Preparation method of activated coke for water treatment

A technology for activated coke and water treatment, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, inorganic chemistry, etc. Carbonization efficiency, high moisture content, and high volatile content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

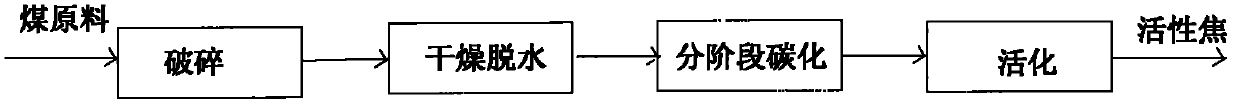

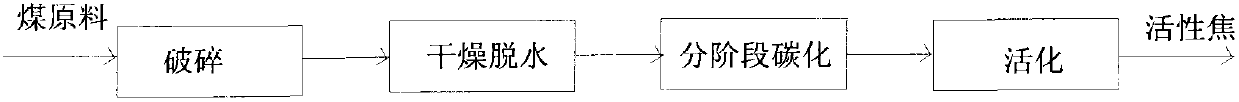

[0030] A specific embodiment of a method for preparing activated coke for water treatment according to the present invention is given below, and its production process includes the following steps, such as figure 1 Shown:

[0031] ① After crushing the coal raw material, use a vibrating screen to sieve it to a suitable particle size. Here, the particle size range is 4-8 mesh. The industrial analysis results of the lignite sample are shown in the following table:

[0032] project

Volatile

Sulfur content

Ash

value

26.1%

33.0%

0.2%

15%

25.7%

[0033] Volatile matter refers to the components of easily volatile substances contained in coal raw materials. The content of volatile matter and moisture in lignite is relatively high, so the loss on ignition rate is relatively high.

[0034] ②Put the crushed coal raw material into a small fixed-bed preparation furnace for drying and dehydration, from...

Embodiment 2

[0040] As a changeable embodiment, in the step (2), the drying and dehydration temperature is 90-110°C, and the residence time is 60-120 minutes; in the step (3), the temperature in the first stage is 400°C-450°C, The residence time is 60-120 minutes, the temperature of the second stage is 600 ℃-650 ℃, and the residence time is 60-120 minutes; in the step ④, the activator is water vapor, carbon dioxide and ammonia, and the activation temperature is 750 -850℃, the residence time is 60-120 minutes.

[0041] Another specific embodiment of the preparation method of the active coke for water treatment of the present invention, its working process is as follows:

[0042] ① After crushing the coal raw material, use a vibrating screen to sieve it to an appropriate particle size, and the particle size range is selected to be 4-8 mesh;

[0043] ② Add the crushed coal raw material to the carbonization furnace for drying and dehydration, keep the drying and dehydration temperature at 110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com