Bamboo charing heating furnace, kettle, system and process

A heating furnace and carbonization technology, which is applied in the field of heating furnace, kettle body, carbonization system and carbonization process for bamboo carbonization, can solve the problems of long carbonization cycle, energy waste, etc., achieve recycling, improve activity, and improve bamboo charcoal Effect of quality and carbonization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

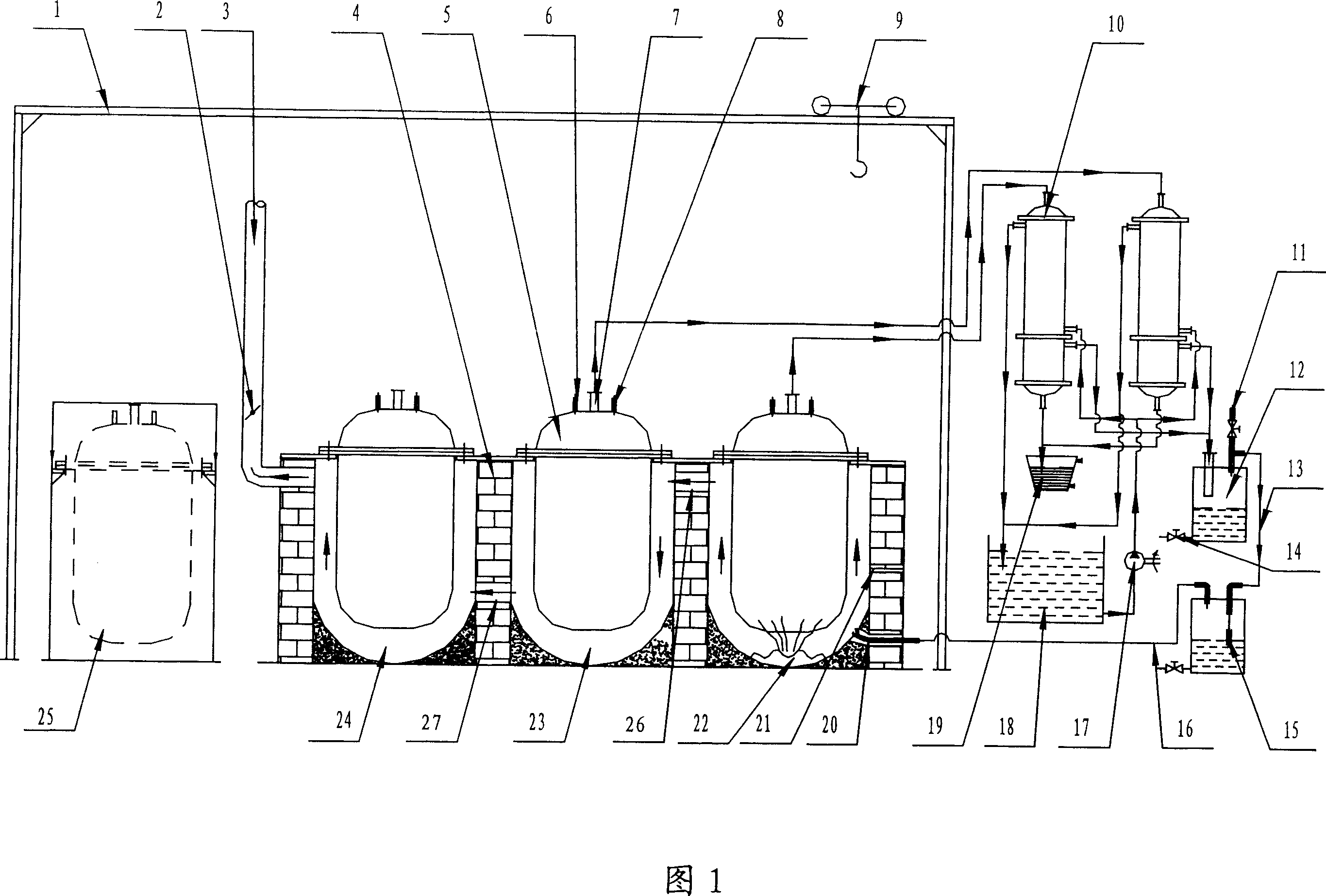

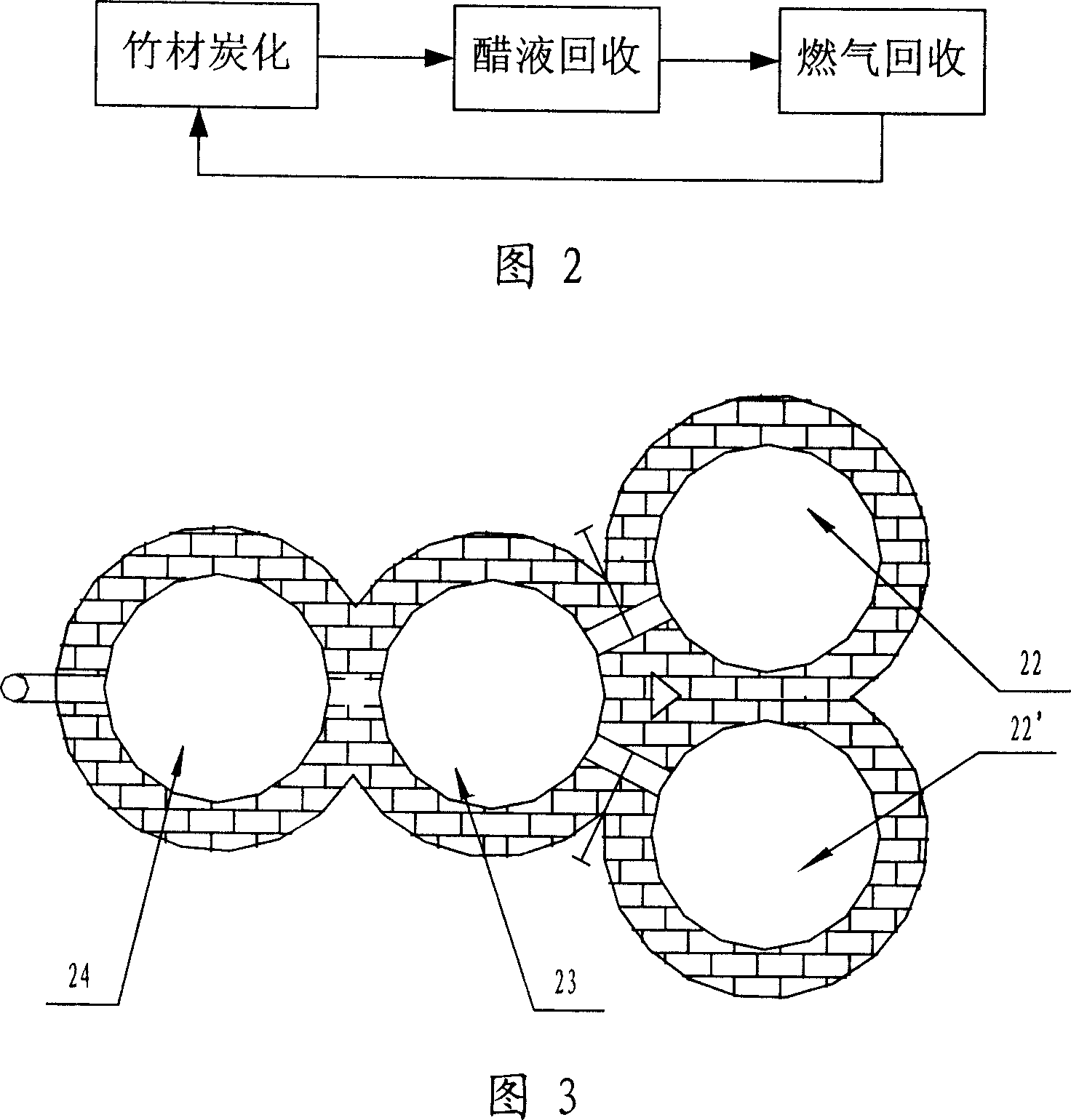

[0056] The invention provides a bamboo carbonization system, comprising: bamboo carbonization equipment, vinegar liquid recovery equipment and gas recovery equipment, which are respectively used for bamboo carbonization, vinegar liquid recovery and combustible gas recovery.

[0057] Specifically, as shown in Figure 1, it is a structural diagram of an embodiment of the system of the present invention, wherein the bamboo carbonization equipment includes: lifting device support 1, lifting device 9, kettle body water seal cooling device 25, heating furnace 4 and Kettle body 5. The lifting device 9 is located on the lifting bracket 1, the kettle body water seal cooling device 25, the heating furnace 4 and the kettle body 5 are located at the lower part of the lifting device 9 and between the two legs of the lifting device bracket 1, and the kettle body 5 is lifted by the lifting device 9 out or hoist into the heating furnace 4.

[0058] In this embodiment, the heating furnace 4 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com