Regeneration system and regeneration method for waste activated carbon

An activated carbon and carbonization technology, which is applied to the waste activated carbon regeneration system and its regeneration field, can solve the problems of large carbon loss, high energy consumption and high carbon loss rate, and achieve the effects of low moisture content, uniform texture and reduced carbon loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

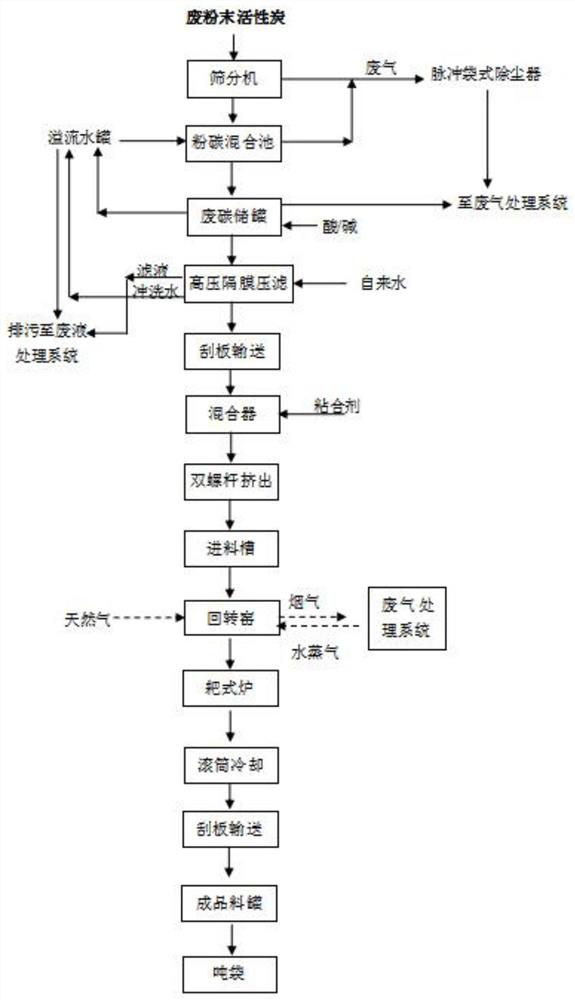

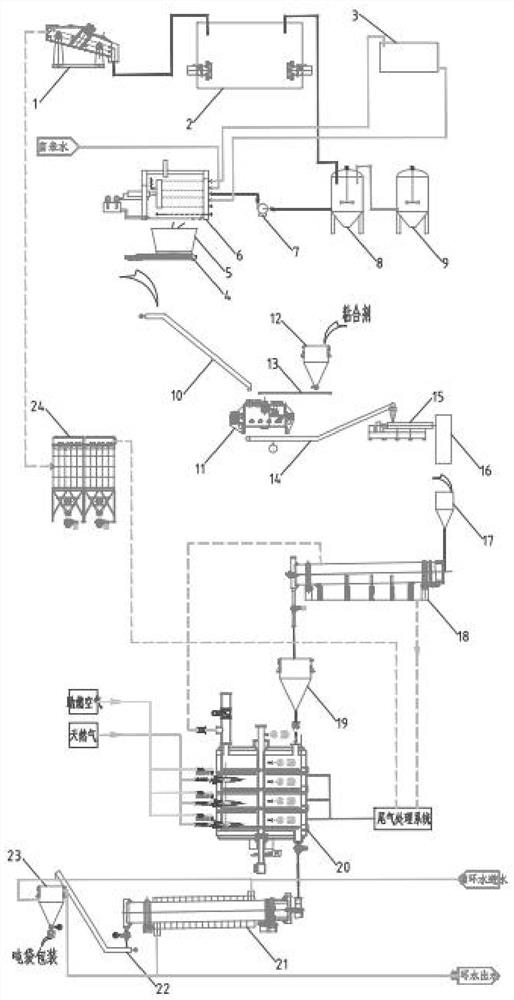

[0048] A waste activated carbon regeneration system, the innovation of the present invention is that it includes a waste particle processing unit, a dry carbonization unit and a finished product cooling unit installed in sequence, and the waste particle processing unit is used to introduce waste particles and screen the waste particles Separation, mixing, neutralization and washing; the particles are dried, carbonized and activated by the dry carbonization unit to form high-temperature finished products; the high-temperature finished products are cooled by the finished product cooling unit to form finished products.

Embodiment 2

[0050] A system for regenerating waste activated carbon, the innovation of the present invention is that it includes a waste activated carbon treatment unit, a mixing and granulation unit, a dry carbonization unit and a finished product cooling unit installed in sequence, the waste activated carbon treatment unit is used to import waste activated carbon, and Sieve, mix, neutralize and wash the waste activated carbon; add binder to the washed secondary raw materials through the mixing and granulation unit and extrude them to form semi-finished granules; the granules are dried, carbonized and activated by the drying and carbonization unit to form high-temperature finished products ; The high-temperature finished product is cooled by the finished product cooling unit to form a finished product.

[0051] In this embodiment, the mixing and granulating device includes a mixer 11 and a granulating machine 15, wherein the feed end of the mixer introduces secondary raw materials, and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com