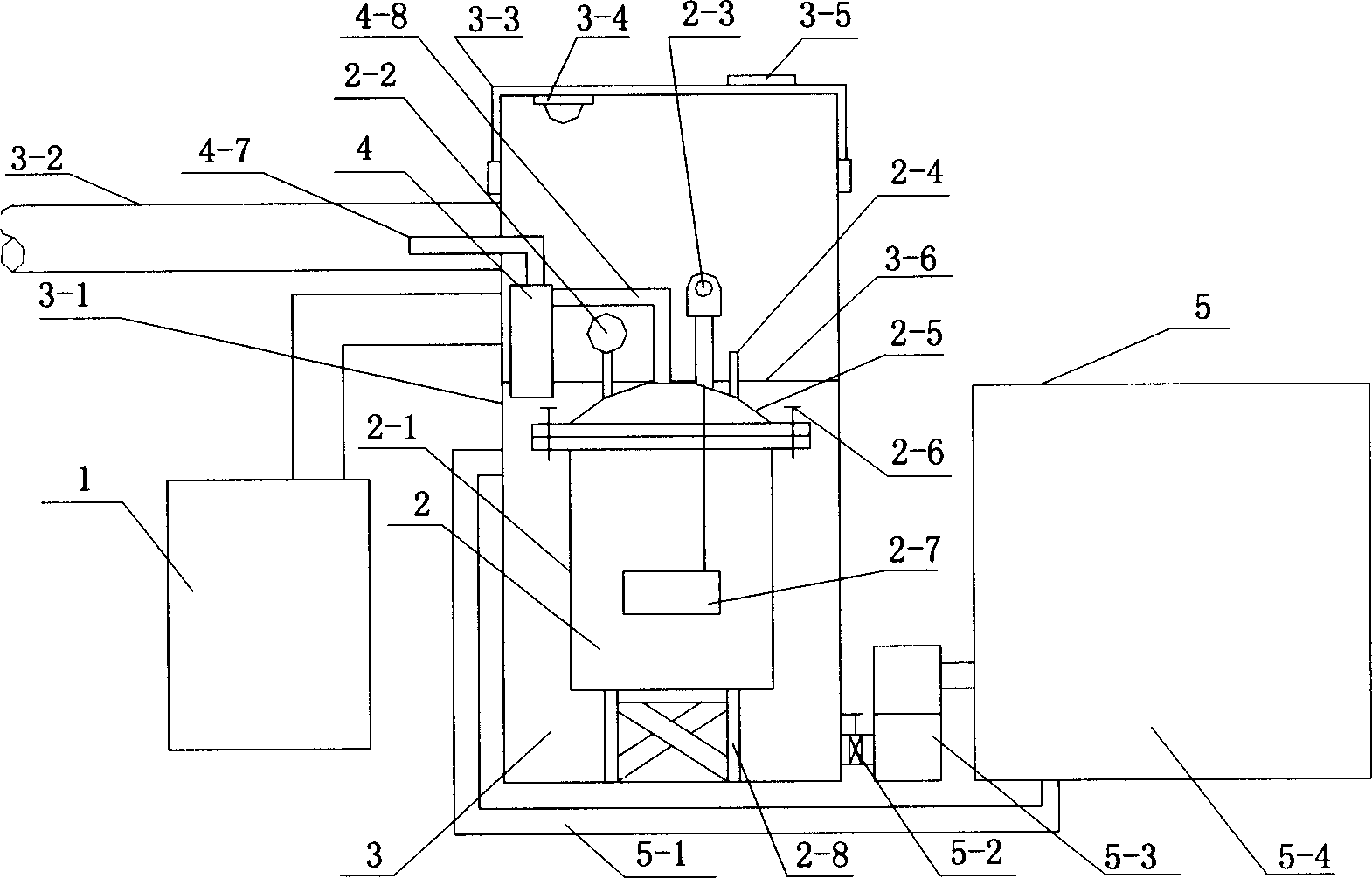

Apparatus and process for preparing carbon fiber reinforced silicon carbide composite material

A composite material and preparation process technology, which is applied in the field of devices for preparing carbon fiber reinforced silicon carbide composite materials, can solve problems such as insecurity, time-consuming, and energy consumption, and achieve the effects of convenient operation, reduced production costs, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

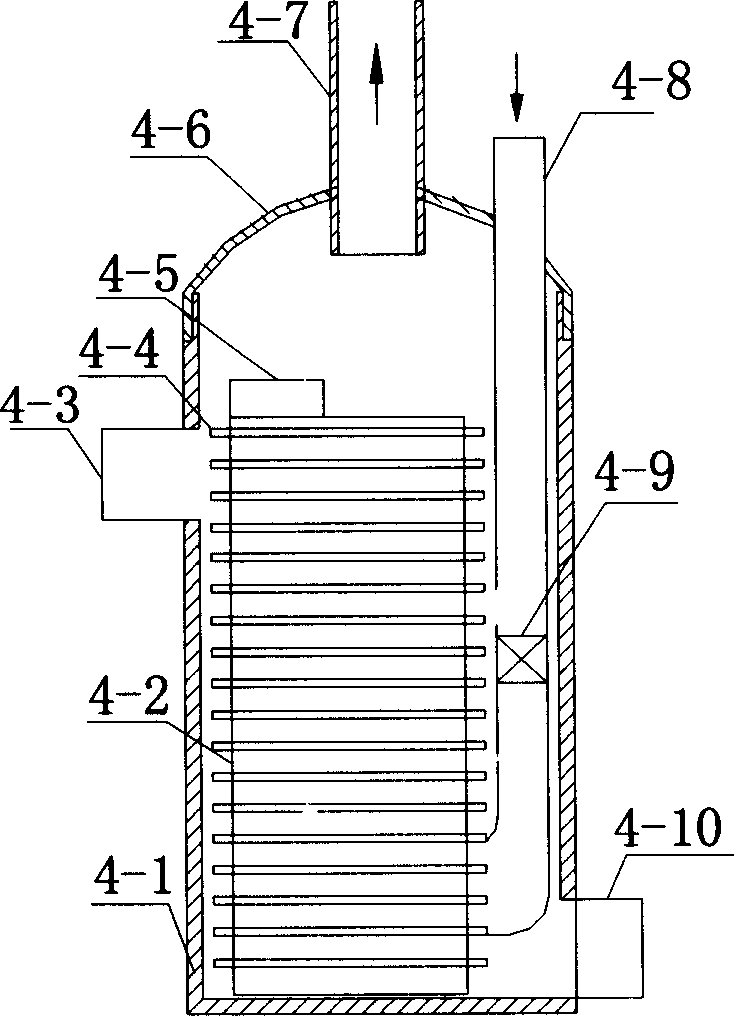

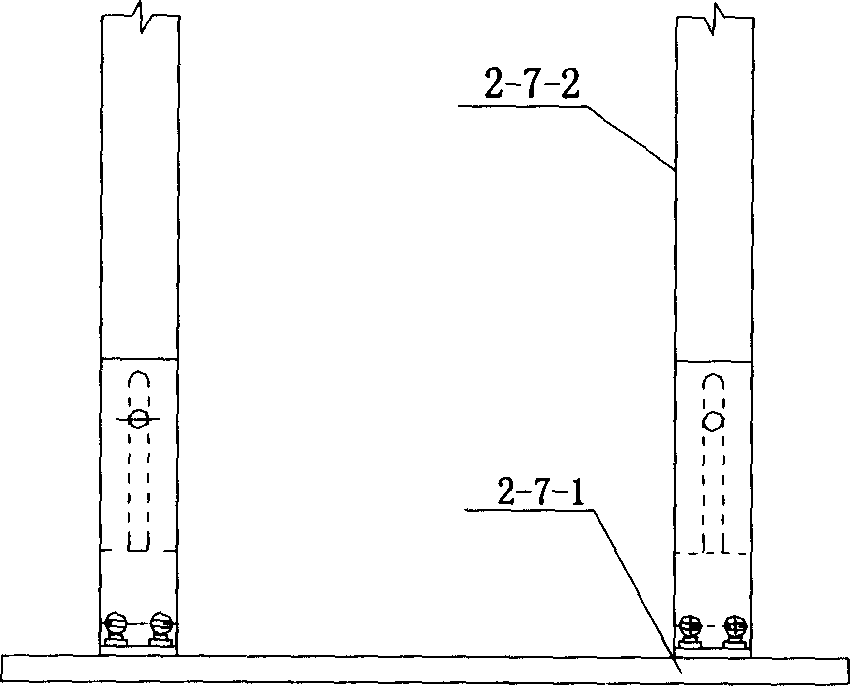

Method used

Image

Examples

Embodiment Construction

[0027] The process of prefabricated parts preparation:

[0028] The preparation process of the protective layer material is as follows: select a carbon fiber rod with a length of 178 mm and a diameter of 6 mm. The carbon fiber rod is firstly immersed in xylene solvent for about 45 minutes, then taken out, and then carbonized for 24 hours in a nitrogen protective atmosphere and a constant temperature of 180°C, and finally a protective layer material is formed on the surface of the carbon fiber rod.

[0029] Strengthening layer material preparation process: Mix xylene and silicon carbide powder into a viscous solution, homogenize it with ultrasonic waves, add carbon powder to the liquid to make the viscosity reach 50-100Pa.s, and make a strengthening layer material solution ; Then put the carbon fiber rod coated with the protective layer material into the solution, and fully impregnate it under the action of ultrasonic waves; finally, dry it under a nitrogen protective atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com