Method for preparing crystal nucleus prefabricated nano calcium carbonate and special equipment

A nano calcium carbonate, crystal nucleus technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, single crystal growth, etc., can solve the problems of large particle size, wide range and narrow distribution of nano calcium carbonate crystals, and achieve Narrow distribution, uniform size and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The chemical reactions involved in this system are as follows:

[0039]

[0040]

[0041]

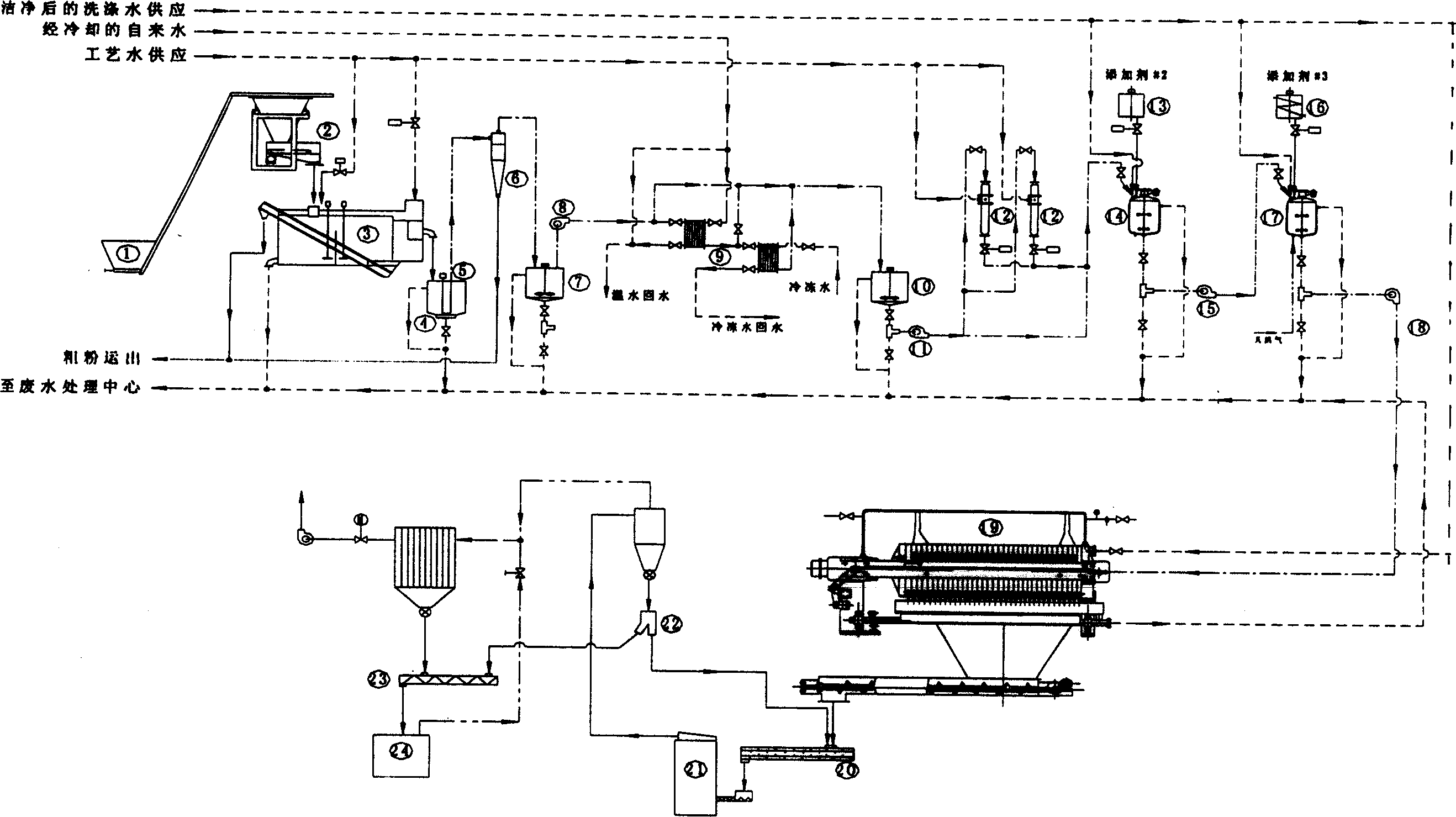

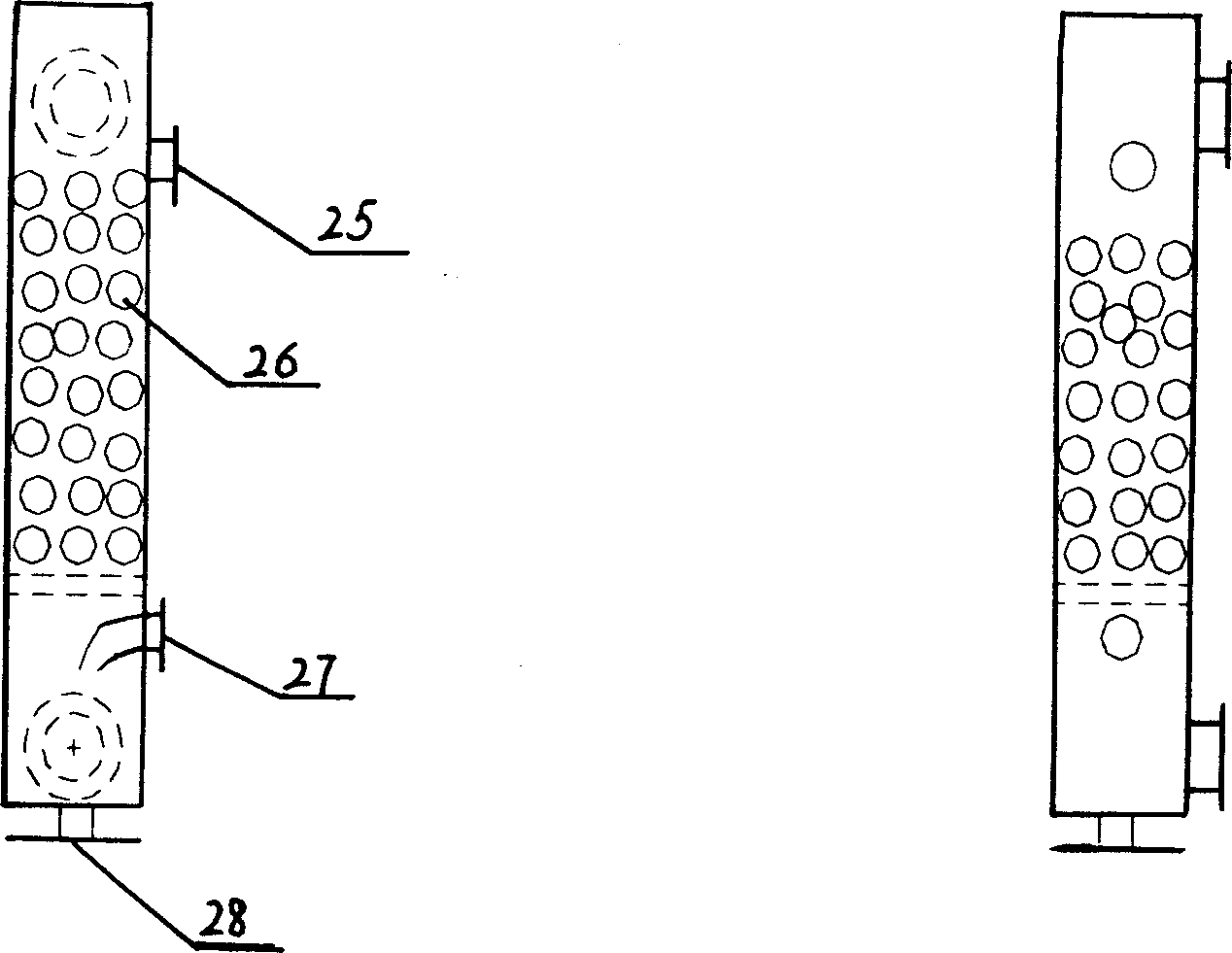

[0042] First, the calcined limestone generates calcium oxide, which is sent to the vibrating quantitative feeder 2 through the lime hopper 1, and then digested into Ca(OH) in the continuous digestion tank 3 2 solution, and then through the gravity separation tank 4 and the 1 μm hydrocyclone 6 to obtain the fine pulp into the storage tank 7, wherein the waste water is discharged to the wastewater treatment center by the liquefied sewage pump 5, and the fine pulp is pumped into the heat exchanger 9 through the thick pulp pump After obtaining the suitable pre-carbonization temperature, enter the adjustment tank 10, and pump it into the crystal nucleus preformer 12 through the thick slurry pump 11, (such as figure 2 Shown) Ca(OH) 2 Slurry from the lower part of the crystal nucleus preformer Ca(OH) 2 The slurry inlet 28 is pumped into the crystal nucleus preform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com