Woodmaking mortising machine and notching method

A tenon and groove machine and woodworking technology, applied in the field of tenon and groove machines, can solve the problems of low work efficiency, low positioning accuracy, difficulty in recruiting workers, etc., and achieve the effect of improving work efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

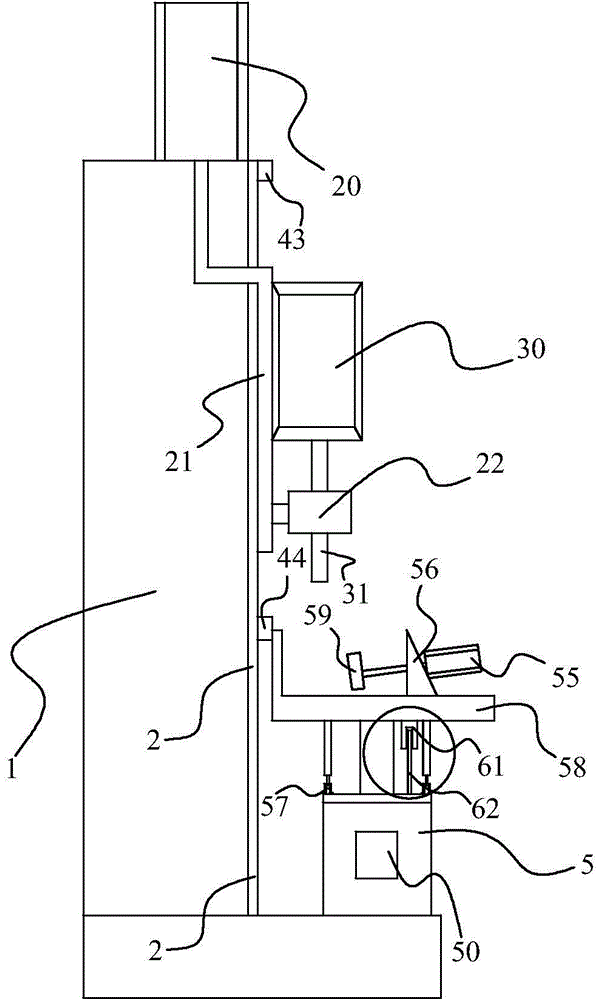

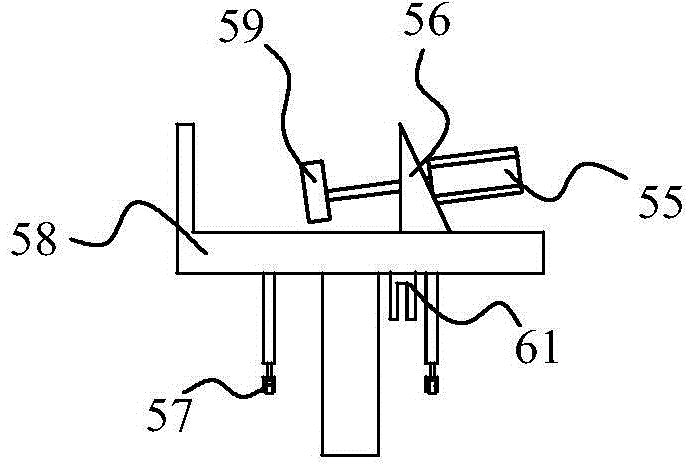

[0027] Embodiment 1, Figure 1 to Figure 6 A woodworking tenon and groove machine and a groove making method are given.

[0028] The woodworking tenon and groove machine includes a frame 1, and a horizontal and vertical device is arranged on the frame 1. The horizontal and vertical device is a horizontal moving device and a vertical moving device controlled by a central control device; The displacement control of the device realizes the precise drilling process of the device in the process of processing wood products.

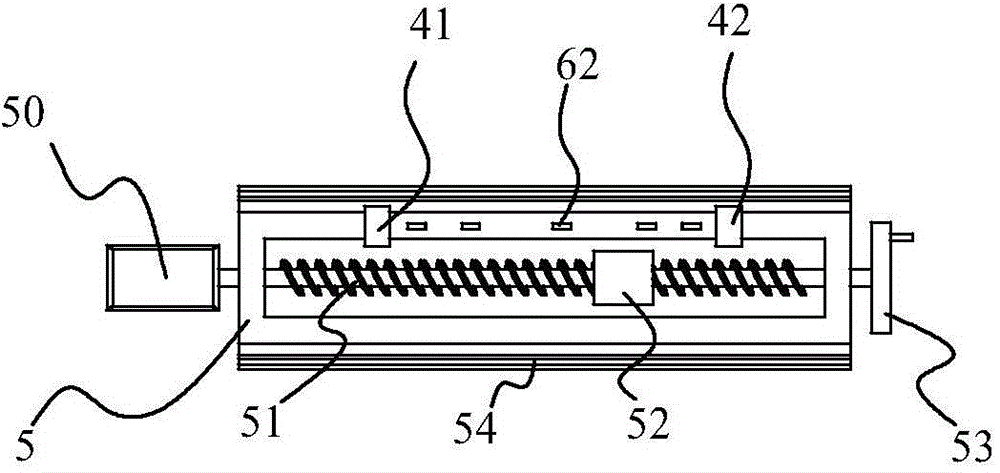

[0029]Transversal moving device comprises transverse support 5, is provided with screw mandrel 51 from left to right in transverse support 5, and the left end of transverse support 5 is fixed with stepper motor 50, and the output shaft of stepper motor 50 is fixed with the left end of screw mandrel 51; The rotation of the screw mandrel 51 can be accurately controlled by the stepper motor 50, and the corresponding information of the rotation of the screw mandre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com