Carbonization device for preparing straw biochar organic fertilizer

A technology of straw biomass and carbonization device, which is applied in the fields of carbon preparation/purification, application, cutting equipment, etc., can solve the problem of low carbonization efficiency, and achieve the effect of improving carbonization efficiency, improving pulverization efficiency, and facilitating collection and finishing of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

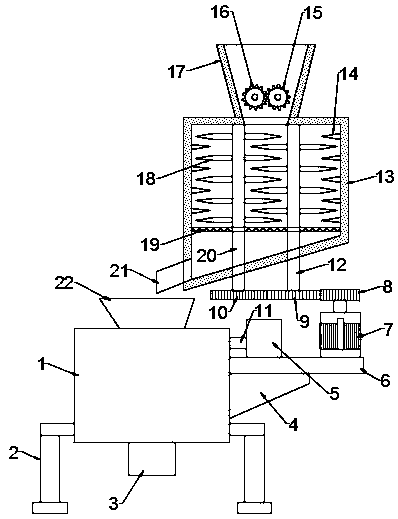

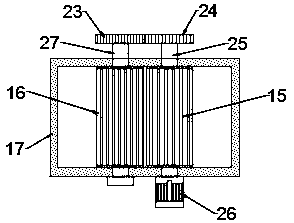

[0029] see Figure 1-2 , in an embodiment of the present invention, a carbonization device for preparing straw biochar organic fertilizer, comprising a carbonization furnace 1 and a microwave generator 5, the bottom of the carbonization furnace 1 is provided with a leg 2, and the carbonization furnace 1 is provided with a feed hopper 22 With the first discharge pipe 3, the microwave generator 5 is connected with the carbonization furnace 1 through the microwave conduit 11; The bottom of the box 13 is designed to be inclined, and the bottom of the crushing box 13 is provided with a discharge pipe 21, and the crushing box 13 is provided with a crushing mechanism for crushing stalks; the straw is added to the hopper 17, and the crushing mechanism can be used for falling into the crushing box. The stalks in 13 are crushed, and the crushed stalks are discharged into the hopper 22 through the discharge pipe 21 , and after entering the carbonization furnace 1 , microwave carbonizatio...

Embodiment 2

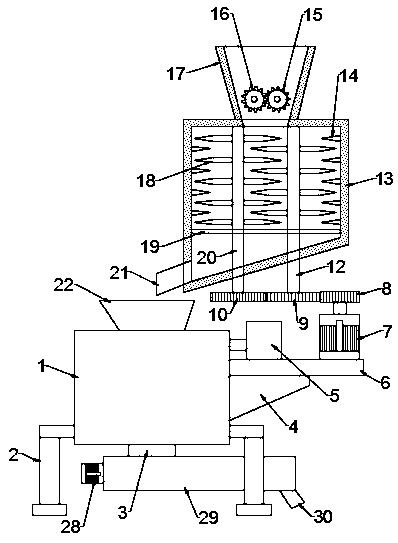

[0041] see Figure 3-5 , in the embodiment of the present invention, a carbonization device for preparing straw biochar organic fertilizer, different from embodiment 1, the lower side of the carbonization furnace 1 is provided with a discharge device 29, and on the top wall of the discharge device 29 There is a port 31 matched with the first discharge pipe 3, and the bottom end of the first discharge pipe 3 extends into the port 31;

[0042] Described discharge device 29 is provided with auger 32, and the 3rd motor 28 is installed on the sidewall of discharge device 29, and the output shaft of the 3rd motor 28 is connected with auger 32, and the bottom of discharge device 29 is provided with the 3rd motor 28. Two discharge pipes 30; the product carbonized by the carbonization furnace 1 enters the discharger 29 from the first discharge pipe 3, and the auger 32 is driven by the third motor 28 to run, so that the product accumulated at the bottom of the discharger 29 can be pushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com