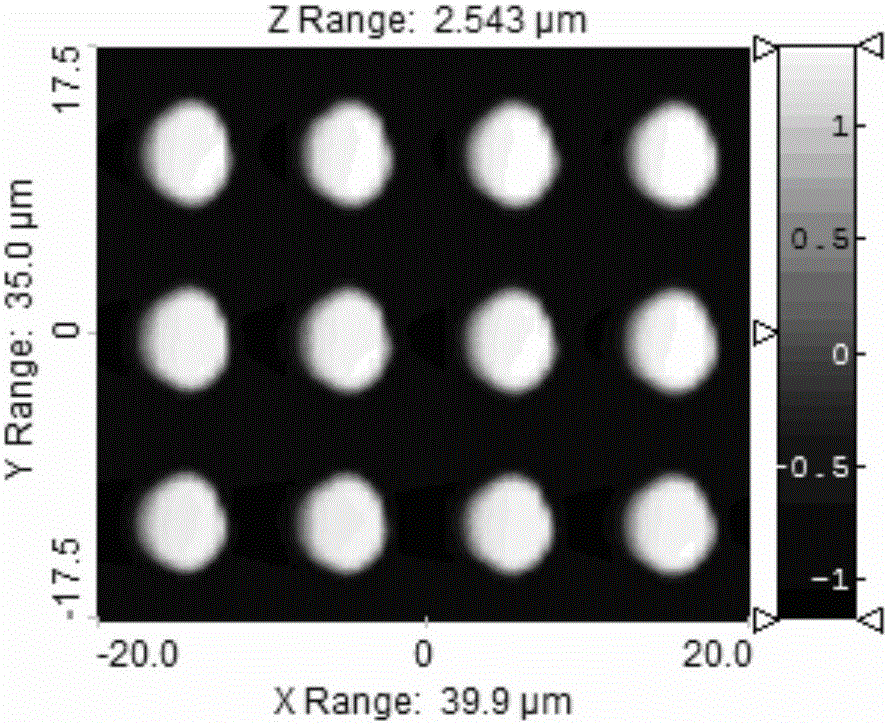

[0017] Step 1, using replica molding method to prepare PDMS with surface microstructure as a stamp for transfer printing: first, mix PDMS prepolymer and crosslinking agent Sylgard184 (purchased from Dow Corning, USA) in a mass ratio of 10:1, Stir well with a glass rod to form a uniform pre-polymer; after degassing the above-mentioned pre-polymer in a circulating water multi-purpose vacuum pump for 1 hour, pour it on a silicon formwork (ie, a master formwork) with a cylindrical array, and the pouring thickness is about 1mm; cured by heating at 70°C for 4h; carefully peel off the PDMS film on the silicon template to form a PDMS stamp, and the PDMS with surface microstructure prepared by the replication molding method (10:1) The surface structure of the stamp is as figure 1 shown.

[0018] Step 2, utilizing the pouring method to prepare a PDMS thick film with a thickness of about 1...

Embodiment 2

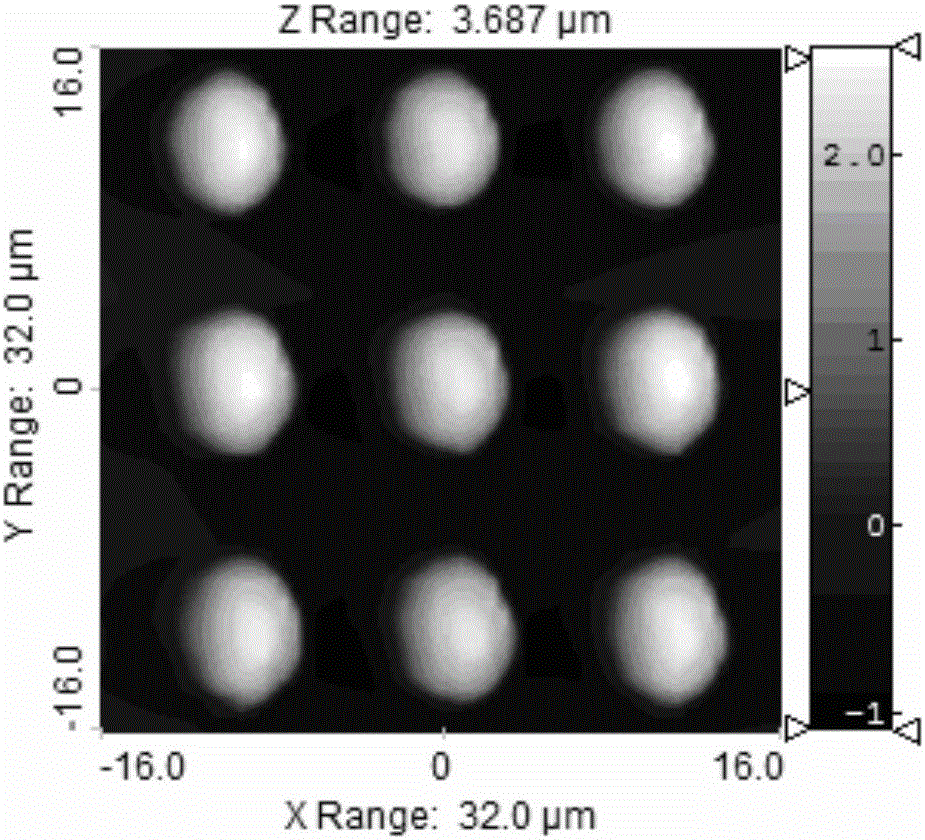

[0021] Embodiment 2: prepare the PDMS membrane of surface patterning, preparation process is basically the same as embodiment 1, the only difference is that the mass ratio of PDMS prepolymer and cross-linking agent in step 1 is changed to 20:1, and the mass ratio in step 2 is changed to 20:1. The mass ratio of PDMS prepolymer and cross-linking agent was changed to 10:1, that is, the cross-linking parameters were determined by PDMS (10:1) / PDMS (20:1) Change to PDMS (20:1) / PDMS (10:1) , the finally obtained PDMS membrane with a regular dot raised pattern on the surface is as follows image 3 The atomic force diagram of .

[0022] As above, by changing the cross-linking agent content in the preparation process, that is, the cross-linking parameters, such as: it can be PDMS (10:1) / PDMS (20:1) 、PDMS (10:1) / PDMS (30:1) 、PDMS (20:1) / PDMS (5:1) 、PDMS (20:1) / PDMS (10:1) any group in .

[0023] In summary, the method of the present invention mainly utilizes the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com