Numerical-control multi-shaft seat mortising machine

A technology of tenon and groove machine and numerical control device, applied in the field of tenon and groove machine, can solve the problems of low processing efficiency and processing accuracy, scraping the surface of the workpiece, complex structure, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

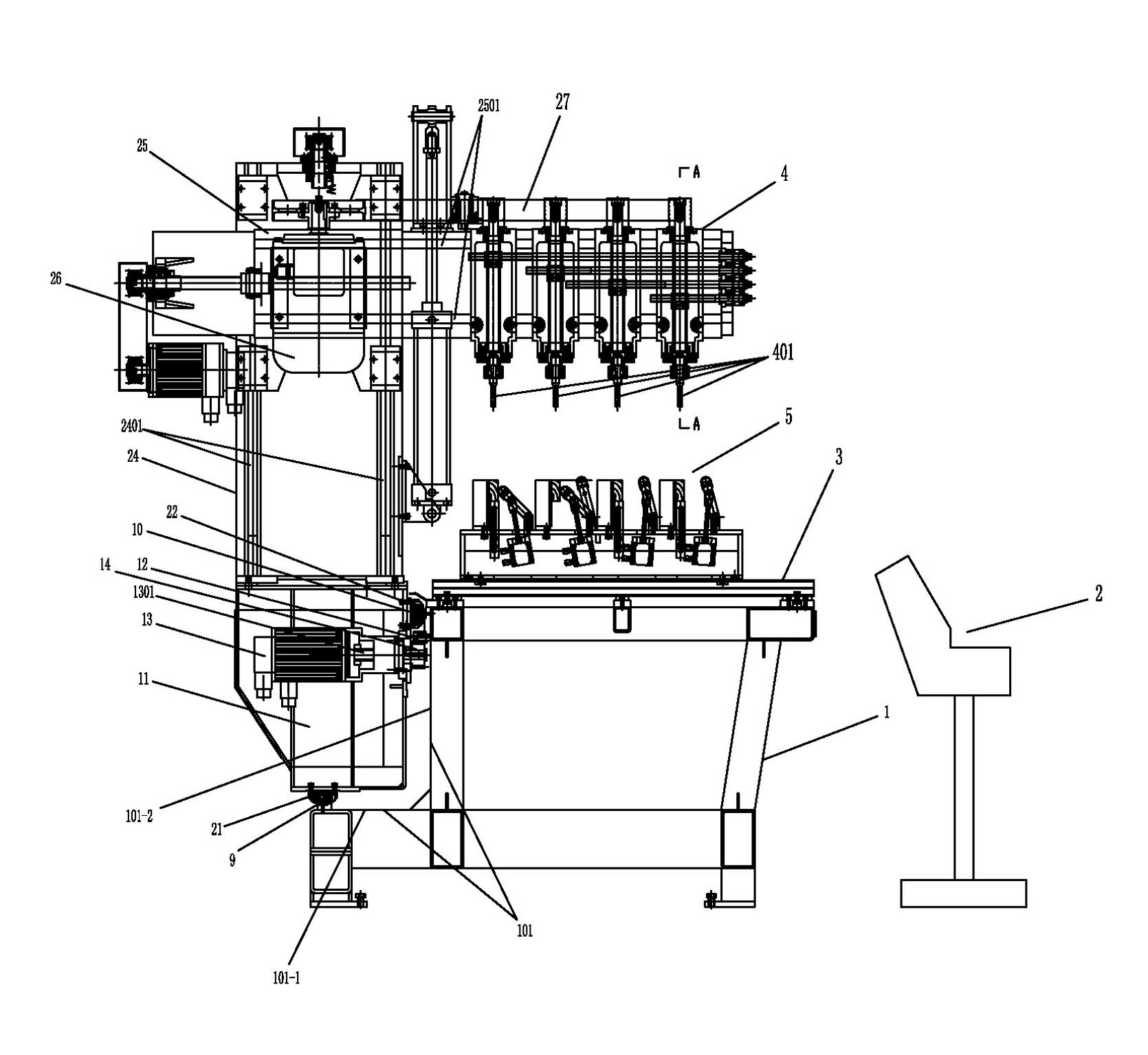

[0036] Such as Figure 1 to Figure 10 As shown, a numerically controlled multi-axis tenon and groove machine includes a machine base 1 and a numerical control device 2. A workbench 3 is arranged on the top surface of the machine base 1, and a cantilevered main shaft seat 4 is arranged above the workbench 3. On the cantilevered main shaft seat 4 A plurality of spindle milling cutters 401 are installed, which is characterized by;

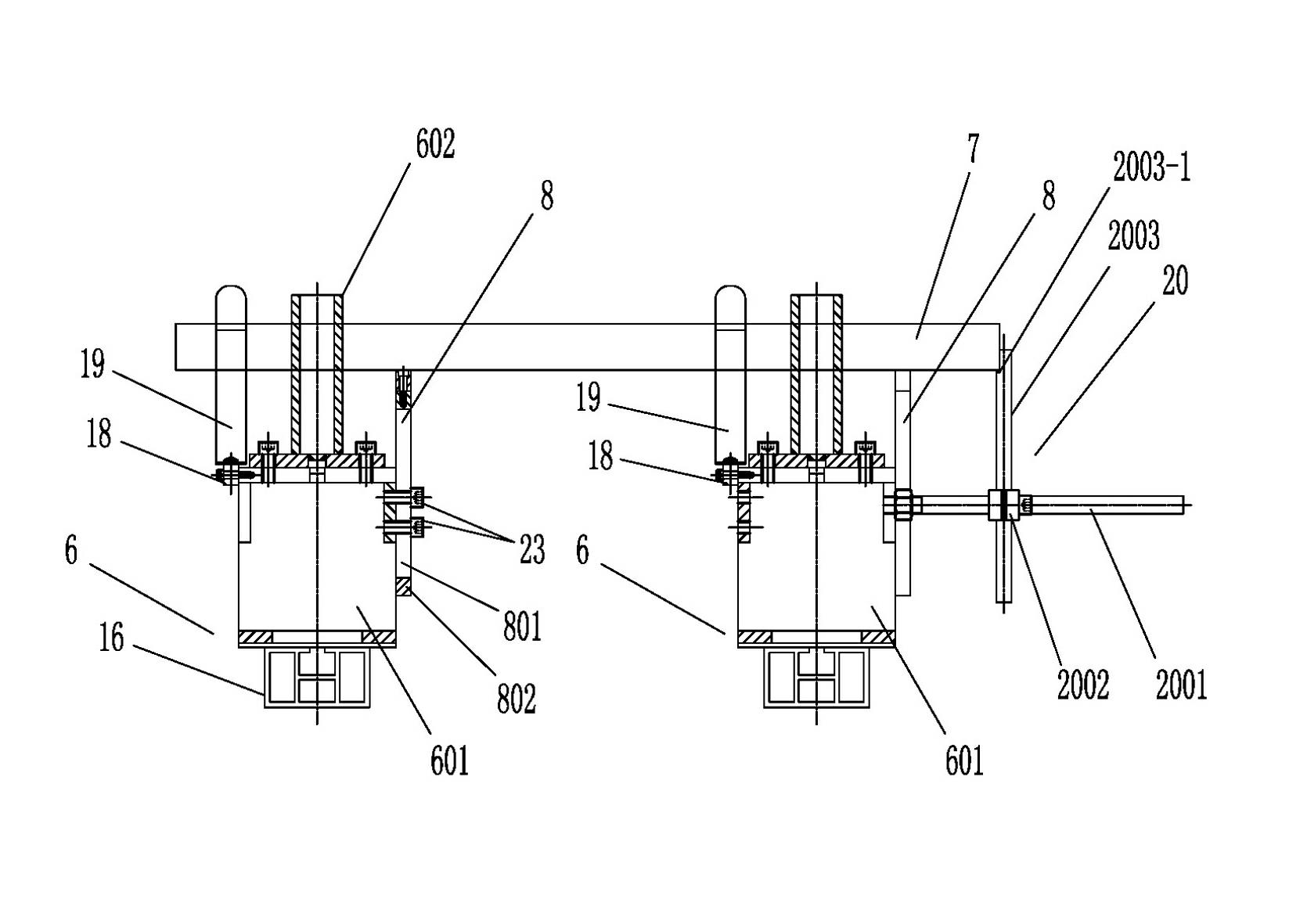

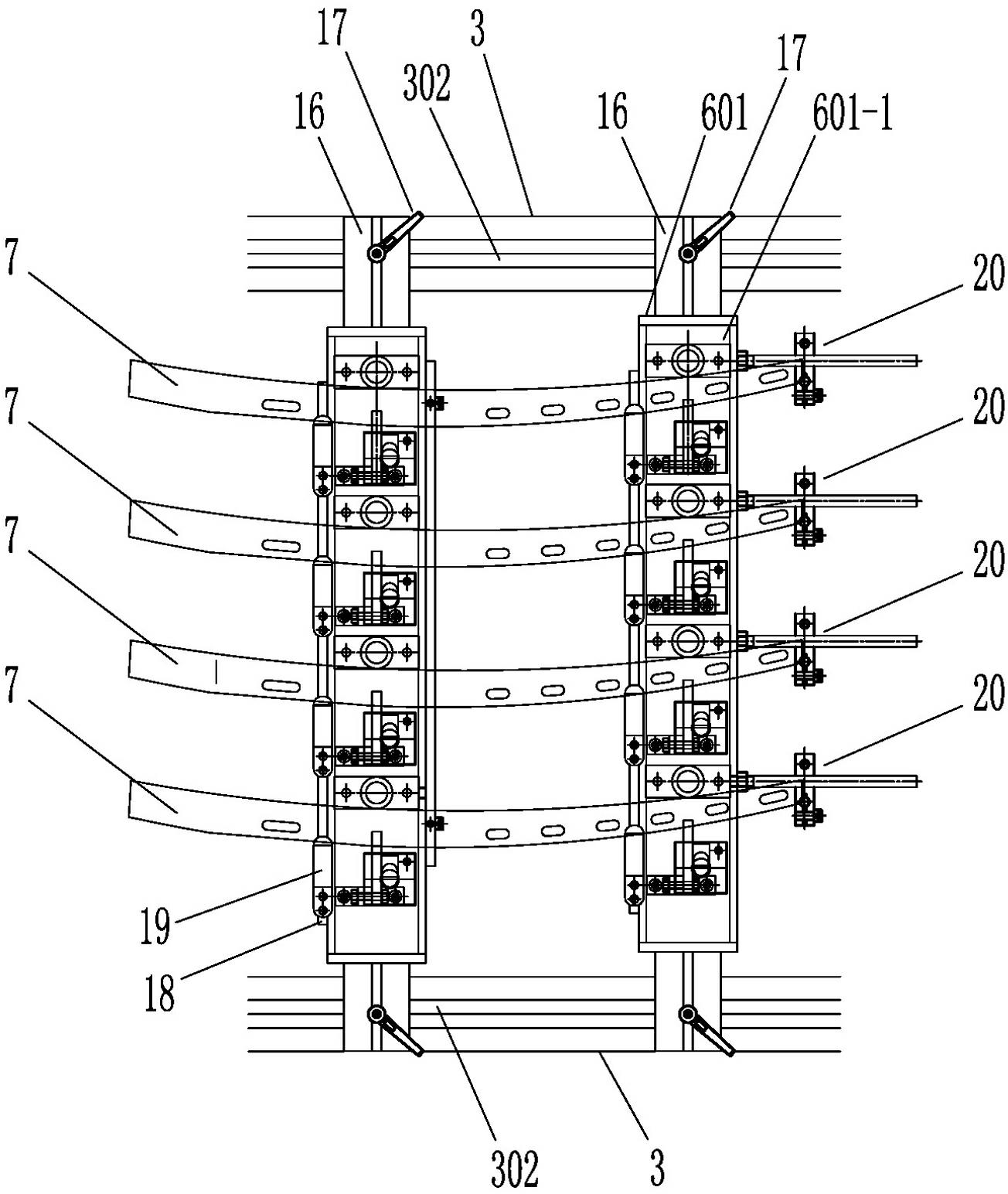

[0037] At least one set of workpiece fixture structures 5 is installed on the workbench 3, and each set of fixture structures 5 is composed of two multi-position fixtures 6, and each multi-position fixture 6 is composed of a clamp seat 601, a clamp column 602, a press Cylinder 603, pressing plate 604, clamp seat 601 is a hollow rectangular frame, clamp seat 601 top surface 601-1 is fixed with a plurality of clamp columns 602 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com