Crop straw carbonization system

A technology for crop straw and carbonization, which is applied in the fields of biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of waste of resources and different quality of straw carbon, and achieve the effect of avoiding waste, high quality and easy to be carbonized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

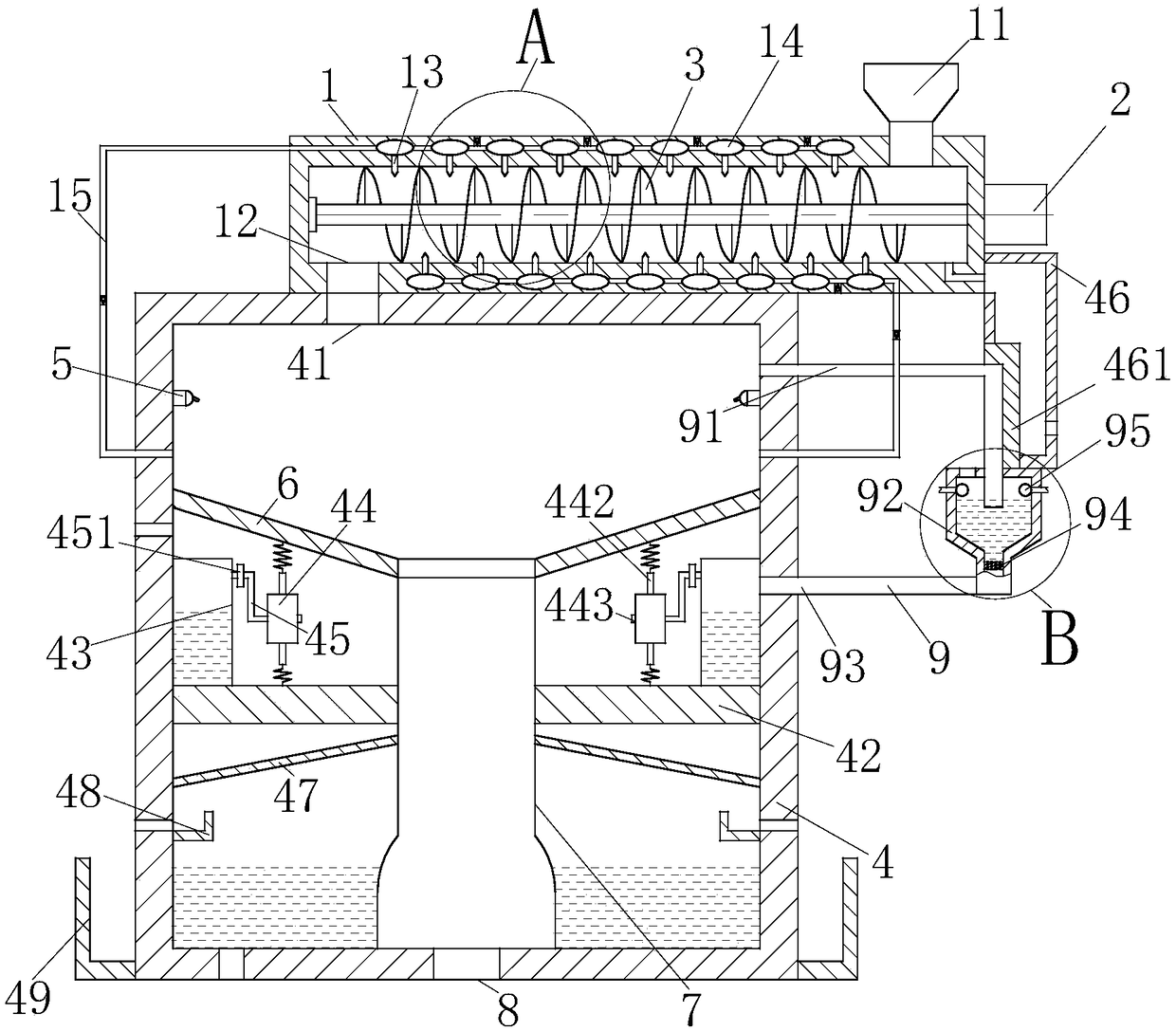

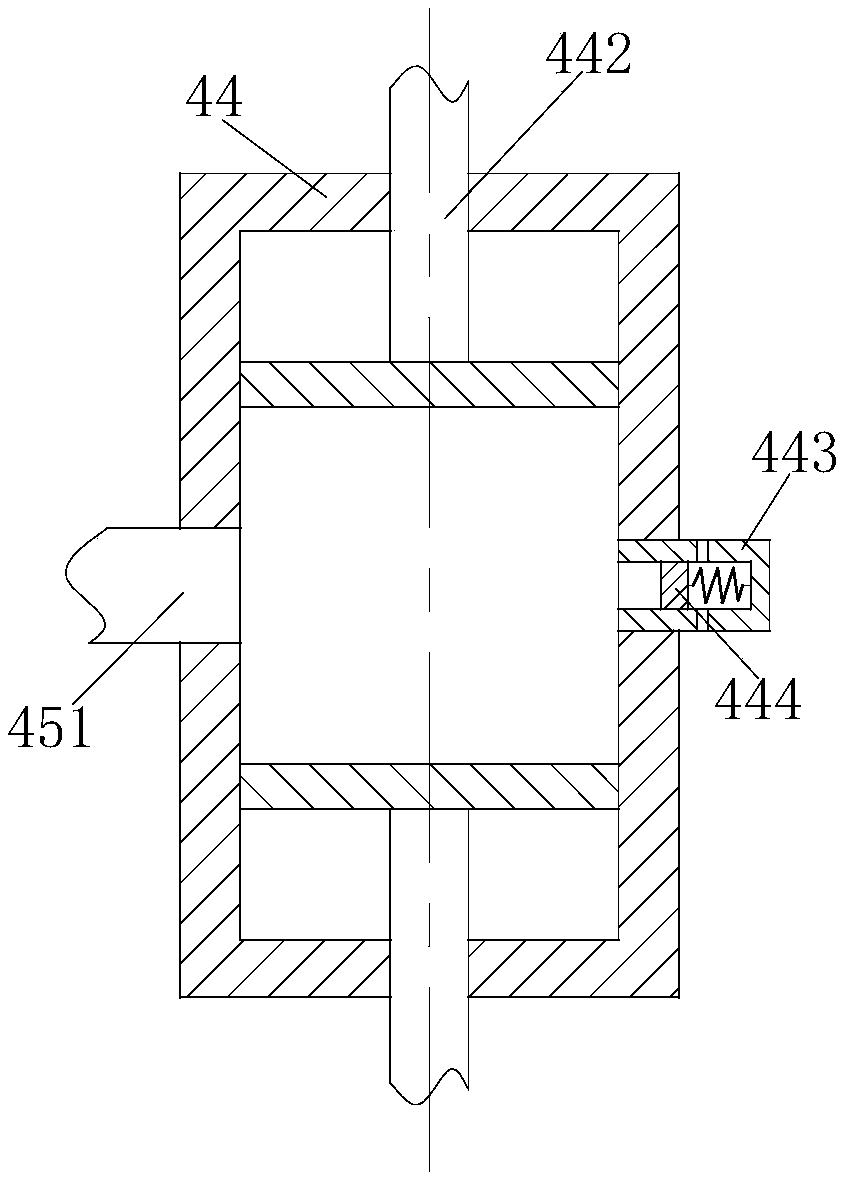

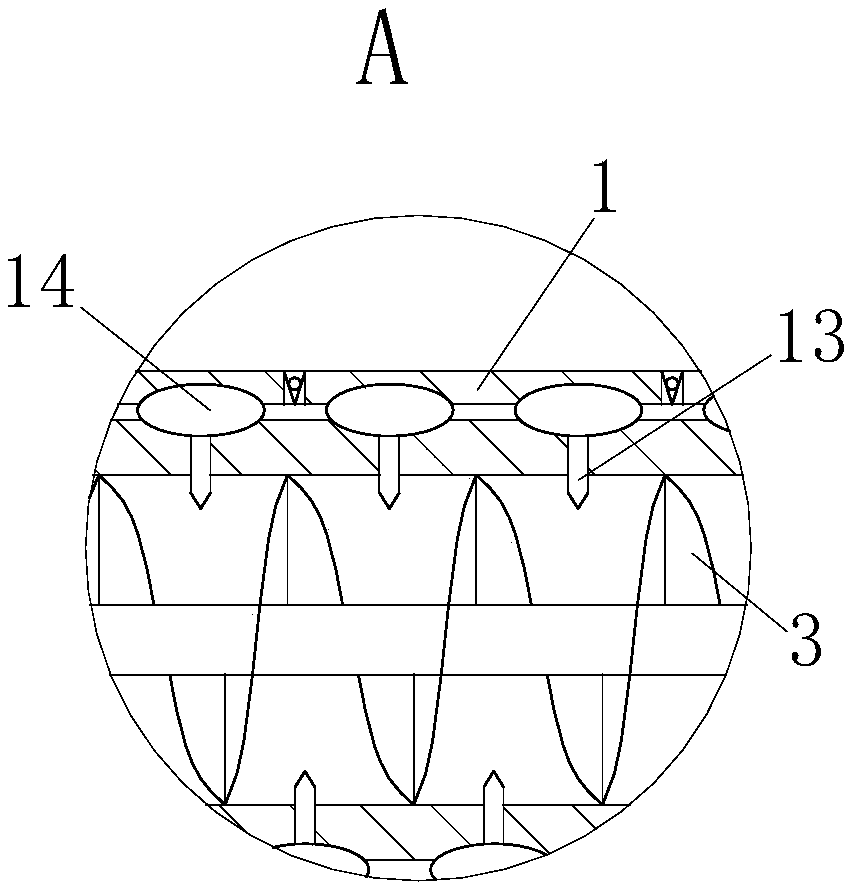

[0022] use Figure 1-Figure 4 The structure of the straw carbonization sewage purification device according to one embodiment of the present invention will be described as follows.

[0023] Such as figure 1 As shown, a crop straw carbonization system according to the present invention includes a push box 1, a motor 2, an auger 3, a carbonization box 4, a fire injection module 5, a partition 6, a collection cover 7 and a charcoal outlet 8; The push box 1 is provided with a feed hopper 11, the feed hopper 11 is located at the top right of the push box 1, and the feed hopper 11 is used to input straw into the push box 1; the motor 2 is installed on the right side of the push box 1; The auger 3 is located in the push box 1, one end of the auger 3 is connected to the right side wall of the push box 1, the other end of the auger 3 is connected with the output shaft of the motor 2, and the auger 3 is used for pushing into the push box 1, so that the straw is evenly pushed; the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com