Multifunctional numerical control tenon and mortise machine and achieving method thereof

A mortise and tenon machine, multi-functional technology, applied in multi-purpose machinery, dovetail tenon processing, wood processing equipment, etc., can solve the problems of safety accidents, broken fingers, etc., and achieve the effect of good safety, fast speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

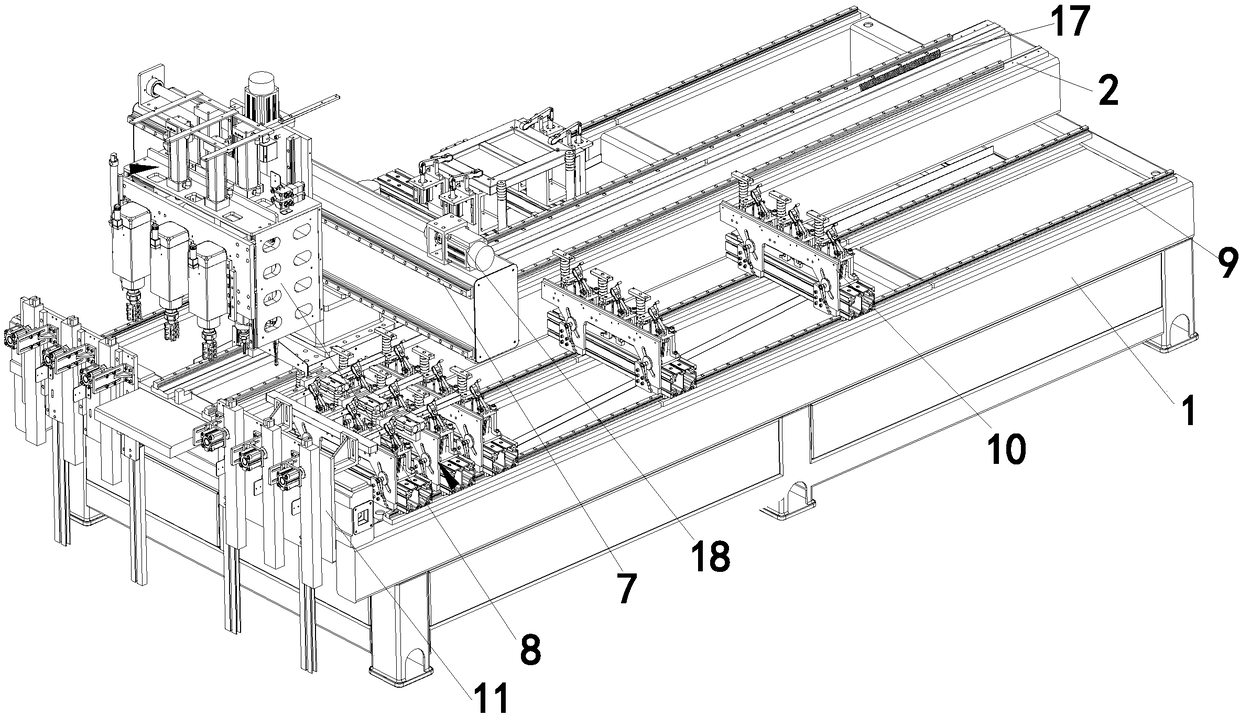

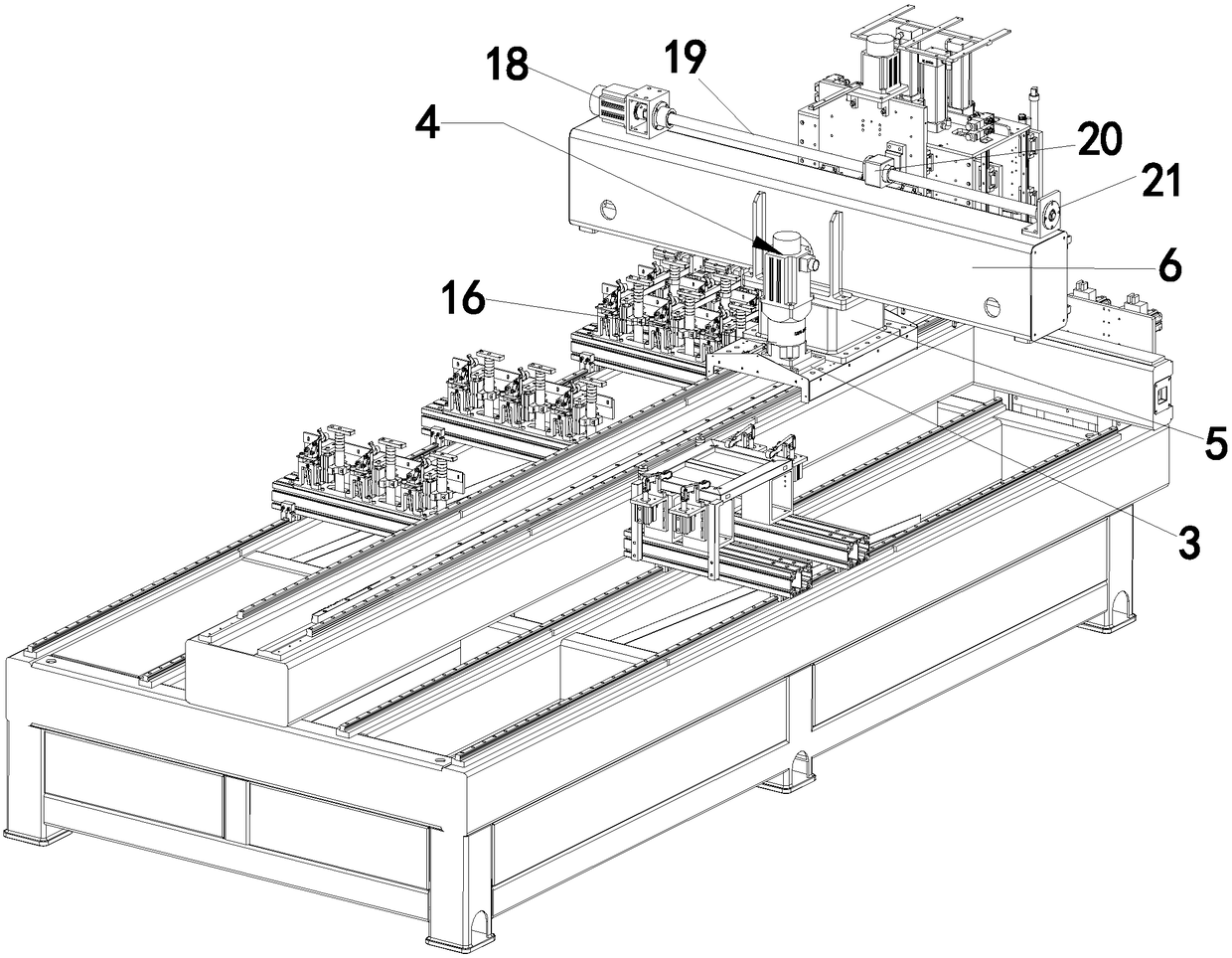

[0041] Such as Figure 1-9 As shown, a multifunctional numerically controlled tenon and tenon machine includes a frame, on which a Y-axis motor guide rail is provided, a Y-axis motor seat is provided on the Y-axis motor guide rail, and a Y-axis motor seat is provided in the Y-axis motor seat to provide the direction of the Y-axis. The Y-axis motor and the fixed bracket of the motion power, the X-axis bracket is arranged on the fixed bracket, the X-axis guide rail is arranged on the side of the X-axis bracket, the X-axis guide rail is connected with the cutter head device, and the X-axis movement device is arranged on the upper end of the X-axis bracket; Both sides of the Y-axis motor guide rail are respectively provided with fixed guide rails, and several fixtures are arranged on the fixed guide rails.

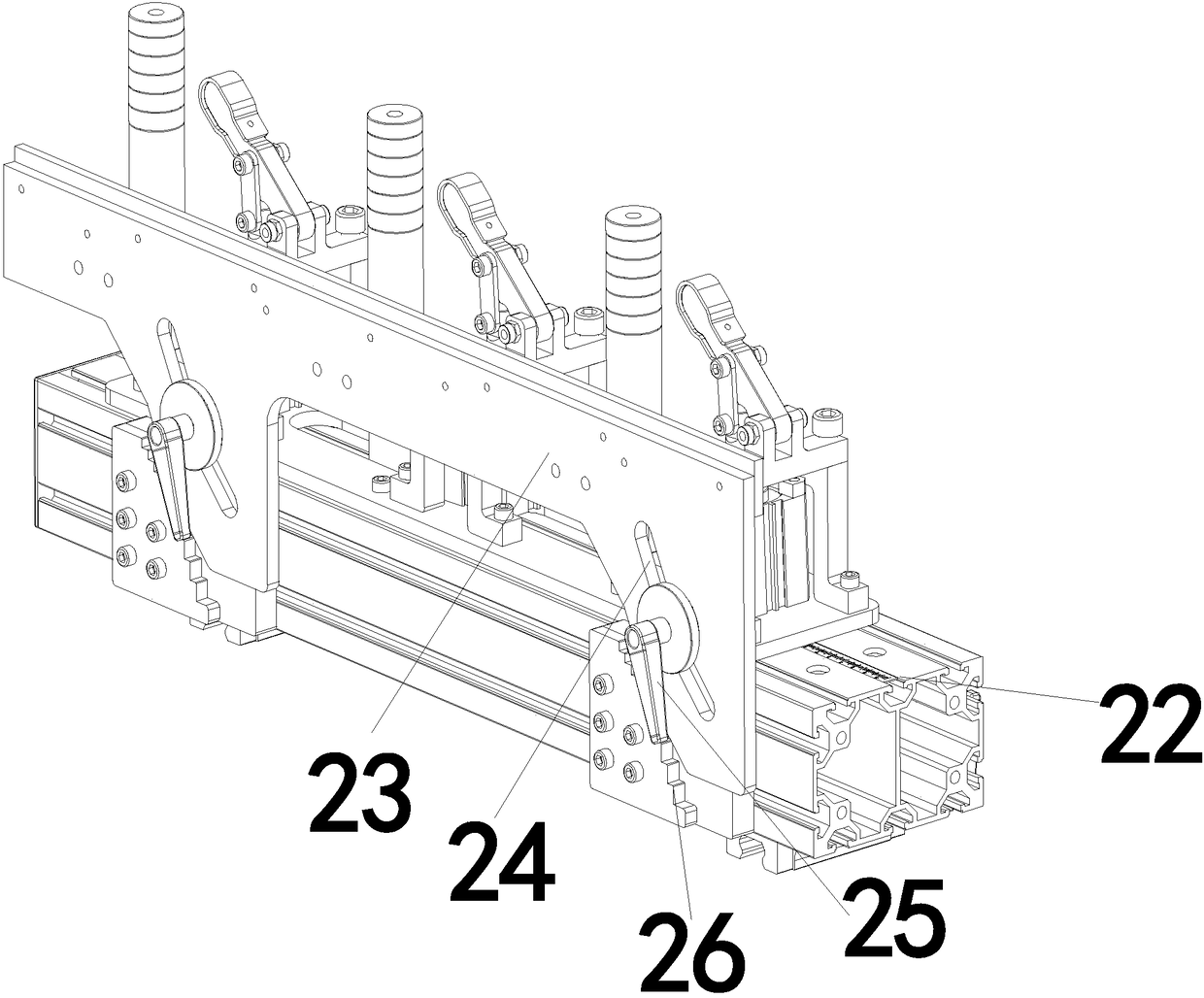

[0042] The outlet end of the frame in this embodiment is provided with a straight tenon fixture; the straight tenon fixture includes a straight tenon fixing plate, and the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com