Mowing machine

A technology of lawn mower and cutting parts, which is applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., which can solve the problems of large volume of lawn mower, heavy machine pushing, and heavy body, so as to improve the efficiency of grass discharge, Reduced size and weight, labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

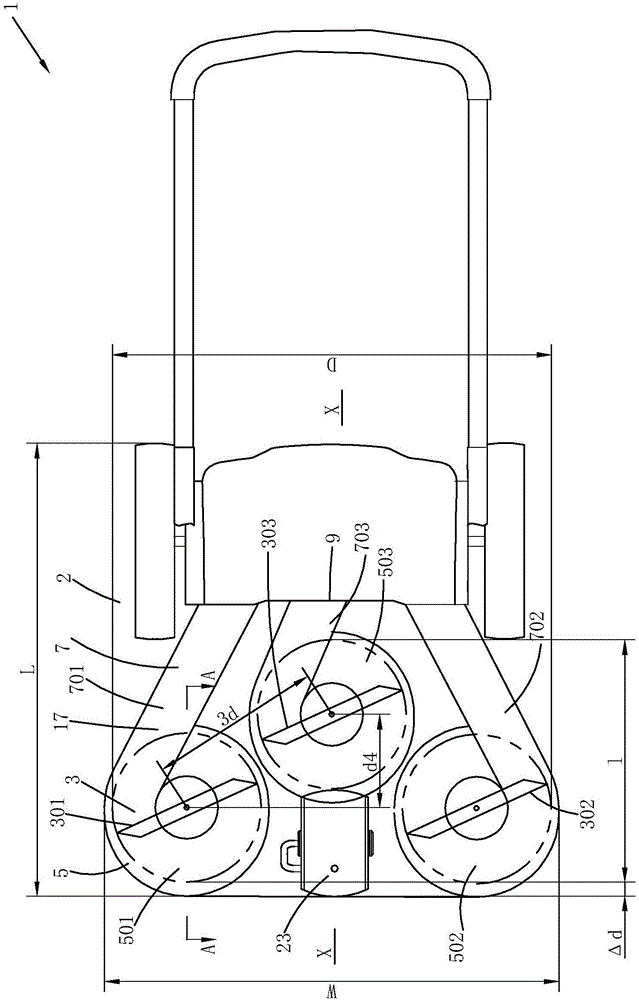

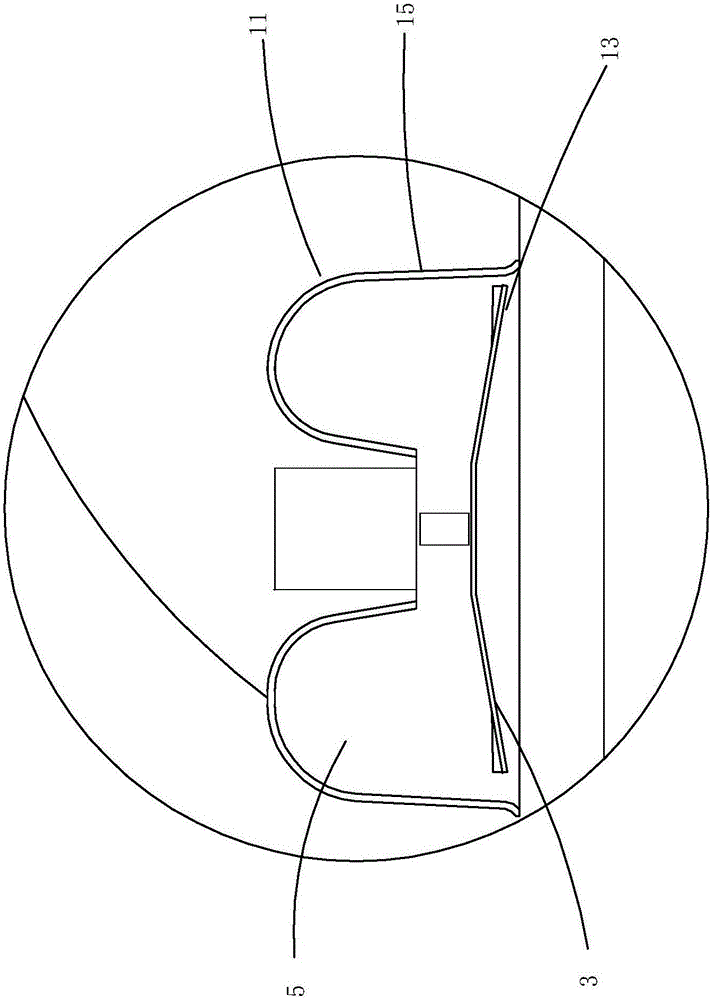

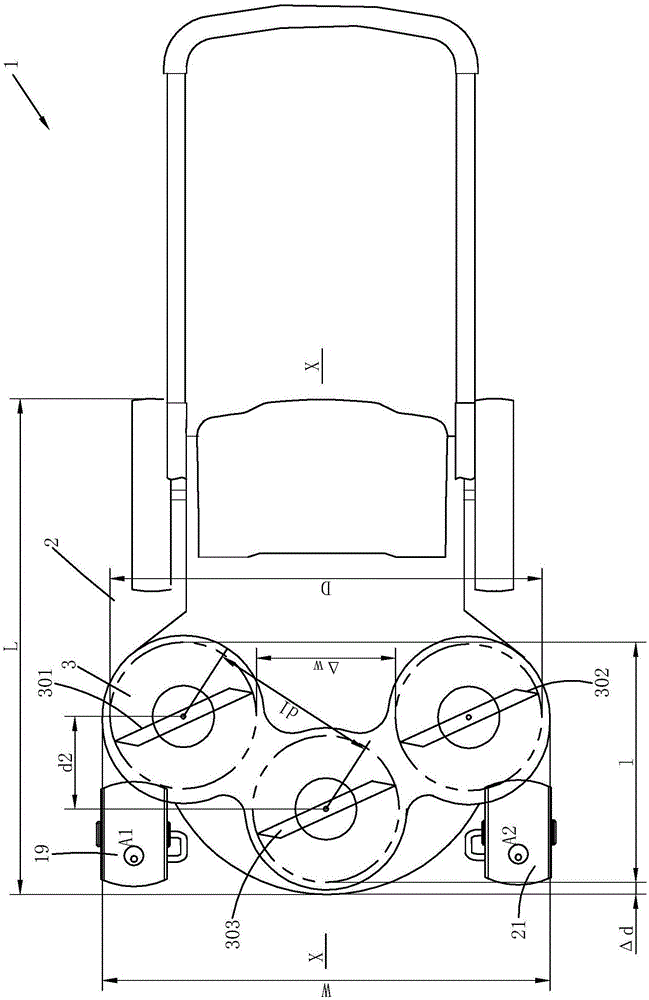

[0057] figure 1 It is a structural diagram of the mower 1 according to the first embodiment of the present invention. Such as figure 1As shown, the mower 1 is placed on the ground, the direction perpendicular to the ground is the vertical direction, the direction parallel to the direction of advancement of the mower 1 is the longitudinal direction of the mower 1, and the direction perpendicular to the direction of advancement of the mower 1 is the vertical direction of the mower 1. The direction is the transverse direction of the lawnmower 1, the top of the drawing is the right side of the lawnmower 1, and the bottom of the drawing is the left side of the lawnmower 1. Lawnmower 1 comprises: housing 2; Cutting motor (not shown in figure), is installed in housing 2, provides driving force; It includes a plurality of cutting cavities 5 corresponding to the cutting parts 3, each cutting cavity accommodates a cutting part, and the cutting cavities 5 are independent of each other;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com